Product Video Display

Technical Parameters Of X6036 Horizontal Manual Milling Machine

| SPECIFICATIONS | Units | X6128 | X6032 | X6036 |

|---|---|---|---|---|

| Table size | mm | 1200*280 | 1500*320 | 1500*360 |

| Table travel | mm | 680/280/400 | 1000/300/400 | 1000/320/450 |

| T slot(number-width*pitch) | 3-14*50 | 3-16*70 | 3-18*80 | |

| Spindle taper | ISO40 7:24 | IS0407:24 | ISO507:24 ISO40 7:24 | |

| Spindle speed range(steps) | rpm | 40-1300(12) | 40-1300(12) | 60-1800(12) |

| Distance between spindle axis and table surface | mm | 0-400 | 0-400 | 0-450 |

| Main motor power | kw | 3 | 3 | 4 |

| Machine weight | kg | 1300 | 2050 | 2400 |

| Overall dimension | mm | 1725*1450*1750 | 2070*1900*1850 | 2220*1790*1860 |

Features Of X6036 Horizontal Lifting Table Milling Machine

- The horizontal rotation angle of the worktable is ±45°. It can expand the processing range of the machine tool. The worktable’s main transmission and feed part of the worktable adopts the gear-shifting structure. It has a wide range of speed regulations and is convenient and fast.

- The main shaft bearing of the machine tool is a tapered roller bearing. The main shaft of the X6036 horizontal universal lifting table milling machine adopts a three-support structure. The main shaft has good system rigidity and strong bearing capacity. The main shaft adopts energy consumption braking, which has ample braking torque and stops quickly.

- The X/Y/Z direction of the worktable has three types: manual feed, motorized feed, and fast-forward. The feed speed of the X6036 horizontal milling machine can meet different processing requirements. Fast feeding can make the workpiece reach the processing position quickly. Processing is convenient and quick.

- The X, Y, and Z three-direction guide rail pair is processed by ultra-frequency quenching, precision grinding, and scraping and cooperates with forced lubrication. It can improve accuracy and prolong the machine tool’s service life.

- The manual lubricating device can forcefully lubricate the lead screw and guide rail.

- The X and Y directions of the X6036 horizontal universal lifting table milling machine are driven by ball screws.

- The base, body, worktable, middle, and lift slide are all cast with high-strength materials. They are processed by artificial aging. It can ensure the stability of the machine tool for long-term use.

- The rotary table can be configured as required. The accessories of the milling machine can also be configured. Such as the indexing head, to realize vertical machining of gears, spiral grooves, etc.

X6036 Horizontal Universal Lifting Table Milling Machine Three Movement Forms

- Main Movement: The main movement of the milling machine refers to the rotational movement of the milling cutter driven by the spindle.

- Feed Movement: The milling machine’s feed movement refers to the worktable’s linear movement to drive the workpiece in three mutually perpendicular directions.

- Auxiliary Movement: The milling machine’s auxiliary movement refers to the workpiece’s rapid movement in three mutually perpendicular directions by the worktable.

Common Accessories Of X6036 Manual Horizontal Milling Machine

- Milling machine handwheel (heavy)

- Single handle counterweight handle (three ball handle)

- Round rim handwheel

- Indexing plate

- Big handle

- Corrugated handwheel on the back

- Inner corrugated handwheel

- Double-spoke handwheel with foldable handle

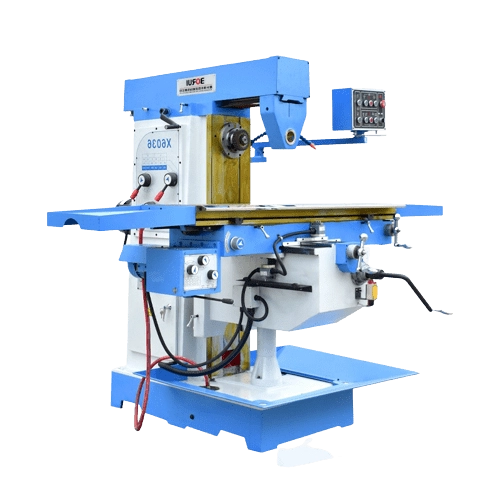

Product Image Display

HORIZONTAL MILLING

Spindle taper 7: 24 ISo50

Spindle speed: 60-1800(12steps)

WORKTABLE

Ultra-audio quenching, precision grinding and scraping guide.

X Y AXIS AUTO FEED

Z axis electric lifting improve processing time.

3 AXIS DRO

3 axis digital readout is

optional, need extra cost

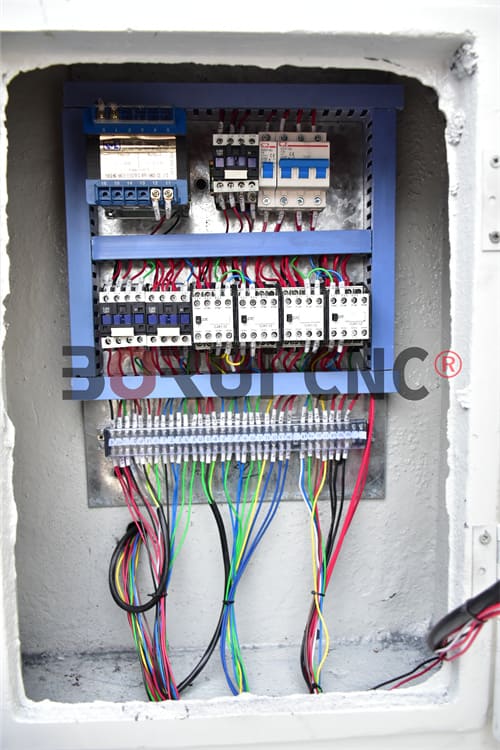

ELECTRIC COMPONENTS

Standard with china brand electric components; Schneider and Siemens.

Reviews

There are no reviews yet.