In today’s world, the cost of labor is getting higher and higher, and automatic processing has become a trend, especially more and more mechanical equipment in the CNC machine tool industry has begun to realize automatic processing. CNC lathe are no exception. Today, let us take a look at a new type of automatic processing CNC lathe – Slant bed CNC lathe.

What Is A Slant Bed CNC Lathe?

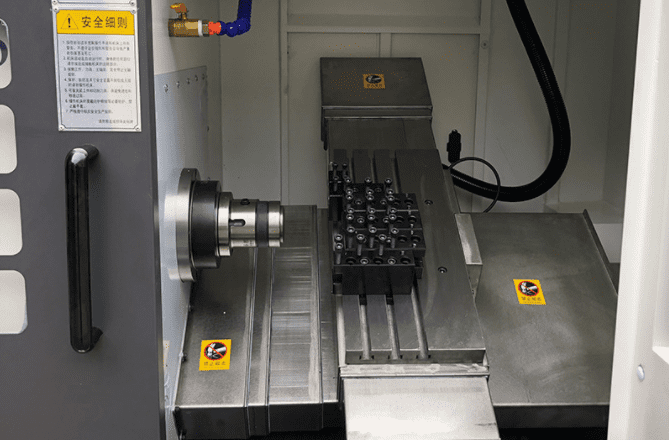

The slant bed CNC lathe belongs to the all-round precision CNC lathe. The main moving parts of the machine tool are driven by ball screw nut pair, linear guide rail and servo motor. The horizontal rails are inclined in pairs, with 35° inclination, 45° inclination and 60° inclination. It has strong processing ability, good rigidity, high precision and stable operation. Usually equipped with a multi-station turret or a power turret, it has a wide range of processing capabilities. The machine tool can realize automatic control and automatically complete complex processing such as inner, outer circle, end face, groove, taper, spherical surface, and thread. CNC slant bed lathe is suitable for precision machining of various high-precision, multi-batch, complex-shaped parts used in aviation, electronics, clocks and other industries, with high processing efficiency and stable and reliable quality.

Features Of Cnc Lathe With Slant Bed:

1. The slant bed CNC lathe is mainly used to process various precision and complex rotating parts, small and medium batches.

2. The optional hydraulic chuck and tailstock can realize automatic loading and unloading. Selected systems and functional components can be clamped in one go for turning and milling functions.

3. The CNC slant bed lathe can meet the processing of common outer circle, inner circle, conical surface, step, spherical surface, groove, various threads and complex curved surfaces. It can meet the roughing and finishing of various superalloys, titanium alloys, heat-resistant alloys, stainless steel, cast iron, cast steel and other materials.

4. The castings are tempered to eliminate internal stress, the X and Z axis guides use linear guides, and the full stroke straightness correction ensures the machine tool movement and maintains good accuracy.

5. The CNC slant bed lathe has good rigidity, good reliability, long life, high precision and fast speed. It can reliably and stably complete rough machining, fine machining and fine machining of various difficult-to-machine materials.

6. The spindle of CNC lathe with slant bed has shorter drag torque and higher spindle speed. The bed is made of cast iron with a 30-degree/45-degree/60-degree sloping bed and is cast as a whole.

Slant Bed CNC Lathe Vs Flatbed CNC Lathe:

Differences in machine tool structure

The bed of the CNC lathe with flat bed is square and the guide rail is parallel to the ground. The guide rail of the CNC lathe with slant bed forms a 30°, 45°, 60°or 75°slant plane with the ground, and the bed is a right-angled triangle. It can be seen that triangles have higher stability than quadrilaterals. From the point of view of the machine tool layout, the X-direction carriage of the slant bed is longer than that of the flat bed, and more tools can be arranged. Multi-station turrets are usually optional, usually 8/12 stations. Compared with the flat car, the general vertical four-station can carry out multi-process processing.

Stability comparison

The cross-sectional area of the slant bed CNC lathe is larger than that of the flat CNC lathe, which determines that its bending and torsion resistance is stronger than that of the flat lathe. Moreover, its cutting direction is consistent with the direction of gravity of the workpiece, so the spindle runs relatively smoothly and is not easy to cause vibration, while the cutting direction of the flatbed lathe is perpendicular to the direction of gravity of the workpiece, which is more likely to cause cutting vibration.

Machining accuracy comparison

The drive screw of the CNC lathe is a high-precision ball screw, and the transmission gap between the screw and the nut is very small. It affects the repeated positioning accuracy of the machine, thereby affecting the machining accuracy.

The bed structure of the slant bed CNC lathe has an inherent precision advantage, which can directly affect the clearance of the ball screw in the X direction. The gravity directly acts on the axial direction of the screw, so that there is almost no backlash during transmission. The X-direction screw of the flat CNC lathe is not affected by the axial gravity, and the gap cannot be directly eliminated.

Comparison of automation capabilities

Under the influence of gravity, the chips generated by CNC lathe with slant bed can slide down along the slant bed to avoid the accumulation of chips on the screw and guide rails. It can also be equipped with automatic chip removal machine, automatic feeding machine or manipulator, automatic feeding, complete all chip cutting processes in one clamping, automatic unloading, automatic chip removal, which greatly saves the effective working time of workers and improves production efficiency. And flat CNC lathes are difficult to achieve automated production.

All in all, the overall configuration of the slant bed lathe is always higher than that of the flat lathe. High precision, fast efficiency, convenient chip removal, more suitable for complex machining.