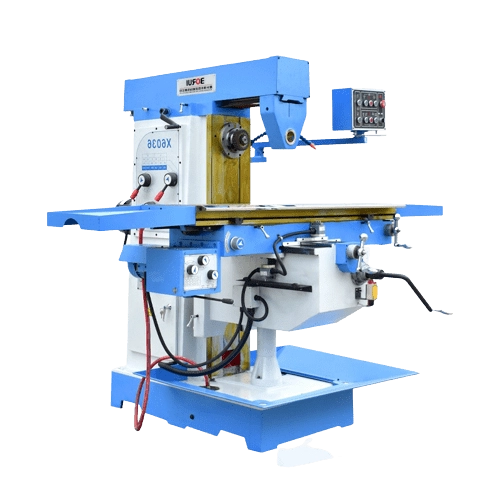

Horizontal Milling Machine

As a top horizontal milling machine manufacturer in China, BORUI has been focusing on designing and manufacturing horizontal milling machines. It is a machine tool used to perform flat surfaces on workpieces.

Suppose you want to know more about BORUI or CNC horizontal milling machines. Please read this page carefully. We will provide you with more details and help you.

Request a Quote!Features of Our Horizontal Milling Machine

Horizontal Cutting Direction

A horizontal milling machine's main feature is that the tool's and the workpiece's relative movement is carried out in a horizontal plane. The cutting process occurs more on the flat surface of the workpiece than on a vertical milling machine.

High-quality Materials

We use only high-quality materials such as Kraft, corrugated, and cardboard to manufacture our paper boxes. These materials are durable and provide excellent protection for the products they contain.Eco-friendly

Our paper boxes are made using eco-friendly materials and manufacturing processes, making them a sustainable packaging solution. We are committed to reducing our environmental impact and ensuring our products are as green as possible.

Wide Range of Sizes

We offer a wide range of standard sizes for our paper boxes, and we can also provide custom sizes per our customers' specific requirements. This flexibility allows customers to choose the appropriate size for their product, reducing waste and improving efficiency.

Horizontal CNC Milling Machine Applications

Horizontal milling machines are widely used in manufacturing industries. It is suitable for some processing tasks that requiring horizontal cutting on the workpiece surface. Here are some of the main application areas for horizontal milling machines.

FAQs About Horizontal Milling Machine

The relative motion of the cutting tool and workpiece of a horizontal milling machine occurs in a horizontal plane. A vertical milling machine cuts in a vertical plane. Horizontal milling machines are suitable for surface machining and large workpieces. The vertical milling machine is suitable for processing three-dimensional parts.

The main components include lathe, spindle, workbench, feed mechanism, tool and tool holder, CNC system, etc.

Tool replacement usually involves opening the tool holder, removing the old tool, and installing the new tool. This process requires ensuring that the tool is properly installed and adjusted.

Maintaining machining accuracy requires regular inspection of the machine tool's geometric accuracy, tool wear, and the operating status of the CNC system. This also includes necessary calibration and maintenance.