Milling machines are of utmost value for manufacturing industries. They help cut and shape the different materials with precision. However, their performance and precision rely on whether you use them correctly. Unfortunately, people don’t get most of these machines due to a lack of awareness. This led me to write on how to use a milling machine.

Small mistakes lead to severe consequences. That’s true when it comes to milling machines. So, people start to believe their machines are malfunctioning. It’s more about using machine conditions on your way instead. I’ll explain how you can avoid those small mistakes. So, let’s get started and discuss the right way!

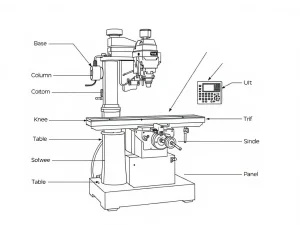

Parts of a Milling Machine

Before going to the central part, let’s discuss the different parts of milling machines. Once you understand these parts, their usage becomes a lot easier. Moreover, these components must work together in harmony. If any of them malfunctions, you won’t get accurate outputs. Here is a table showing the functionality of each element:

| Part | Role |

| Base | Provides stability to the entire milling machine. |

| Column | Holds the machine’s spindle |

| Knee | Supports the table and can move the table up or down. |

| Table | The surface where the workpiece is mounted. It is also called a worktable. |

| Spindle | Rotates and holds the cutting tool to cut and shape the material. |

| Power Feed | Automatically moves the table for consistent and smooth cutting. |

| Control Panel | Allows the operator to program and control the machine (specific to CNC machines). |

You must understand these parts to avoid any problem. For example, you must know how to install the cutting tools on the spindle. Similarly, you should know how to clamp the workpiece on the worktable. Generally, people don’t pay heed to understanding the functionality of these parts.

As a result, they make some unintentional mistakes. Those can include the wrong placement of cutting tools or the lack of improper fixation of the workpiece on the table. The machine does work despite these mistakes. But output comes with some compromised precision. In this article, you’ll get many tips to avoid those unintentional mistakes.

How to Use a Milling Machine?

There are some safety protocols that you must follow while operating a milling machine. Wear goggles and masks to ensure the chips in the workpiece don’t disturb you. Moreover, you should try to stay away from cutting tools when they are moving. Compromising on safety while working can have serious consequences. Let’s go down and discuss the helpful tips and proper ways of using a milling machine.

1- Selection of Cutter

First, you should select the right cutting tool for your task. Remember, there are different cutting tools with varying shapes available. They all can be used in milling machines to achieve different shapes and outputs. Each of them offers unique functionality. To cut some portions of the workpiece, you’ll use sharp cutting tools.

Similarly, gentle finishing of material requires different tools. Cutting tools are made of various materials. Examples include HSS, carbide, and aluminum. If you are cutting strong material, use tools made with HSS material. HSS-made cutting tools are very robust. Conversely, cutting wood or any other soft material does not require such robust tools.

2- Mount the Cutter Carefully

People make mistakes while mounting a cutter on the spindle. Remember, the spindle is part of the machine that holds the cutting tools. During the machine’s working, the spindle moves to rotate the cutters. You should attach cutters with spindles firmly so they don’t move while working. Use a wrench to tighten the cutters with a spindle.

Remember, a small mistake at this step can have serious consequences. Mistakes can lead to cutting tools getting detached from the spindle. It can cause injuries to the operator and damage to the machine. Moreover, loosely attached cutters won’t precisely cut or shape the workpiece. Once you have mounted the tool, make sure to check their installation.

Quick Highlight: Modern milling machines come with a work-holding device. You should tighten this device on the spindle. It would keep the spindle stable and prevent any vibrations. Vibration in the spindle can affect the precision of your work.

3- Placement of Workpiece

Once cutting tools are mounted, it is time to place the workpiece on the table. Remember, the worktable is where you’ll have to clamp the workpiece. In the milling machine, the workpiece remains stationary. The cutting tools mounted on the spindle cut and shaped the stationary workpiece. So, clamping is critical for the stability of the workpiece.

There is no rocket science when it comes to placing the workpiece. Every milling machine comes with a special place marked for the workpiece. All you need to do is to put the workpiece and clamp it. Once done, I recommend you check its stability. It should not be moving separately but firmly attached to the work table.

4- Double Check Screen (In Case of CNC Milling Machine)

There are two types of machines: CNC and manual. If you use a CNC machine, you should also analyze the digital screen. During checking, make sure the computer has the coded instructions fed to it. If everything looks OK, you can switch on the machine. The cutting tools will start to follow computerized instructions.

Sometimes, you feed instructions to the computer and leave it for a while. You don’t see it, but the computer can show errors when you give it the coded instructions. Double-checking the screen ensures everything is perfect. Are you using the manual milling machine? You won’t have a computerized screen to control the machine.

5- Speed of Cutting Tools

The speed of cutting tools is also a crucial factor that influences precision. Cutting harder and softer material requires different cutting tools at various speeds. The tools can get overheated if you cut the more rigid material at a high speed. So, you should cut the more rigid material a bit slower to avoid overheating issues.

On the flip side, the soft materials are easy to cut. They don’t require any additional power from the cutting tools. So, you can set the high speed for cutting tools. They won’t have to put more energy into it, so they won’t face overheating issues. Generally, I recommend the mid-range speed of tools —neither too fast nor too slow.

6- Make Incremental Cuts

The CNC milling machines follow the set-coded instructions, right? You don’t have to do anything to improve the precision. The CNC system takes care of how the cutting tools are cut. However, in manual machines, there is more responsibility on your shoulders. Don’t try to cut a whole piece in one go during cutting.

Instead, you should follow a more gentle approach while milling. I recommend making incremental cuts if cutting any part of the workpiece is needed. Why? Because it improves the precision and smoothness of cutting. Cutting pieces in one go can bring inaccuracies. Once you cut the piece slowly, you get more control of the cutting process.

7- Changing the Tools

During cutting, you might feel the need to change the cutting tools. For example, imagine you need to cut a rigid piece of metal. But you also need to give this part some smooth finishing as well. In this case, you’ll need two different cutting tools. The first would be the sharp cutter. It will cut the required piece of metal correctly.

Once cut, you must use a roughing tool to ensure smoothness. So, you should switch off the machine first to change the tools. Remember, first use a wrench and remove the tools that are already mounted. Now, install the roughing tools and ensure the tools are tightly mounted. They should not be loosely attached to a spindle.

Roughing tools have sharp cutting edges to create finishing on the cut part. Once you have installed roughing tools, you can switch on the machine. Remember, installing the cutting tools on the spindle seems a simple task. But people generally make mistakes while mounting cutters. You should always be careful and tightly bind the tool with a spindle.

How Do Milling Machines Work?

The milling machine is working in a few steps. If you follow them correctly, you’ll get 100% precision in output. Remember, in a milling machine, the workpiece remains in one place (worktable). The cutting tools move or rotate to cut and shape this stationary workpiece. The spindle plays a crucial role in driving these tools.

The spindle is a part that holds the cutting tools. It can move vertically or horizontally, depending on the machine type. The cutting tools mounted on it also move. During this movement, these tools come close to stationary material and cut it. The operator controls the speed of these cutting tools and workpiece adjustment.

However, the workings of CNC milling machines are very different. They utilized the CNC system, which automates the process and improves their precision. In these machines, operators make designs, convert them into codes, and then feed them to the computer. Once the machine is switched, the computer executes those codes.

The cutting tools follow the coded instructions and cut accordingly. However, manual milling machines require more work from the operator. You’ll have to mount the cutter, set the workpiece, and adjust the speed of the cutters. Precision and accuracy depend on the skill of operators.

What Are the Main Types of Milling Machines?

As I said, there are different types of milling machines. Each of them offers a unique cutting experience. Moreover, those types are particular in their work. Here is the list of those types:

- Turret Milling Machines

- Vertical Milling Machines

- Benchtop Milling Machines

- Horizontal Milling Machines

The turret milling machines are more advanced and modern. They come with movable heads, which enhance their versatility. You can use them to cut the workpiece from different angles. Vertical and horizontal milling differ in terms of the orientation of shingles. The vertical machines have a vertically oriented spindle.

So, they cut the work up and down (vertically). Conversely, the horizontal milling machines have a horizontally oriented spindle. So, these spindles move the cutting tool sideways. Benchtop milling machines are generally helpful for hobbyists. They are compact and less expensive, with compromised performance.

Conclusion

Milling machines have become inevitable for manufacturing industries. They cut the material with excellent precision. However, if misused, they can primarily affect precision. Unfortunately, many people use it without proper guidance.

As a result, they end up making unintentional mistakes. There are small things in these machines that can have a significant impact. They tend to blame the machine once they don’t get the desired precision. However, you won’t undergo this situation. I’ve explained how to use the milling machines to get ideal precision.