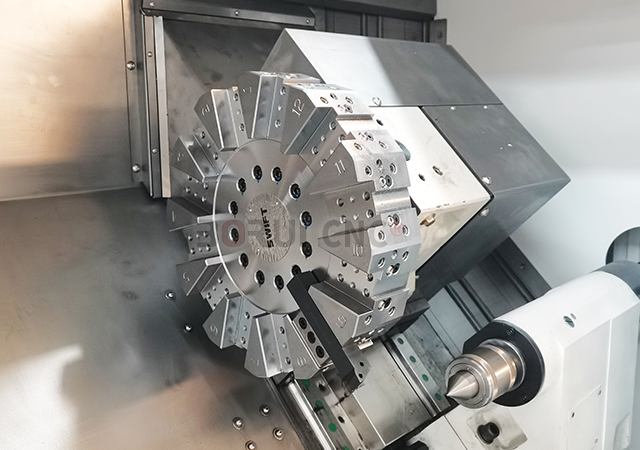

The turret of the CNC lathe is a part used to clamp and fix the turning tool, and usually consists of a turret body, a tool holder and a blade. The turret body is a cylindrical member with multiple clamping holes, which can clamp different types and specifications of tool holders. The tool holder is a part fixed on the turret, which can hold the blade. According to different processing needs, different types and specifications of the blade can be replaced. The blade is a part installed on the tool holder, which directly contacts the material to be processed to complete different processing operations.

The turret of the CNC lathe has the advantages of high clamping precision, convenient blade replacement, and high processing efficiency, which can meet different processing needs. At the same time, it is necessary to pay attention to the cleaning, maintenance and maintenance of the turret during use to ensure its normal operation and life.

The turret of the CNC lathe is one of the important parts of the CNC lathe. It is a device for installing and controlling the turning tool. The turret can hold turning tools in different angles and positions to complete machining operations of different shapes and sizes. The turret can also rotate automatically as needed, allowing the lathe to perform efficient automated machining.

The turrets of CNC lathes can be divided into hydraulic turrets and servo turrets. What is the difference between the two turrets?

Hydraulic Turret

- Strong power: The hydraulic turret is driven by a hydraulic system, which has a high power output and can easily perform operations such as cutting and drilling.

- High precision: The hydraulic turret is controlled by a hydraulic system, which has high control precision and can achieve precise cutting and drilling.

- Simple maintenance: The hydraulic turret has simple structure, easy maintenance and long service life.

- Safe and reliable: The hydraulic turret has safety protection measures such as overload protection and overheat protection, so it is safe and reliable to use.

- Wide range of application: The hydraulic turret can be applied to cutting and drilling of various materials, and is widely used in machinery manufacturing, automobile manufacturing, aerospace and other fields.

Servo Turret

- High precision: The CNC lathe servo system can realize high-precision processing, which can meet the processing needs of high precision in some industrial fields.

- High degree of automation: CNC lathe servo system can automatically complete the processing process through preset programs, reducing manual intervention and improving production efficiency.

- Fast response speed: CNC lathe servo system has fast response speed, which can realize high-speed processing and improve production efficiency.

- Good stability: CNC lathe servo system adopts advanced control technology, has good stability and reliability, and can guarantee the processing quality.