Long before, manual milling machines were the backbone of every machine shop. Machinists relied on their skill and steady hands to shape metal into useful parts. Every move depended on the machinist’s skill and their deep understanding of tools and materials.

Today, CNC milling machines have changed the game. Now, these machines make parts fast and precisely using digital instructions. When choosing between manual and CNC milling, you are really choosing between tradition and technology. Both have their place, but each offers a different path to precision and creativity.

Understanding Manual Milling Machines

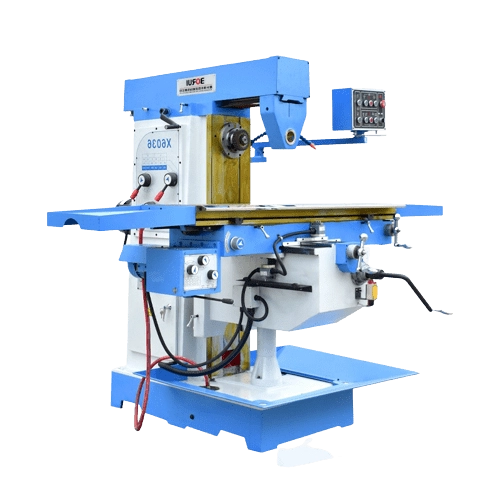

Manual Milling Machines are hand-controlled machines for shaping metal and other materials. The operator controls the machine, using wheels and levers. There are no computers or automatic controls. Every movement is made by the person using the machine. Manual milling machines have been used in workshops for many years. They are valued for their versatility and direct control.

- Hands-on control: Manual milling machines are operated entirely by hand. The machinist uses handwheels and levers to move the workpiece and cutting tool.

- Customization: Manual machines are optimal for producing unique customized pieces or single units. An operator can alter their cutting method to achieve specific product shapes whenever needed.

- Cost-effective solution for small projects: These machines offer lower prices than CNC machines. Manual milling machines serve as excellent tools for small shops. Also, hobbyists and individuals benefit who need to make limited runs of special projects.

Exploring CNC Milling Machines

Modern CNC milling machines perform material cutting operations through computer-operated controls. The machines operate with metal along with plastic, wood, and other materials. The machine executes digital instructions that include cutting, drilling, and shaping operations.

CNC mills perform simultaneous movement in multiple directions. The machine proves beneficial for creating various parts and products. The widespread use of CNC machines extends across multiple production sectors.

Factors to Consider Before Choosing

Deciding between CNC milling machines and manual milling machines needs careful understanding. Some key factors for your consideration are:

1. Intended Use and Project Requirements

Determine your intended outcome with the machine. What type of objects do you need to produce through your machine setup? The decision between CNC machines and manual machines depends on your work requirements. Suppose they need repetitive tasks, high precision, or intricate shapes. Manual machines provide the best solution for single-use projects and maintenance work. It allows users to maintain direct machine operation.

2. Material Compatibility

Check if the machine can handle the materials you plan to use, such as metals, plastics, or wood. Some machines are designed for softer materials. Others can cut hard metals like steel or titanium. So, select the right match. It will ensure good performance and longer tool life.

3. Precision and Accuracy

The successful completion of numerous projects depends on precision. CNC machines offer high accuracy and repeatability. This makes them ideal for tight tolerances and detailed work. Manual machines rely more on the operator’s skill. This can limit precision for complex or repetitive tasks.

4. Production Volume and Speed

Consider how many parts you need to produce. CNC machines are built for high-volume, fast, and repeatable production. Manual machines are more suited for low-volume or custom work. If you need to make many identical parts, CNC is usually the better choice.

5. Budget and Total Cost

Budget is always a key factor. Manual milling machines are generally less expensive to buy and maintain. CNC machines have higher upfront costs. But they can save money in the long run through speed, automation, and reduced labor. Also, consider costs for software, maintenance, and spare parts.

6. Customization Needs

When you need customized pieces or parts for a small project or require a prototype, go for manual machines. They allow for easy, on-the-spot changes during the machining process. CNC machines can produce customized parts, too, but changes often need reprogramming. Think about how often you need to adjust or customize your parts.

7. Maintenance Requirements

Manual machines require more maintenance. This is because the wear and tear is more with manual operations. On the other hand, CNC machines are low-maintenance machines. They may need software updates, calibration, and specialized maintenance after long periods.

Manual Milling Machines

Advantages of Manual Milling Machines

Manual milling machines present affordability combined with user-friendly operation. These machines provide complete control to operators during their cutting operations. Operators can easily modify their work or implement spot adjustments through the manual control system. Manual mills serve in custom work and repairs. They work well for small-scale operations. These machines provide both reliability and ease of maintenance. They enable machinists to develop practical operational skills.

These machines prove several strong points. However, they present fundamental limitations to their operation.

Disadvantages of Manual Milling Machines

- Slower Production: Manual milling produces work at a significantly slower rate compared to CNC machining. The machine operates too slowly to handle high-volume or repetitive work requirements.

- Operator Skill Required: A proficient operator must properly handle this machine. Achieving precise results with reliable quality requires operators who have significant experience. Mistakes during operation result in faulty workpieces and production errors.

- Limited Complexity: Manual mills face problems when working with complex shapes AND tight tolerances for repetitive tasks. The production process for complex structures demands both extended time and skilled efforts.

- Higher Risk of Human Error: Hand-controlled operations create numerous possibilities for human errors. The probability is high throughout extended and intricate production tasks.

- Material Waste: Human mistakes during manual operations cause material waste through inefficient material usage and increased scrap rates.

- Not Ideal for Large Runs: Manual milling shows limitations when manufacturing large product volumes since automated systems perform better at lower costs.

Key Applications of Manual Milling Machines

Manual milling machines are used throughout workshops and repair facilities. Their applications include repairing broken equipment, building prototypes, and fabricating custom parts. Machinists can handle quick change requirements during their small-scale production runs. Technical training centers use manual mills as teaching tools. These machines serve jobs that require immediate control adjustments in real-time. Quick fixes or performing single-use tasks can be easily done. They provide essential functionality to those who need flexible control over machining operations.

CNC Milling Machines

Benefits of CNC Milling Machines

These machines offer many advantages for modern manufacturing. They deliver high precision and repeatability. This allows the production of complex parts with tight tolerances. Once a program is set, the machine can make many identical parts with little human effort. This reduces errors and saves time.

CNC machines can handle complex shapes and detailed designs that are hard to make by hand. They work with many materials, including metal, plastic, and wood. CNC milling also increases productivity, as one operator manages multiple machines at once. Additionally, CNC milling is also safer, as less manual handling is needed. CNC machines are efficient, accurate, and perfect for both large and small production runs.

Limitations of CNC Milling Machines

- High Initial and Operating Costs: CNC machines are expensive to purchase, set up, and maintain. Specialized software, tooling, and skilled operators add to the overall expense.

- Size and Work Envelope Restrictions: Each CNC machine has a fixed work area. It limits the maximum size of parts it can produce. Large or cumbersome components may not fit or may require special setups.

- Need for Skilled Technicians: Despite automation, CNC machines require trained technicians. They program, operate, and oversee troubleshooting. If the operator is not skilled enough, it can lead to errors and lower-quality parts.

- Maintenance and Downtime: CNC machines require frequent maintenance and repair operations. The maintenance tasks are costly, which leads to delayed production when problems occur.

- Programming and Setup Time: Creating or reprogramming for new parts can take significant time. This is especially for complex jobs or one-off projects.

- Not Ideal for Complex Customized Parts: The setup and programming take time for single or complex parts. Manual machining proves more cost-effective than this machining method.

Key Applications of CNC Milling Machines

Many industries rely on CNC milling machines to produce accurate, complex parts. These machines serve in automotive production plants, aerospace facilities, and electronics production facilities. At the same time, they are commonly used in medical product manufacturing. The precise capabilities of CNC mills enable the production of engine parts and gears as well as molds and custom tools. These machines serve both prototyping needs and produce small batches of products.

A CNC machine system can execute the same production sequence multiple times because it operates based on programmed instructions. CNC machines follow computer instructions, which is why they are suitable for both mass production and customized work.

CNC milling machines are the best choice for any job requiring speed, precision, and repeatability.

Top CNC Machine Tool Manufacturers – BORUI CNC

BORUI CNC stands as a premier company in the CNC machine tool market that manufacturers worldwide trust. BORUI CNC machines achieve recognition through their precise components, dependable structure, and innovative technological features. Through our customized solutions, we serve various industries. This results in improved quality and increased productivity for our business clients. The company leads modern machining through its global support network and innovative focus. View all our products.