Offering precision engineering and industrial-grade durability, CNC machines are critical tools in the aerospace and manufacturing industries. These computer-controlled systems execute programmed specifications to manufacture parts with precise dimensional accuracy. Requirements vary widely across industries, so choosing the right equipment is critical to production efficiency.

We analyzed 10 well-known CNC manufacturers, evaluating their technical capabilities and industry specialization to facilitate an informed purchasing decision.

What is CNC Machine?

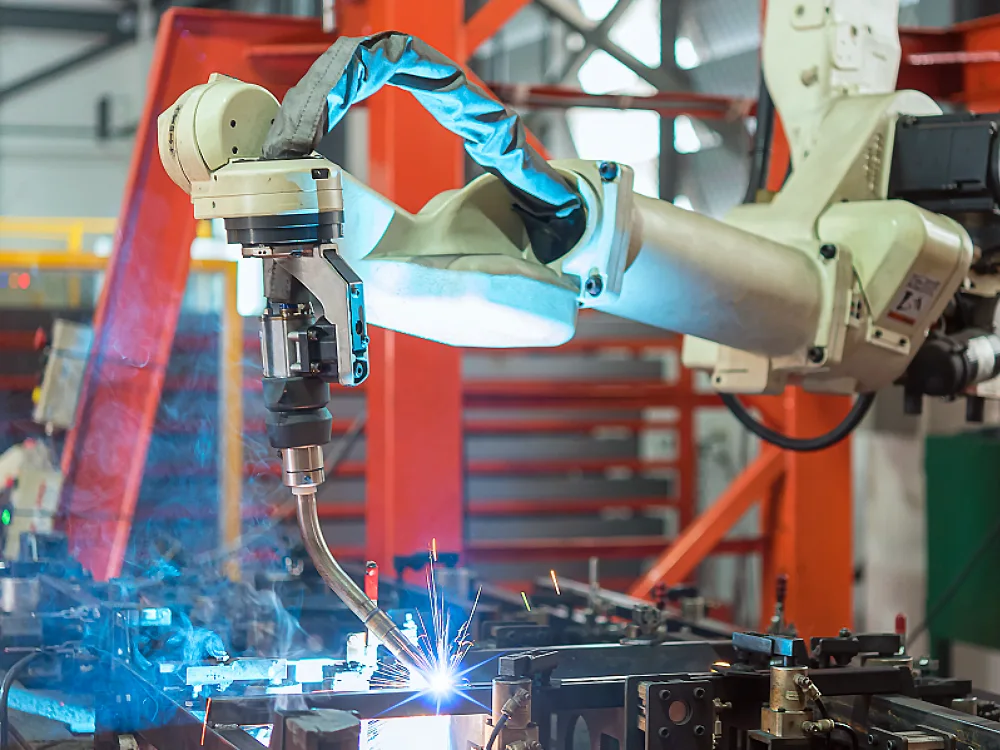

CNC machines cut, shape, or engrave materials. They are controlled by a computerized system. Due to their automation, these machines offer 100% precision. Above all, they can cut large materials in minutes and are helpful in mass production. Therefore, big manufacturers always prefer these machines.

In the past, metalwork used to be very slow. Even for simple cutting and shaping, the manufacturer had to spend much time. Things have changed with the emergence of these CNC machines. They can cut the material within minutes with ideal precision. The chances of error are zero as cutting tools are controlled by computerized software.

Let’s understand the workings of these CNC machines. First, the required parts are designed with CAD software. This design then goes into the CAM (Computer Aided Manufacturing) software, which changes the file into G-code programmed instructions. The CNC machines follow these instructions.

The operator feeds these instructions to the machine. As a result, the cutting tool follows the instructions. So, they move according to these pre-programmed directions and cut the material. The computerized system controls the whole system. These machines can easily cut the material into any complex shape.

Types Of CNC Machines

CNC (Computerized Numerical Control) is being used in numerous machines. Those tools offer different functionalities in metal fabrication. CNC technology is taking over the market, from press brakes to laser cutters. Here is the list of different types of CNC machines:

- CNC Lathe

- CNC Router

- CNC Laser Cutter

- CNC plasma Cutter

- CNC Punch Presses

- CNC Milling Machines

- CNC Grinding Machine

The list goes on as this technology is being incorporated into various machines. No matter what machine you use, the presence of CNC ensures 100% precision and quick turnaround. CNC machines have replaced manual labor in many industries.

Leading 10 CNC Machine Manufacturers

In the section above, we discussed the basics of CNC machines. Buying these machines can be tricky. Many manufacturers claim to be the best, and trusting without doing research may result in purchasing a low-grade product.

As you know, the CNC machines are costly. When you make a mistake while choosing a manufacturer, your budget can be at risk. That’s why I am here to help you out. In the section below, we will discuss the leading CNC machine manufacturers.

1- Yamazaki Mazak (Japan)

This is a Japanese company founded in 1919. It is one of the oldest CNC machine manufacturers. This corporation specializes in producing different types of CNC machines, including CNC Lathes, Milling machines, CNC turning machines, and laser processing machines.

What makes this company stand out is its wide range of products. Moreover, Yamazaki Mazak has over 8,700 employees as of 2023, indicating its success. Keep in mind that this company exports its CNC machines all over the world.

However, it has 11 manufacturing plants in different parts of the world. The primary manufacturing of their product is done in Japan, as this company has its headquarters in Japan. However, it produces machines in the United States, the United Kingdom, Singapore, China, and India.

2- Okuma (Japan)

The Okuma company started as a noodle machine manufacturer. However, with time, they evolved and became significant players in the CNC industry. From 1898 to the present, this company has kept up with the changing times. They started incorporating CNC technology in their products in 1955.

What makes a corporation unique from competitors is its in-house component manufacturing. Unlike other companies, it manufactures many of its components. So, it controls the quality by offering high-quality components. For this reason, they have combined all the manufacturing processes under one roof.

The Okuma company has branches in many parts of the world, including the USA, Europe, Singapore, Taiwan, Australia, Thailand, and China. Moreover, CNC machines made by this company are made in a green-friendly environment, ensuring that less carbon will be in the atmosphere.

Let’s discuss their strive to be the best. The company makes 50% of its profit from the overseas market. However, it heavily invests in research and development. Due to such extensive investment, Okuma quickly adapts to new technologies and designs. This company is considered a pioneer in innovation.

Quick Tip: This company does not import anything from small to large machine components. They have a complete manufacturing setup. As they make every part themselves, they always ensure the quality. This is why the CNC machines made by this company offer better durability.

3- Haas Automation (USA)

Haas Automation is a USA-based CNC machine manufacturer. Gene Haas founded the company in 1983, so it has been producing CNC machines for over thirty decades. To date, this company has produced more than 300,000 CNC machines.

These numbers are taken from official sources, so they indicate rapid success. Moreover, the company has a worldwide presence. Its headquarters are in Oxnard, California, USA. Haas has a dealership network in many countries, so you can buy their product no matter where you are.

One thing that I noticed is that the CNC machines produced by this company are expensive. The reason is that these machines are made in the USA. The higher labor cost impacts the product price. However, the quality of their products is top-notch due to the strict quality standards.

This corporation offers different types of CNC machines, including CNC milling, lathe, drilling, etc. Moreover, they have a complete inventory of spare parts for their machines. You can quickly get the required parts if your machine has any issues.

4- DMG Mori (Germany)

This is one of the oldest companies. Its headquarters are in Germany and Japan. The dual headquarters might sound strange to you, but it’s true. This company was founded by merging two companies, including Gildemeister and Mori Seiki.

This company’s headquarters are in Bielefeld, Germany, and Nara, Japan. The German headquarters was founded in 1870. The company produces high-quality CNC machines and has 17 manufacturing plants worldwide.

It is considered one of the most respectable names among CNC manufacturers. It has over 13,000 employees. This company uses Japanese and German laborers, making its products excellent. Both countries are famous for engineering and have the best talent for manufacturing CNC machines.

5- AMADA (Japan)

Amada is a Japanese company that is considered one of the best in the manufacturing process. It offers a full range of services, not only CNC machines. Those include repairing, parts manufacturing, rebuilding, integration, etc. The company was established on September 10, 1946.

In 1955, Amada created the first saw disk with a curved profile, a great innovation. After that, the company progressed and started manufacturing different CNC machines. However, it was not limited to this. It also manufactures machines for sheet metal processing, welding, laser cutting, etc.

This company has a worldwide presence. Its CNC machines and other manufacturing tools are sold in over 100 countries. According to the 2023 report, the company has 8,958 employees, which indicates its success. Amada has been in the industry for the last seven decades, so you can trust its experience.

6- BORUI(China)

Are you looking for manufacturers that offer CNC machines at affordable pricing? If so, this BORUI company will meet your expectations. It is a relatively newer company than the other brands discussed above. Founded in 2015, this business has made quick progress in manufacturing CNC machines.

This company is based in Tengzhou City, China. As the labor cost in China is low, this company offers machines at relatively affordable prices. Affordable pricing never means a compromise on quality. They have a strict quality system to ensure every machine that goes out is reliable.

Having decent success in just a few years indicates their dedication to the business. Moreover, many organizations certified this company for its excellent manufacturing system. Some standard certifications include ISO9001, CE, GMP, GSV, OHSAS18001, and SA8000. Their product line is not limited to a few machines.

Instead, it offers complete CNC solutions. The company provides CNC lathes, milling machines, grinders, vertical/horizontal machining centers, saws, etc. Moreover, they can also create machines as per your custom instructions. Therefore, you should contact the team at BORUI to get started!

7- Trumpf (Germany)

When founded in 1923, this company did not start as a CNC machine manufacturer. Instead, it was more focused on manual machines. However, they shifted their business after almost 50 years. They made the first fabrication machine with a CNC system in 1968.

After that, the company focused on CNC machines and is considered a pioneer. Interestingly, they have focused on making CNC machines for cutting and shaping only. Instead, they have also introduced CNC machines in laser machines, electronics, and other power tools.

The question that might be in your mind is: Should you trust this brand? I would say yes. The reason is that this company has a good reputation. Along with years of experience, they have served the industry for decades. No matter where you are, their products are available worldwide. They also have subsidiaries in the United States, Switzerland, Japan, and other countries.

8- Makino (Japan)

Makino is considered one of the earliest Japanese manufacturers. The company’s journey started when Tsunezo Makino launched the first machine shop in Tokyo, Japan. However, the company Makino was registered in 1937.

Makino introduced Japan’s first CNC machines in 1958 when no other brands focused on this field. They also launched the first machining center in 1966, which gave the company a big boost. Right now, they are producing CNC machines on a large scale.

Their machines are sold worldwide. Makino will serve you right at your doorstep in Asia, China, the USA, or Europe. According to official statistics, the company has 4,731 employees. These are decent numbers, indicating the company’s workload and success.

Quick Info: All the parts and components of their CNC machines are made in Japan. In other words, they supervise every process involved in manufacturing CNC machines. This makes them unique and stand out. So, you can trust their quality.

9- Hardinge (USA)

This is one of the oldest companies operational since the 1890s. Henry and Franklin started this company in Chicago, Illinois. Initially, the company manufactured tools for watch-making. However, with time, it saw a massive shift from watching-making tools to CNC machines.

The first Hardinge CNC machine was created in the 1960s. Before that, the company was only focused on making manual tools. With the success of the first CNC machine, they did not look back. It is interesting to note that their first CNC machine was sold to China.

In the 1990s, the company changed from Hardinge Brothers Inc. to Hardinge Inc. One thing that makes this company a bad option is its higher prices. Being USA-based, it has to face higher labor cost issues in the United States.

To cope with this issue, they have to increase the prices of their products. On the contrary, the brands made in Japan and China offer inexpensive CNC machines. Hardginge also has a worldwide presence. You can get their machine from anywhere in the world.

10- EMAG (Germany)

This is another German company headquartered in Salah, near Stuttgart, Germany. Interestingly, the company is ancient but has undergone many transformations. In the 1870s, it was a cast iron factory in Bauzen, Saxony.

However, it was rebuilt in 1952. After its reappearance, the company was more focused on CNC-based tools. The 1980s proved to be a game-changing year for this venture. During this time, it was a leading manufacturer of automated CNC lathe cells. Not only this, it is also used to make inverted lathe machines.

This brand’s CNC machines are mid-range in terms of pricing. Their quality could be better, so I chose it at number ten in this guide. If you are from Germany, you can opt for this. However, I don’t recommend it to someone in Japan or the USA. You can find options in these countries.

Criteria for selecting brands for CNC Machines

As I said earlier, choosing the right manufacturer makes a big difference. The reliable brand offers better quality products. Not only this, but you get a mental piece that your order is in safe hands.

In the section above, we discussed some reputable names in the industry. However, you might not like those, and look to find yourself. In this case, I would like you to know the most essential criteria for selecting a CNC manufacturer. Let’s go down and discuss.

1- Customer Reviews & Reputation

Before choosing any manufacturer, you must know its reputation. You should visit the manufacturer’s official website and read the reviews to do this. Many websites show the reviews of previous customers. If you see a positive rating, chances are high that the manufacturing is legit.

Moreover, you can visit different communities or forums. You can ask questions about your specific shortlisted manufacturer. There will be many people in the community who might have worked with that manufacturer. So they can share their experience with that manufacturer. This will help you make better decisions.

2- Know What You Need

The CNC manufacturers aim to sell you maximum to make their maximum profit. However, you will have to be wise in decision-making. Before you visit the manufacturer, you must know what you need. For example, there are different CNC tools. Each of those works differently and serves a specific function.

Are you looking for a machine to cut, shape, or drill? You should understand your needs. This will help you pre-decide the machine you need. Moreover, machines have different sizes. Larger ones are super expensive. So, consider the size of the parts you’ll be working on. This will help you find the best-size CNC machine.

3- Support and Service

This is one of the most critical factors. A manufacturer that doesn’t offer support after purchase should never be considered. CNC machines are complex and wear and tear are common in them. If your brand provides support, it will be much easier for you to fix the issues.

You can discuss this with the manufacturer from the comfort of your home. Moreover, it will be ideal if the manufacturer gives you gentle training about the machine. This won’t take much time, but it will make you aware of the machines. You’ll be able to operate the machine efficiently.

4- Warranty

I believe that machines should never be trusted. They can go crazy and show wear and tear anytime. In such cases, the warranty comes in handy. You can send your faulty machine to the official manufacturer and have it fixed.

That is why I highly recommend you choose the manufacturer that offers a warranty. It will give you peace of mind. Even if your product has any issues, the brand stands tall behind you. Those manufacturers that hesitate to offer a warranty must be rejected. If they don’t trust their products, then why should you?

Price & Affordability

This is a dealer maker or breaker. It is a reality that not all of us have the same handsome budget. Some people prefer affordable options, while others spend more for better quality. So, what kind of person are you? CNC-made in the USA is expensive.

On the flip side, the Japanese, Chinese, and German machines are affordable. The reason is that labor costs in these countries are lower. So, the manufacturer reduces the prices to get price benefits over competitors. To reduce price, the quality of these machines is slightly compromised.

However, USA brands focus more on quality rather than prices. So, if you are on a tight budget, go with Japanese brands. On the other hand, if quality is your top priority, USA-made CNC machines should be preferred.

Quick Note: The Chinese and Japanese markets were notorious in the past. But things have changed. The Chinese manufacturers mentioned above, such as BORUI, are top-notch. They make machines under strict quality checks. You can trust them, as their price and quality are optimal.

Future Trends in CNC Manufacturing

The future of CNC manufacturing is bright. As I mentioned, fabricators and manufacturers have started to understand the potential of these machines. So, they are also rapidly shifting to CNC machines. Old machines that required extensive human efforts are becoming less common.

Due to this, the demand for CNC machines is increasing daily. This makes the manufacturer produce more machines and earn profits. It won’t be wrong to say that CNC manufacturing is in trend. The adaptability of CNC is increasing, so the trend seems to continue to grow.

Frequently Asked Questions

Q1: Who is the largest CNC machine manufacturer in the world?

There are many manufacturers available, each with its advantages and disadvantages. However, DMG Mori is reliable and currently the largest CNC machine manufacturer in the world.

Q2: Which company is best for CNC machines?

Many brands and companies focus on the CNC field. However, BORUI CNC is a reliable option. Haas Automation, Mazak, and Okuma are decent options.

Q3: Which country is best for CNC machine manufacturing?

China, Japan, Germany, and the USA are the top countries producing CNC machines.

Q4: How do you choose the proper CNC machine manufacturer?

It takes work to choose a reliable manufacturer. However, it would be best to consider reputation, customer reviews, warranties, and experience. If a manufacturer meets these criteria, it should be considered.

Conclusion

CNC machines have revolutionized many industries. Numerous manufacturers rely on these machines for quick, precise metalwork. However, buying these machines is more challenging than using them. You’ll have to do complete market research before choosing the proper manufacturer.

Slight mistakes can put your budget on the verge of risk. But you don’t need to worry. This guide provides the top 10 CNC machine makers. All of them are picked after detailed market research and customer feedback. If you choose any of those, you won’t regret it.