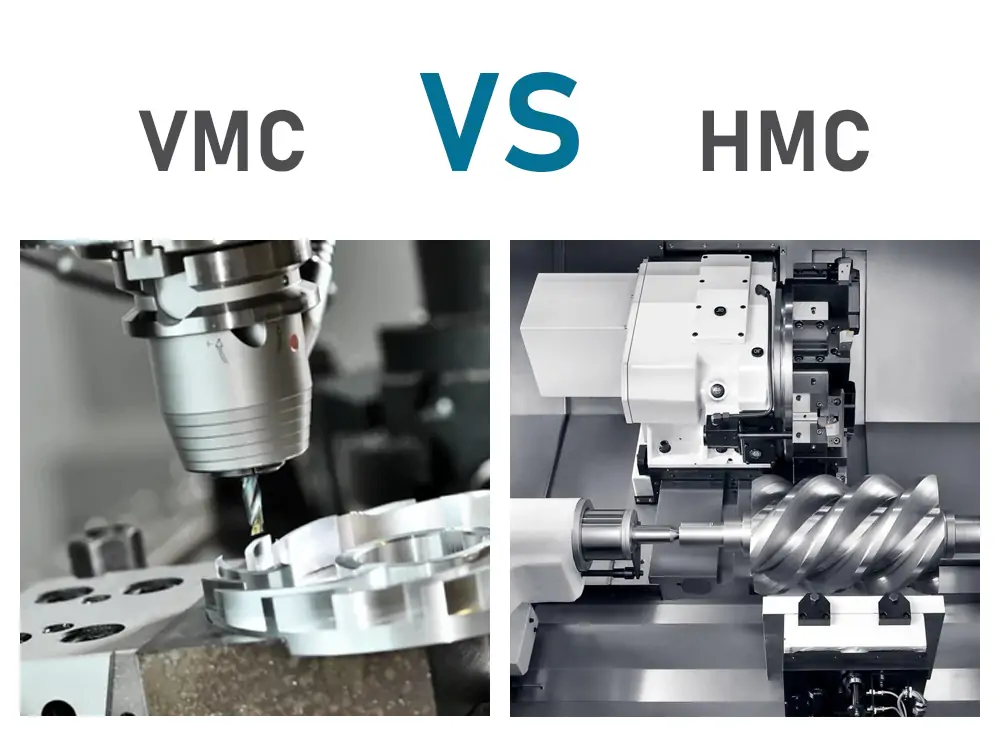

CNC technology has revolutionized the manufacturing industries. Different types of CNC machines are available. They are well known due to their precision. However, the differences between VMC and HMC are often confusing for many. Nevertheless, it won’t be after this detailed piece.

Both horizontal and vertical machining centers are excellent for their purpose. But they suit people with different preferences. For example, the beginner-level manufacturer prefers VMCs. However, the HMCs are advanced and ideal for established manufacturers. Let’s dive in and explore the differences between these machines.

What are VMC and HMC?

Both of these machining centers vary in terms of their spindle orientation. The spindle is a component in these machines that holds the cutting tools. The VMC has a vertically oriented spindle. On the contrary, the HMC has horizontally oriented spindles, making it more versatile and advanced.

VMC stands for Vertical Machining Centers, and HMC stands for Horizontal Machining Centers. Let me explain these two in more detail. Both are machining centers equipped with an automated tool-changing system. So, they are swift, and the CNC system makes them precise.

But they differ in the way their spindle moves. Remember, these machining centers cut, shape, and design that workpiece using cutting tools. Spindle movement controls the movement of cutting tools. In VMC, the spindle moves in a vertical axis or up-and-down direction. In HMC, the spindle movement is horizontal or sideways (side-to-side).

What is the Difference Between VMC and HMC?

In the section above, I gave a basic overview. However, there are many differences between these VMCs and HMCs. I know a bird’ s-eye view is insufficient for you to understand, so let’s go into more detail. Explanation of their differences will make your buying decision easier.

1- Structural Differences

It won’t be wrong to say that these machines differ in their structures. This is their primary dysfunctioning factor. In VMC, the spindles move in the vertical plane. In simple words, the movement of cutting tools is up and down. Keep in mind that the spindles hold the cutting tools. So, the spindle’s movement affects the cutting tools’ movement.

The worktable moves in the X and Y axes. The worktable has no rotatory motion, but the HMC is more advanced. The spindle moves in horizontal axes. The cutting tools move sideways and cut the workpieces. The work table moves in multiple axes. It can also rotate following the B-axis, offering various angles for cutting tools.

So, the cutting tools can remove the chip from the workpiece in many directions. This allows them to make complex designs and shapes with ease. Such work of tools from different angles ensures better performance. The worktable moves in a limited direction when it comes to VMC. So, the movement of cutting tools is restricted, hence the performance.

2- Differences in Worktables

The worktable in the VMC is very simple and easy to use. It has a plane shape with t-slots. The operator simply places the workpiece on it. This table also has clamps that hold the workpiece steady. However, the HMC has a more advanced and modern worktable.

What makes this table unique is its rotary movement on the B-axis. This movement allows the workpiece to move to different angles. So, it becomes easier for the cutting tools to cut and shape the material. Keep in mind that HMC has a full four-axis worktable. It can rotate and move the table in four directions.

3- Chips Evacuations

This is another factor that makes HMC superior. Chip evacuation means pieces that are removed from the material during cutting. In the VMC, these pieces do not fall off. Instead, they remain in the working area due to the vertical positioning of cutting tools. Operators have to remove them manually.

But that’s different when it comes to HMCs. The chips fall off quickly due to the impact of gravity. The spindle’s horizontal position automatically removes the chips. So those chips or pieces don’t accumulate in the working area. So, this makes the working area cleaner. Moreover, if the chips accumulate in the working area, they can cause wear and tear.

Point to Remember: If the pieces remain on the machines, they can cause heating issues. The machines start to malfunction or slow down. VMCs require manual cleaning of chips after regular intervals. But HMCs don’t need such cleaning and offer quick work without regular breaks.

4- Performance and Efficiency

Have you read the above part carefully? If yes, you will bet that HMC is better than VMC in terms of performance. But why is that? HMCs have more axes of movement. Their cutting tools get more angles at which to work. The worktable can rotate, giving more angles for cutting. So, complex shapes can be made with ease.

Moreover, their automatic chip evacuation makes these machines quick. The operator doesn’t have to remove the chips manually. On the flip side, the VMCs are slow and limited in terms of their angle and axes of movement. The worktable doesn’t rotate in B-axes. This is why HMCs are advanced, efficient, and super.

Advantages and Disadvantages of HMC

As I said earlier, these machining centers have strengths and weaknesses. It is vital to comprehend those realities to make wise decisions. Here is the table showing their positives and negatives.

Advantages of HMC

- Efficient chip evacuation

- Make complex parts with high-precision

- Ideal for more extensive and heavier workpieces

- Quick and high-volume production

- Suitable for making complex shapes

Disadvantages of HMC

- High initial cost

- Complex setup and components

- High Maintenance cost due to complex parts and components

Advantages and Disadvantages of VMC

Like the horizontal machining center, the VMC has some advantages and disadvantages. One thing that I like about VMCs is their simplicity. You won’t need an expert operator for them to work. Let’s highlight their key pros and cons.

Advantages of VMC

- Simple and easy to operator

- Inexpensive and less maintenance cost

- Installing and clamping the workpiece is easy

- Less wear and tear due to a less complex setup

Disadvantages of VMC

- Limited axes for movement

- Cannot create a complex shape

- Unfit for large workpieces

- No proper chip evacuation system

- Slow and can take more time to complete simple tasks

Which One Should I Choose: HMC or VMC?

There is no definite answer to this question. Their selection depends on the users’ needs. If you are an established business, choose HMC, which offers better performance and efficiency. However, VMC is suitable for someone new to the manufacturing business.

The HMC is ideal if you aim to improve performance. Its multiple axes movements ensure that it easily achieves complex tasks. However, it is costly, which is a big drawback. Someone with a tight budget won’t be able to afford it. So, I don’t recommend these machines to someone starting new.

Instead, choosing VMC is a suitable option for small or new manufacturers. The reason is that it is inexpensive. You can buy them and start your business quickly. In summary, HMC is suitable for established companies. The VMC is ideal for small manufacturing. Analyze yourself in which category you fall and then make decisions accordingly.

Conclusion

Undoubtedly, both HMC and VMC are excellent in their ways. Some people consider them competitors. But I don’t! The reason is that they both are suitable for different users with different needs. They meet their requirements. In simple words, both of them make manufacturers’ lives easier. This guide compares them and lets you know which to choose.