A Vertical Machining Center is a complex productive machine that operates on flat surfaces to create holes. Modern CNC technology depends on Vertical Machining Centers (VMCs) to function as its critical industrial equipment. A vertical spindle enables VMCs to approach workpieces through an elevated position.

These machines are known for stability and accuracy. VMCs excel in shaping metals, cutting, drilling, and milling industrial parts. They combine advanced technology with multi-functional design to deliver exceptional accuracy and efficiency.

In this article, we will explore these industrial workhorses. We will discover their components and applications and learn how to choose one for your project.

What is a VMC Machine?

Vertical Machining Centers- also referred to as Vertical Milling Machines, use a computer-controlled system to shape metals and other materials.

The term “vertical” refers to the spindle axis, which runs up and down. The design structure positions the cutting tool above the workpiece that rests on a movable table operating on the X and Y axes with the spindle moving along the Z axis.

VMCs are distinguished from other machining equipment by their vertical spindle configuration. This arrangement allows gravity to assist with chip evacuation and coolant flow. It makes the machining process more efficient. The vertical orientation also gives operators better visibility and easier access to the workpiece during setup and operation.

The machines operate to perform automated processes which manage complex manufacturing tasks. They employ computer control automation methods and automatic tool changer alongside contour control to ensure repeatability. The production process attains higher efficiency, which results in better product consistency, combined with reduced delivery periods.

There is a wide range of machining centers. They differ based on their axes, functional capabilities, and other equipment features.

How many axis are in VMC machines?

VMC machines typically have three axes in the x, y, and z axes, with the cutter operating in the z-axis.

Some VMC machines can be upgraded to include additional axes. A 4-axis VMC adds a rotary axis (usually the A-axis) that allows rotation along the X-axis. This lets the machine work on four sides of a part without repositioning it.

For more complex parts, 5-axis VMC machines are available. These add two rotary axes to the three linear axes. A vertical machining center equipped with a trunnion-style rotating table enables movement across the A and B axes. The machine design enables reaching every workpiece part through a single setup.

The number of axes directly affects the amount of parts a VMC can make. More axes mean more complex parts but also higher machine costs. Many shops use 3-axis VMCs for most work since they handle common jobs well. Only specialized industries needing intricate parts typically invest in 5-axis machines.

Components of A Vertical Machining Center

Rotating Spindle

The milling spindle sits vertically to the work table. It rotates and holds tools or workpieces. This shaft acts as position support and rotary drive for workpieces. The spindle approaches the workpiece from above to perform cutting operations.

Work Table

The work table is flat and holds workpieces directly or with fixtures like clamps. It moves along the X-axis (left and right) and Y-axis (front and back). Combined with the Z-axis, these movements allow unlimited features across motion planes.

Tool Changer

The tool changer boosts VMC productivity. It lets the machine pick tools automatically for different jobs, from rough cutting to fine boring. Tool changers come in disc type (for under 30 tools) and chain type (for over 30 tools). This automation reduces tool changing time and maintains high positioning accuracy.

Rotating Tables

Adding rotating tables upgrades a basic 3-axis mill to a 4-axis or 5-axis machine. This enhancement allows machining complex parts with varying surfaces like turbine blades. Some designs use angled rotary tables at 44.5 degrees to improve rigidity during high-speed machining.

Coolant System

Most VMCs use recirculating coolant systems to keep parts and cutters lubricated. These systems typically use water mixed with soluble oil or other fluids. A complete coolant system includes reservoirs, pumps, filters, pipes, nozzles, and control valves.

Enclosures/Full Covers

The covers installed on machines minimize the amount of material that splashes during milling operations. Machining enclosures function to protect workers who operate machines and the surrounding area from the industrial process. Controlled enclosures function to contain both coolant and chips.

Quick Loading Loaders

Automated part-loading systems and shuttle tables boost VMC productivity by decreasing machine downtime. These systems allow the spindle to operate more frequently by cutting down loading and unloading times.

Screw/Chip Conveyor

Augers and chip conveyors collect scraps from manufacturing areas to transport them outside the work environment. As a result, production efficiency rises through the elimination of time required to manually remove chips. Various types of conveyors with chain or screw mechanics ensure smooth clearance of machining spaces.

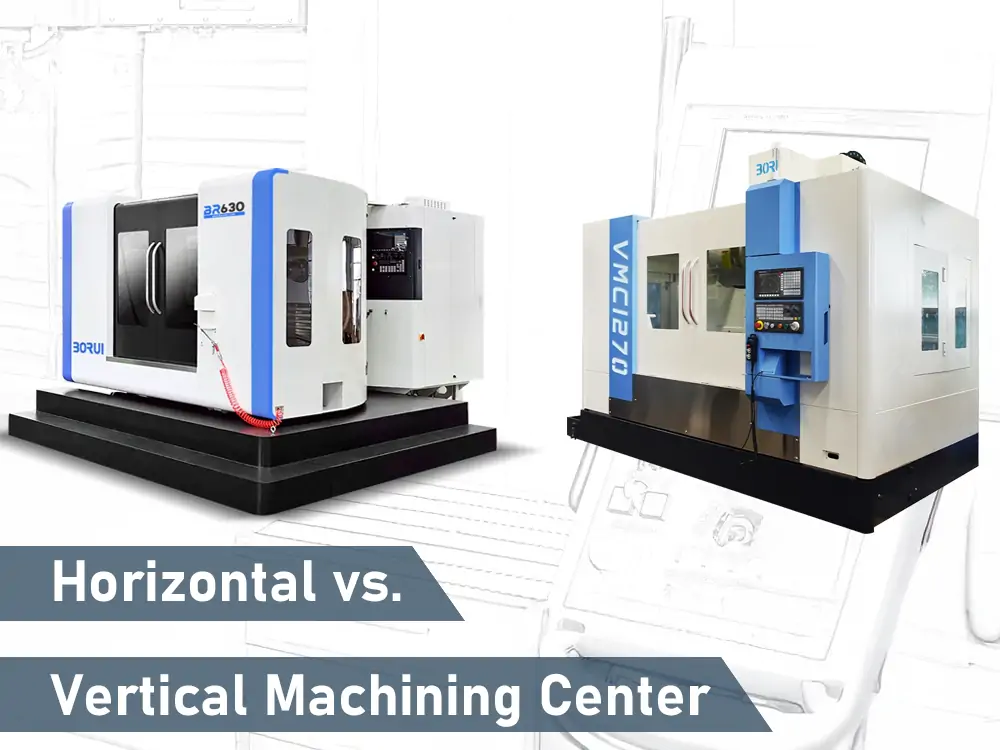

Vertical vs Horizontal Machining Center

Spindle Orientation

Vertical machining centers have spindles arranged vertically. The workpiece sits flat on a table below the spindle. This design lets gravity help secure heavy parts. The position of the horizontal machining centers spins parallel to the floor. The workpiece sits between centers or in a chuck along this horizontal axis.

Workpiece Handling

Vertical machining centers excel with large, heavy parts. They can handle weights up to several tons. The workpiece weight pushes straight down into the machine foundation. This creates no off-axis loads on the spindle. Horizontal machining centers work better with longer, slimmer parts like shafts and tubes. They struggle with very heavy items due to uneven weight distribution.

Space Requirements

Vertical machining centers take up less floor space. Their design builds upward rather than outward. A vertical machining center might use half the footprint of a comparable horizontal machine. This matters in tight workshops. Horizontal machining centers may be difficult to operate in small spaces.

Chip Management

Chips fall away naturally due to gravity in horizontal machining centers. This improves surface finish and reduces tool wear. Since chips don’t fall away on their own, vertical machining centers need more complex chip removal systems.

Cost Factors

Vertical machining centers typically cost less than horizontal models. Their construction and maintenance require less materials and are simpler to handle. Horizontal machining centers are more complex and hard to monitor. Their parts can be obstructed, and it becomes limited to view the project.

Uses of VMC Machines

VMC machines are widely used in the manufacturing industry. Following are some of the main uses of these machines:

Aerospace Industry

VMC machines make critical aircraft parts. They cut turbine blades, engine components, and structural pieces with tight tolerances. These machines handle complex shapes needed for fuselage sections and landing gear. Aerospace needs extreme precision, which VMCs deliver consistently. A single error could cause catastrophic failures, so manufacturers rely on VMCs for quality control.

Automotive Manufacturing

Car makers use VMCs to produce engine blocks, transmission housings, and brake systems. These machines cut complex parts in one setup, saving time. Box-type parts with multiple cavities, common in cars, benefit from VMC processing. Engine blocks require precise boring and facing operations that VMCs handle easily. The machines perform 60-95% of operations in a single clamping.

Medical Device Production

VMCs produce healthcare instruments, implants, and prosthetic devices. Medical sector manufacturers expect high precision and finished product quality because it guarantees patient safety. These machines mill titanium and other biocompatible materials with precision. Medical devices featuring curved surfaces require multi-axis machining capabilities that VMCs effectively provide. Private medical tool manufacturing operations use VMC machines for their diverse capabilities.

Electronics Industry

The production of circuit boards and connectors requires production of miniscule precise holes along with channels. VMCs deliver accurate drilling operations on vulnerable materials. The machines carry out complex pattern creation for electronic components manufacturing requirements. VMCs execute delicate operations which PCB production needs. Electronic parts can be produced at high speeds using high-speed spindles that generate smooth edges.

Mold and Die Making

VMCs demonstrate exceptional capability in fabricating injection mold tools and stamping die components. The machines efficiently produce complex cavities that deliver smooth surfaces appropriate for plastic components. Die making operations are supported by the ability to work with hardened steels. Mold components produced by the machines achieve precise dimensions needed for correct component placement. VMCs enable users to create mold cavities with special combinations of dimensions including hidden features.

Prototype Development

New parts in trial production benefit from VMC flexibility. The software enables fast alteration of programs between different product versions. Through the zoom function operators can generate multiple parts at various sizes. The production preparation time for new products becomes shorter. Small batch operations run more efficiently on VMCs because of their beneficial capabilities for prototyping processes.

How to Choose the Right Machining Center for Your Project?

Vertical machining centers have become essential tools, and there is no doubt that choosing them is important in modern manufacturing facilities. However, selecting the appropriate VMC requires careful consideration of your specific project requirements.

An examination of VMCs must account for the different machine capabilities that are available in the market. The machine performs effectively for multiple operations, which include milling, drilling, tapping, and boring functions. Various machines serve particular functions such as exact work or demanding material requirements.

VMCs achieve enhanced manufacturing performance through their multi-axis operation system which reduces the need for setup adjustments thus boosting operational efficiency. Investors must conduct a detailed assessment of their project specifications that cover part dimensions as well as material types, production volume, and tolerance requirements. BORUI CNC is committed to supplying customers with high-quality Vertical Machining Centers. Contact us today for more information or assistance.