In today’s era of rapid development, numerical control technology has become a necessary tool in various fields. In the field of machinery manufacturing, CNC lathes have become an important part of the manufacturing industry.

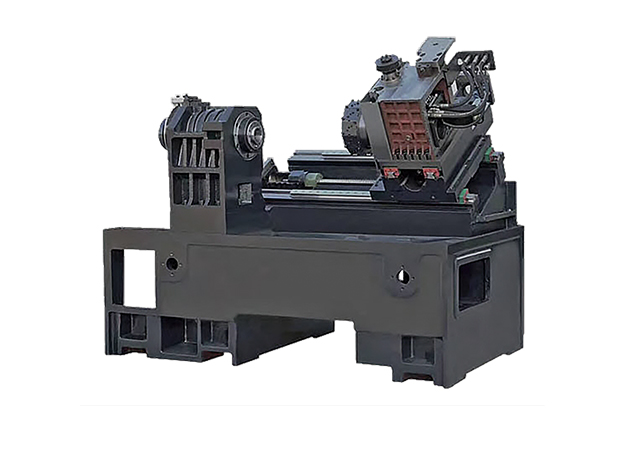

30° CNC Slant Bed Lathe Machine

CNC lathe bed tilt Angle is 30 degrees, this is a very special design. Compared with the traditional horizontal bed lathe, the 30 degree inclined bed CNC lathe has better cutting performance and higher stability. At the same time, this lathe also adopts numerical control technology, which can realize high precision machining through computer programs, greatly improving the manufacturing efficiency and quality.

Not only that, 30 degree inclined bed CNC lathe also has a very wide range of applications. It can be used to process a variety of metal materials, including steel, aluminum, copper and so on, but also can process a variety of shapes of parts, such as shafts, gears, threads and so on. Moreover, this lathe also has the advantages of high automation, simple operation and easy maintenance, which is very suitable for the needs of modern manufacturing industry.

In general, the 30 degree inclined bed CNC lathe is a very special CNC lathe, its design and technology are very advanced, has a wide range of application and excellent performance. It is believed that in the future development of manufacturing industry, this lathe will play an increasingly important role and make greater contribution to the development of manufacturing industry.

.

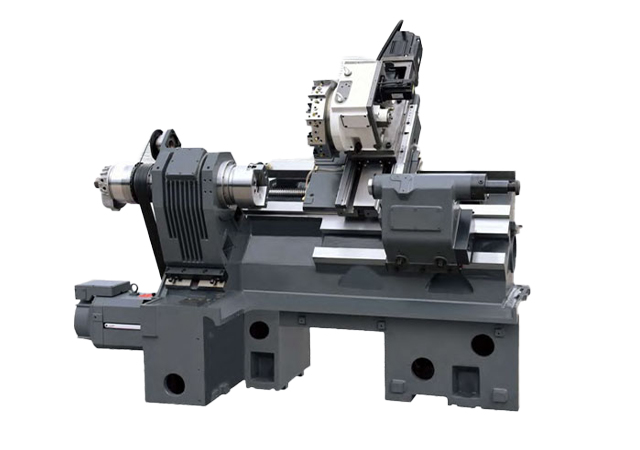

45° CNC Slant Bed Lathe Machine

The 45 degree inclined bed CNC lathe is a kind of high precision and high efficiency CNC equipment, which is characterized by its bed tilt Angle of 45 degrees, so it has better rigidity and stability, and can easily cope with the needs of complex machining workpiece. At the same time, the equipment adopts numerical control technology, which can control the machining process through preset program, so as to achieve high precision machining effect.

In the actual production, the 45 degree inclined bed CNC lathe is widely used in aerospace, automobile manufacturing, mold manufacturing and other fields, its main role is to process various precision parts, such as shaft, gear, thread and so on. Compared with traditional lathes, CNC lathes with 45 degrees inclined bed have higher machining accuracy and efficiency, but also reduce manual operation error rate and labor intensity, improve production efficiency and production quality.

In a word, 45 degrees inclined bed CNC lathe is an indispensable equipment in the field of modern machinery manufacturing. Its characteristics of high precision, high efficiency and a wide range of applications make it an important force to promote the development of machinery manufacturing industry.

The Difference Between 30° And 45 ° CNC Slant Bed

CNC skew is a tool commonly used in modern machining. It can tilt the workpiece at a certain Angle during machining, so as to realize more complex machining. In CNC incline car, there are two commonly used incline angles of 30 degrees and 45 degrees. There are the following differences between them.

- the Angle of tilt is different. A 30 degree NC incline tilts the work piece at a 30 degree Angle, while a 45 degree NC incline tilts the work piece at a 45 degree Angle. The choice of these two angles mainly depends on the shape of the workpiece and processing requirements.

- the processing effect is different. Because of the difference of inclination Angle, the 30 degree NC incline and 45 degree NC incline will produce different cutting force and cutting heat during machining, thus affecting the machining effect. Generally speaking, 30 degrees NC skew is suitable for processing smaller workpiece, can obtain better processing effect; And 45 degrees NC skew is suitable for processing larger workpiece, can improve the processing efficiency.

- the difficulty of use is different. Due to the difference in inclination Angle, the 30 degree NC incline and 45 degree NC incline need to pay attention to different machining parameters and tool selection, so the difficulty of use is also different.

To sum up, the inclination Angle of NC incline is an important factor affecting the machining effect and the difficulty of use. In the selection of NC inclined car, it is necessary to choose the appropriate tilt Angle according to the specific machining requirements and workpiece shape, in order to obtain the best machining effect.

https://www.youtube.com/watch?v=FyVVfK-ThaY

Request Quotation