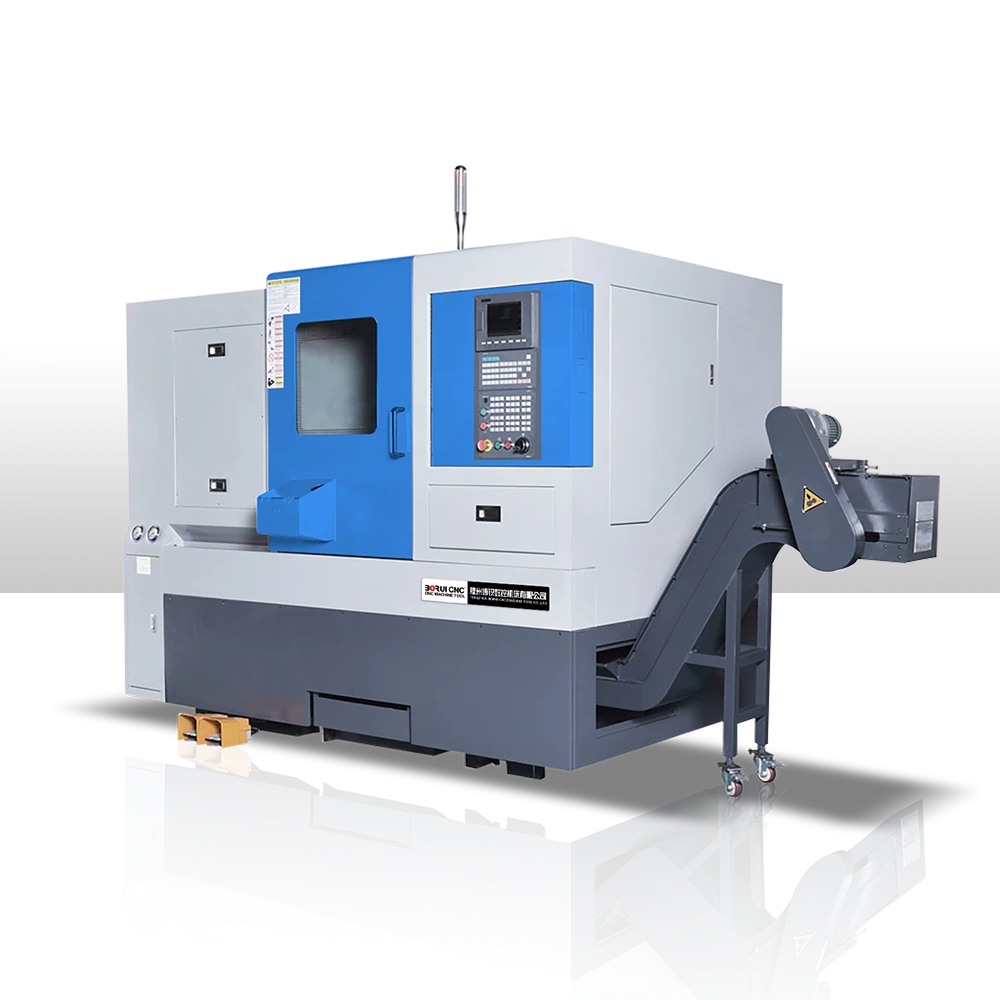

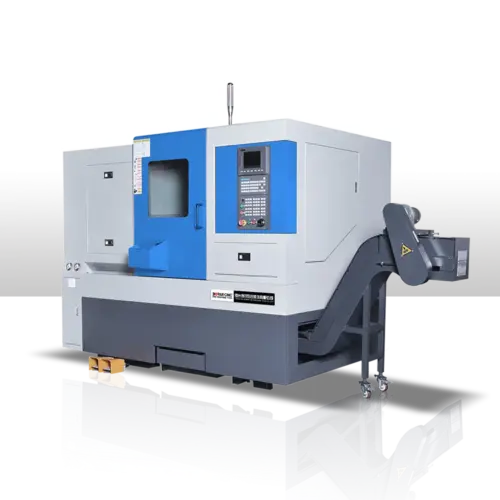

BR-160L Linear Guide Rail CNC Slant Bed Lathe Features

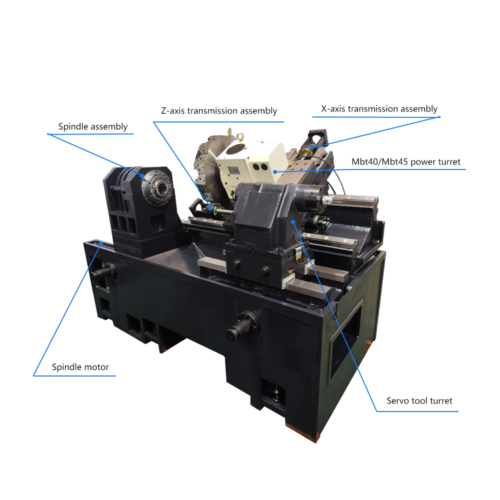

- 30 degree integral bed

- 8〞hydraulic hollow chuck

- Spindle infinitely variable speed

- 8 station tool

- 10 and 12 stations are optional

- 4500rpm Spindle speeds

- 7.5kw Main motor power

- With the full cover

- Hydraulic tailstock

- Ball Screw Bearing

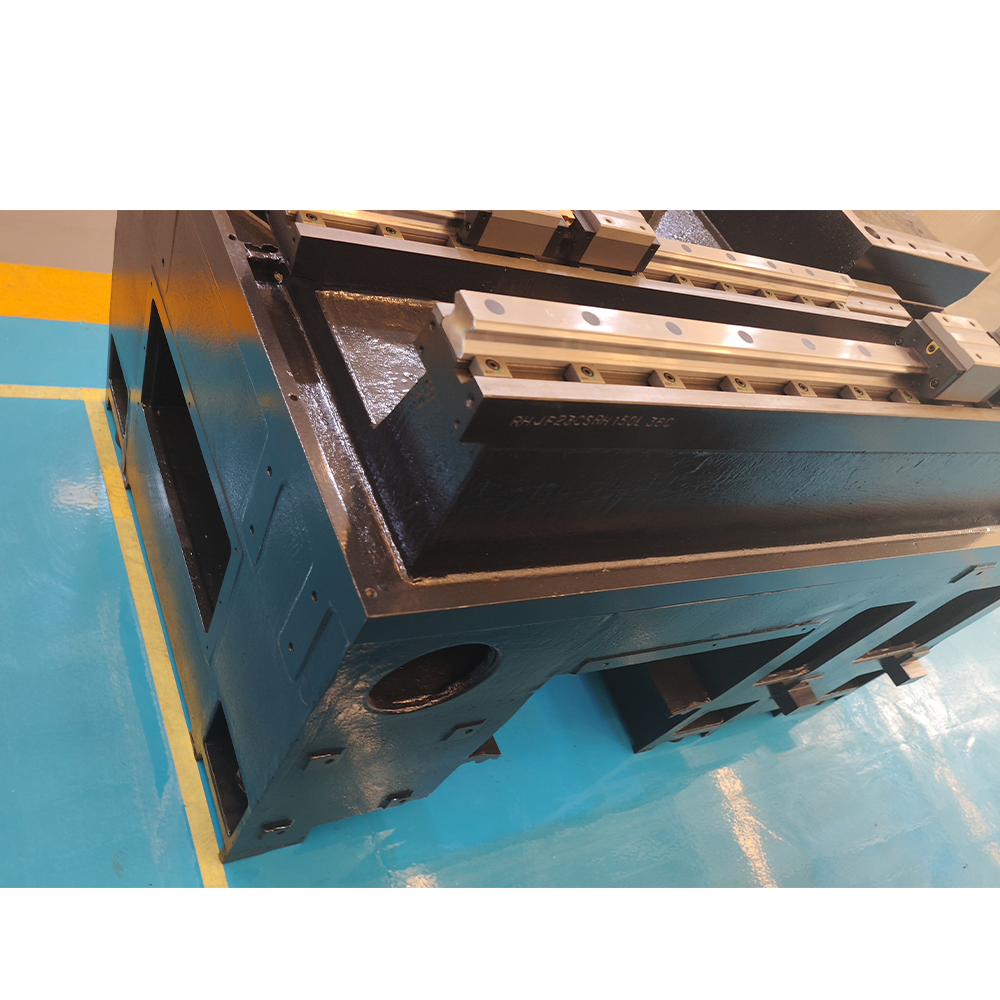

- Roller line rail

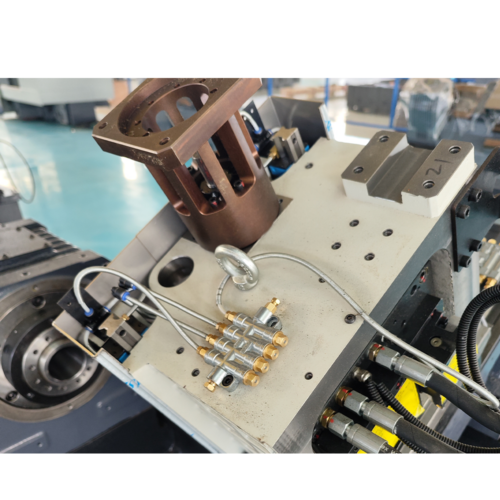

- lubrication, coolant system

- 380v 50hz 3phases

- High rigidity structure

- High precision and high stability

- CNC system Standard: GSK, Optional: Siemens, Fanuc, Mitsubishi and others

Video Display

BR-160L CNC Slant Bed Lathe Machine Technical Parameters

| Item | BR-160L | BR-160LA | BR-160LD | BR-160LAD | BR-160LDY | BR-160LADY | |

|---|---|---|---|---|---|---|---|

| Main Parameter | The max.swing diameter over bed | Φ460 | Φ460 | Φ500 | |||

| Max. machining diameter | Φ400 | Φ350 | Φ400 | ||||

| Max. swing diameter over cross slide | Φ200 | Φ200 | Φ200 | ||||

| Max. processing length | 410mm | 390mm | 350mm | 330mm | 370mm | 330mm | |

| Spindle And Chuck | Spindle end type | A2-5 | A2-6 | A2-5 | A2-6 | A2-5(6 ″) | A2-6(8 ″) |

| Spindle motor power | 7.5KW | 11KW | 7.5KW | 11KW | 7.5KW | 11KW | |

| Spindle speed | 4500rpm | 3000rpm | 4500rpm | 3000rpm | 4500rpm | 3000rpm | |

| Spindle through hole diameter | Φ56 | Φ66 | Φ56 | Φ66 | Φ56 | Φ66 | |

| Through the bar diameter | Φ46 | Φ52 | Φ45 | Φ52 | Φ45 | Φ52 | |

| Feed | X/Z axis lead screw specification | 3210/3210 | 3210/3210 | 3210/3210 | |||

| Y axis lead screw specification | 2508 | ||||||

| X/Z axis linear guide specifications | 35/35 | 35/35 | 35/35 | ||||

| Y axis linear guide specifications | 25 | ||||||

| X/Z axis limit travel | 210/475 | 210/475 | 210/475 | ||||

| Y axis limit travel | 60(±30) | ||||||

| X/Z axis motor torque | 11N.M/11N.M | 11N.M/11N.M | 11N.M/11N.M | ||||

| Y axis motor torque | 7 N.M | ||||||

| X、Z axis connection type | Direct connection | Direct connection | Direct connection | ||||

| Turret | Turret | 80825 | BMT45/ER20 | ||||

| Tower station | 8T/10T/12T | 12T | 12T | ||||

| Power tower | Y-axis power tower | ||||||

| Power head specification | BMT40/ER20 | ||||||

| Power head speed | 4500rpm | ||||||

| Power head motor | 2.5Kw | ||||||

| Power head to motor transmission ratio | 1∶1 | ||||||

| Turret center height size | 80mm | 80mm | |||||

| Tailstock | Sleeve diameter | 65mm | |||||

| Sleeve travel | 80mm | ||||||

| Tailstock max.travel | 300mm | ||||||

| Tailstock sleeve taper | MT4 | ||||||

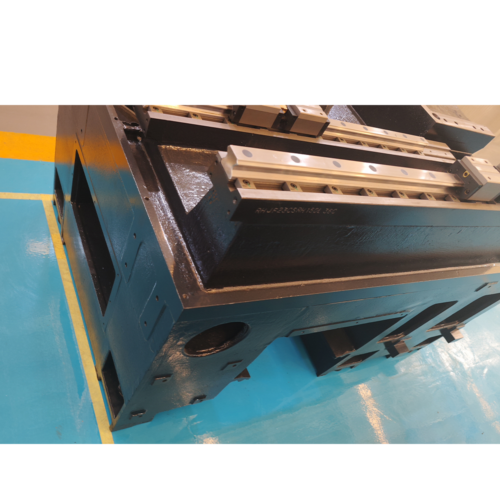

| Overall Dimension | Bed type and inclination | Integrated/30° | Integrated/30° | Integrated/30° | |||

| Machine size(L * W * H) | 1730×1273×1328 | 1730×1273×1328 | 1730×1473×1700 | ||||

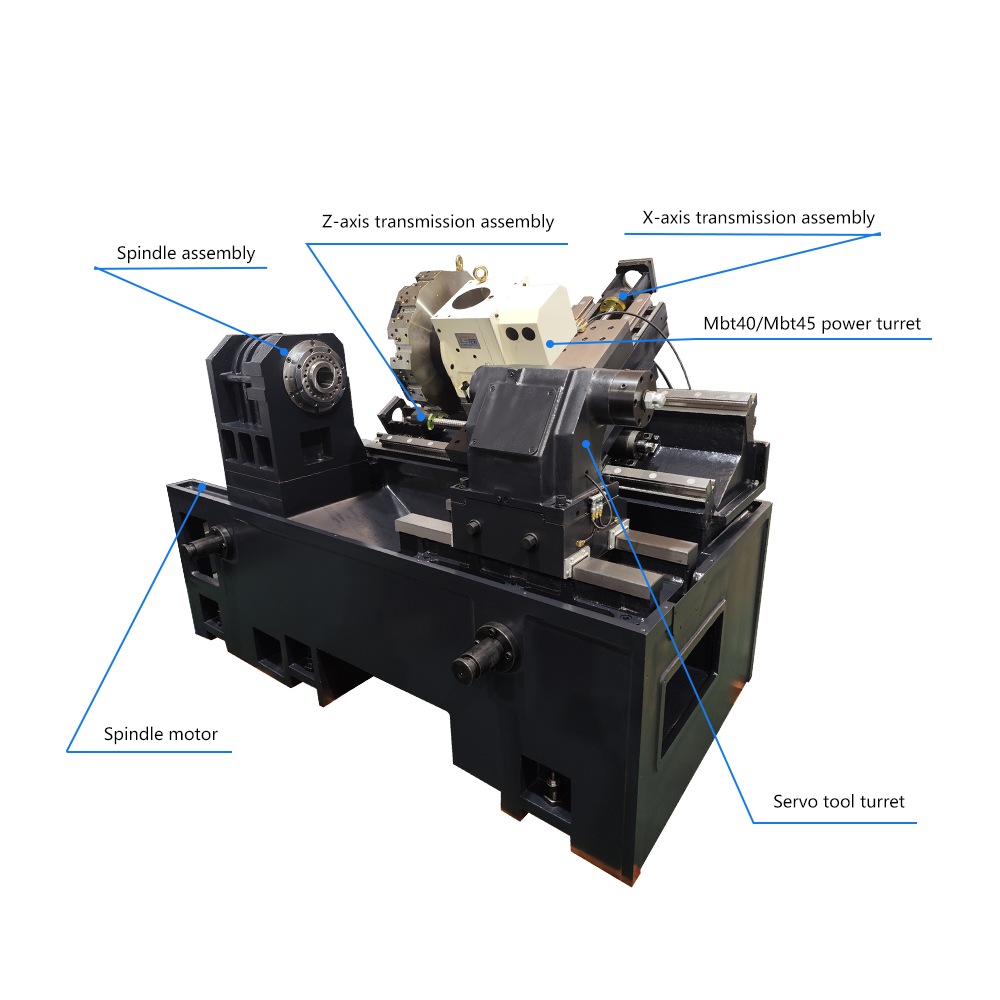

Advantages Of Linear Guide Slant Bed CNC Lathe

- Chuck high rigidity cast iron, workpiece clamping fastening. It has a long service life.

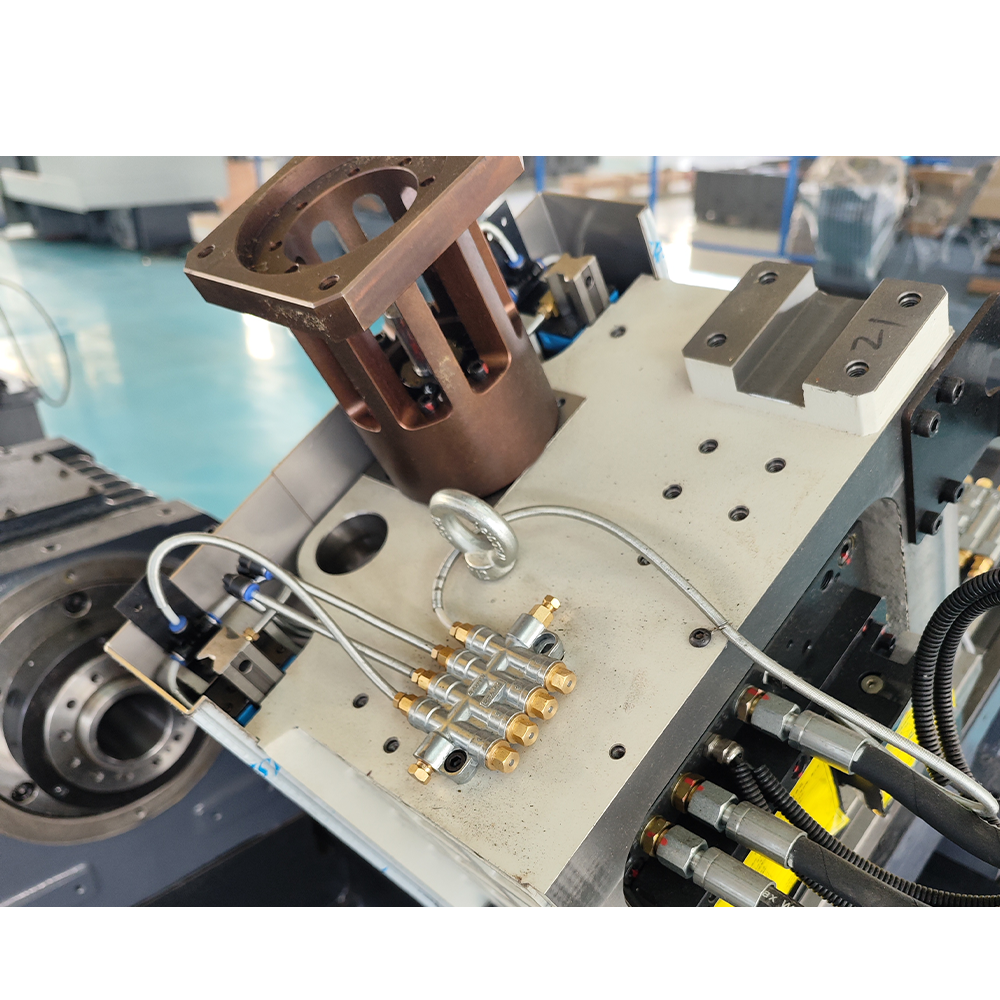

- The hydraulic tool tower adopts a servo motor with a fast tool change speed. It has a precision deceleration mechanism with low noise and ample load torque.

- The whole casting by tempering treatment and vibration natural aging treatment. It can reduce the internal stress accuracy to keep a long time.

- It is fully closed stainless steel inner protection. The CNC lathe slant bed machine is both beautiful and practical.

- It adopts a precision ball screw and an imported linear guide rail. The machine has high precision and long life.

- The screw bearing adopts an imported angular contact bearing, which is adjusted by pre-drawing. It can improve the positioning accuracy of cold and heat engines.

- The spindle unit adopts imported precision bearings. The machine has high precision, a long life, and easy maintenance.

- This CNC slant bed lathe suits high efficiency and precision shaft and disc parts machining.

Reviews

There are no reviews yet.