Introduction Landing a job is the primary consideration for every new fabrication shop. In the beginning, securing new clients might appear daunting, but having the correct equipment can take you a long way. Clients in the manufacturing sector have well-defined requirements, be it machine parts, OEM, or finished goods. Matching these conditions involves production in…

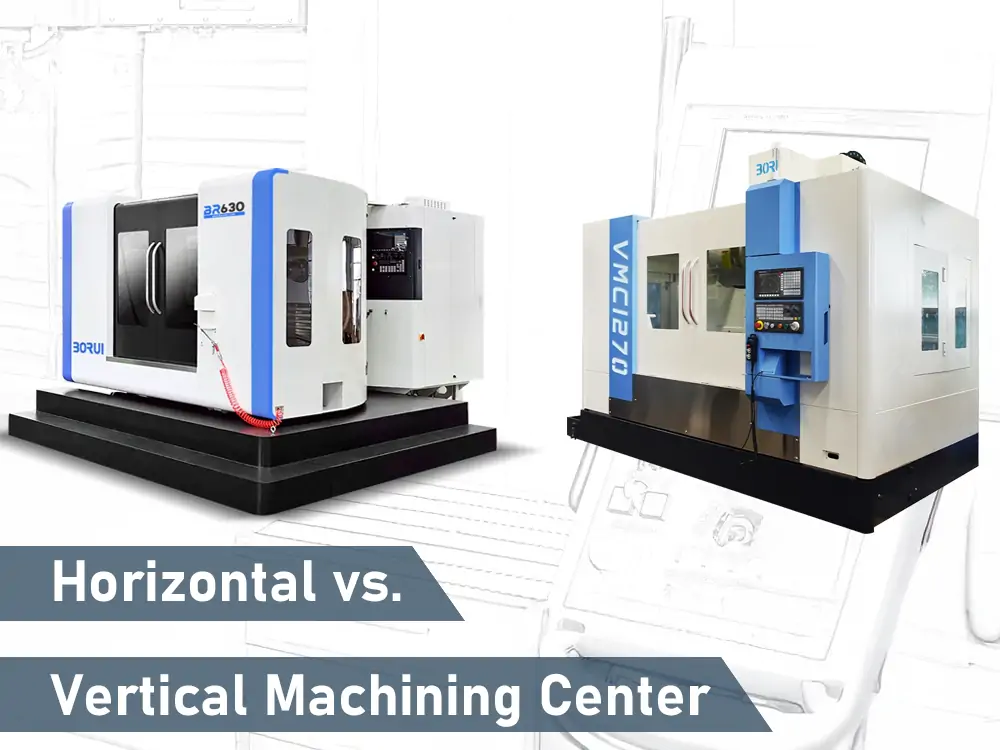

Vertical and horizontal CNC machining centers each have distinct advantages. Vertical machining centers are cost-effective and ideal for smaller, precise tasks. Horizontal machining centers, while more expensive, are more efficient for high-volume production, offering the ability to machine multiple parts at once. Choosing between the two depends on the scale and complexity of the job at hand.

5-axis CNC machining demonstrates its ability to produce complex designs with unmatched precision and efficiency. From reducing setup time to machining multiple faces in a single operation, these machines are ideal for handling complex geometries and hard-to-reach angles.

In modern manufacturing, CNC lathes play a vital role and are widely used in metal processing and precision parts manufacturing. In this article, we will provide you with the characteristics and advantages of each manufacturer to help you better understand industry trends and choose the right CNC lathe.

A cutting-edge manufacturing technology where computer-guided tools transform raw materials into high-precision components, with tolerances down to microns. This advanced process ensures exceptional accuracy for complex industrial parts.

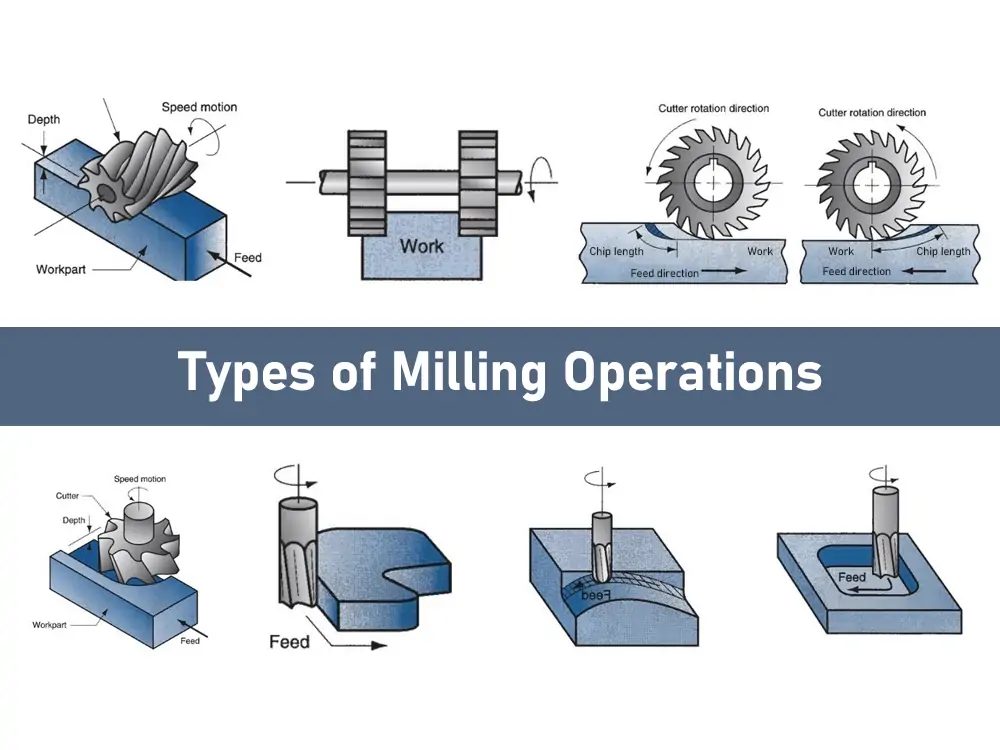

This guide delves into various milling methods essential in modern manufacturing, including end milling, slot milling, and shoulder milling processes. Whether for precision machining or large-scale production, understanding these distinct operations remains crucial for achieving optimal results in metalworking and CNC manufacturing applications.

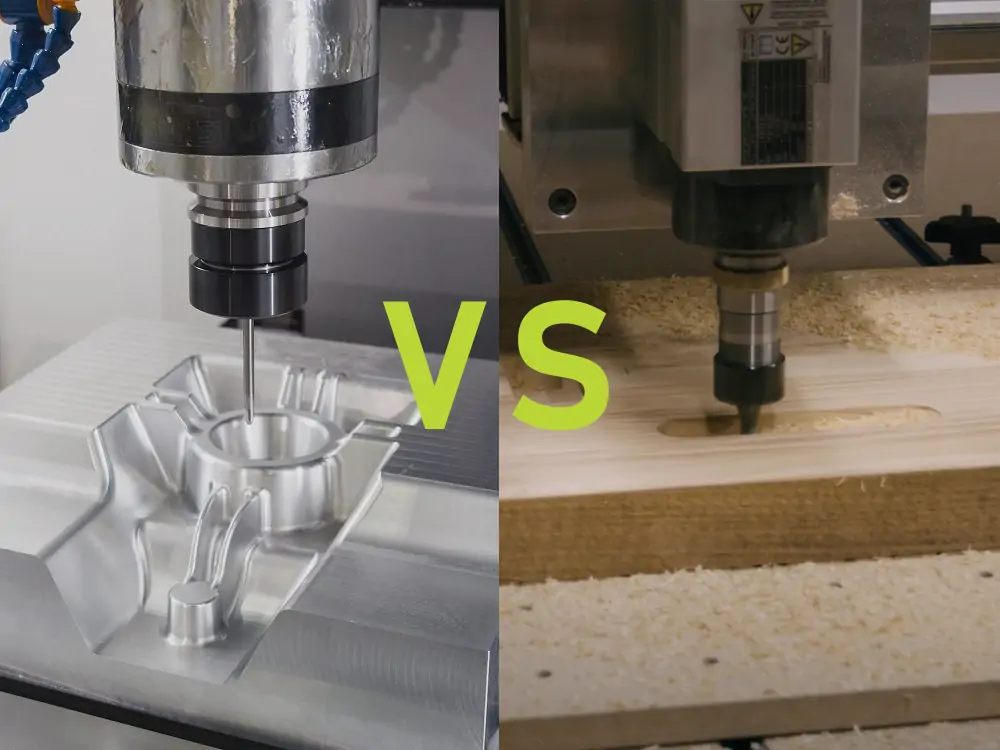

CNC mills are renowned for their accuracy. When multiple pieces are required, the shorter machining cycles of CNC routers make them an ideal choice. Ultimately, the decision between a CNC router and a CNC mill hinges on the specific needs of the operation.

CNC machines have changed the landscape of manufacturing, increasing production precision and efficiency. This article takes a deep dive into the countless ways individuals and businesses can use CNC technology to generate income. From making custom parts to creating intricate designs for a variety of industries, the profit potential is huge.

The CNC machine tool manufacturing industry in the United States is a field full of innovation and competition, shaping the face of modern manufacturing. This article takes an in-depth look at the top 10 CNC machine tool manufacturers in the United States and reveals how they excel in this highly specialized market.

Milling machines are of utmost value for manufacturing industries. They help cut and shape the different materials with precision. However, their performance and precision rely on whether you use them correctly. Unfortunately, people don’t get most of these machines due to a lack of awareness. This led me to write on how to use a…