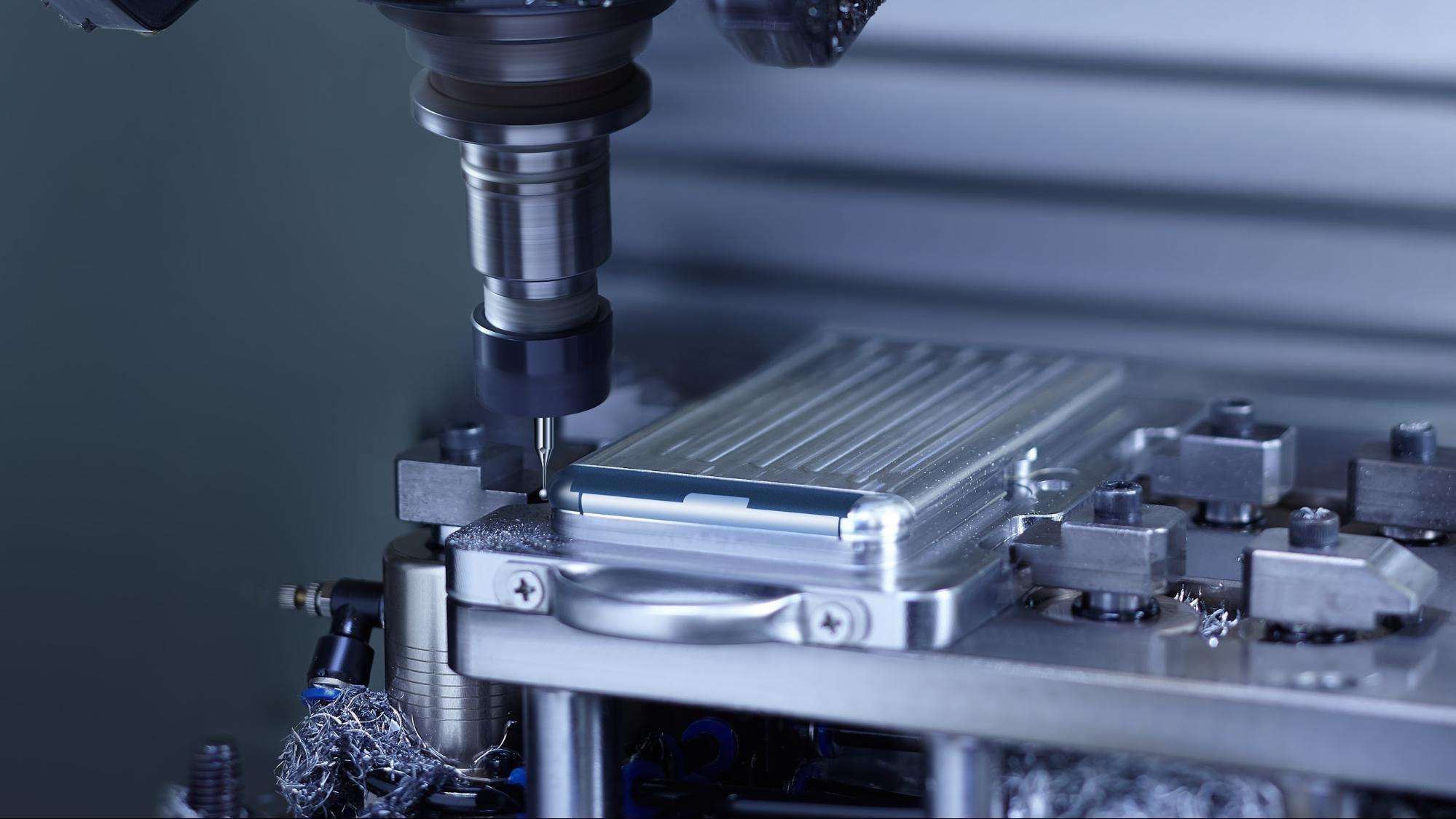

With the development of modern manufacturing technology, CNC machining equipment and its supporting CAM system have been widely used and developed. The machining tool path generated by CAM system (i.e. cutting mode) is the core to control the machining operation of the equipment. The cutting path is the motion path and direction of the tool relative to the workpiece in the process of exponential control. The reasonable choice of processing route is very important, which relates to the precision and surface quality of the processing center. It directly affects the precision of the workpiece, surface roughness, the overall processing time, the service life of the machine tool and other aspects, and ultimately determines the production efficiency. In NC machining, cutting mode refers to the path planning mode when the tool finishes cutting the workpiece. In the same part processing, a variety of cutting ways can reach the size and accuracy requirements of the parts, but the processing efficiency is not the same.

The cutting mode can be divided into four categories: one-way cutting, reciprocating cutting, loop cutting and compound cutting. Compound walking knife is a hybrid walking knife of the first three. The use of one-way or reciprocating cutting tool, from the processing strategy is the line cutting tool. Therefore, according to the different processing strategies, cutting methods can be divided into line cutting, loop cutting and other special methods. Row and loop cuts are commonly used.

Line Cutting Processing:

It is beneficial to the maximum feed speed of the machine tool and the quality of the cutting surface is better than that of the ring cutting. However, when the complex plane cavity with multiple bosses to form multiple internal profiles, often produce additional tool lifting action, that is, somewhere in the tool path, or to avoid interference between the tool and the boss, or to make the tool back to the remaining unprocessed area, it is necessary to let the tool lift, so that it is a certain height from the machining plane, and then translation to the start of another tool path, Then continue the cutting action.

The tool path of line cutting is mainly composed of a series of straight lines parallel to a fixed direction, which is easy to calculate. Suitable for simple cavity finishing or rough machining with large margin removed.

Ring Cutting Process:

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

The tool follows a path with similar boundary profile and is composed of a set of closed curves to ensure that the tool keeps the same cutting state when cutting parts. The calculation of the next ring track is complicated and time-consuming because the current ring track is constructed by continuous bias. Suitable for complex cavity and surface machining.

https://www.youtube.com/watch?v=U6i15lZbriI

Request Quotation