CNC lathes are excellent when you need precision and repeatability simultaneously. These machines can easily shape any complex part and component. Previously, limited types of lathe machines with restricted functionality were available. However, things have changed now, and CNC has taken over. Now, manufacturers use different types of CNC lathes.

Each of those lathe machines varies in terms of their capabilities. However, one thing common in all those types is precision. They all move the workpiece around the stationary cutting tools. The workpiece moves in different axes depending on the type of machine. Let’s get into the groove and discuss various types of these CNC lathe machines.

Brief Overview of CNC Lathe

The CNC lathe uses different axes and moves the workpiece around the cutting tools. The machine follows computerized instructions. The cutting tools don’t rotate. Instead, the machine moves the workpiece to cut and shape it at angles. What makes lathes stand out is their 100% precision.

What makes CNC lathe special is its repeatability. Suppose you need 500 parts, and their shapes and sizes must be identical. In such cases, these lathe machines work their magic. They will shape 500 components with 100% identical design. You won’t notice any slight difference between all those components.

It is based on CNC (Computer Numerical Control), and its operation depends on the computer. What instruction you give it will give you the same result you will get. If you make an error in design, you’ll get the same error in the end product. These machines are rapid and give output in seconds with 100% precision.

Different Types of CNC Lathes

As mentioned at the start, these lathe machines have different types. They differ in many ways, including axes of movement, structure, and functionality. This does not indicate that some machines are better than others. It is about serving a specific purpose. Each CNC lathe machine is specific in terms of how it works.

For example, two-axis CNC lathe machines are inexpensive and suitable for simple tasks. On the other hand, the machine with multiple axes of rotation is more advanced and ideal for complex tasks, and it does them simultaneously. Let’s dive deeper and discuss those types of CNC lathes.

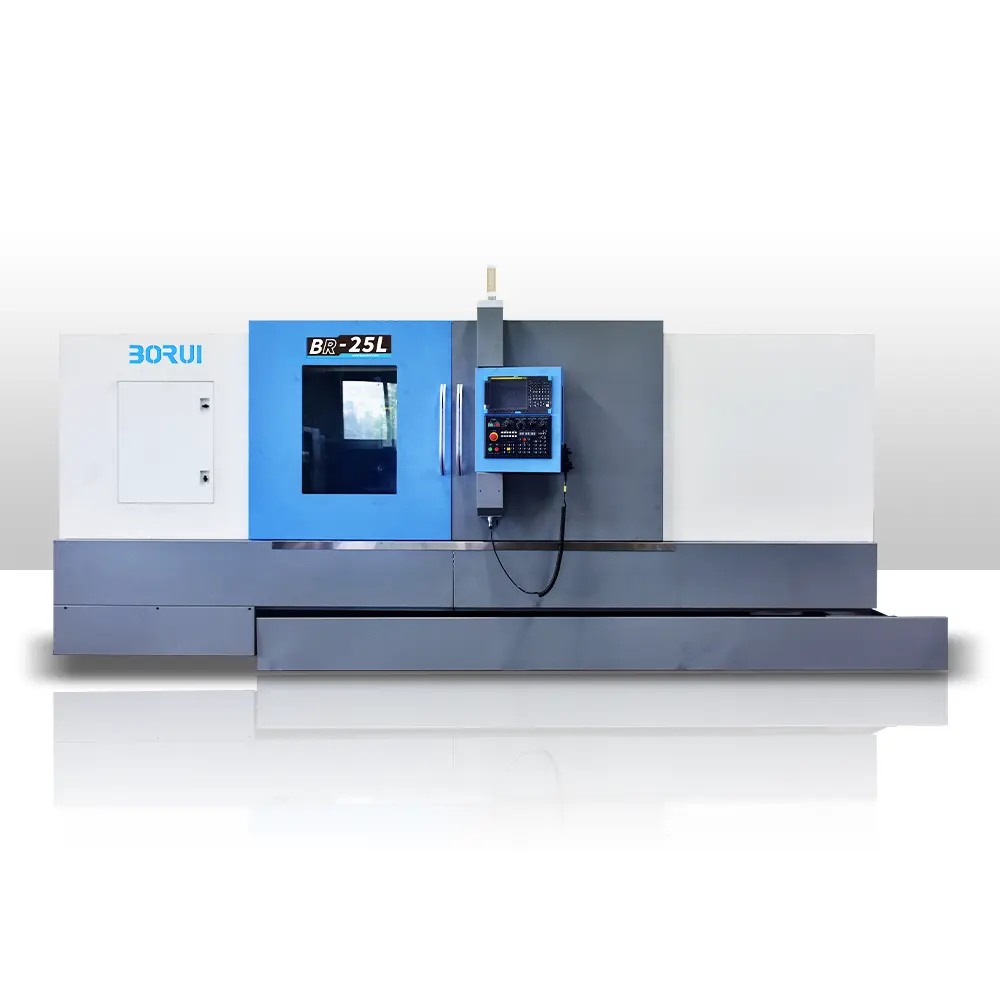

1. Slant Bed CNC Lathe

These CNC lathes offer excellent stability during their operation. The reason is that their bed is at an angle or slanted. A slope or incline of around 30 to 45 degrees is beneficial. It makes the evacuation of the ships or pieces very smooth. Remember that these machines are shaped by removing some parts of the workpieces.

The removal of these pieces or chips is critical. If these chips remain on machines, they could affect their performance. This is where the slanting or sloped base comes in handy. As they consist of CNC, their precision is top-notch. You’ll get everything done according to the instructions programmed on the computer. Check out the difference between flat bed CNC lathe and slant bed CNC lathe here.

2. Vertical CNC Lathe

This type is more about the orientation of the spindle, which is vertically mounted. So, the workpiece attached to the spinel moves vertically. In simple words, it moves up and down around the cutting tools. Their compact size is something that sets them apart from other types of lathes.

The spindle and workpiece orientation is vertical, so they do not occupy more space. There are no significant components or parts horizontally. This feature makes them compact, and you won’t need more space to use them. These machines are ideal for working and shaping heavy-duty material. Notably, the aerospace industry widely uses these machines. For more advantages of vertical CNC lathes, please check out.

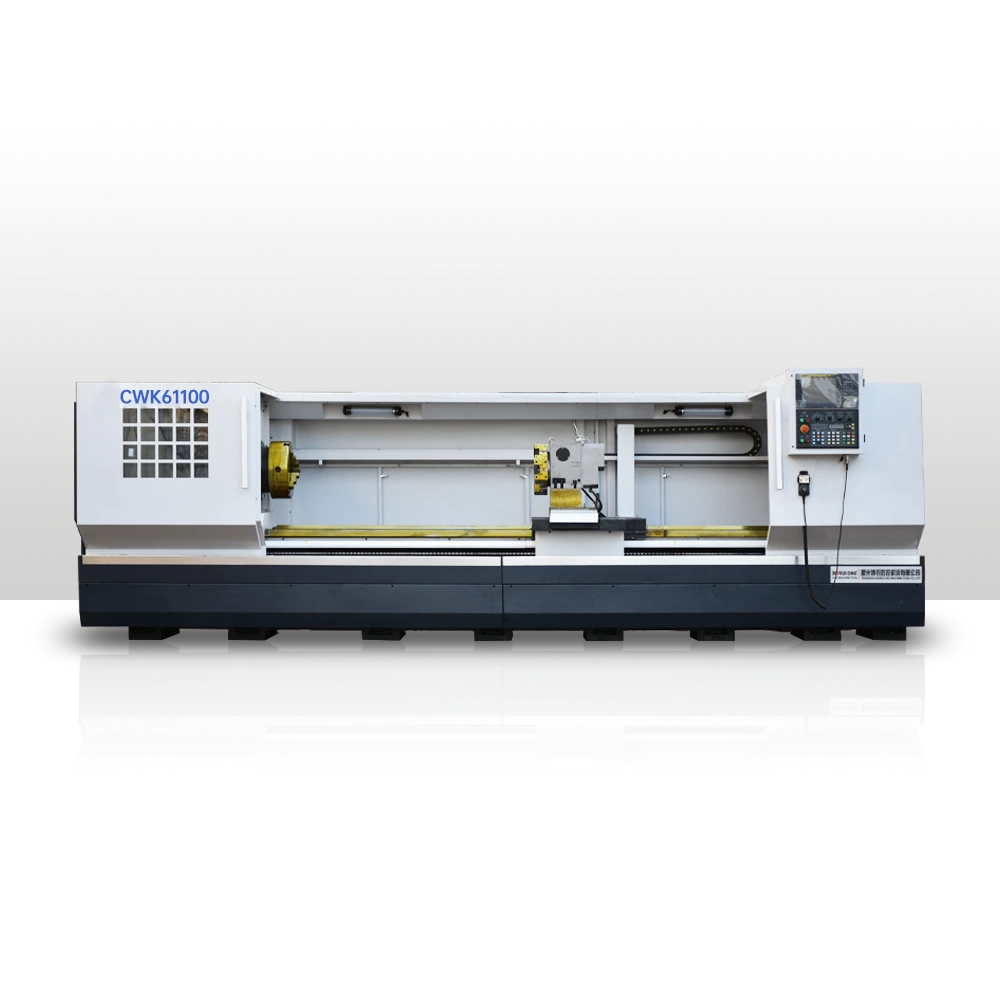

3. Horizontal CNC Lathe

These lathe machines are very advanced compared to 2 axes. The additional axes allow the rotation of the workpiece, while two axes, X and Y, allow the movement of cutting tools. Those axes include C, X, and Z. The X and Z axes are responsible for horizontal and longitudinal movement.

These machines are suitable for smaller tasks. Manufacturers generally use them for turning, drilling, and threading. Moreover, their size is not compact, which is a drawback. They will occupy more space. However, their ease of operation attracts customers. It is straightforward to load and unload the workpiece on the clamp.

This type of CNC lathe differs from all others in function. It comes in handy when pipes need to be threaded. As you know, different pipes are threaded together to make big pipelines. This is particularly essential in the oil and gas industry.

These CNC lathe machines make those threads on the pipes quickly. What makes this thread special is its strength and durability. If a human makes those threads, the chances of eros are high. But these machines make identically strong threads that are leakproof. There is no chance of error when these lathes do threading instead of human labor.

5. Flat Bed CNC Lathe Machine

Unlike slant bed lathes, these machines have a flat base. The spindle and workpiece remain on this base. However, the evacuation of chips is not very smooth. The operator has to remove those pieces manually. However, the main benefits of using this lathe is that it is very versatile in terms of how it works. It can easily cut and shape both lightweight and heavy-duty materials.

Categorization of Lathes in Term of CNC Axis

The above section discusses the most common types of CNC lathes. However, some lathes are also categorized in terms of axis of movement. These axes allow the workpiece to move in different directions. More axes mean more machine capability. Let’s discuss each type of CNC lathe and its axes.

-

2-Axis CNC Lathe

These lathes are very basic and suitable for simple functionality. They have two axes: X and Z. The X-axis allows the cutting tools to move sideways. On the flip side, the Z axes allow longitudinal movement. However, the confusion remains: What is the longitudinal movement of the axis?

These axes allow the cutting tools to move in two directions. Those movements include forward and backward towards the workpiece. In simple words, this movement is parallel to the rotatory workpiece. This type of CNC lathe machine is suitable for making cylindrical shapes. These machines are not ideal for creating complex shaped parts.

-

3-Axis CNC Lathe

These lathe machines are very advanced compared to 2 axes. The additional axes allow the rotation of the workpiece, while two axes X and Y allow the movement of cutting tools. Those axes include C, X, and Z. The X and Z axes are responsible for horizontal and longitudinal movement.

However, the C axis is a new axis that allows the rotation of the workpiece. This is an additional movement that enhances their functionality. These machines are capable of making products with complex shapes.

-

4- Axis CNC Lathe

These CNC lathe machines have four axes for rotation. These control the movement of both the workpiece and the cutting tools. Those four axes are as follows:

- X-axis: Horizontal movement of cutting tools

- Y-axis: Vertical movement of cutting tools

- Z-axis: Allows longitudinal movement of cutting towards the workpiece

- C-axis: Allows rotation of the workpiece, which allows for shaping the workpiece.

These four axes allow the machines to cut and make shapes that are very complex. They don’t face any issues no matter how complex instructions are fed to their computers. Manufacturers use them for turning, milling, and various other operations. These 4-axis lathes are suitable for multiple operations and save time changing machines for different work.

-

5-Axis and 6-Axis CNC Lathe

These lathe machines fall in the premium category and are very expensive. They offer five and six axes, respectively. Those additional movements include tilting and rotation of the workpiece. Here is the list of their axes names:

- X-axis

- Y-axis

- Z-axis

- C-axis

- A-axis (allow titling of workpiece)

- B-axis (allow rotation of workpiece)

A 5-axis CNC lathe consists of the A or B axes and the other four axes. However, in the 6-axis CNC lathe, all the six axes that are mentioned above. The tilting and rotation provide an additional angle for the workpiece. In this way, the workpiece gets shaped as per the computerized instructions.

Prominent features make these lathes stand out in terms of efficiency. They are capable of doing multiple functions at a time. So, manufacturers use one machine to get all the work done. They don’t feel the need to use various machines for milling, drilling, and so on. In this way, they can meet high production demand with quick turnaround.

Frequently Asked Questions

Q1: What is a CNC lathe, and what is it used for?

It is a machine that works using computerized instruction. Its purpose is to cut and shape material and complex parts and components.

Q2: What are the primary types of CNC lathes?

CNC lathes have many types that differ from one another. Here is the list of their most commonly used types:

- Flat bed CNC Lathe

- Vertical CNC Lathes

- Slant Bed CNC Lathe

- Multi-Axis CNC Lathes

- Horizontal CNC Lathes

Q3: What are the advantages of using a multi-axis CNC lathe?

These lathes have multiple axes where the workpiece or cutting can move. So, they are very efficient in making complex shapes with ease. Moreover, they are also capable of completing multiple tasks at a time.

Q4: What should you take into account when selecting a CNC lathe?

Choosing or buying a lathe machine is a complex process. You will have to consider different factors. Some of those factors are as follows:

- Number of Axes

- Precision and Tolerance

- Workpiece Size and Weight

- Software and Control System

- Budget and Cost of Maintenance

Conclusion

CNC lathes are excellent inventions that have revolutionized the manufacturing process. These machines have increased the productivity of the manufacturing industries. However, various CNC lathes are out in the market, making the selection process very challenging.

Each type of Lathe is particular. However, I have made things a lot easier by explaining each type. Hopefully, this will make your life easier.