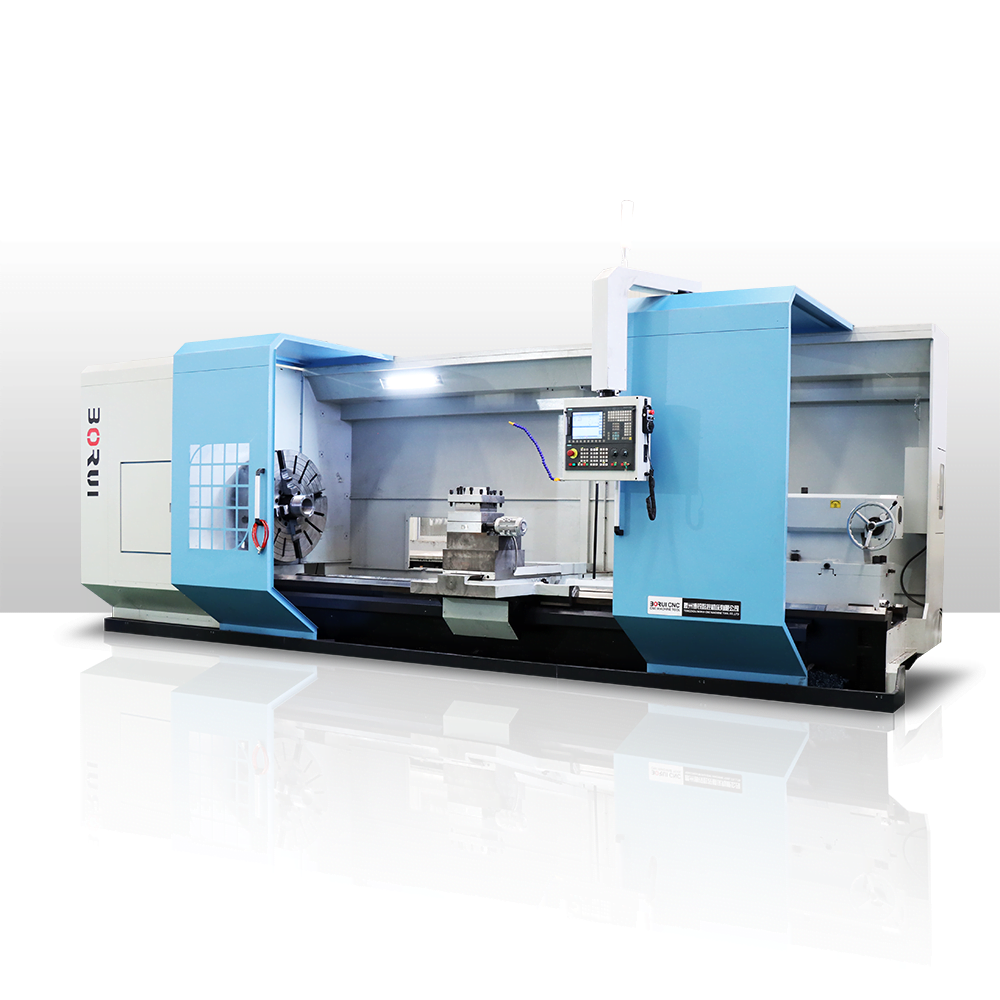

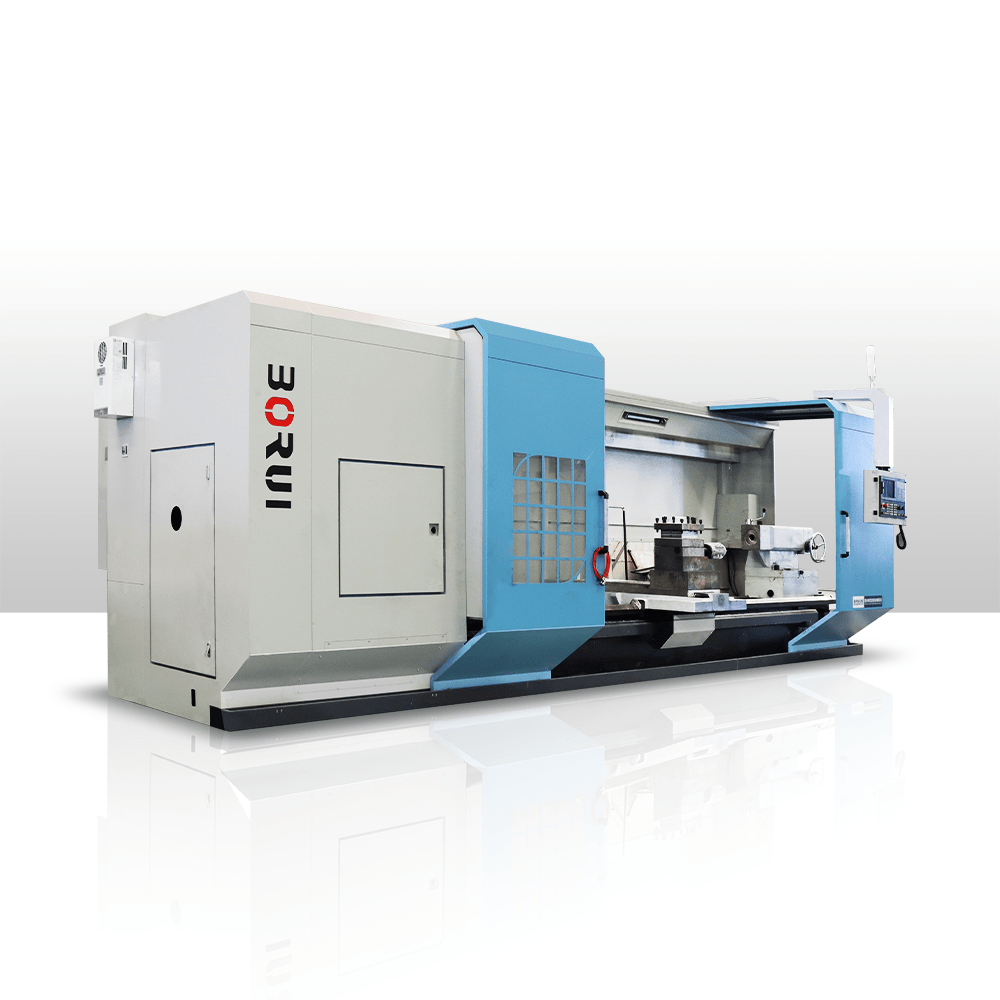

Large bore CNC lathe is a kind of high-precision and high-efficiency machine tool, which plays an important role in modern industrial production and provides strong support for the development of all walks of life. It has a wide range of applications in industrial production, and can meet the needs of all walks of life for processing large and high-precision parts. It has the characteristics of wide processing range, high precision, high automation, high production efficiency and high reliability, and is an indispensable important equipment for modern industrial production.

1. What Is A Large Bore CNC Lathe?

CNC lathe with the large bore is a kind of high precision and high-efficiency machine tool, which has the ability to process large diameter, long axis parts, and difficult workpieces. It uses digital control technology to control the movement and rotation of the turning tool through the program to precisely cut and process the workpiece, so as to achieve high precision and high quality processing effect. In addition, the large bore CNC lathe also has the advantages of high automation and high production efficiency, and is widely used in aviation, aerospace, weapons, automobiles, machinery manufacturing and other fields.

The core component of the large bore CNC lathe is the main shaft, which drives the workpiece to rotate through the motor, and the turning tool cuts along the surface of the workpiece to realize the processing of the workpiece. In addition, the large bore CNC lathe is also equipped with an automatic tool change system, automatic measurement system, automatic feeding system, and other equipment so that the processing process is more automatic and intelligent. In the processing process, the operator only needs to write a good processing program and debug. The machine can run automatically, greatly improving production efficiency and product quality.

2. Features Of Large Bore CNC Lathes:

- Wide processing range: large bore CNC lathe can process large diameter, long axis parts and difficult workpieces, suitable for aviation, aerospace, weapons, automobiles, machinery manufacturing and other fields.

- High precision: large bore CNC lathe using digital control technology, through the program to control the movement and rotation of the tool, can achieve high precision, high quality processing effect.

- High degree of automation: The large boreCNC lathe is equipped with an automatic tool change system, automatic measurement system, automatic feeding system, and other equipment, making the processing more automatic and intelligent.

- High production efficiency: in the processing process, the operator only needs to write a good processing program and debug, the machine can run automatically, greatly improving production efficiency and product quality.

- High reliability: large bore CNC lathe adopts advanced electronic control technology and mechanical design, has stable and reliable performance, can run stably for a long time, and reduces the cost of maintenance and troubleshooting.

3. Scope Of Use Of Large Aperture CNC Lathes:

- Aerospace: CNC lathes with large bores can process aircraft engines, hydraulic cylinders, bearing seats, and other parts in the aerospace field.

- Weapons and equipment: large bore CNC lathe can process large-caliber guns, missile engines, tank gun barrels, and other weapons and equipment components.

- Automotive manufacturing: Large-bore CNC lathes can process automotive hubs, steering gears, engine blocks, and other automotive manufacturing components.

- Machinery manufacturing: Large-bore CNC lathes can process large machine tools, molds, textile machinery, and other machinery manufacturing parts.

- Energy equipment: large bore CNC lathe can process nuclear power plants, hydropower stations, thermal power stations, and other energy equipment components.