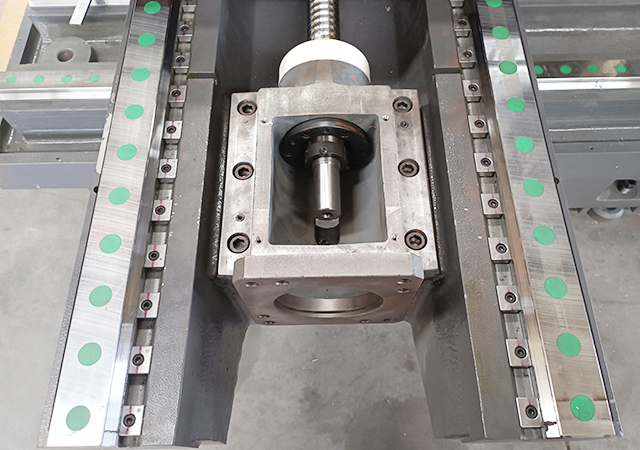

The new guide system enables the machine to achieve fast feed speed, which is the characteristic of the linear guide at the same spindle speed. Linear guide and plane guide, there are two basic components; One is the stationary element that acts as the guide and the other is the moving element. In order to ensure the accuracy of the machine tool, a small number of bed or column shovel flower is essential, under normal circumstances, the installation is relatively simple. There is no intermediate medium between the moving element and the fixed element of the linear guide, and rolling steel ball is used. Because the rolling steel ball is suitable for high-speed movement, small friction coefficient, high sensitivity, to meet the working requirements of moving parts, such as the tool rest of machine tools, drag plate, etc.

Linear guide is an important component used in the field of industrial automation. It can provide high precision, high speed and high stiffness linear motion control. The main function of linear guide rail is to make robots, CNC machine tools and other equipment in motion to maintain stability and accuracy, so as to improve production efficiency and product quality.

The design and manufacture of linear guide requires highly precise machining technology and materials. Generally speaking, linear guide is composed of guide body, guide slide and guide ball. The body of the guide rail is usually made of high-strength aluminum alloy or steel, and its surface is finely ground and polished to ensure its surface accuracy and smoothness. Guide slide is the core component of linear guide, which is equipped with ball or roller, which can achieve high speed and high precision linear motion.

In industrial production, linear guide rail has been widely used in various CNC machine tools, semiconductor equipment, electronic equipment, automatic production line and other fields. The advantage of linear guide rail is that it can provide high precision linear motion control, so that robots and CNC machine tools and other equipment in motion more stable and accurate. At the same time, linear guides can also improve production efficiency and product quality, driving the development of the entire manufacturing industry.

In a word, linear guide is a very important industrial automation component, its development and application to promote the development of manufacturing industry and improve product quality are of great significance.

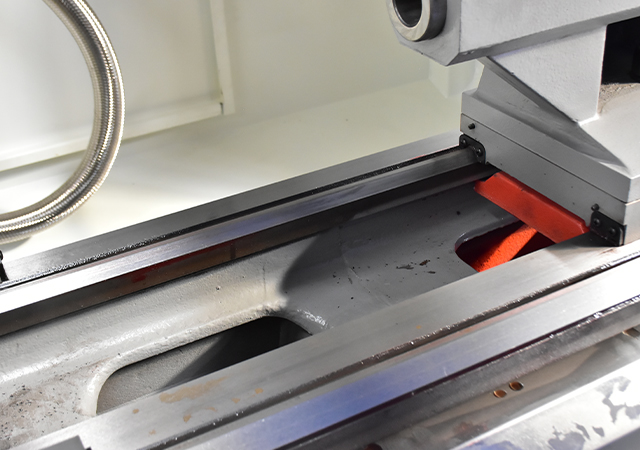

Machine tool hard rail is a kind of guide rail structure used in machine tool, which is composed of steel rail, slide block, guide rail seat, etc. Its main function is to provide the linear motion control of the machine table, so as to achieve high precision and high speed machining. The advantage of machine tool hard rail is that it has high stiffness and stability, can withstand high load, high speed processing, and has a long service life and low maintenance cost. In the field of machine tool manufacturing and processing, machine tool hard rail is an indispensable part.

Hard rail and line rail are both track structures used for railway transportation or machine tools, but they have the following differences:

1. Different Structure:

The track structure of hard rail is more complex, composed of rail, sleeper, turnout and so on; Rail, on the other hand, is relatively simple, consisting of a single steel rail and the supporting parts that hold it in place.

2. Different Application Scenarios:

Hard rail is mainly used for railway transportation, while line rail is mainly used for machine tools.

3. Different Bearing Capacity:

Because hard rail needs to bear high load and high speed trains, its bearing capacity is stronger; The line rail does not need to bear such a high load and speed, so its carrying capacity is relatively weak.

4. Different Accuracy:

The manufacturing accuracy of hard rail is higher to ensure the smooth and safe running of the train; The precision of the line rail is relatively low, because the machining accuracy of the machine tool is affected by many factors.

In conclusion, although hard rail and wire rail are both track structures, they are different in terms of structure, usage scenarios, carrying capacity and accuracy.