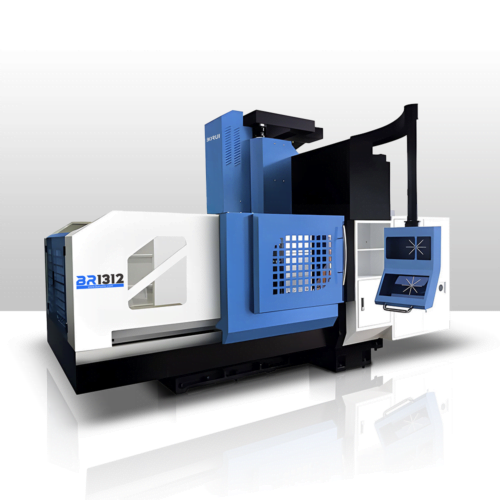

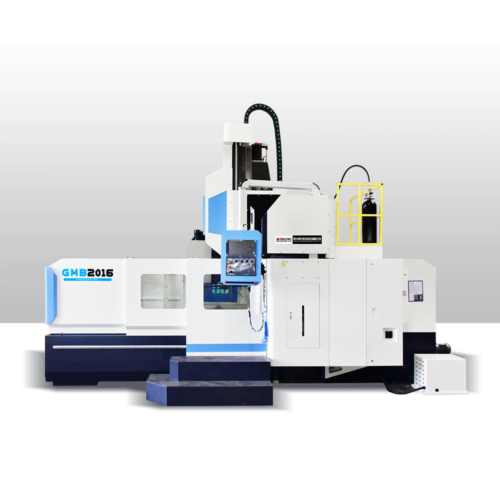

Product Features

- 24 Disc ATC

- The spindle is stepless in its speed range

- Three-axis lubricating system

- Separate hand-wheel

- Machine tool lighting work light

- Random technology document

- Resin sand casting

- linear guide

- Vertical frame layout

- Systems can be selected according to customer requirement

- SYSTEMCNC CONTROL

- SIEMENS, KND, FANUC, MITSUBISHl, GSK and other operating

- Full protection

- High hardness bed castings

- Spindle cone Hole cleaning air

- Electric cabinet cooling and heat exchanger

- Cleaning air gun

- Chip storage tank

- Servo transformer

- Foundation pad iron and adjusting bolt

Video Display

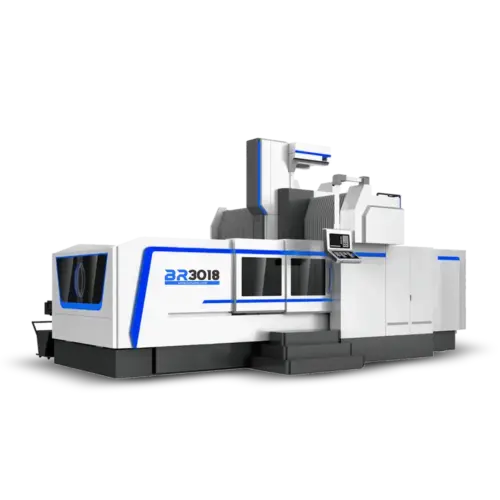

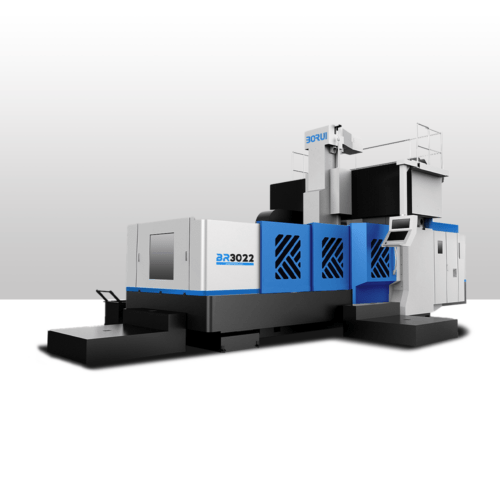

Advantages Of BR2516 CNC Gantry Milling Machine

- Cutting and twisting load has enough rigidity, strong cutting resistance, high precision.

-

After hardening and then tight grinding, the guide rail has strong rigidity and is suitable for re-cutting.

- After manual scraping process, to ensure that the combination surface of the machine tool is larger, the accuracy of the machine tool is good, the accuracy is high.

- The scraping surface retains lubricating oil, to ensure that the guide rail is fully lubricated and durable.

-

Composed of screw and servo motor, X, Y, Z three-axis drive system.

- Each drive is lubricated by the lubrication system, reducing friction resistance and increasing the service life of the machine.

-

Fast moving speed, three-axis linkage.

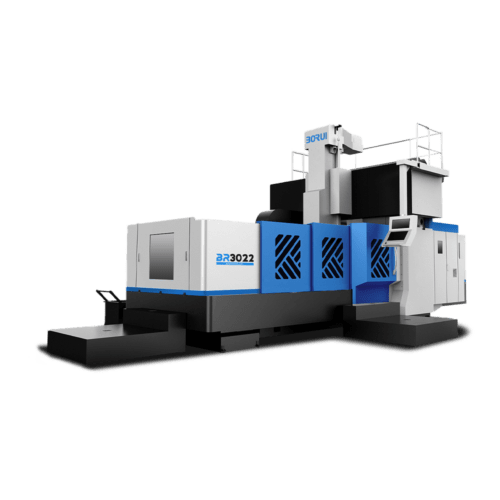

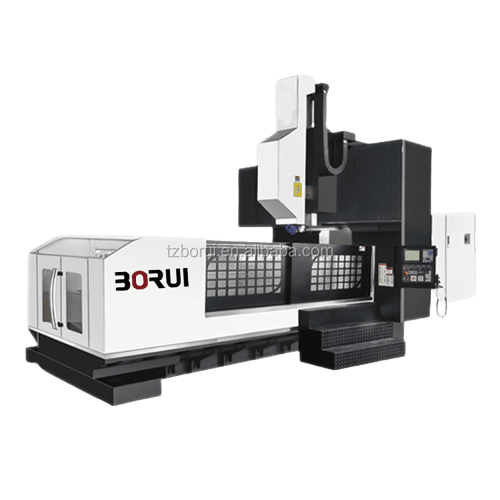

Technical Parameters Of BR2516 CNC Gantry Milling Machine

| Specifications | BR2516 | |

|---|---|---|

| Control system | ||

| Software :AICC2/R660/nano smooth/arc inflection point/mirror processing | FANUC 0I MF PLUS 3pcs | |

| Monitor :Chinese and English display dual screen | 10.4″color screen/10″color screen | |

| CF card interface、handheld portable operating syste | ||

| Working travel | ||

| x-axis | 2500 | mm |

| y-axis | 1650 | mm |

| z-axis | 750 | mm |

| Spindle nose to table | 150~900 | mm |

| Worktable | ||

| Table size | 2500X1300 | mm |

| Max. loading capacity | 5 | T |

| Size of T-slot | 22x180x7 | mm |

| Spindle | ||

| Spindle speed | 6000 | rpm |

| Spindle taper | BT50 | |

| Spindle motor | 15/18.5 | KW |

| Spindle torque | 236 | N.m |

| Spindle at both ends | 4 | Pcs |

| Slide way | ||

| x-axis 2 guide | 55×2 roller P grade | mm |

| y-axis 2 guide | 55×2 roller P grade | mm |

| z-axis T-shaped ram | Hard way | mm |

| Driving screw | ||

| Ball screw accuracy | C3 grade | |

| Ball screw diameter x.y.z | 63/50/50 | mm |

| Three-axis lead | 10 | mm |

| Motor connection | Direct | |

| Number of bearings at both ends | 6/6/5 | Pcs |

| Three-axis motor | ||

| x z axis motor | bis40 | N.m |

| y zaxis motor | bis40 | N.m |

| z zaxis motor (nitrogen balance) | bis40(Brake) | N.m |

| Feed rate | ||

| x axis rapid feed rate | 15000 | mm/min |

| Y axis rapid feed rate | 15000 | mm/min |

| Z axis rapid feed rate | 12000 | mm/min |

| Three-axis cutting feed rate | 0-10000 | mm/min |

| Tool (Optional) | ||

| Max. tool length | 300 | mm |

| Max. tool dia | Ø100 | mm |

| Max. tool weight | 15 | kg |

| Tool specification | BT50 | |

| Tool change time | 6 | second |

| Factory precision | ||

| Positioning | 0.010/1000 | mm |

| Repeat positioning | 0.006/1000 | mm |

| Least input increment | 0.001 | mm |

| Other | ||

| Power Capacity | 55 | KVA |

| Net weight (bilayer structure) | 19 | t |

| Packing dimensions(L x W x H) | 7200x3900x3500 | mm |

Reviews

There are no reviews yet.