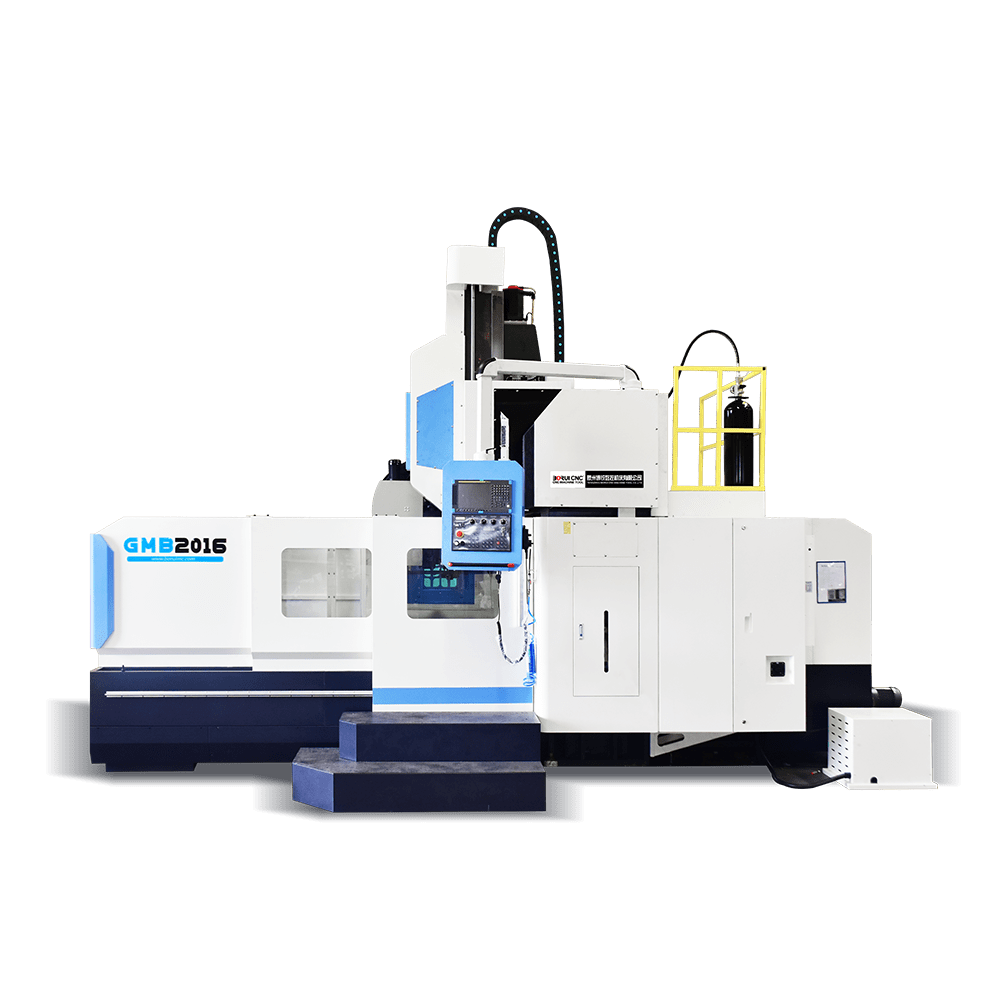

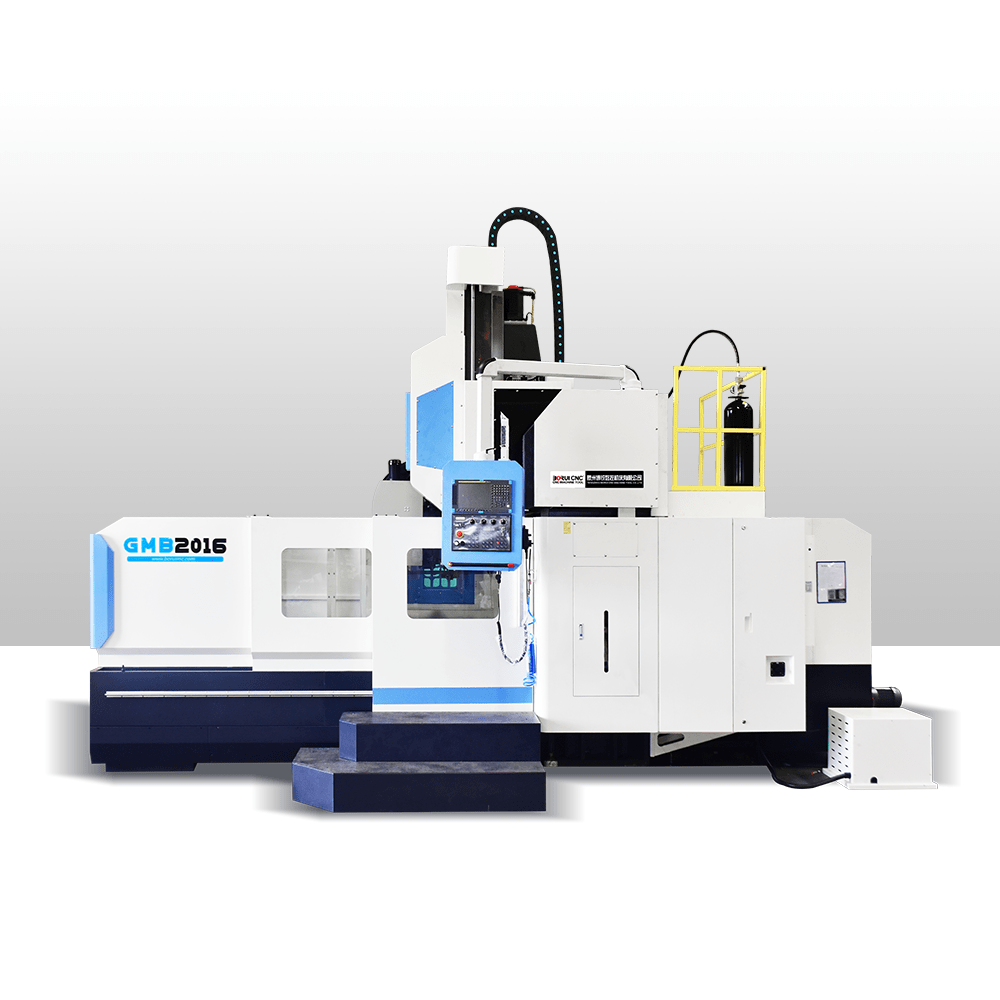

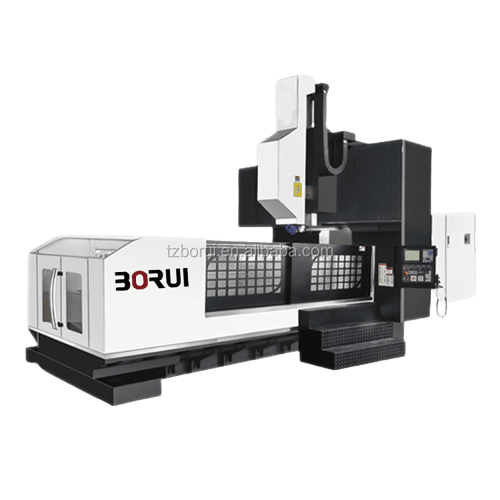

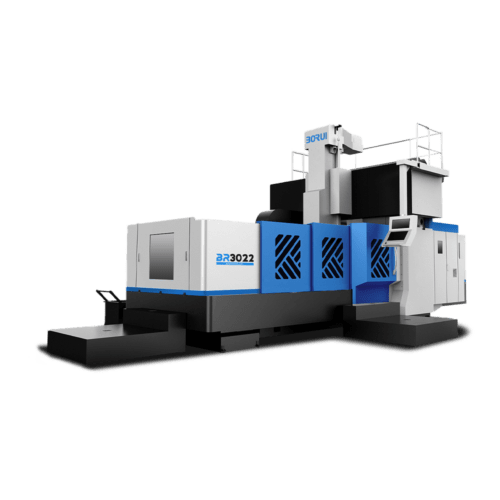

Product Advantages

- The machine tool is high-quality cast iron. An aging treatment eliminates stress. It suppresses deformation and vibration from cutting forces. The layout is reasonable.

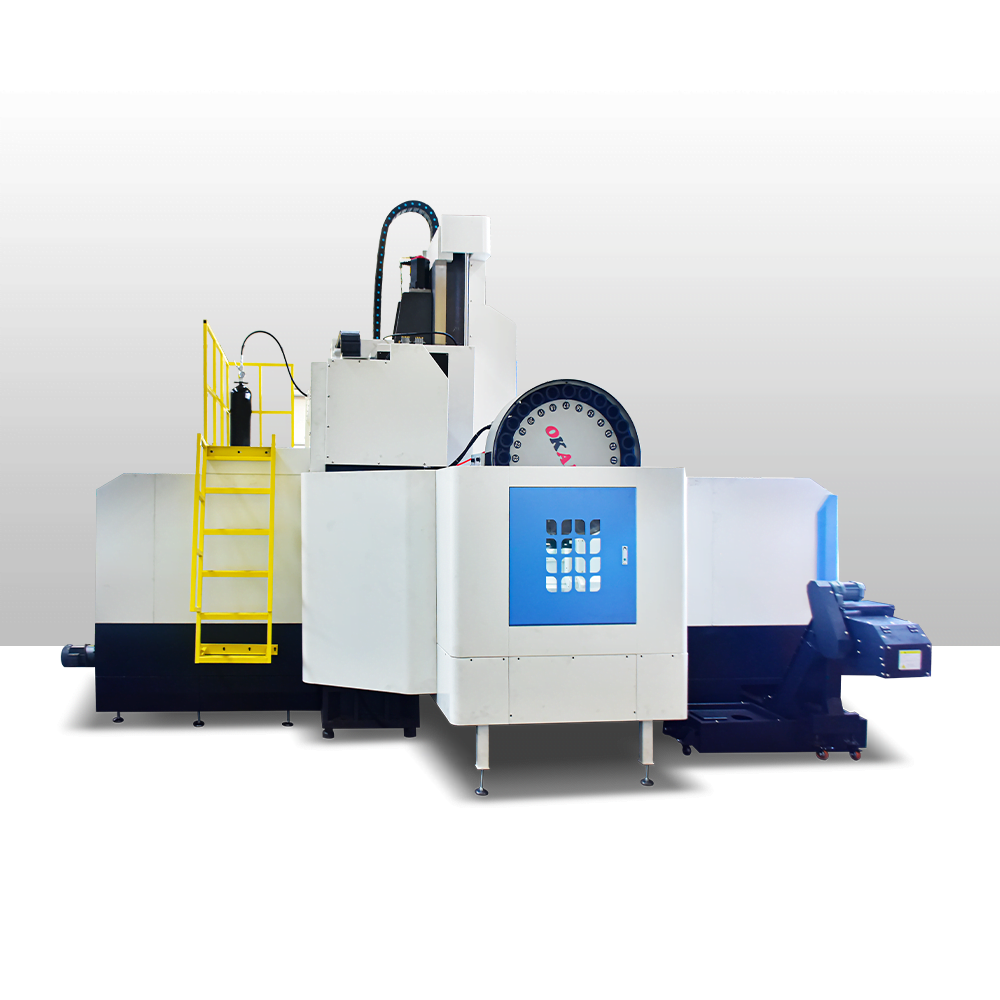

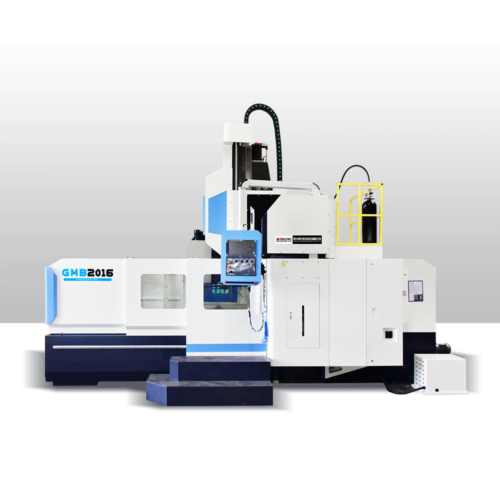

- The machine tool has a moving column gantry structure. It has a large stroke but a small footprint. This saves workshop space for customers.

- The processing of key parts of the machine tool is processed by advanced equipment. First-class equipment ensures precise machining of machine tool parts. It is vital to the machine tools’ performance.

- The machine tool has high machining accuracy and long-term precision. Its workpieces are consistent. This is due to its advanced design and perfect processes.

- Using Taiwan famous brand tool magazine, tool change is stable and durable.

- Optional SIEMENS, KND, FANUC, MITSUBISHI, GSK and other domestic and foreign operating systems.

- The bed worktable and other large parts, including the columns, beams, saddles, and spindle boxes, are all cast with high-strength iron and resin sand technology. These large pieces are designed with 3D software. The rib plate design improves their rigidity.

- The machine tool uses a mechatronics design. Its layout is compact and reasonable. It operates cheaply. The centralized control panel is easy to maintain.

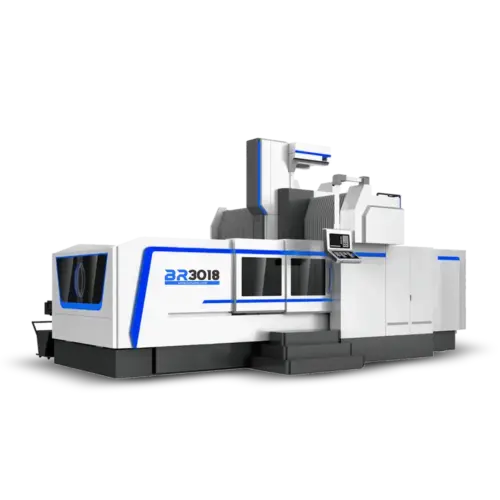

Function of GMB2016 CNC Gantry Milling Machine

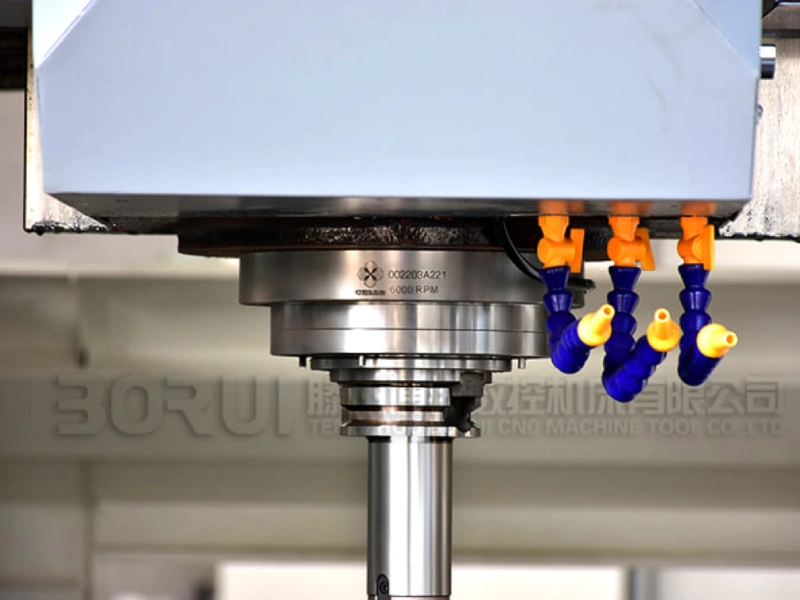

TAIWAN SPINDLE

Famous Taiwan spindle.High speed,high precision,Good surface finishing.

STAND COLUMN

24 Arm ATC

WORKBENCH

Made of high-density,high-rigidity materials,high strength and good wear resistance.

CNC CONTROL SYSTEM

Optional:GSK/KND/SIEMENS /FANUC /MITSUBISHI

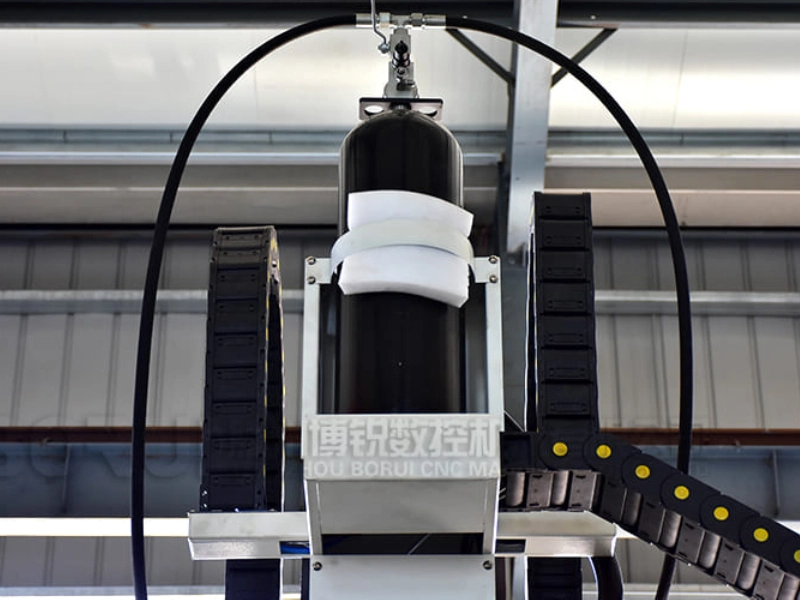

NITROGEN BALANCE CYLINDER

The servo motor of the spindle head moves up and down

Flat and horizontal spindle head weight

Realize high-speed, high-precision machining

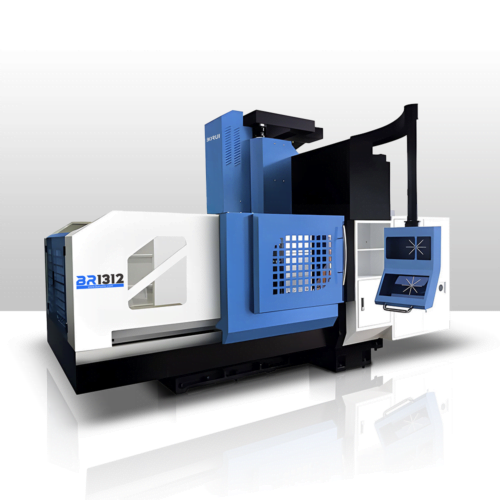

Main Component:Controller

System:GSK/KND/SIEMENS /FANUC /MITSUBISHI

Tool change:OKADA (Taiwan)/DETA /HDW

Spindle UNIT :TaiWan Posa/ Taiwan VOLIS / Roral

X/Y/Z BALL SCREW:Hiwin/PMI

Pneumatic element:Air TAC (Taiwan)

Unclamping cylinder:Hao cheng (Taiwan)

Auto oil lubricator:Hu run (Taiwan)/Japanese HERG

Screw Bearing:TPI (Taiwan brand)/NSK/SKF

Three axis motor:Unit with the cnc controller

Cooling the pump:PMY-25-5

Lubrication system:Single wire damping

Optional accessories:

- Dividing Head

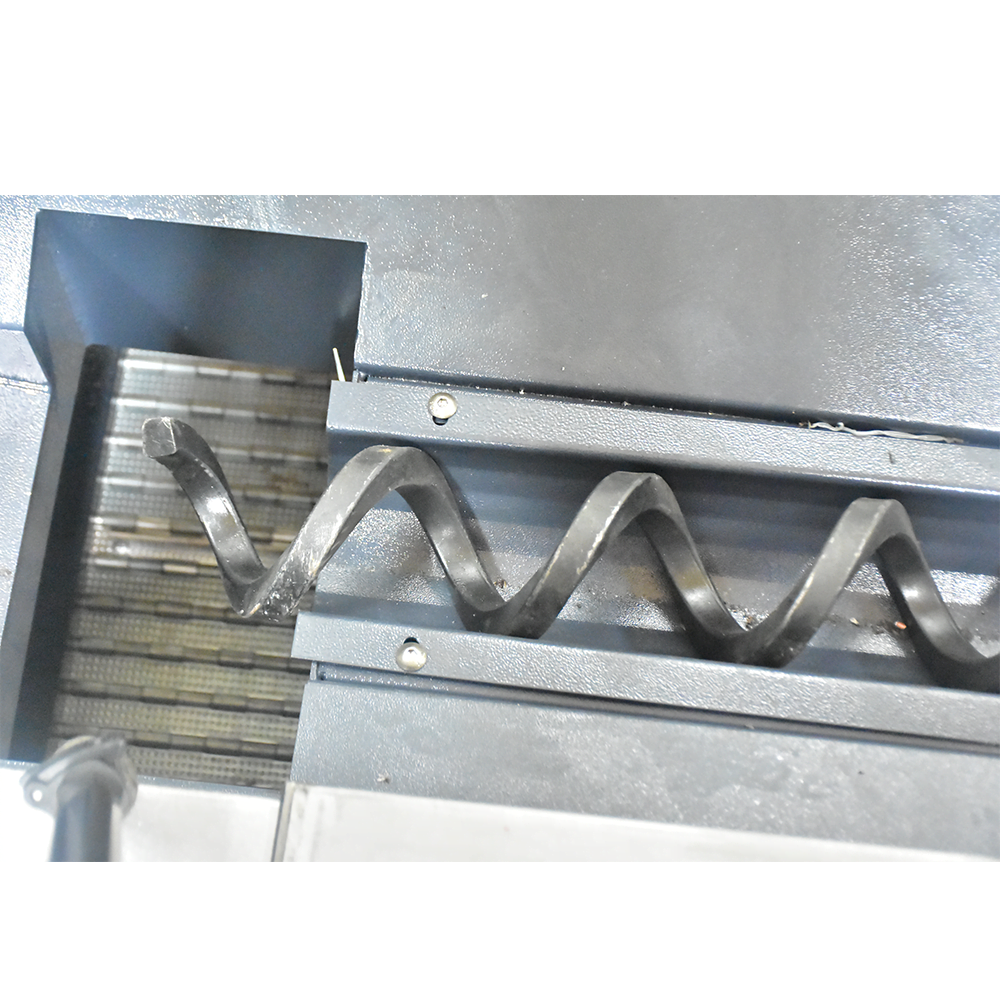

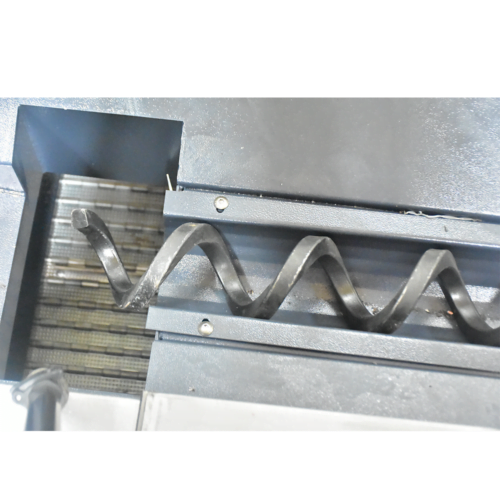

- Automatic chip conveyor

- Clamping kits

- Flat vice

- Spindle speed above 12000rpm (Spindle directly contact)

- Centering 65mm +seperate needle

- Z axis Indictor

- The spindle out the water itself +oil-water separator

- Spindle 10000rpm

Video Display

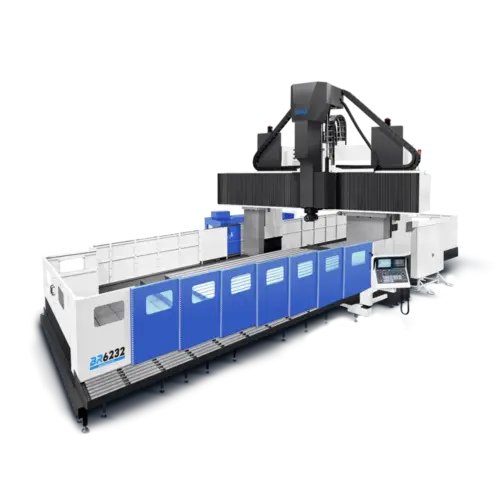

Technical Specs

| Specifications | Units | LM3020 | LM4024 |

|---|---|---|---|

| Table size | mm | 3000×1800 | 4000×2070 |

| X-axis travel | mm | 3000 | 4000 |

| Y-axis travel | mm | 2200 | 2400 |

| Z-axis travel | mm | 1000 | 1000 |

| T-slot (slot number*width*pitch) | mm | 9-22-180 | 9-28-220 |

| Column spacing | mm | 2200 | 2400 |

| Spindle nose to table | mm | 200-1200 | 200-1200 |

| Spindle taper | BT50 | BT50 | |

| Feed rate(X/Y) | mm/min | 8000 | 8000 |

| Feed rate(Z) | mm/min | 6000 | 6000 |

| Rapid traverse (X/Y) | mm/min | 15000 | 15000 |

| Rapid traverse (Z) | mm/min | 12000 | 12000 |

| Spindle speed | rpm | 30-6000 | 30-6000 |

| Spindle power | kw | 18 | 22 |

| Positioning accuracy | mm | 0.022 | 0.022 |

| Repeat accuracy | mm | 0.012 | 0.012 |

| Dimensions | mm | 8800*4000 | 9300*4300 |

| Machine weight | kg | 30000 | 38000 |

Reviews

There are no reviews yet.