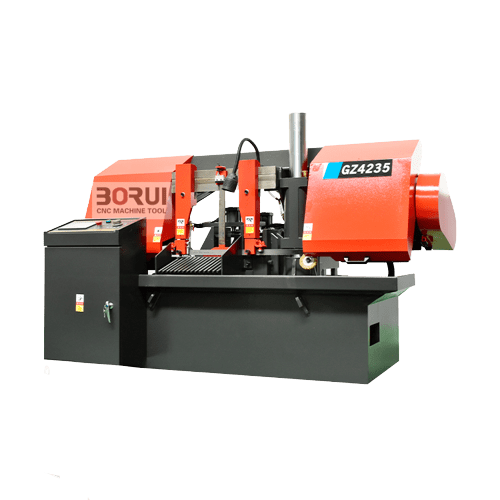

Corner Band Sawing Machine Features

- The corner band sawing machine is mainly used for sawing workpieces with cross-sections such as H-beam, channel steel, box-beam, and round steel.

- The moving guide of the band saw blade guide device is also guided by double guide rails.

- The guide device of the saw blade is more stable, so the life of the saw blade can be increased by 10%.

- The machine tool’s upper pressing device automatically adjusts the position. Operators can change according to the size of the steel section.

- The band saw blade adopts hydraulic tension. The saw blade also maintains a reasonable tension force in the fast movement. It can prolong the saw blade’s life.

- The user can adjust the pressure according to the steel section size.

- There is a detection device when the saw blade is broken. If the machine tool is defective or fails, the machine will automatically sense and stop.

- The safety protection of the machine tool is perfect. The appearance design is more humanized.

Product Video

Technical Parameters of The Corner Band Saw

| Model | GHZ4230 | GHZ4235 | GHZ4240 | GHZ4250 |

|---|---|---|---|---|

| 90°Cutting capacity (mm) | 300-320*300 | 350-380*350 | 400-600*400 | 500-700*500 |

| 45°Cutting capacity (mm) | 200- 200*220 | 220-240*220 | 300- 400*300 | 400- 500*400 |

| Blade speed(m/min) | 27、45、69 | 27、45、69 | 27、45、69 | 27、45、69 |

| Blade size(mm) | 3850 X 27 X 0.9 | 4525 X 34 X 1.1 | 5050 X 41 X 1.3 | 5880 X 41 X 1.3 |

| Main motor Power(Kw) | 3 | 4 | 5.5 | 5.5 |

| Hydraulic motor power(kw) | 0.55 | 0.55 | 1.5 | 1.5 |

| Cooling pump(w) | 40 | 40 | 125 | 125 |

| Worktable Clamping type | hydraulic clamping | hydraulic clamping | hydraulic clamping | hydraulic clamping |

| Main driving struction | Turbine drive | Turbine drive | Turbine drive | Turbine drive |

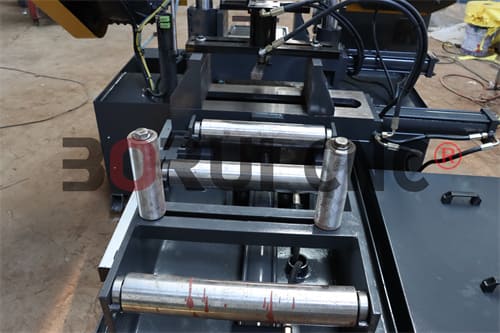

| Feeding way | Wheel sliding | Wheel sliding | Wheel sliding | Wheel sliding |

| Machine overall size (mm) | 2100 X 1300 X 1550 | 2300 X 1350 X 1650 | 2460 X 1950 X 2000 | 2960 X 2150 X 2200 |

| Machine weight | 850KG | 950KG | 1500KG | 1800KG |

Product Details Display

AUTOMATIC BALANCING DISC

Automatic balancing disc The surface is sprayed with special plastic. It takes work to rust.

BUTTON OPERATION

The left electrical cabinet has an easy-to-operate button control, a simple operation, an optional frequency control, and a more comprehensive speed range.

SAW BAND TENSION

Standard: manual tension

FEED/RETURN SET

Manual feed and return settings and front stop settings can effectively adjust the feeding and returning materials.

ROTATABLE WORKTABLE

The guide rail surface is heat-treated, with high hardness and rigidity, and the worktable can rotate at 45°.

ELECTRIC CHIP REMOVAL

Electric chip removal has high conveying efficiency.

Reviews

There are no reviews yet.