Product Description

Main Features:

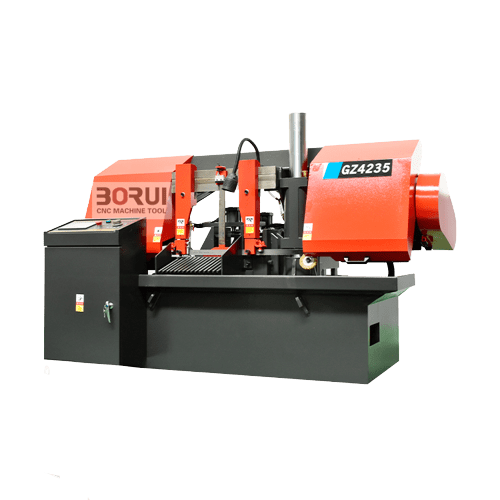

The corner band sawing machine is mainly used for sawing workpieces with cross-sections such as H-beam, channel steel, box-beam, and round steel.

1. The moving guide of the saw blade guide device of the band saw is also guided by double guide rails, and the guide device of the saw blade is more stable, so that the life of the saw blade can be increased by 10%.

2. The upper pressing device of the machine tool realizes automatic adjustment of the position, and the position can be adjusted according to the size of the section steel.

3. The band saw blade adopts hydraulic tension, and the saw blade also maintains a good tension force in the fast movement, which prolongs the life of the saw blade. The user can adjust the pressure according to the size of the section steel; and there is a detection device when the saw blade is broken. If the machine tool is defective In the event of a situation or failure, the machine will automatically sense and stop.

4. The safety protection of the machine tool is more perfect, and the appearance design is more humanized.

Technical Specs

| Model | GHZ4230 | GHZ4235 | GHZ4240 | GHZ4250 |

|---|---|---|---|---|

| 90°Cutting capacity (mm) | 300-320*300 | 350-380*350 | 400-600*400 | 500-700*500 |

| 45°Cutting capacity (mm) | 200- 200*220 | 220-240*220 | 300- 400*300 | 400- 500*400 |

| Blade speed(m/min) | 27、45、69 | 27、45、69 | 27、45、69 | 27、45、69 |

| Blade size(mm) | 3850 X 27 X 0.9 | 4525 X 34 X 1.1 | 5050 X 41 X 1.3 | 5880 X 41 X 1.3 |

| Main motor Power(Kw) | 3 | 4 | 5.5 | 5.5 |

| Hydraulic motor power(kw) | 0.55 | 0.55 | 1.5 | 1.5 |

| Cooling pump(w) | 40 | 40 | 125 | 125 |

| Worktable Clamping type | hydraulic clamping | hydraulic clamping | hydraulic clamping | hydraulic clamping |

| Main driving struction | Turbine drive | Turbine drive | Turbine drive | Turbine drive |

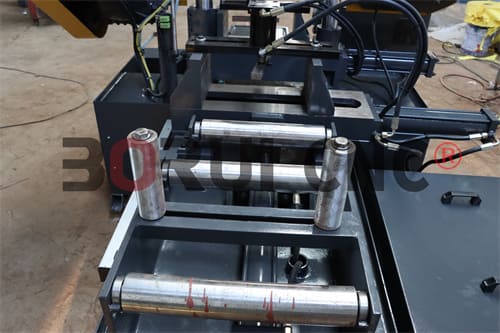

| Feeding way | Wheel sliding | Wheel sliding | Wheel sliding | Wheel sliding |

| Machine overall size (mm) | 2100 X 1300 X 1550 | 2300 X 1350 X 1650 | 2460 X 1950 X 2000 | 2960 X 2150 X 2200 |

| Machine weight | 850KG | 950KG | 1500KG | 1800KG |

ATUOMATIC BALANCING DISC

Automatic balancing disc The surface is sprayedwith special plastic Not easy to rust.

BUTTON OPERATION

The left electricalcabinet is easy to opertae button control,simple operation,Optional frequency control wider speed range.

SAW BAND TENSION

Standard:manual tension

FEED/RETURN SET

Manual feed and return settings,and front stop settingslt can effectively adjust thefeeding and returning materials.

ROTATABLE WORKTABLE

The surface of guide rail is heattreated,with high hardness andrigidity,and the worktable canrotate 45°.

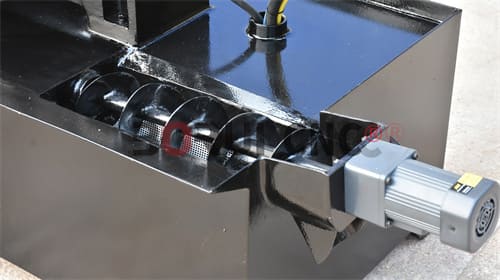

ELECTRIC CHIP REMOVAL

Electric chip removal high converying efficiency.

Video Display

Reviews

There are no reviews yet.