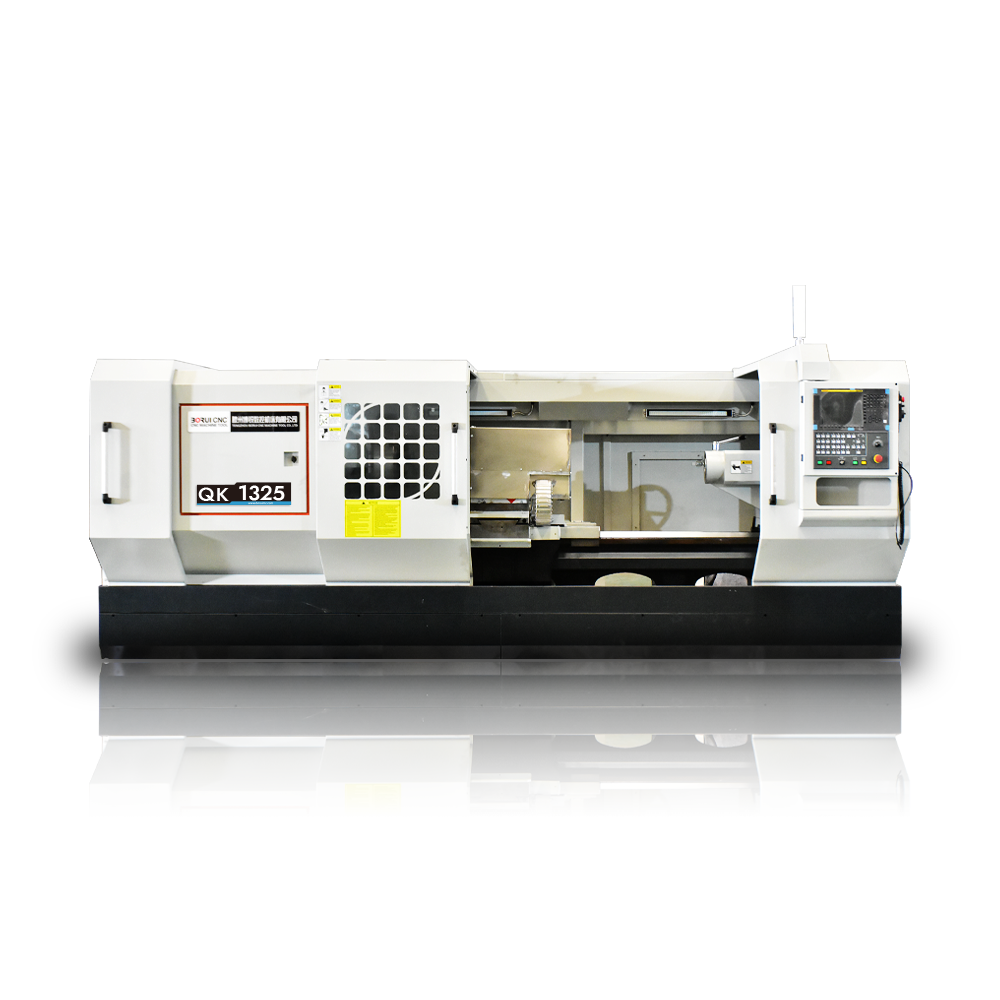

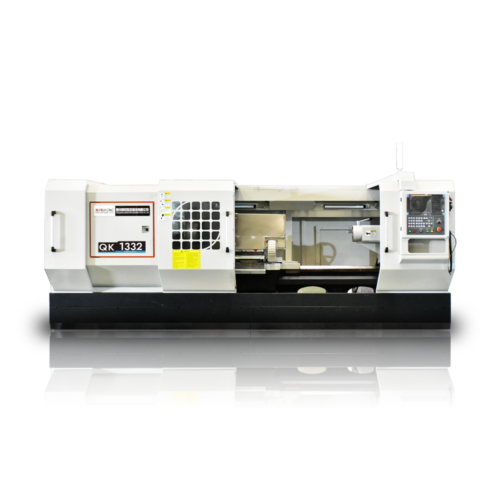

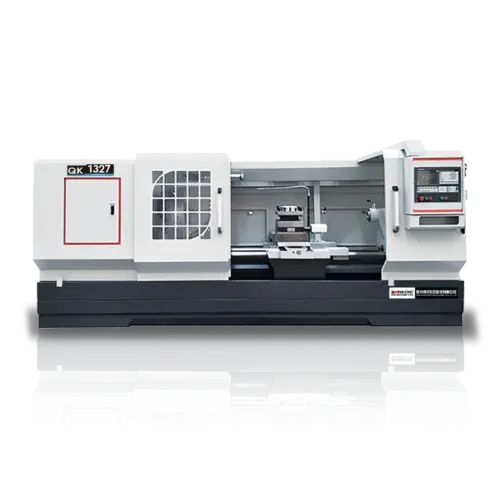

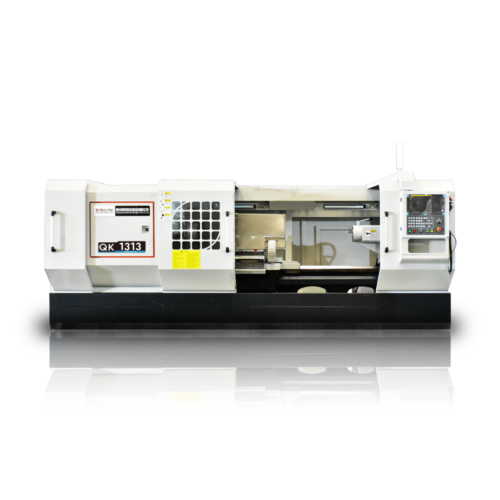

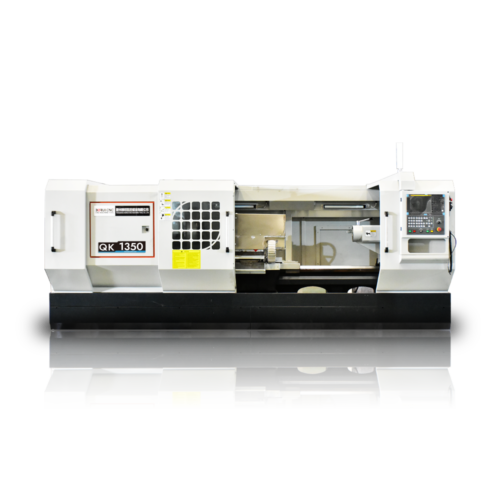

Advantages Of CNC Pipe Threading Lathe Machine:

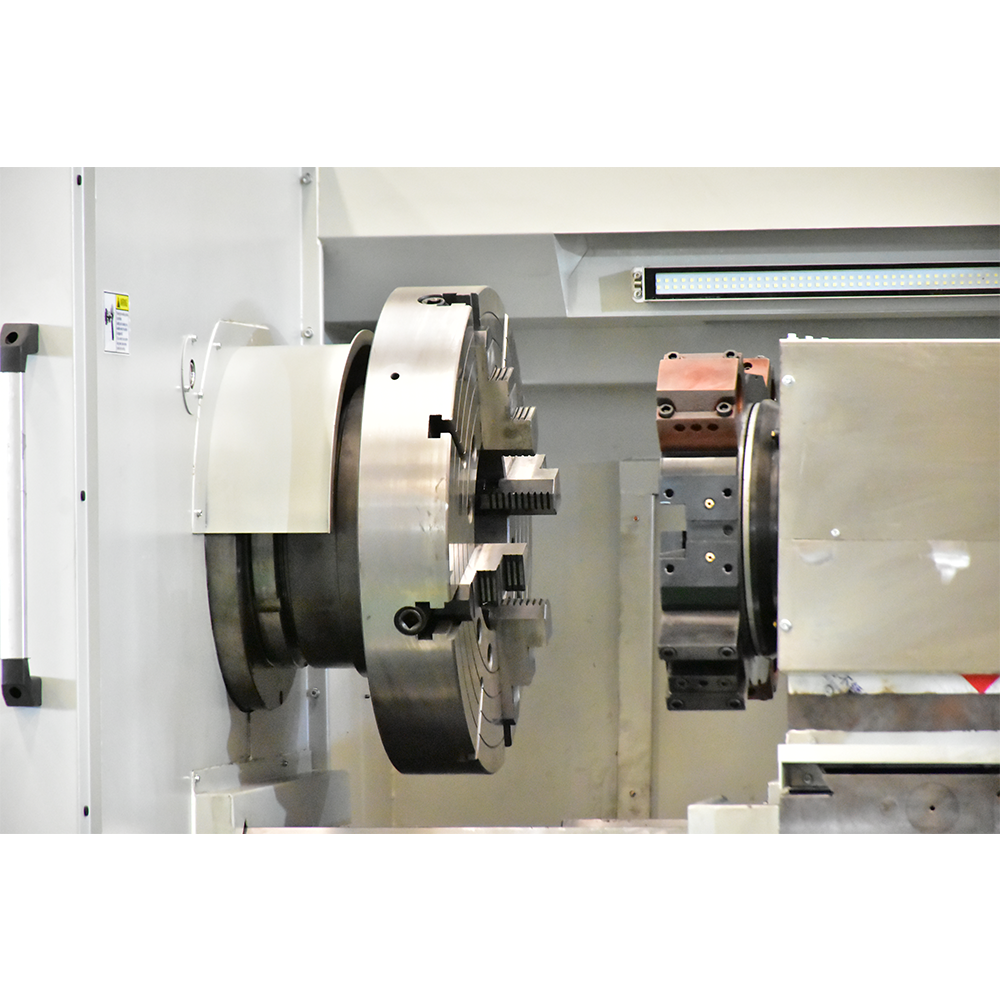

- Spindle hole diameter drilling,double chuck workpiece clamping stability.

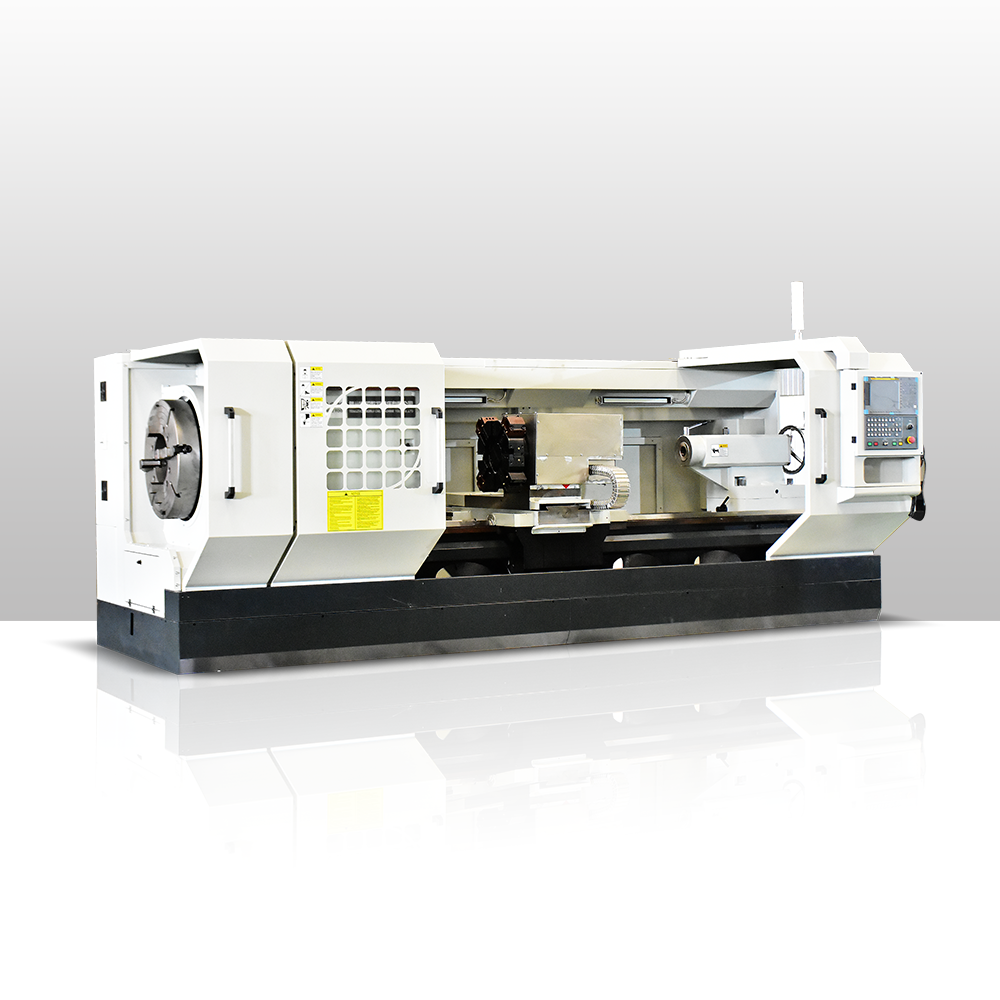

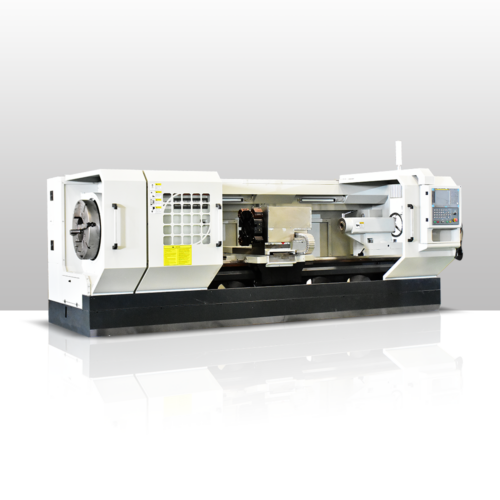

- High-quality high-strength cast iron casting, the overall bed has good rigidity and high precision.

- The surface of the guide rail has been treated with super-audio frequency quenching, which has high hardness and long service life.

- The carriage adopts the guide rail surface sticking plastic process, which has good wear resistance and high precision.

- It is mainly used to process internal and external threads of pipeline tools, and has the function of CNC lathe at the same time.

- Machining the outer circle, inner hole and end face of workpieces such as shafts and discs.

- Widely used in the processing and repair of drill pipes, joints, casings and other parts in some industries.

- Applied to thread processing of various pipes and drill pipes in chemical, coal, geological and other industries.

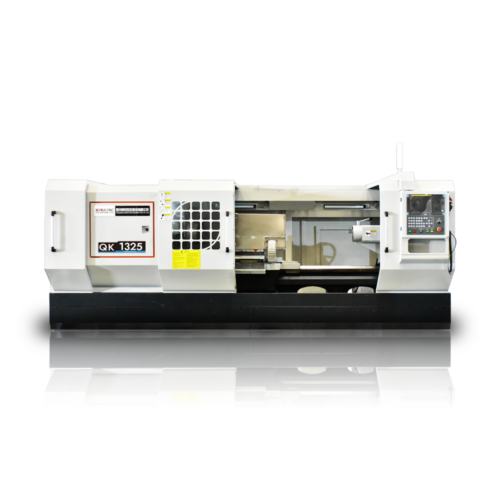

Product Main Technical Parameters:

| Specification | QK1325 | |

|---|---|---|

| Swing over bed | mm | 800-1000 |

| Swing over cross slide | mm | 480-680 |

| Distance between centers | mm | 1000-6000 |

| Pipe threading range | mm | 50-255 |

| Guideway width | mm | 600 |

| Max.load capacity | T | 4 |

| Spindle bore | mm | 255 |

| Spindle speed steps | — | VF.4 steps |

| Spindle speed range | rpm | 20-420 |

| Chuck | mm | Φ630/4-jaw manual |

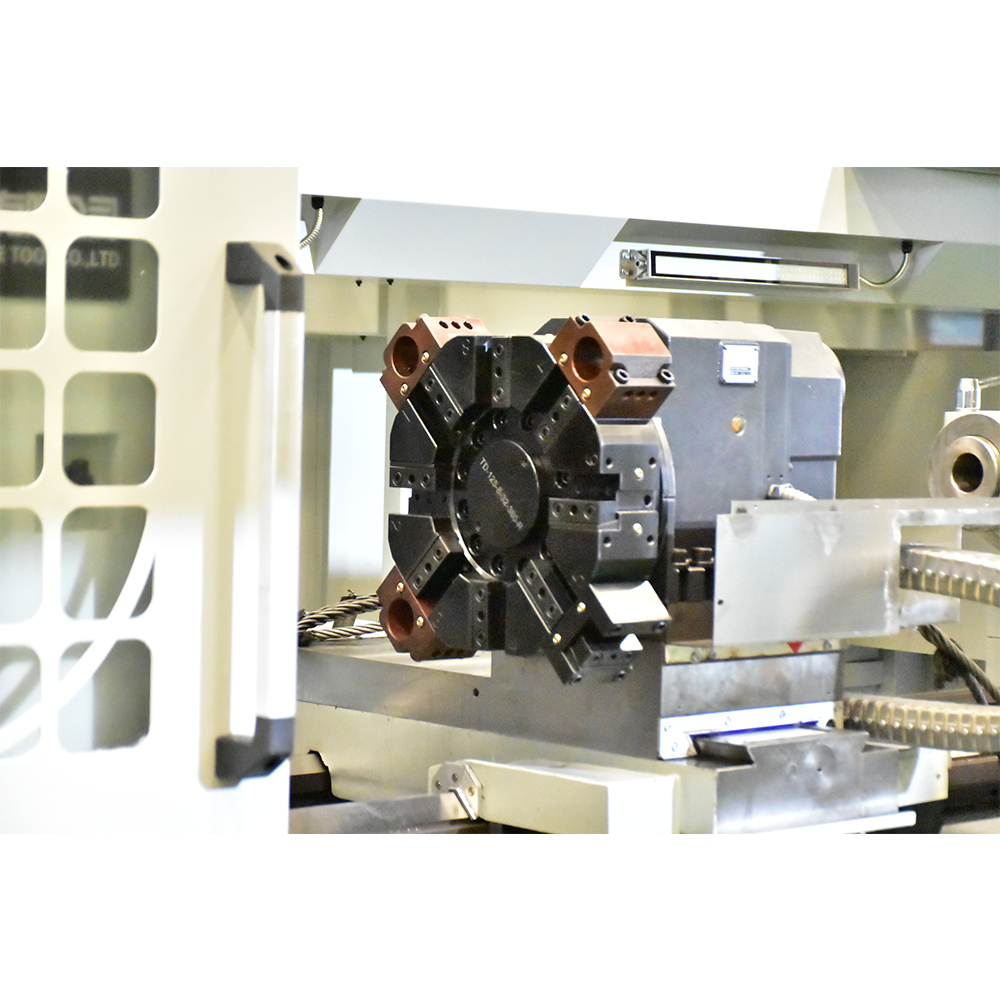

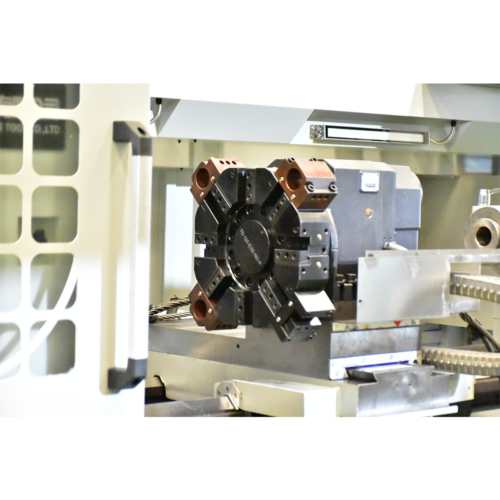

| Turret/tool post | — | NC turret 4 position |

| Tool shank size | mm | 32×32 |

| Y axis travel | mm | 420 |

| Z axis travel | mm | 1000-6000 |

| X axis rapid traverse | mm/min | 4000 |

| Z axis rapid traverse | mm/min | 6000 |

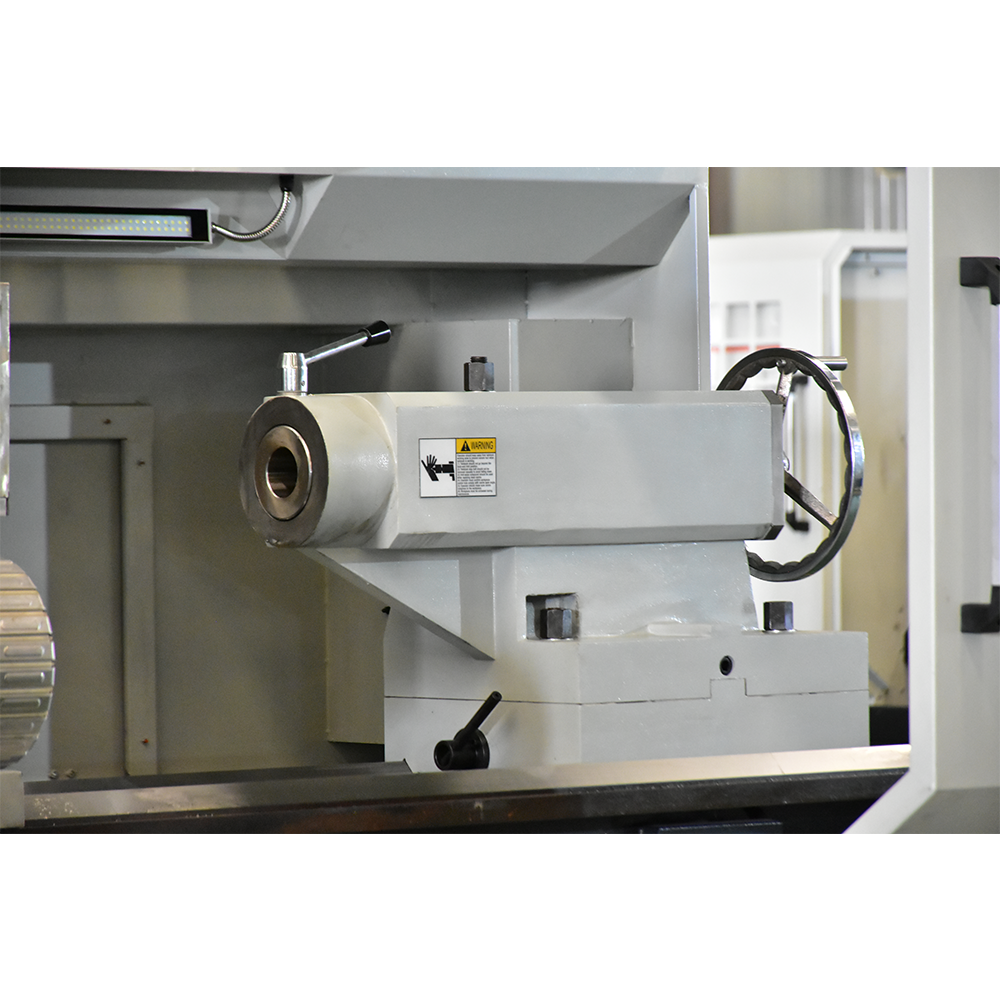

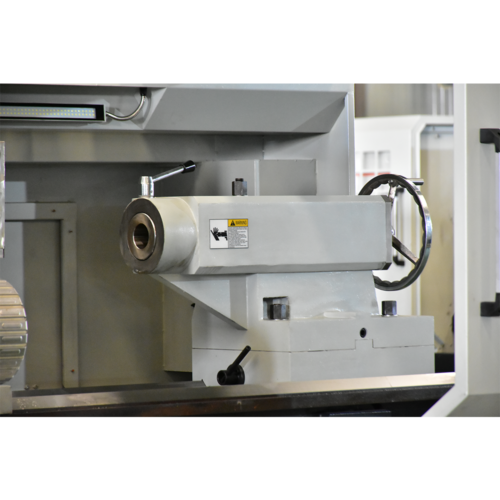

| Teilstock quill diameter | mm | φ120 |

| Tailstosk quill taper | mm | MT6 |

| Tailstock quill travel | mm | 250 |

| Main spindle motor | kW | 15 |

| Coolant pump motor | kW | 0.25 |

| Width x Height | mm | 1930×1900 |

| Length | mm | 3600/8600 |

| Net weight | T | 6-9.5 |

Video Display

Reviews

There are no reviews yet.