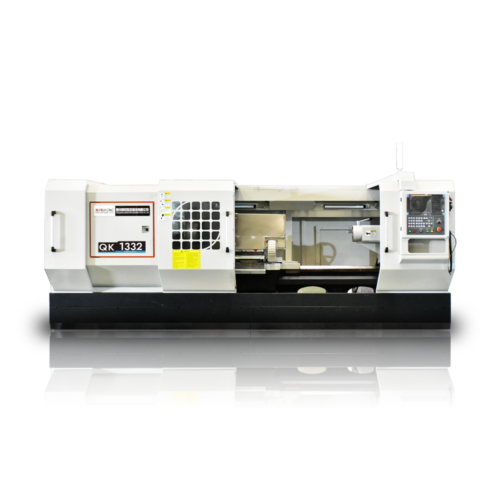

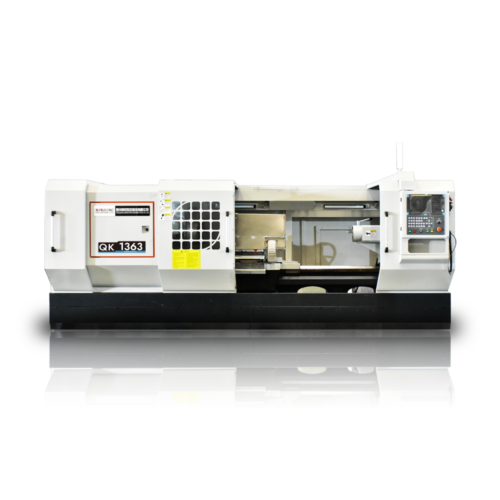

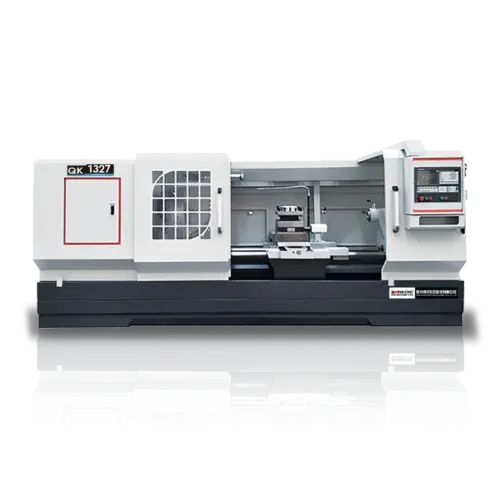

Advantages Of CNC Pipe Threading Lathe Machine:

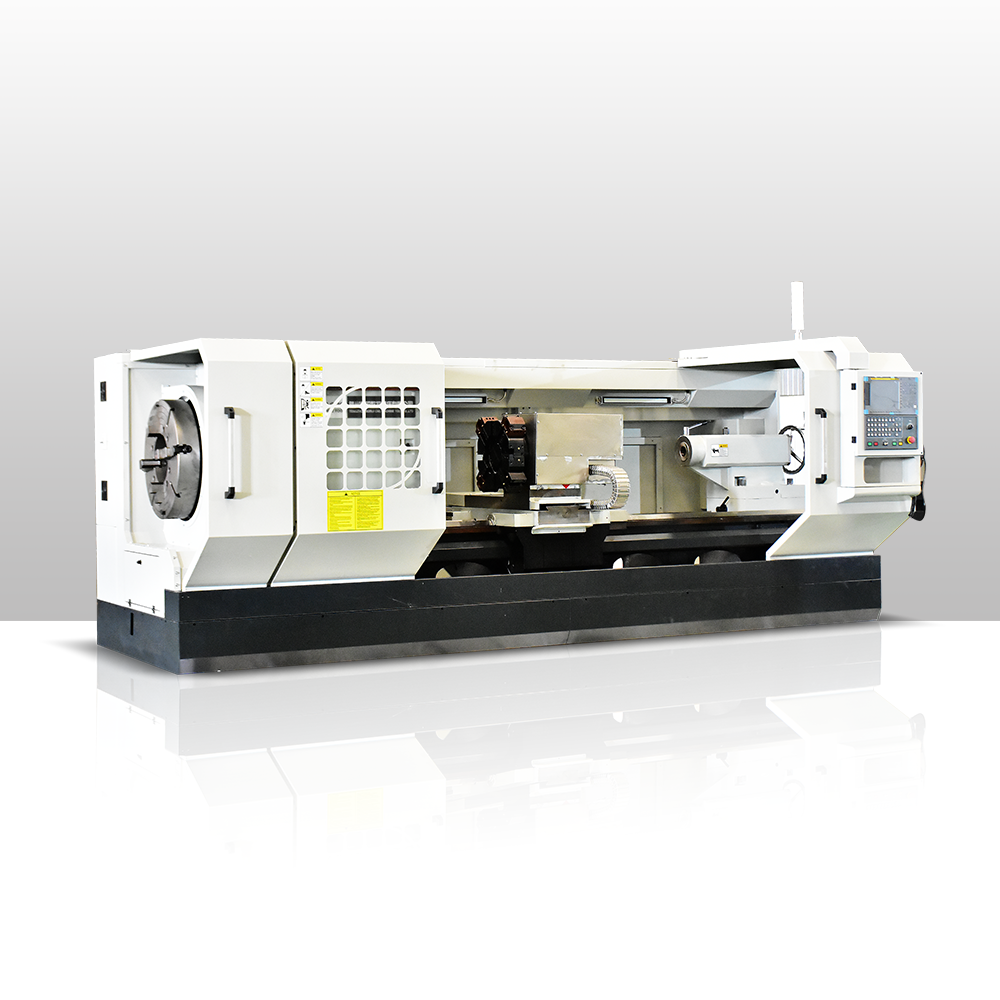

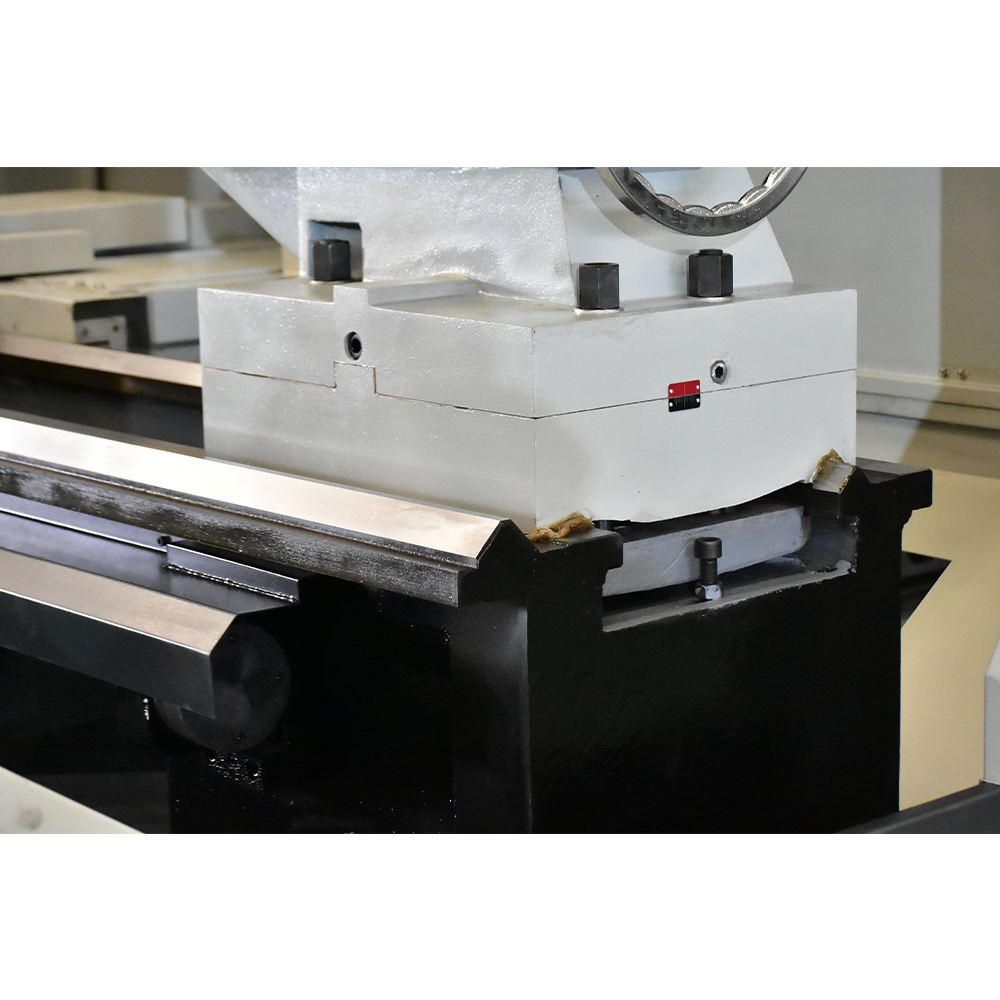

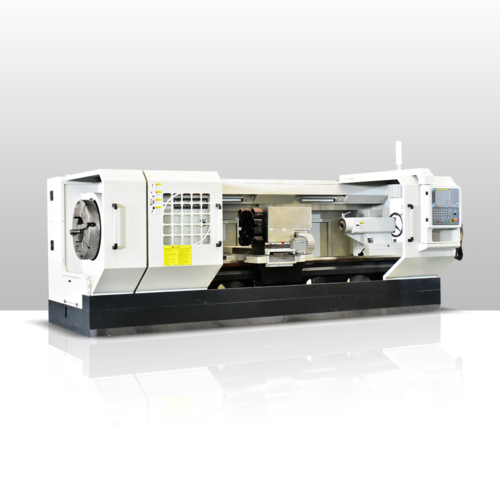

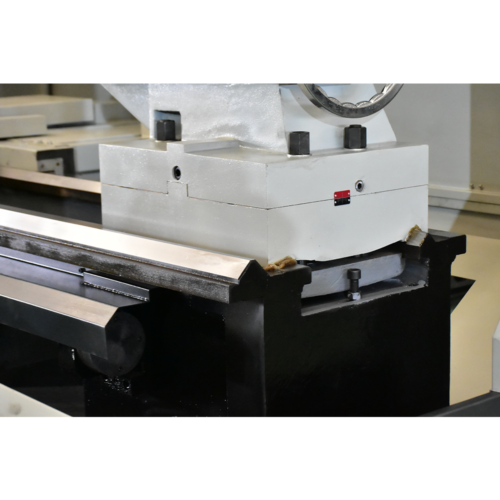

- The bed adopts the overall floor structure, the guide rail surface of the bed is widened, and is subjected to high-frequency quenching and precision grinding.

- High-frequency quenching and precision grinding improve the rigidity and stability of the machine tool and ensure the accuracy and service life of the machine tool.

- After manual scraping and grinding, the guiding precision and durability of the machine tool are improved.

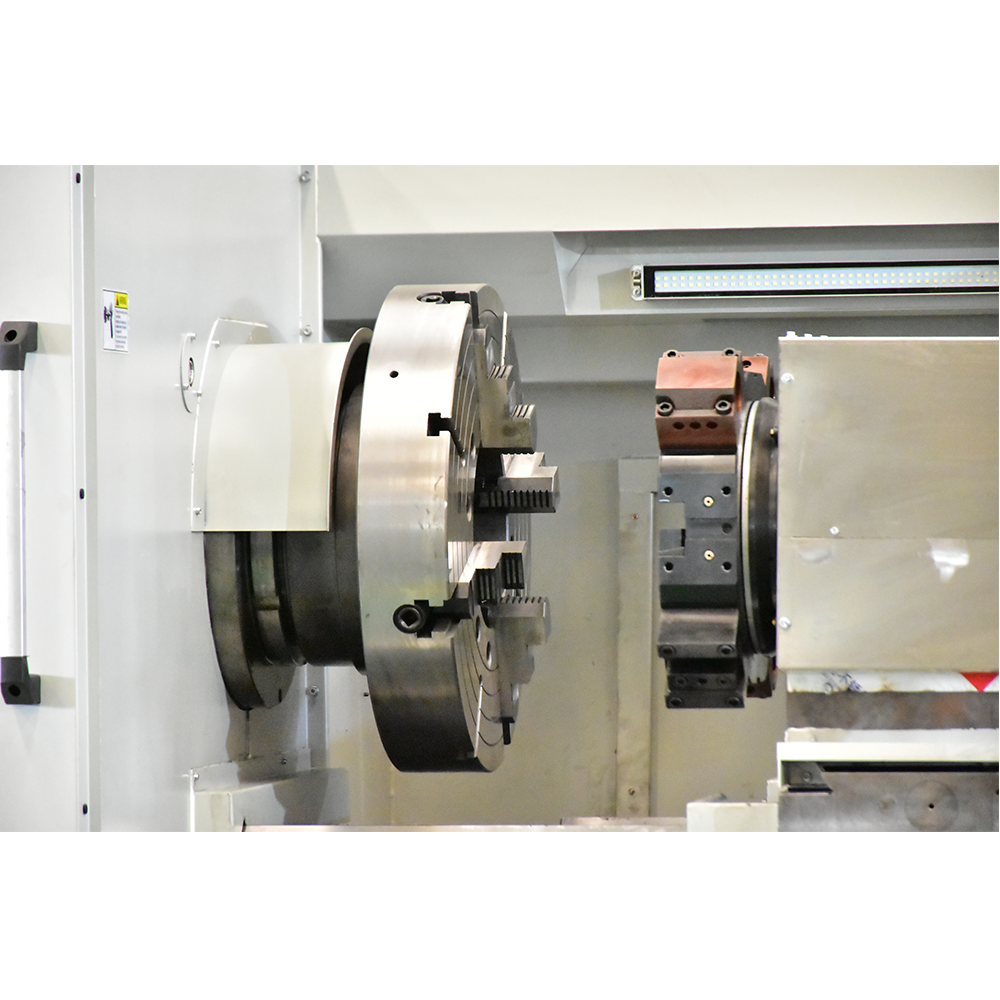

- Spindle box gears are high-frequency quenched and ground, and the main motor is built into the body, with compact structure and small footprint.

- The spindle speed is controlled by two-speed frequency conversion speed regulation in the box, which is easier to operate.

- The speed range is large, which can not only meet the high-torque machining of workpieces, but also achieve high-efficiency cutting.

- Cooling and lubricating inside the bedside box adopts powerful external circulation system.

- The ball screw adopts a direct drive with the motor and a prestressed tension structure, with high transmission accuracy.

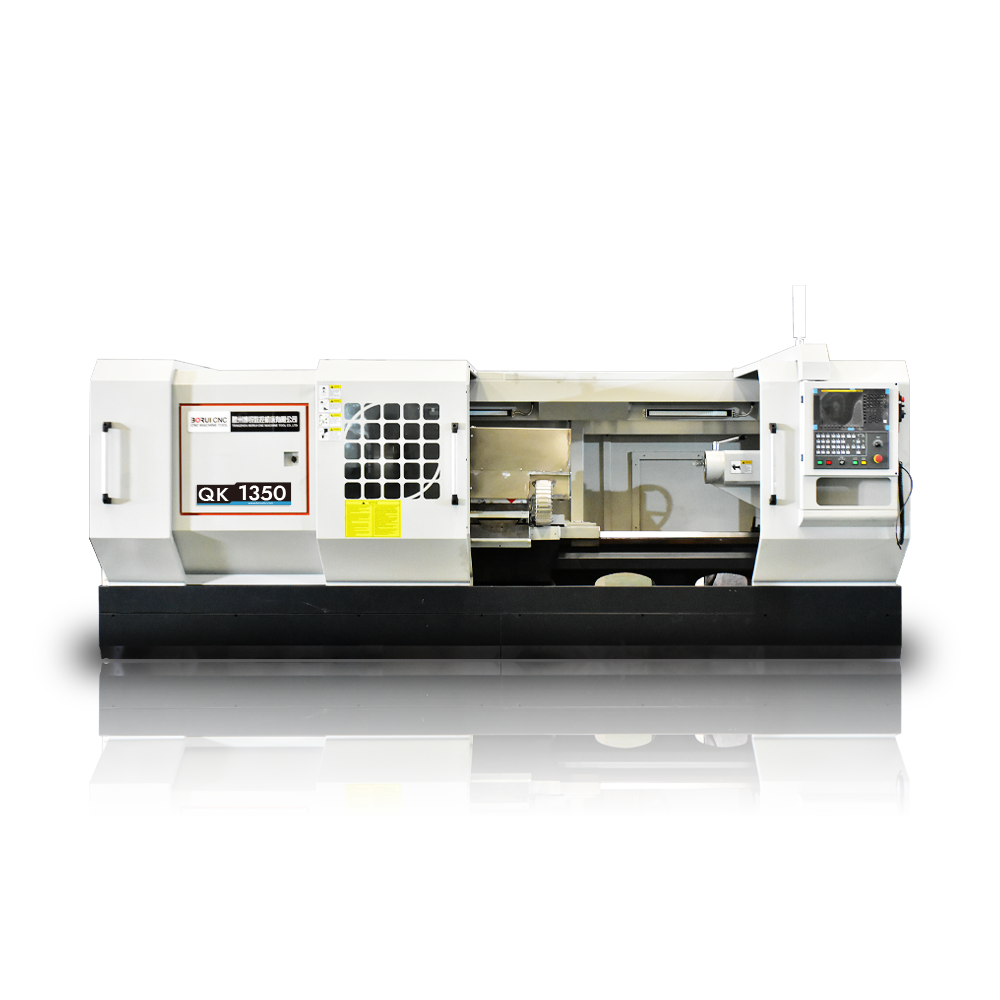

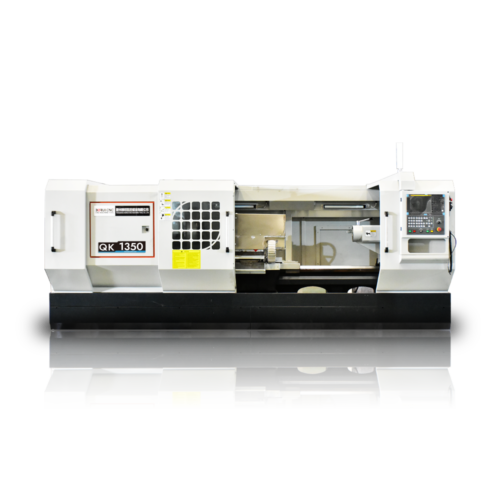

Product Main Technical Parameters:

| Specification | QK1350 | |

|---|---|---|

| Swing over bed | mm | 1200 |

| Swing over cross slide | mm | 710 |

| Distance between centers | mm | 1500/3000 |

| Pipe threading range | mm | 330-510 |

| Guideway width | mm | 765 |

| Max.load capacity | T | 6 |

| Spindle bore | mm | 520 |

| Spindle speed steps | — | VF.3 steps |

| Spindle speed range | rpm | 8-190 |

| Chuck | mm | Φ1000/4-jaw manual |

| Turret/tool post | — | NC turret 4 position |

| Tool shank size | mm | 50×50 |

| Y axis travel | mm | 520 |

| Z axis travel | mm | 1250/2750 |

| X axis rapid traverse | mm/min | 4000 |

| Z axis rapid traverse | mm/min | 4000 |

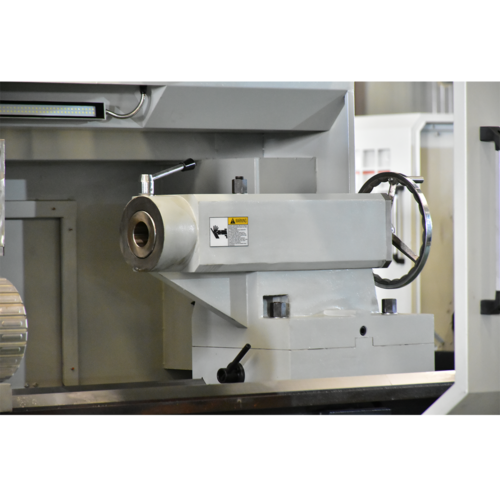

| Tailstock quill diameter | mm | φ160 |

| Tailstosk quill taper | mm | MT6 |

| Tailstock quill travel | mm | 300 |

| Main spindle motor | kW | 22 |

| Coolant pump motor | kW | 0.25 |

| Width x Height | mm | 2300×2200 |

| Length | mm | 5000/6500 |

| Net weight | T | 15/16 |

Video Display

Reviews

There are no reviews yet.