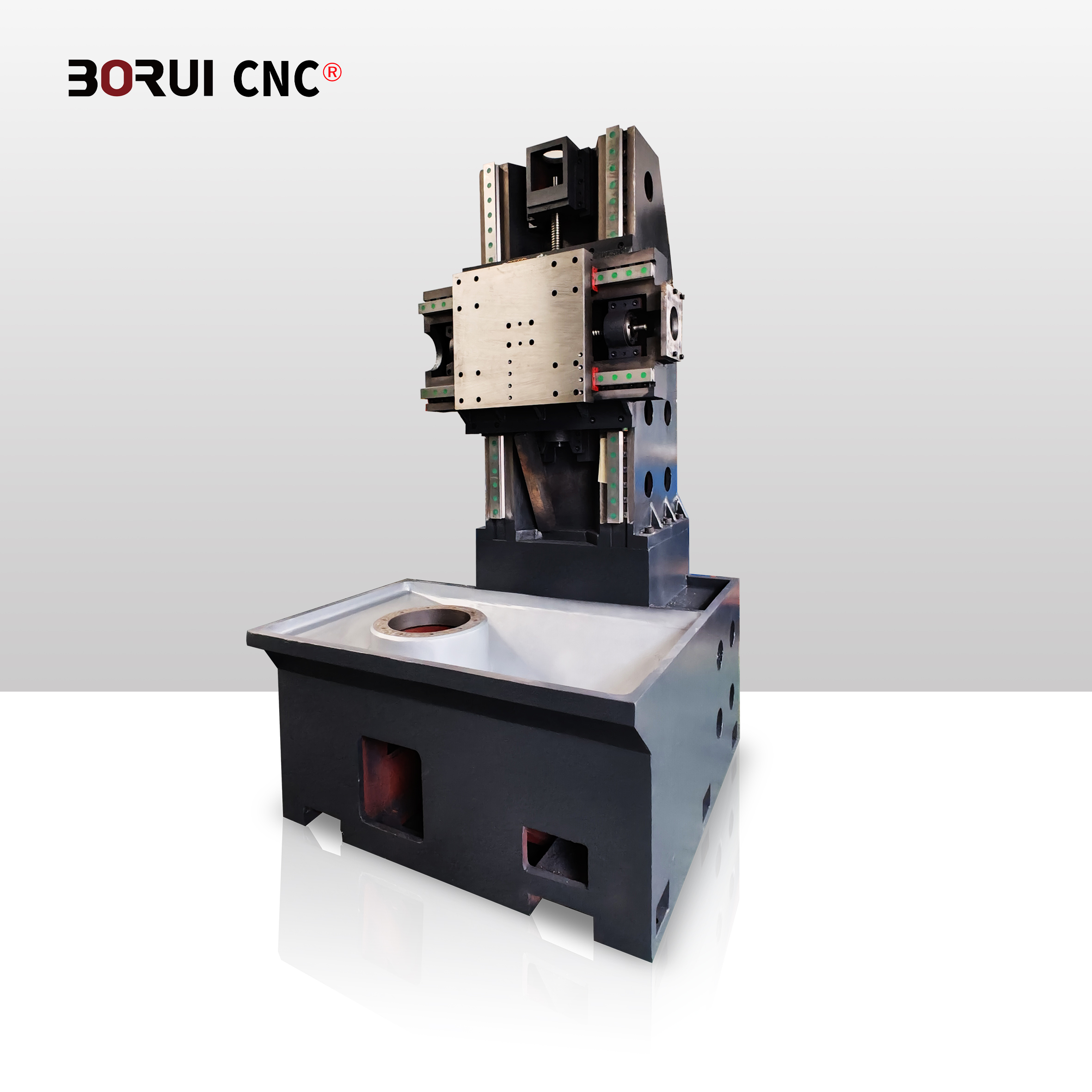

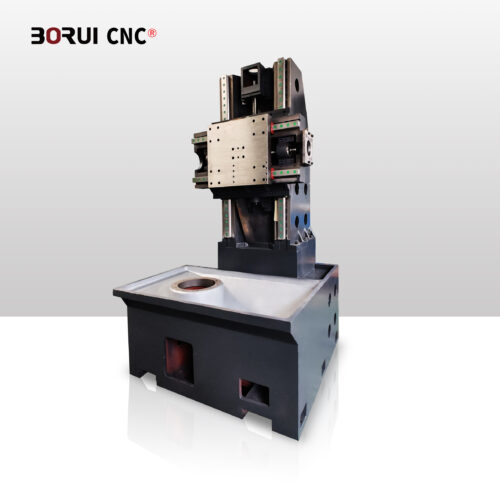

VTC Vertical CNC Lathe Machine Features

- Full protection

- Three-jaw chuck

- Foot switch

- Hydraulic unit

- Automatic lubrication system

- Working lamp

- Tri-color warning light

- Workpiece counter

- Cooling flushing system

- Electrical box air conditioner

- Toolbox

- Chip conveyor

- Iron filings cart

- Operation Manual

- CNC system Standard: GSK, Optional: Siemens, Fanuc, Mitsubishi and others

Video Display

VTC Vertical CNC Lathe Technical Parameters

|

SPECIFICATIONS

|

UNITS

|

VTC50

|

VTC60

|

VTC70

|

VTC100A

|

|

X axis travel

|

mm

|

-350

|

-675

|

-700

|

-870

|

|

Z axis travel

|

mm

|

120-620

|

65-715

|

130-830

|

60-1110

|

|

Max swing diameter

|

mm

|

650

|

650

|

800

|

1200

|

|

Max turning diameter

|

mm

|

500

|

600

|

700

|

1000

|

|

Max cutting height

|

mm

|

500

|

600

|

700

|

1000

|

|

Spindle speed range

|

rpm

|

100-1000

|

100-1000

|

100-800

|

100-800

|

|

Spindle motor

|

kw

|

15

|

18.5

|

22

|

37

|

|

Spindle outer diameter

|

mm

|

130

|

160

|

160

|

200

|

|

Chuck type and diameter

|

Inch

|

Hydraulic chuck 15”

|

Hydraulic chuck 18”

|

Hydraulic chuck 21”

|

Hydraulic chuck 32”

|

|

Turret type

|

|

4-station,8-station(optional)

|

4-station,8-station(optional)

|

4-station,8-station(optional)

|

4-station,8-station(optional)

|

|

Coolant motor

|

w

|

450+450

|

450+450

|

450+750

|

750+750

|

|

Pump output

|

M3/h

|

2m³/h

|

2m³/h

|

4m³/h

|

4m³/h

|

|

Positioning accuracy

|

mm

|

±0.005

|

±0.005

|

±0.005

|

±0.008

|

|

Repeat positioning accuracy

|

mm

|

±0.01

|

±0.01

|

±0.01

|

±0.01

|

|

Overall dimensions

|

mm

|

2100x2500x2750

|

1710x2050x2910

|

2400x1800x3200

|

2800x2400x3870

|

|

Machine weight

|

kgs

|

5500

|

7500

|

8000

|

11000

|

Advantages Of Vertical Lathe CNC Machine

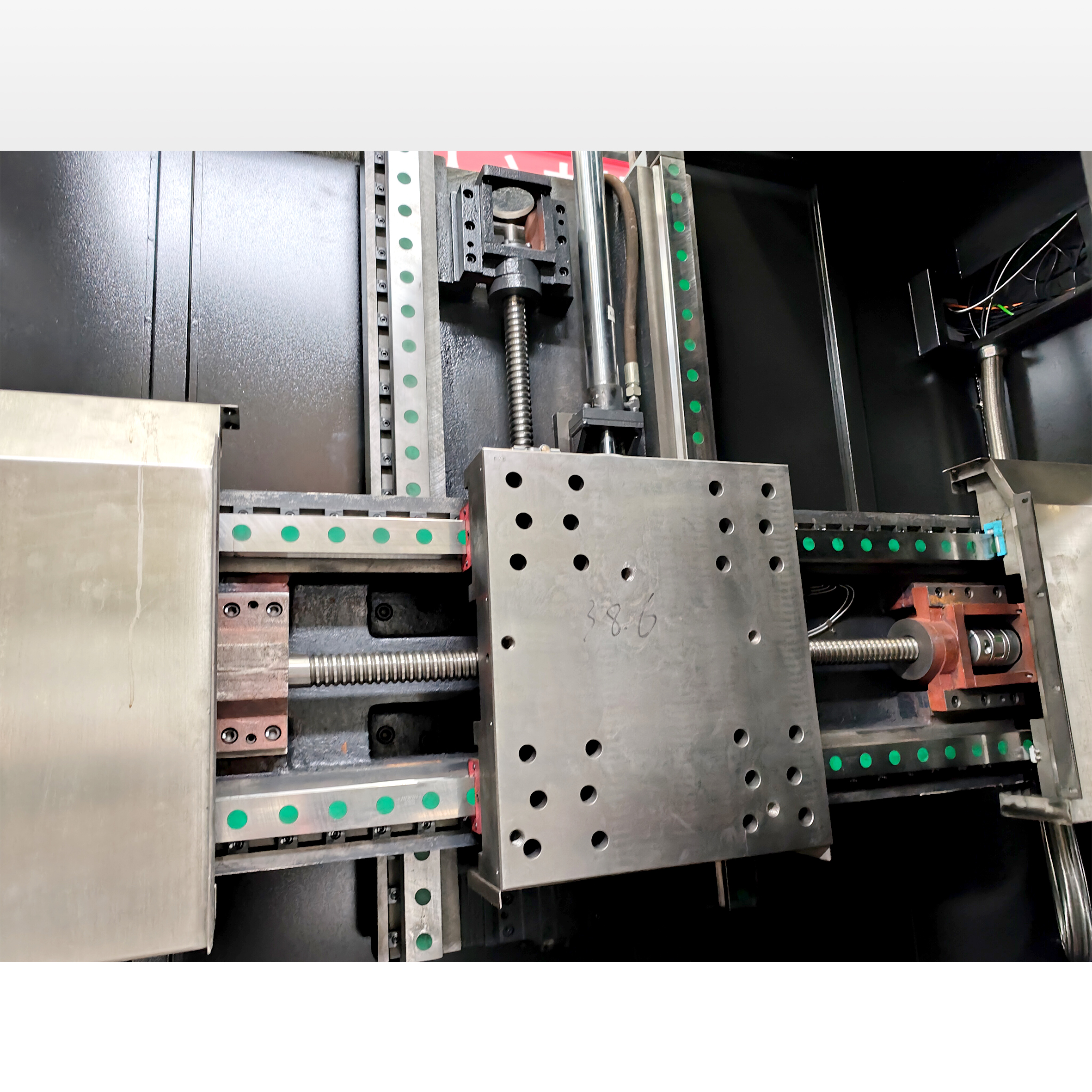

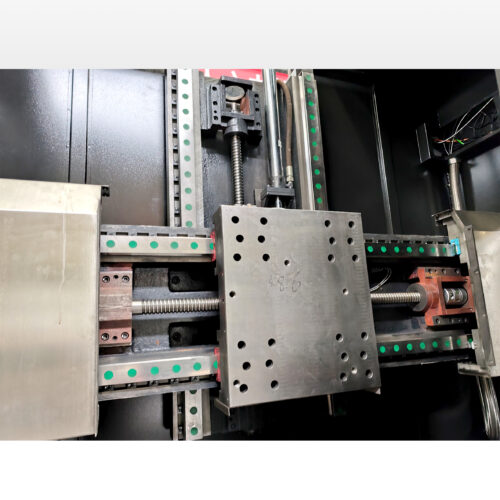

- The machine tool is a roller-type linear slide. It has ultrahigh rigidity and overload capacity;

- The machine tool spindle belt pulley is connected with the spindle numerical control servo motor through a belt.

- This vertical CNC lathe can satisfy different spindle speeds required for rough parts machining and finish machining.

- The machine tool rest is of horizontal or vertical multi-station numerical control structure.

- It can shorten tool changing time and significantly improve work efficiency.

- The upper end of the spindle may be equipped with a type of workbench or hydraulic chuck based on the user’s requirements.

- The angling cylinder applies to the lower end of the spindle. It is for compressing the processed workpieces or for controlling the hydraulic chuck.

- This machine tool may be equipped with a domestic numerical control system of HNC, KND, and GSK. It can also be imported into the system optionally by users.

Reviews

There are no reviews yet.