Multiple workshops rely on band saw machines as essential operational tools. In 2025, a number of companies will manufacture these precise cutting machines. These devices use advanced technology to perform precise cuts on wood, metal, and other materials. They perform essential operations in the automotive, aerospace, and construction industries.

In this guide, we will walk you through the top makers in the market. The global market for these machines is growing fast. It may reach $3.5 billion by 2035. These companies discussed below have set history and stand apart in producing the top band saw technology that works better.

So, before diving into the list of the top 10 band saw machines, let’s review the basics.

Understanding Band Saws

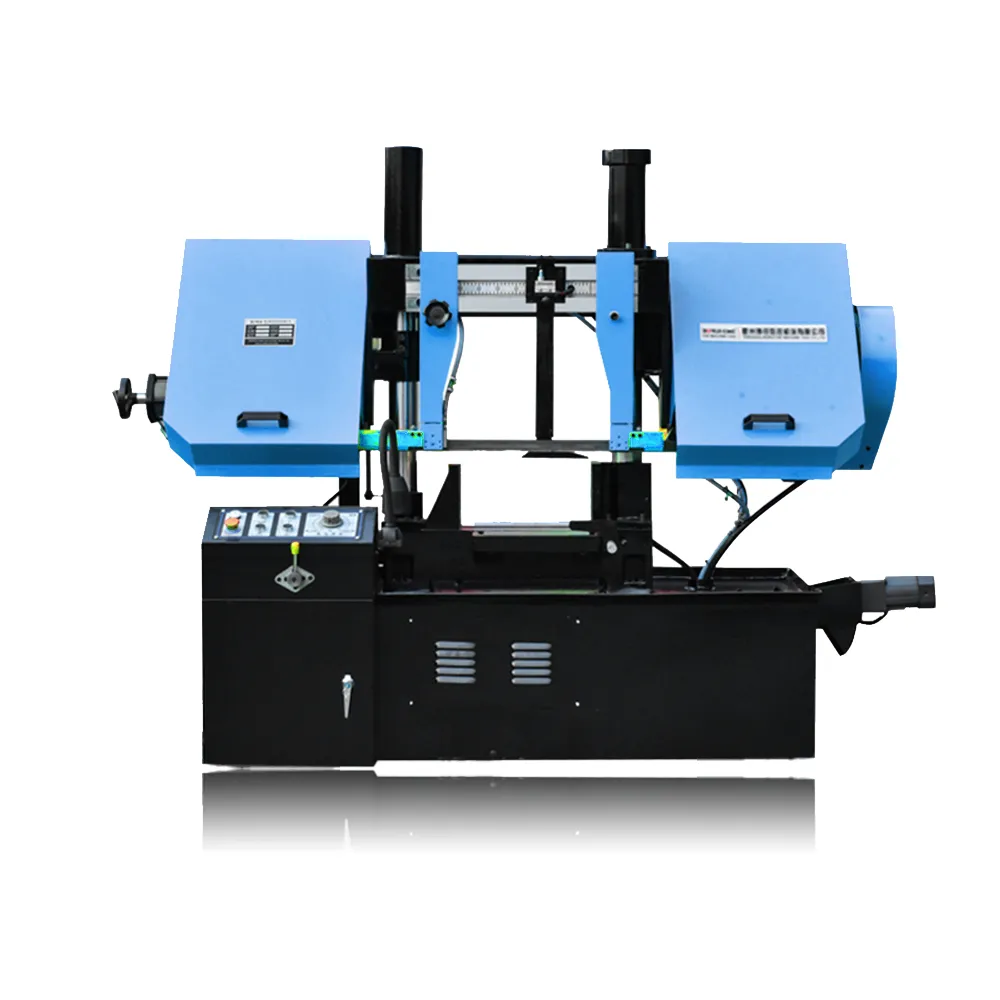

Band saw machines function as power tools that use a continuous toothed metal blade loop stretched between wheels to perform material cutting actions. There are different types of band saws. The blade operates only in one single direction. A uniform cutting motion occurs when tooth load distribution remains consistent.

These versatile cutting tools find applications throughout the woodworking, metalworking, and lumber industries. They demonstrate remarkable capability in processing straight and complex cuts. They work well on metal plates and cylindrical parts.

The wheels rotate in the same plane, with one powered by an electric motor. The machines typically include a table where materials are placed for cutting. The table can often tilt for angled cuts. Different types of adjustable blades can enhance the machine’s versatility.

Factors to Consider When Purchasing a Band Saw

Cutting Capacity

Check the throat depth and cutting height of the bandsaw. These tell you the maximum size of material the saw can handle. You can choose according to the material and complexity you may be working with. Make sure the machine can slice your largest workpieces.

The saw’s selection for metalwork applications must match the thickness of your typical metal projects. Select a saw that exceeds your current requirements by capacity because it will accommodate your expanding needs.

Before making a purchase, you need to verify that the manufacturer is compatible with the unique characteristics of your intended product.

Motor Power

Look at the motor’s horsepower. It affects the material and thickness of the workpiece.

Higher-power motors can cut through thicker and harder materials without stalling. Check that the power supply requirements match your workshop’s electrical setup.

Motor power affects how well the saw performs on tough cuts. More power is needed to cut hardened metals and larger stock. When choosing, consider a wide range of materials you will be working with.

Blade Size and Type

Wider blades make straighter cuts and last longer. The blade width your machine can handle shows the saw’s strength and cutting ability.

Various materials correspond to specific cutting blade requirements. Bi-metal blades excel with diverse metal types, yet carbide-tipped blades function best with tough metals. Tooth design and pitch also matter in different cutting jobs.

Select a machine that supports variations in blade size and tooth configuration.

Construction and Stability

A strong frame reduces vibration during cutting. Your search should focus on machines constructed from premium materials, including cast iron and steel. Solid construction methods extend the saw’s durability and accurate cutting performance.

Check for stable bases and durable components that can withstand regular use. Good vibration damping improves cut quality and operator comfort.

Ease of Blade Changes

Choose a saw with a simple blade-change system. This will save time and reduce downtime in your work. User-friendly features make the saw more efficient to operate. Easy access for maintenance tasks helps keep the saw running well. Quick-release systems are worth looking for in better models. You can also choose a tool-less feature for efficiency.

Safety Features

Good band saws include blade guards and emergency stop buttons. These protect the operator and prevent accidents. Look for clear visibility of the cutting area. Safety keys on power switches prevent unauthorized use. Some models have automatic shut-off features for added protection.

Dust Collection System

A good dust port helps keep your work area clean. Many band saws come with built-in dust extraction systems. Others have ports where you can attach your workshop vacuum. Effective dust collection improves the visibility of your work and reduces airborne particles.

Price Range and Value for Money

The price of the band saw machine must be balanced against its features and quality. Buying cheap machinery doesn’t mean it will last long. The warranty conditions of the machine should be examined. Assess the manufacturer and brand’s reputation and check their support services. Think about how often you’ll use the saw and choose accordingly. A good band saw should last for years of regular use.

Top 10 Band Saw Manufacturers

1. BORUI CNC Machine Tool Co., Ltd.

BORUI was founded in 2015 as a high-tech enterprise that develops, manufactures, and sells CNC machines, including band saws. BORUI operates from the Economic Development Zone within Tengzhou City in China. The product lineup includes band saw machines, which complement their CNC machining centers and milling machines. The band saw machines from BORUI provide exact sawing capabilities. The dependable structure guarantees their machines operate without vibrations while maintaining stability throughout operations. The company’s dedication to product quality has earned it a position as a reliable tool manufacturer. BORUI provides a diverse product selection that lets you depend on them for multiple requirements.

2. DoALL

DoALL is a leading producer of industrial metal band saws with over 90 years of experience. They have various band saw models for different uses. These include vertical contour saws, high-speed contour saws, and dual-column models. DoALL is the only manufacturer worldwide that produces sawing machines, fluids, and blades under one brand. Their machines are known for their versatility, performance, safety, and precision.

3. Marvel

Marvel established itself as a metal-cutting saws market leader since its inception in 1904 and continues under the name Amada Marvel Inc. The company produces exceptional band saws, which improve productivity by delivering precise and durable solutions. Their product line includes vertical tilt-frame band saws together with bundle-cutting saws and horizontal mitering saws. The company provides engineered solutions that address unique cutting demands.

- MEP Group

The product line of MEP includes multiple band saw models that cover different cutting dimensions. The Italian manufacturer MEP established its market dominance in metal cutting band saws starting from its foundation in 1964 at Pergola. The company produces band saws, aluminum saws, and length-measuring systems. These machines implement hydraulic band tensioning systems in combination with electric pumps to support blade lubrication.MEP Group delivers metal-cutting products that demonstrate exceptional precision and dependable performance.

- Amada

The company Amada produces high-performance band saws through the implementation of advanced technologies. The HFA430CNC model from the company has a dynamic frame design that uses vibration-dampening rollers. The new innovations enable quicker and quieter cutting operations while extending blade operational periods. Efficient design characterizes Amada band saws because they incorporate features that minimize material waste and optimize chip removal.

6. Eisele

Eisele produces quality metal band saws at various price points. Their 2025 models include the TS360 semi-automatic and TA360 fully automatic band saws. These machines feature adjustable cutting speeds and angles, making them versatile for different cutting tasks. Eisele band saws are manufactured with precision components for reliable performance.

7. Ellis Mfg. Co., Inc.

Ellis specializes in miter band saws with models that can cut at 45° left or right. They offer several models of mitering band saws designed to fit various applications. Ellis offers eight different models of band saws that use blades ranging from 1/2″ to 1-1/4″ in width. Their most popular models are the 1600 and 1800 series. Though optional air systems are available, Ellis band saws are known for their dry-cutting ability.

8. Cosen Mechatronics Co., Ltd.

The company Cosen established itself in 1976 before developing into one of the world’s premier band saw manufacturers. The company offers three main bandsaw categories: vertical, horizontal, and miter-cutting band saws, as well as NC and CNC automatic models. Cosen’s North American headquarters is in Charlotte, NC. It has over 100 new machines in its warehouse, always ready to ship. Cosen’s saw machines operate with cutting ranges starting from 200mm and extending to 3200mm. Their machines can cut various materials from steel to titanium, chromium, and silicon.

9. Kaka Industrial

Kaka Industrial offers a variety of industrial metal band saws that fit different budget sizes. Their product line includes mini band saws, vertical band saws, and variable speed models. They also provide accessories like blades, spare parts, and toggle switches. Kaka’s band saws are engineered for accurate metal cutting and come in both horizontal and vertical configurations.

10. Behringer

Behringer produces high-performance metal-cutting band saws for the steel industry. Their extensive product range includes horizontal band saws, vertical band saws, and large band saws for cutting solid materials. The HBE Dynamic Series includes servo-feed systems. These systems have cutting pressure control for the best performance. Behringer also makes specialized 3D saws for additively manufactured components.

Conclusion

The bandsaw machine plays an essential role as an industrial tool across various sectors in 2025. Top bandsaw manufacturers like BORUI, DoALL, Cosen, Ellis, and others produce quality products. The different brands present distinctive attributes that fulfill specific cutting requirements. Buyers need to consider machine-cutting abilities and power sources, along with blade choices.

The advancement of technology enables these machines to develop additional smart capabilities while incorporating stronger structural elements. Select a manufacturer within your budget range and operational requirements. A suitable bandsaw provides enhanced performance and increased workability for various tasks.