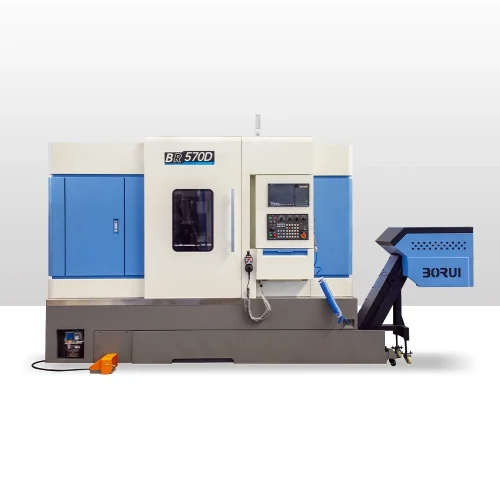

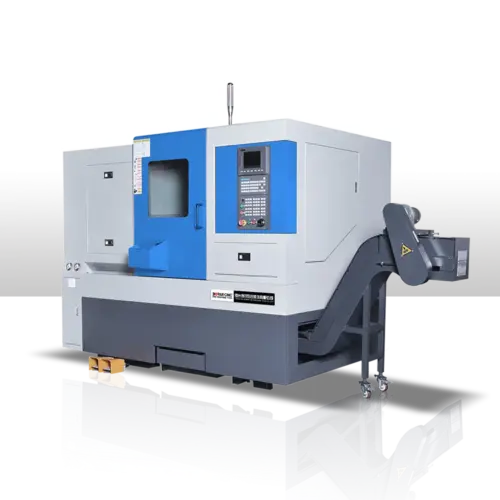

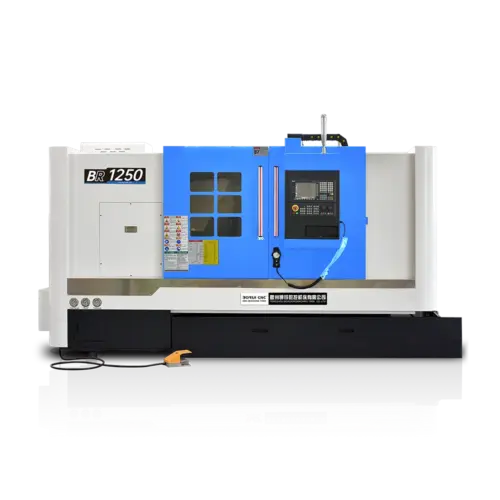

50ZWT Slant Bed CNC Lathe Highlights

- The CNC lathe with the inclined bed makes it easier to remove chips than the CNC lathe with a flatbed.

- The bed is cast as a whole, with good rigidity, stability, chip removal, high speed, and accuracy guarantee.

- The CNC lathe’s inclined bed has a linear rolling guide. It meets the needs for high speed and efficiency. It reduces friction and heat, improving machining accuracy. It ensures stable cutting accuracy over time.

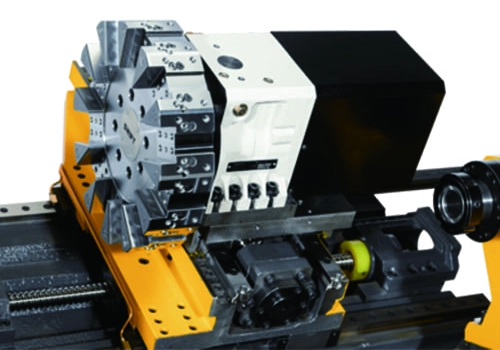

- The CNC lathe with an inclined bed uses a high-rigidity turret tool rest, either domestic or imported. It has high accuracy and low deformation during heavy cutting.

- The inclined-bed CNC lathe has an all-inclined-bed design. It can still maintain stability and accuracy during heavy cutting.

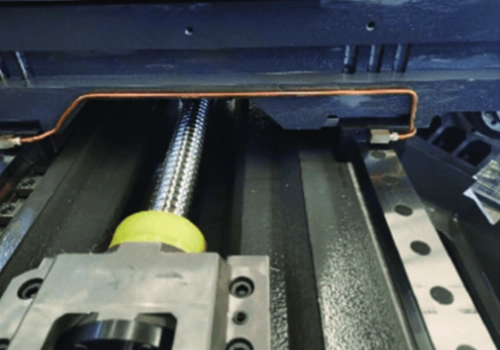

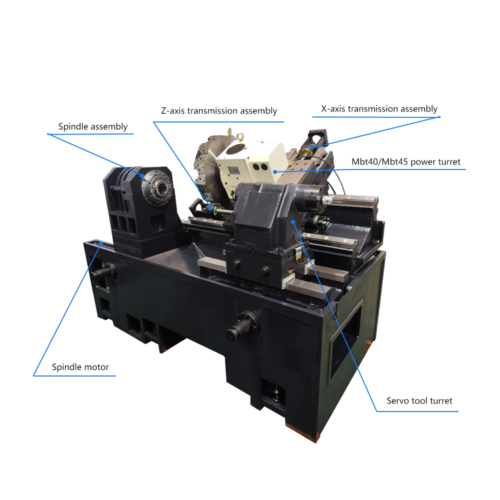

- The X and Z axis servo motors are connected to the precision ball screw via elastic coupling. This high-precision setup has fixed ends on the screw. It improves the support seat’s rigidity. This enables frequent high-speed positioning, but it causes wire issues from heavy cutting. Bar distortion is minimized.

- High-precision, high-rigidity programmable tailstock.

- In the design of a CNC lathe with an inclined bed, the spindle box uses measures to reduce thermal deformation. This maintains the stability of the spindle axis during long runs.

Main Technical Parameters Of 50ZWT

| 50ZWT | A2-5 | A2-6 | A2-8 | |

|---|---|---|---|---|

| Machine tool structure | Bed frame | Overall 30° inclined bed | ||

| Saddle | Motor bearing seat integrated saddle | |||

| Headstock | Lay flat | |||

| Tailstock | Square rail plus V rail | |||

| Drainage | Rear or side row | |||

| Water tank | Rear-mounted independent water tank or side-mounted independent water tank |

|||

| Chip conveyor | Rear chip removal tank integrated or side chip removal tank split | |||

| Spindle motor installation | Horizontal or vertical | |||

| Feed axis motor installation dimensions | 130mm flange 110mm spigot | |||

| Protection method | Stainless steel full protection | |||

| Travel parameters | X-axis travel | 260mm-280mm | ||

| Z-axis travel | 510mm | |||

| Working desk size | 350mm×267mm | |||

| Countertop center height | 110mm | |||

| The maximum rotation of the machine | 500mm | |||

| Disc processing diameter | 300mm | 350mm | 350mm | |

| Shaft processing diameter × length | 150mm×500mm | 200mm×500mm | 250mm×400mm | |

| Spindle parameters | Spindle model | A2-5 | A2-6 | A2-8 |

| Spindle outer diameter | 170mm | 200mm | 230mm | |

| Spindle speed | 5000rpm | 4500rpm | 3500rpm | |

| Spindle through hole | 56mm | 66mm | 86mm | |

| Equipped with fixture | A2-5/6寸 | A2-6/8 寸 Inch | A2-8/10 寸 Inch | |

| Tail top parameter | Tailstock structure | Precision sleeve | ||

| Tailstock movement | Slide | |||

| Tip model | Morse 4 | Morse4/5 | Morse 5 | |

| Sleeve outer diameter | 75mm | 95mm | 95mm | |

| Tip job pressure | 5-20KG | |||

| Tip itinerary | 100mm | |||

| Tailstock travel | 420mm | |||

| Chuck tip distance | 600mm | |||

| Precision configuration | X-axis repeat positioning | ±0.003mm | ||

| Z axis repeat positioning | ±0.005mm | |||

| X-axis guide model | 30 rollers | |||

| Z-axis guide model | 35 rollers | |||

| X-axis screw model | 3208/3210 | |||

| Z-axis screw model | 3210/3208/4010 | |||

| Screw bearing | 2562 | |||

| Outline weight | Optical machine size | 2200mm×1100mm×1250mm | ||

| Cover size | 2650mm×1500mm×1700mm | |||

| Optical weight | 3000KG | 3050KG | 3100KG | |

| Total Weight | 3200KG | 3250KG | 3350KG | |

50ZWT Slant Bed CNC Lathe Features

X-Axis Servo Motor Seat

Detail Processing

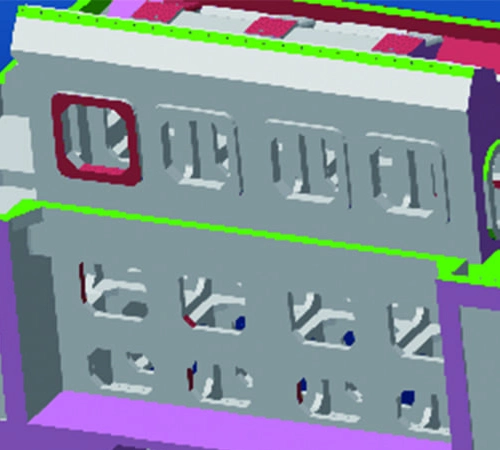

Scraping And Guinding Process

Reviews

There are no reviews yet.