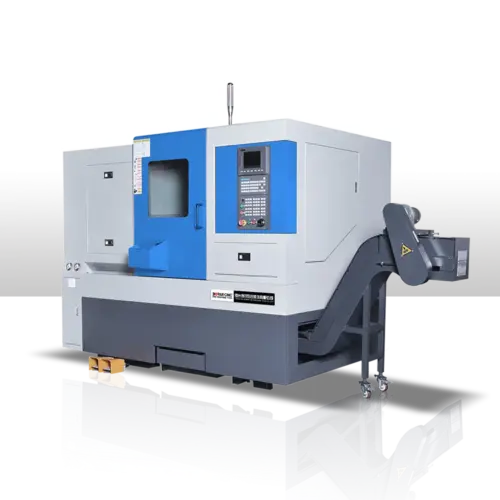

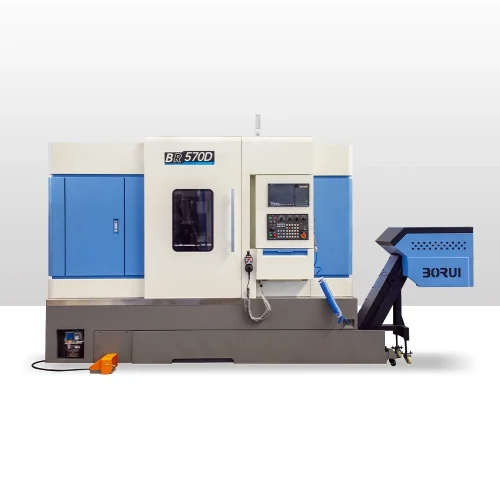

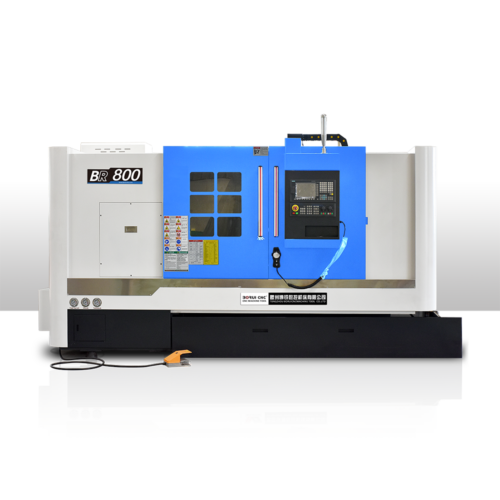

TCK630 BR-650 Slant Bed CNC Lathe Machine Advantages

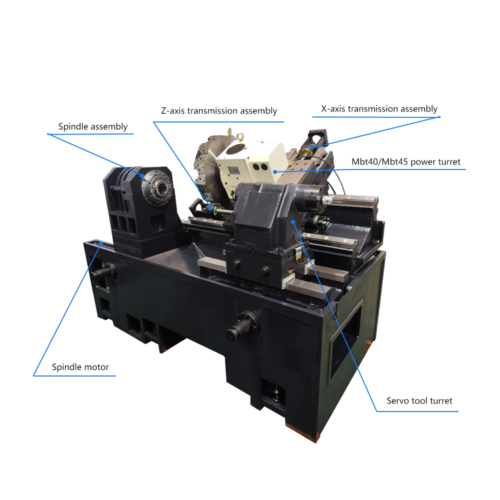

- Equipped with Taiwan hydraulic turret, using famous brand oil motor, good quietness, high torque and fast tool change.

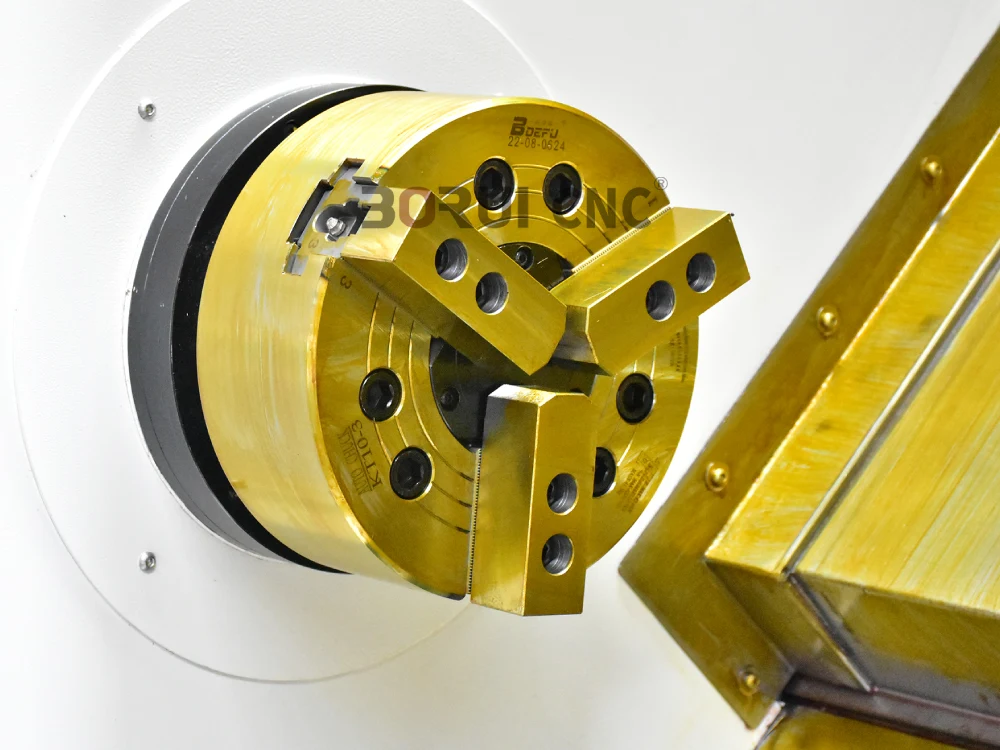

- Reinforced hydraulic chuck: High-rigidity cast iron casting with a diameter of 250MM, the workpiece is firmly clampedSolid, long service life.

- The Taiwan Shangyin/Yintai screw is the machine tool’s core part. It ensures good work quality.

- The machine tool is equipped with Siemens CNC system as standard, and Guangzhou CNC, Fanuc,Mitsubishi, new generation and other CNC systems.

- The tailstock moves as a whole on the guide rail through the saddle, using one hill and one level hard guide rail, Stable lateral line accuracy.

- The overall bed is cast by resin sand process. After aging treatment, it has beautiful appearance, good rigidity and high precision.

- A 45° inclined bed and linear guides improve speed and accuracy.

- High-quality scrapers prevent guide rails from scratching. They use a plastic, wear-resistant, and precise surface.

Main Technical Parameters Of TCK630 BR-650

| ITEM | UNIT | BR-500 | BR570-600/1000/1500/2000/3000 | BR-650-750/1000/1500/2000/3000 |

|---|---|---|---|---|

| Maximum turning diameter of bed body | mm | 500 | Φ570 | Φ650 |

| Maximum turning diameter on a skateboard | mm | 240 | Φ320 | Φ500 |

| Maximum cutting length | mm | 450 | 500/750/1500/2000/3000 | 750/1000/1500/2000/3000 |

| Maximum cutting diameter - disc class | mm | Φ320 | Φ360 | Φ540 |

| Maximum cutting diameter - shaft class | mm | Φ260 | Φ250 | Φ400 |

| Spindle end type and code | A2-6 | A2-8 | A2-11 optional A2-8 | |

| Diameter of spindle through hole | mm | Φ62 | Φ86 | optionalΦ112 Φ86 |

| chuck | inch | 8 "hydraulic hollow chuck | 10 "hydraulic hollow chuck optional 8" | Hollow 15 inches optional 10 inches 12 inches |

| Spindle speed range | r/min | 3500 | 2000rpm,optional 3000rpm | 1200rmin |

| Main motor power | KW | 7.5kw | 11kw optional 15kw | 22KW |

| Fast moving speed on the X-axis | m/min | 20 | 20 | 16 |

| Z-axis fast moving velocity | m/min | 20 | 16 | 16 |

| Stroke of X axis | mm | 210 | 250 | 380 |

| Z axis stroke | mm | 450 | 600/860/1550/2050/3050 | 600/850/1350/1850/2850 |

| Form of guide rail | HIWIN/PMI line track in Taiwan | HIWIN/PMI line track in Taiwan | HIWIN/PMI line track in Taiwan | |

| Tool holder form | 8 station servo cutter tower | 8 station servo cutter tower (12 stations optional)) | 12 station servo cutter tower | |

| Tool size | mm | 25X25 Φ32 | 25X25 Φ40 | 32×32 Φ40 |

| Tail seat sleeve diameter/stroke | mm | φ75/L100 | φ110/L100 | φ150/L150 |

| Taper of tail seat sleeve | MT4 | MT4 | MT-5 | |

| Positioning accuracy X/Z | mm | 0.01/0.01 | 0.01/0.012 | 0.01/0.018 |

| Repeat positioning accuracy X/Z | mm | 0.006/0.006 | 0.006/0.008 | 0.008/0.010 |

| Precision of machining | level | IT6 | IT6 | IT6 |

| Roughness of surface | um | Ra≤0.8 | Ra≤1.6 | Ra≤1.6 |

| Overall dimensions of machine tool | mm | 2800x1800x1600 | 2900/3100/4300/5000/5600x2000x2000 | 3450/3700/4200/4700/5700×2200×2200 |

| Machine tool weight | kg | 3000 | 3600/4000/5000/6100/7500 | 5000/5800/6800/7800/9000 |

TCK630 BR-650 Slant Bed CNC Lathe Machine Features

Adopt High -speed Bearing Technology TCK630 BR-650

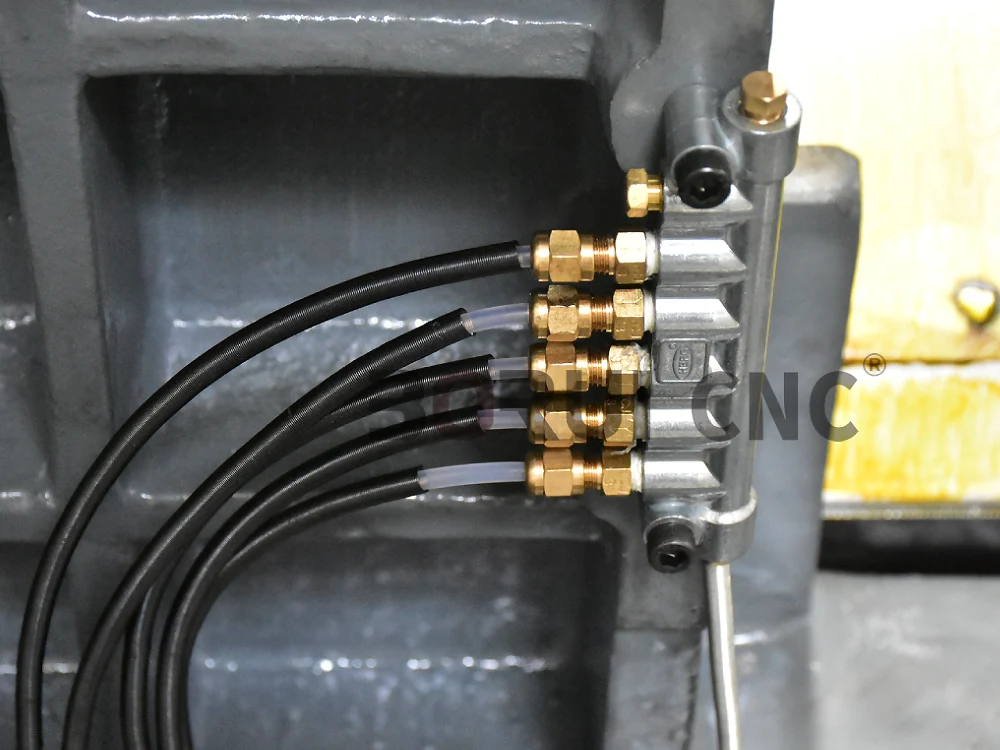

Large Aperture Oil Pipes TCK630 BR-650

Standard Three-jaw Chuck, Optional Four-jaw Chuck TCK630 BR-650

Reviews

There are no reviews yet.