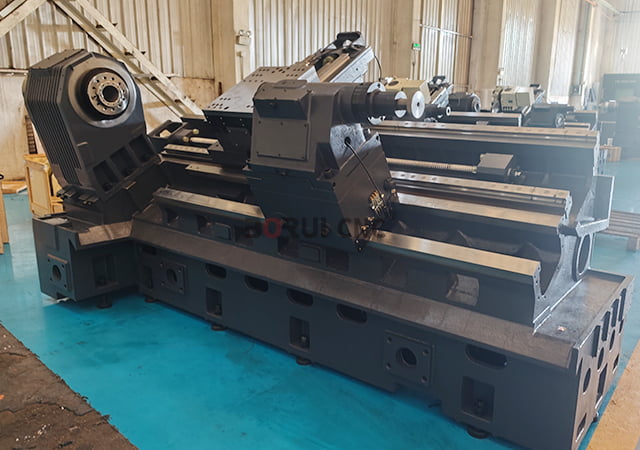

CNC lathe with inclined bed is a kind of automatic machine tool with high precision and high efficiency. Equipped with multi-station tower or power tower, the machine tool has a wide range of processing performance, inclined bed CNC lathe, as a modern mechanical equipment, has many unique structural characteristics. With its unique design…

Drilling Hole Drilling refers to a process of drilling through the use of drilling tools. In engineering and construction, drilling is a common operation used to open holes for the installation of pipes, wires, bolts, etc. Drilling can be done by rotation, percussion, or vibration, depending on the desired hole size and geological…

Machining center is an indispensable and important equipment in modern industrial production, and its accuracy has a crucial impact on the quality and performance of the product. Accuracy refers to the size, shape and position accuracy of the machining center in the processing process, which is directly related to the accuracy, stability and…

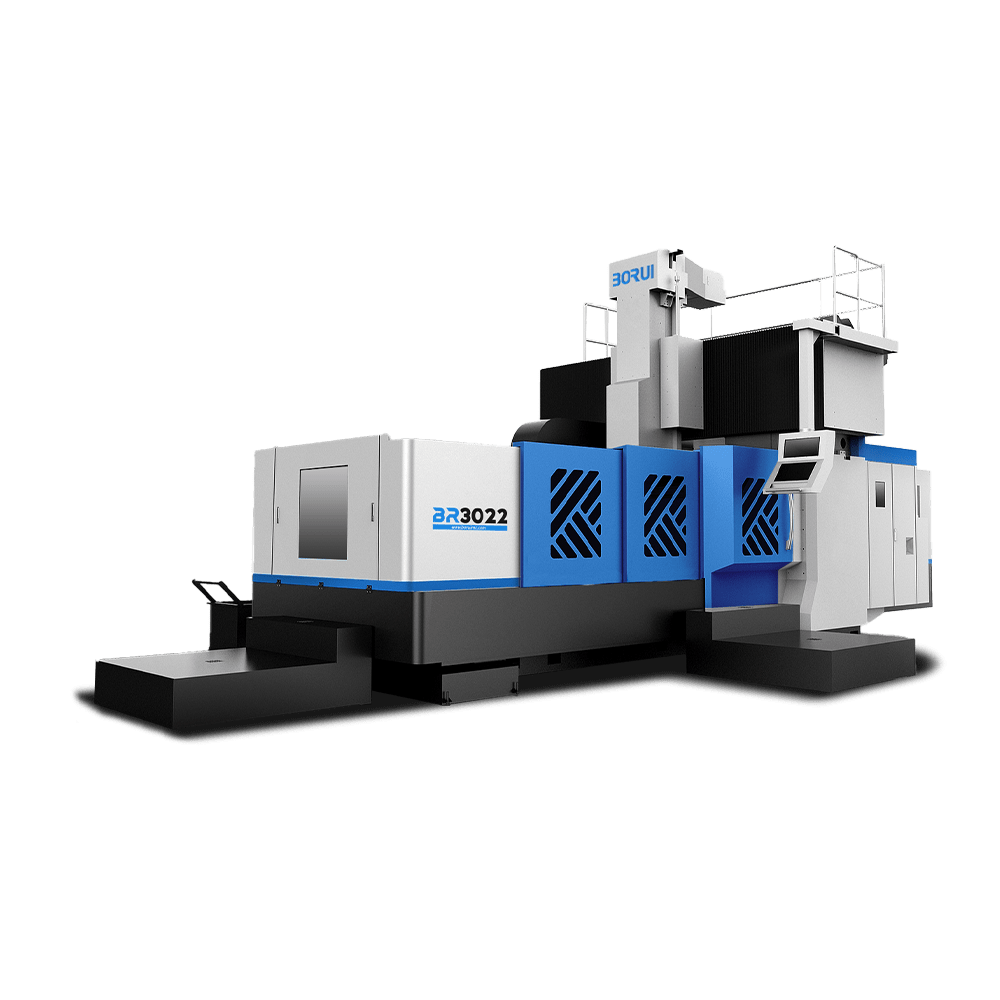

Gantry milling machine is a common metal processing equipment, its structural characteristics are unique and practical. Below I will introduce the structural characteristics of the gantry milling machine in detail. 1.It Is Structure Mainly Includes The Following Parts: Bed: The bed is the main part of the gantry milling machine, usually made of…

The significance of drilling drives the development of society. It plays an important role in the manufacturing industry, providing essential parts and processes for various industries. It is with the application of machine tool drilling technology that we can enjoy modern life and convenience. The process of drilling machine tools needs to go through a…

CNC lathe is a kind of machining equipment with high precision and high efficiency, which is widely used in many fields. Next, I will introduce the application fields of CNC lathes. First of all, CNC lathes play an important role in the aerospace field. The aerospace field has very high requirements for the accuracy, quality…

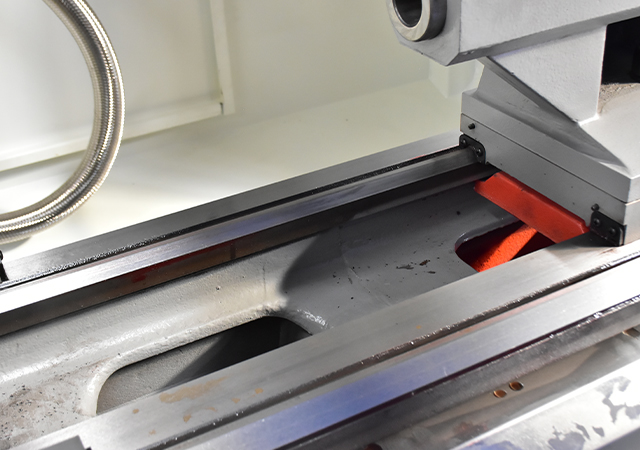

As the position detection element of the CNC machine tool linear axis, the grating ruler is equivalent to the human “eye”, which is to “monitor” the linear axis after the execution of the CNC system’s moving instructions, whether the linear axis really runs accurately to the position required by the CNC system instructions….

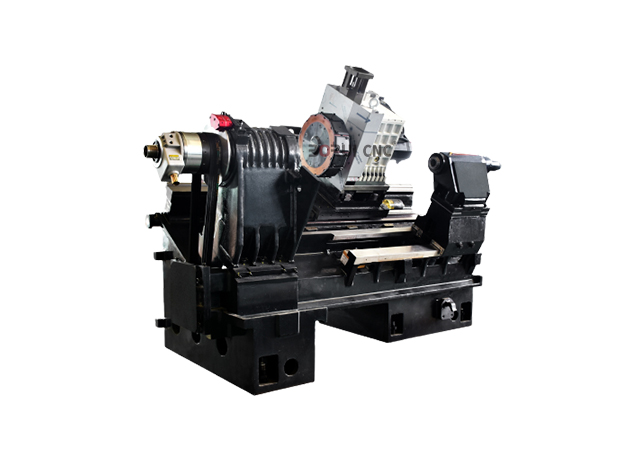

Large bore CNC lathe is a kind of high-precision and high-efficiency machine tool, which plays an important role in modern industrial production and provides strong support for the development of all walks of life. It has a wide range of applications in industrial production, and can meet the needs of all walks of life for…

The new guide system enables the machine to achieve fast feed speed, which is the characteristic of the linear guide at the same spindle speed. Linear guide and plane guide, there are two basic components; One is the stationary element that acts as the guide and the other is the moving element. In…

With the development of electronic technology, automatic information processing, data processing and the appearance of electronic computer, automation technology has brought a new concept, using digital signals to control the motion and machining process of CNC lathe inclined bed, promote the development of machine tool automation. CNC lathe as a kind of high…