Drilling center and turn-milling combined drilling are two kinds of drilling drilling tapping center used in machining. They have different characteristics and uses in practical applications.

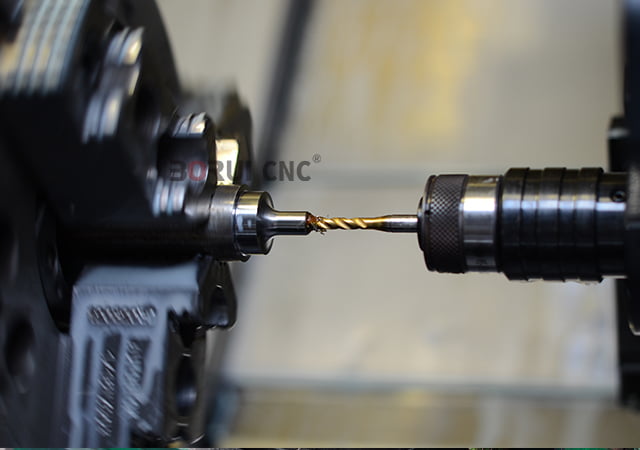

Turn-milling combined drilling refers to the drilling tapping center on the turn-milling combined machining center. The Turning and milling complex machining center is a multifunctional machine tool that can perform both turning and milling operations. When drilling, efficient and accurate drilling can be achieved through reasonable process arrangement and tool selection.

Drilling drilling tapping center refers to the drilling operation on the drilling center. The drilling and tapping center is a machine tool specially designed for drilling and tapping, featuring high speed, high precision and high efficiency.

During the drilling tapping center, the drilling center uses the drill bit to drill the hole. Through the rotation and feed movement of the drill, the surface of the material is cut to form a hole. The drilling process of the drilling center is simple and direct, which is suitable for the drilling needs of various materials.

First, the drilling and tapping center is a processing method that combines the functions of drilling and tapping. It uses special tools to drill and tap simultaneously by means of rotation and feed. This method has the characteristics of high efficiency and accuracy, and is suitable for the workpiece with high precision of hole position. The drilling and tapping center can complete drilling and tapping operations at one time, eliminating the trouble of multiple processes and improving processing efficiency.

Secondly, turn-milling combined drilling is a machining method that combines turning and milling operations with drilling. It uses a tool on a lathe or milling machine to perform turning and milling operations respectively, and then drilling. This method is suitable for the workpiece that the accuracy of the hole position is not too high, but the aperture and hole depth are required. The combination of turning and milling drilling can realize the control of aperture and hole depth while ensuring the accuracy of hole position, and improve the machining quality of the workpiece.

In general, the drilling center and turn-milling combined drilling are commonly used in the machining process of drilling methods, they each have different characteristics and scope of application. The drilling and tapping center is suitable for the workpiece that requires high precision of the hole position, and can complete the drilling and tapping operation at one time; The turn-milling combined drilling is suitable for the workpieces that require not too much precision of hole position, but have the requirements of aperture and hole depth. In practical application, according to the specific processing requirements and workpiece characteristics, choose the appropriate drilling method, can improve the processing efficiency and workpiece quality.