What Is A CNC Machine ?

CNC machine tool is a kind of high-precision and high-efficiency automatic mechanical equipment, which realizes the workpiece processing through the computer control system. Compared with traditional machine tools, CNC machine tools have higher accuracy, faster processing speed and greater production capacity.

The emergence of CNC machine tools has not only greatly improved the processing quality and efficiency, but also brought revolutionary changes to industrial production. Its development has made industrial manufacturing enter a new era, providing strong support for the development of all walks of life.

The core of CNC machine tool is computer control system. According to pre-programmed instructions, it can automatically control the parameters of the machine tool’s motion trajectory, working speed and machining depth. By cooperating with sensors, actuators and other equipment, the workpiece can be machined with high precision.

The advantages of CNC machine tools are not only high precision and high efficiency, but also their flexibility and versatility. On the same machine tool, a variety of different shapes and sizes of the workpiece can be processed, greatly improving the flexibility and adaptability of production.

The application range of CNC machine tools is very wide. From aerospace, automotive manufacturing to electronic equipment, medical devices, almost all industrial fields are inseparable from the support of CNC machine tools. It can not only process metal materials, but also process non-metallic materials such as plastics and ceramics, and has a wide range of adaptability.

In general, the emergence and development of CNC machine tools has brought revolutionary changes to industrial manufacturing. It not only improves the processing quality and efficiency, but also promotes the intelligent and automated development of the industry. In the future development, CNC machine tools will continue to play an important role in injecting new vitality into industrial manufacturing.

What Machine Does CNC Machine?

CNC machine tools include many different types of machines, each with a specific function and scope of application. Here are some common types of CNC machine tools:

- CNC Milling Machine : Used for milling the workpiece, which can be plane processing, surface processing and hole processing.

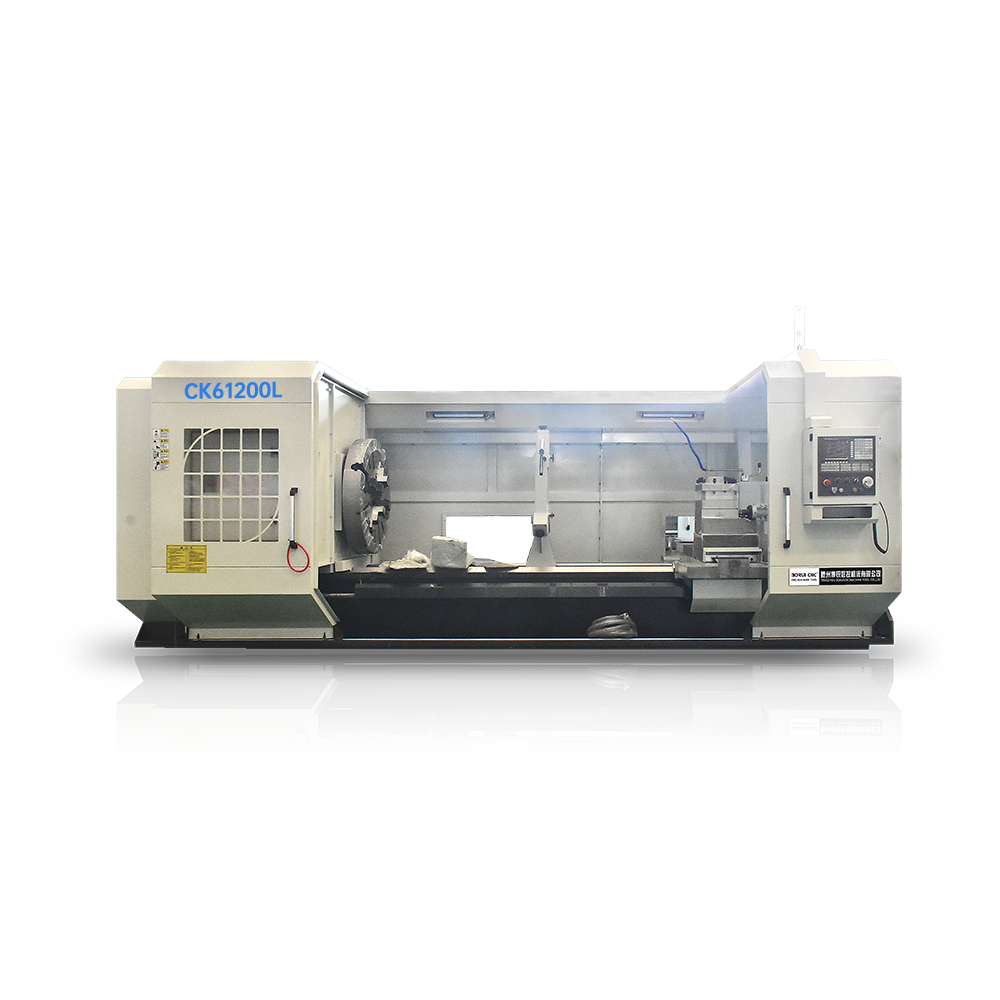

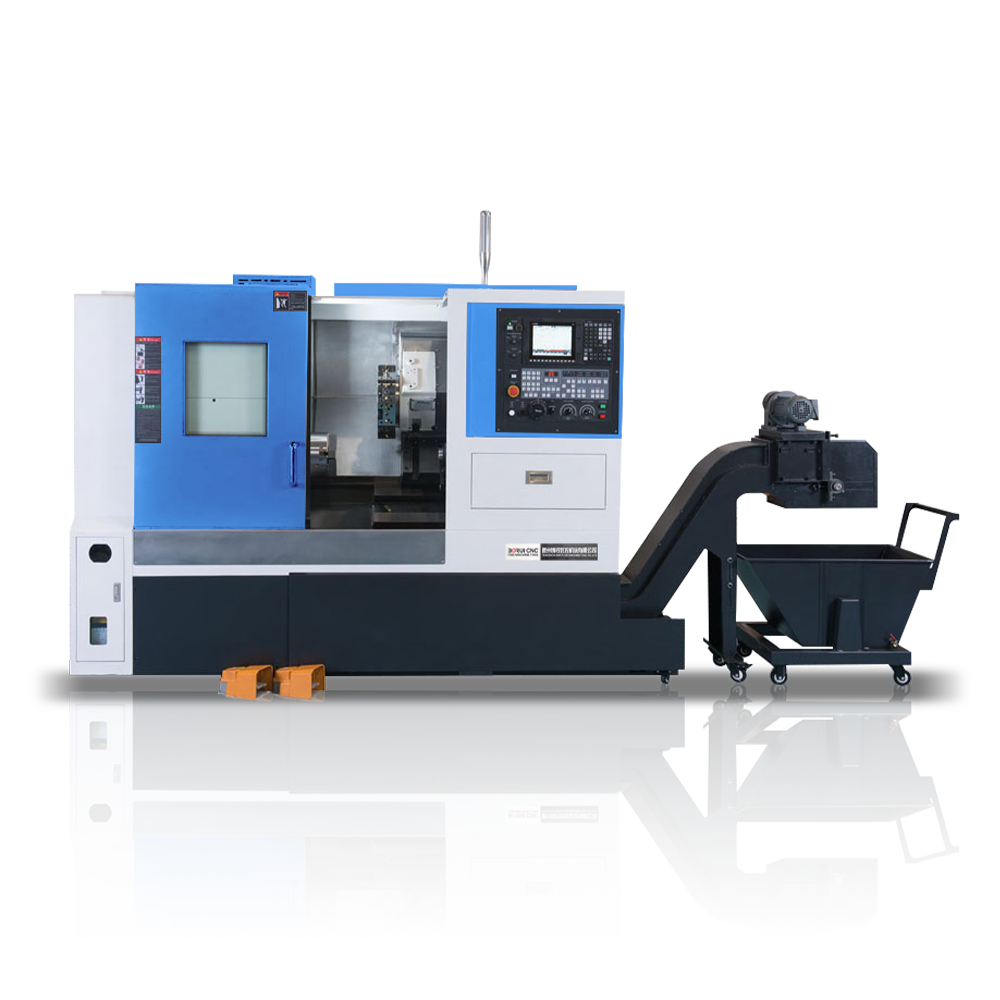

- CNC Lathe: Used for rotating machining of the workpiece, which can carry out cylindrical machining, internal machining and thread machining.

- CNC Drilling Machine: It is used for drilling the workpiece, which can carry out single-hole drilling and multi-hole drilling.

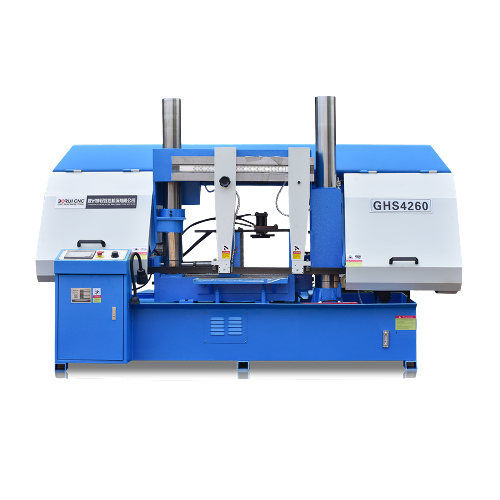

- CNC Cutting Machine : Used for cutting the workpiece, can be laser cutting, plasma cutting and water knife cutting.

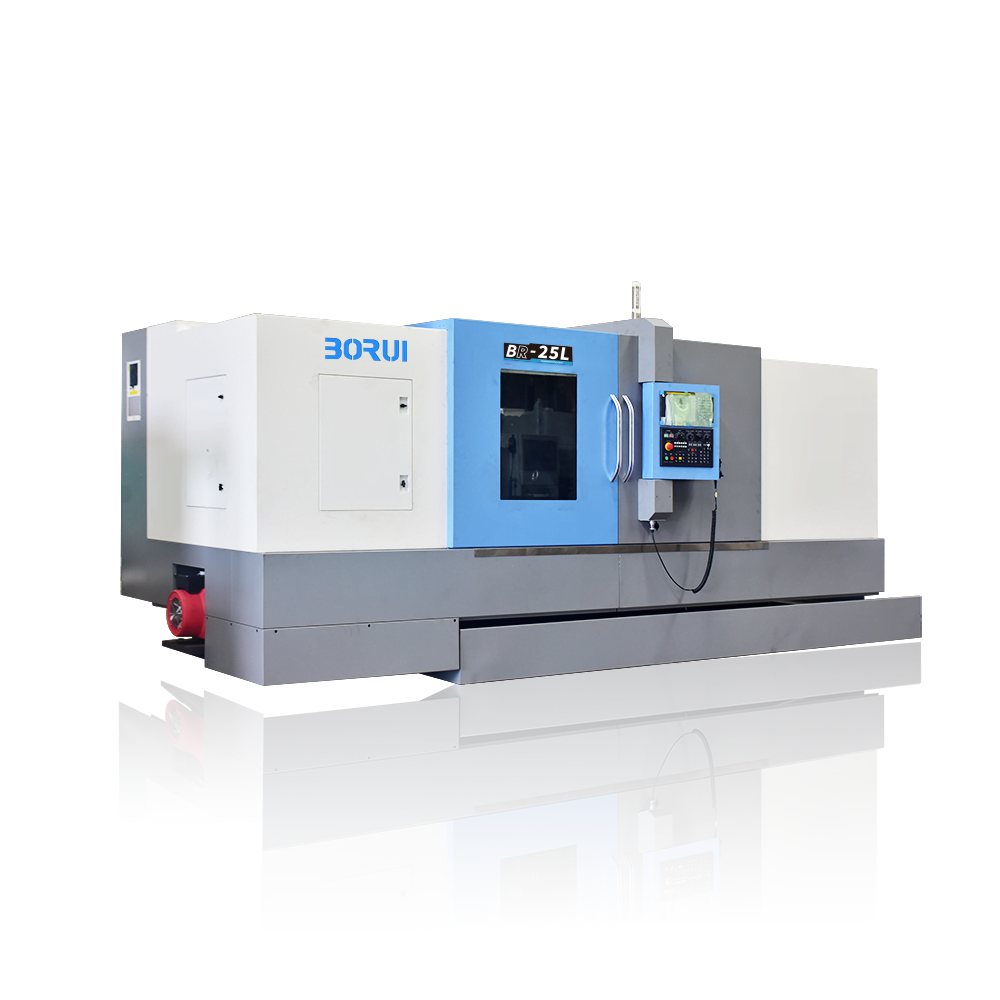

- CNC Turning and Milling Center : A machine tool that integrates the functions of a lathe and a milling machine, and can simultaneously perform turning and milling processing.

These CNC machine tools play an important role in industrial production, their emergence and development, greatly improve the processing quality and efficiency, promote the progress of industrial manufacturing. With the continuous development of technology, the types and functions of CNC machine tools will continue to enrich and improve.

https://www.youtube.com/watch?v=0vyYBTXLN-g

Request Quotation