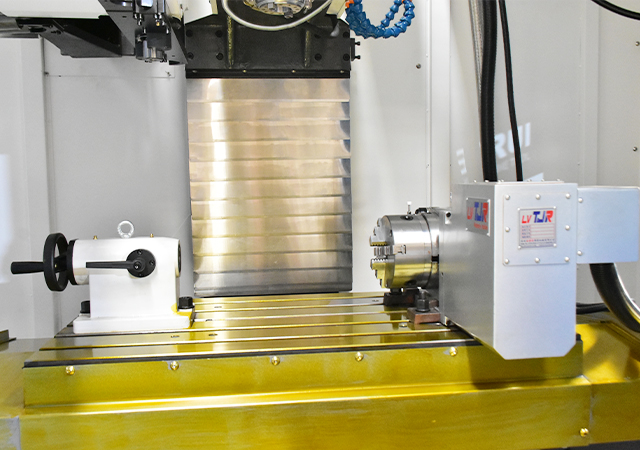

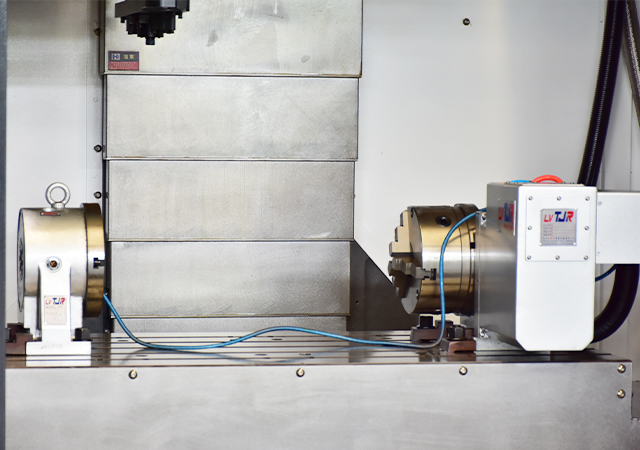

The four-axis machining center is a high-precision, high-efficiency processing equipment that can move and position in three directions (X, Y, Z axes), and can also rotate at the same time, that is, the fourth axis.

The four-axis machining center is widely used and can be used to process various metal and non-metal materials, such as aluminum alloy, titanium alloy, stainless steel, copper, iron, plastic, etc. It is widely used in aviation, automobile, electronics, machinery, medical and other industries.

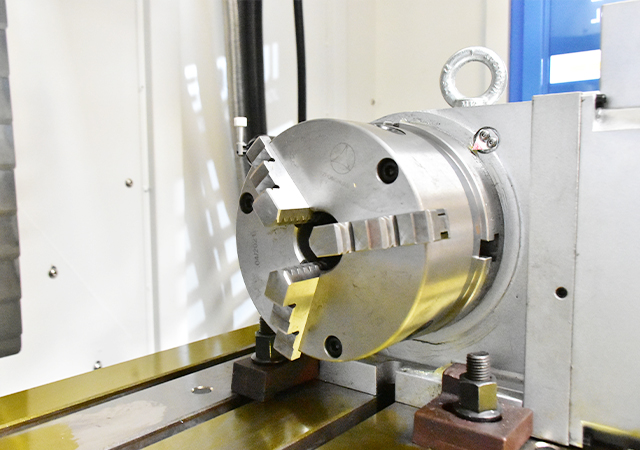

During the machining process, the four-axis rotation axis of the machining center can control the angle of the tool so that it can cut at different angles. This processing method can greatly improve processing efficiency and processing accuracy, and can also reduce repeated operations in the processing process.

In general, the four-axis machining center has the advantages of high efficiency, high precision, and multi-function, and is an indispensable and important equipment in modern manufacturing.

The four-axis machining center is usually used for multi-face machining and complex contour machining on the machining center. The four-axis can make the workpiece rotate along the X, Y, Z axes and one rotation axis during the machining process, so as to realize the multi-face machining of the workpiece and the machining of complex contours. The four-axis machining center can program the four-axis through the control system to make it rotate according to the predetermined path and angle, so as to realize the processing of various shapes. Four-axis machining centers are widely used in aerospace, automotive, medical equipment and other fields, which can greatly improve production efficiency and processing accuracy.

Machining Center 4 Axis Advantages:

- Higher processing efficiency: The four-axis machining center can complete the processing of multiple surfaces without changing the position of the workpiece, thereby reducing the number of times the table moves and improving the processing efficiency.

- Higher machining accuracy: The four-axis machining center can realize machining at different angles by rotating the workpiece, so that the workpiece can be processed more finely and the machining accuracy can be improved.

- Wider scope of application: The four-axis machining center can be applied to the processing of workpieces with complex shapes, such as cylinders, spheres, etc., thereby expanding its application scope.

- More flexible processing methods: the four-axis machining center can realize a variety of processing methods, such as three-dimensional engraving, curved surface processing, etc., and can adapt to different processing needs.