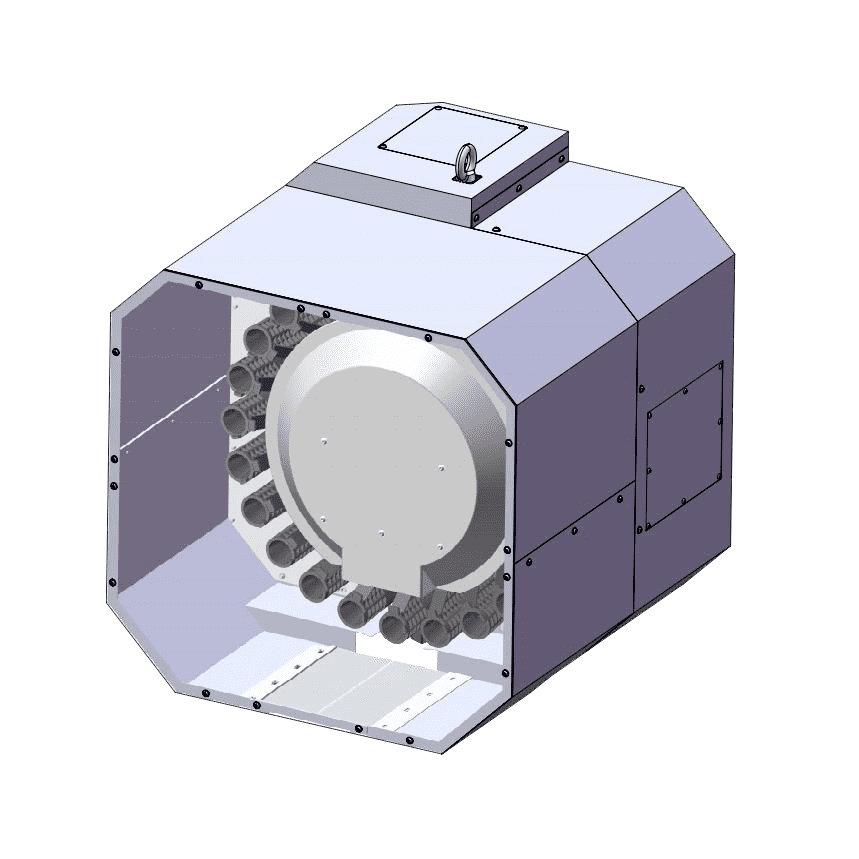

The ATC is a very important part of the vertical machining center. At present, the ATCs on the market include hat type, disc type, etc., and this time I want to introduce the fully enclosed self-developed from China SHENZHEN DEJIE MACHINERY CO.,LTD. This type of ATC is also widely used in the vertical machining centers produced by our company.

Feature 1: Simple structure

Compared with most ATC, this ATC has a simpler structure, is easy to install and maintain, and greatly shortens the disassembly time.

Feature 2: Wide range of applications

There are two options of mechanical brakes and electronic brakes.

There are full-cover protection and half-passport protection of the disc ATC, and the two types are freely selected according to the processing environment.

Mechanical brake product features

- Fully enclosed sheet metal shield, effectively preventing foreign objects such as iron filings from entering.

- Adopt carburizing grinding cam and dividing mechanism, with high precision and low failure rate.

- The operation of the cutter head adopts a cylindrical roller design, which can rotate smoothly and accurately locate.

- The tool cover is made of composite engineering plastics, with high strength, suitable temperature -20~120C, light weight, anti-aging, corrosion resistance, beautiful appearance, good interchangeability, and the damage rate of the tool cover is close to 0% under normal use conditions.

- The slideway of the knife sleeve adopts hollow design, which effectively reduces the contact between the knife handle and the knife sleeve, and the positioning is more accurate.

- The knife arm is made of one-piece casting, with good rigidity. It adopts chrome-plated knife claw rod and fully sealed protective structure, and has a long service life.

- The cylinder adopts the self-locking buffer function to reduce the impact of the knife sleeve.

- The reverse knife structure adopts the front reverse knife design, which effectively shortens the disassembly and maintenance time, and the speed is high.

- The overall structure of the ATC has good rigidity, which can bear rapid tool change and large tool impact.

- Reverse knife cylinder, solenoid valve, bearing, adopt Japanese brand. The wires and terminals are of German brand.

Electronic brake product characteristics (with the above characteristics at the same time)

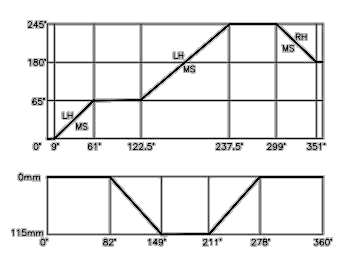

- The positioning of the ATC motor and ATC motor is controlled by the electronic brake of the inverter. There is no brake failure problem, the positioning is accurate, the stability of the ATC is increased, and the problem of sales and service is reduced.

- The ATC motor is controlled by the frequency converter at multiple speeds, and has the characteristics of buffering the knife, buffering the knife, and protecting the spindle from impact.

- The ATC module card switches the control mode to realize the 1-to-2 function.

ATC performance parameters of vertical machining center:

| Tool Specifications | #40BT | ACT form | DEX-65° |

| Tool capacity | 24T | Arm length | 530 |

| Maximum diameter full knife | 80 | Arm type | 40#BT,DIN,CAT |

| Maximum diameter adjacent empty knife | 150 | Tool change angle | 65°,75°,80° |

| Maximum tool weight/length | 7kg/300mm | offset angle | 0 |

| ATC speed | 0.6 | Pocket Specifications | 40#BT,DIN,CAT |

| Tool change time | 1.2sec/60hz | working pressure | 0.5~0.7MPa |

| Knife selection transmission type | Roller Cam Segmentation | Operating Voltage | 220V&380V/50&60Hz |

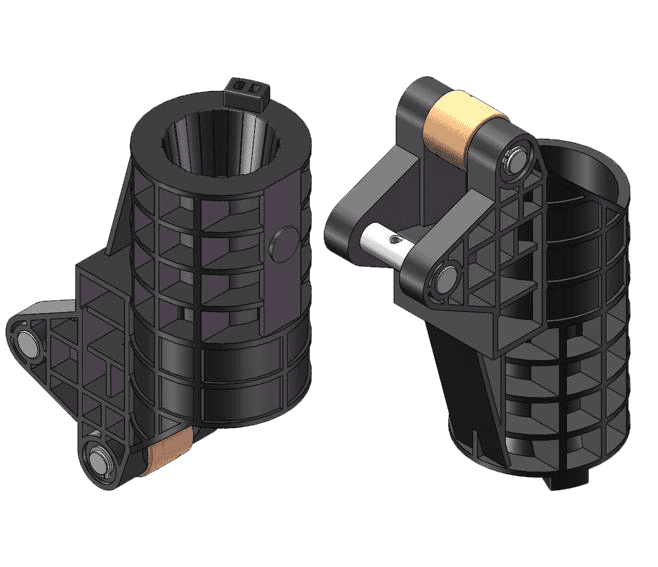

Pocket Specifications and Features

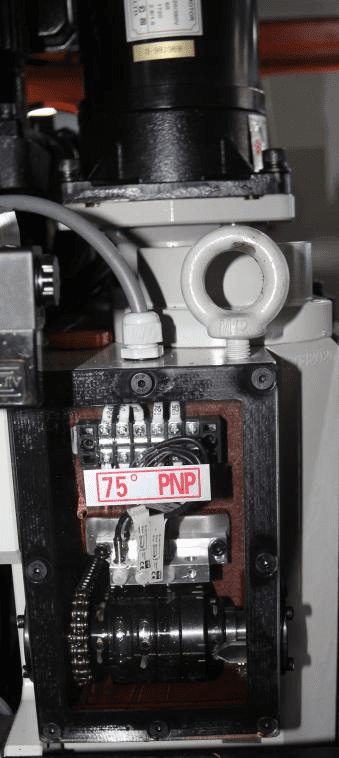

- Knife sleeve specification: 40# BT 65º/ 75º.

- The tool cover is made of composite engineering plastics, with high strength, suitable temperature -20~120C, light weight, anti-aging, corrosion resistance, and the damage rate of the tool cover is close to 0% under normal use conditions.

- Modular parts make assembly and maintenance operations more convenient and quality guaranteed.

- The tool pocket slideway is designed to avoid air, which effectively reduces the contact between the tool holder and the tool pocket, and the positioning is more accurate.

- Cylindrical design is adopted for the connection of the reverse knife, which reduces the contact surface and the non-fixed surface and effectively reduces the wear.

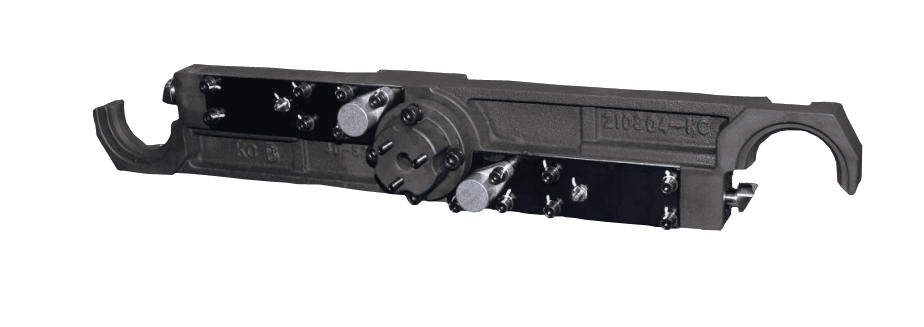

Arm Specifications and Characteristics

- Arm specification: 40# BT 530mm.

- The knife arm is integrally cast with QT550 high-strength wear-resistant material.

- Use 4 sets of high-strength expansion sleeves to lock the ATC spindle with high concentricity, which can effectively prevent the tool arm from loosening.

- The fully enclosed structure design can effectively prevent foreign matter such as iron filings from entering the inside of the knife arm.

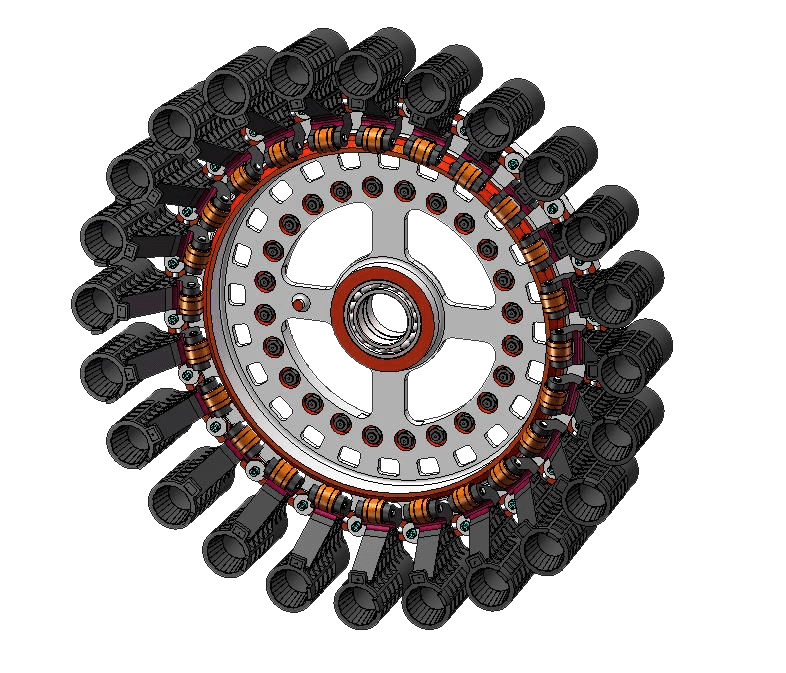

Cutter Specifications and Features

- Cutter specification: 24 knives

- The cutter head is integrally formed with HT250 casting material, and CNC machining effectively ensures the machining accuracy.

- The operation of the cutter head adopts cam drive, cylindrical roller design, smooth operation, low noise and accurate positioning.

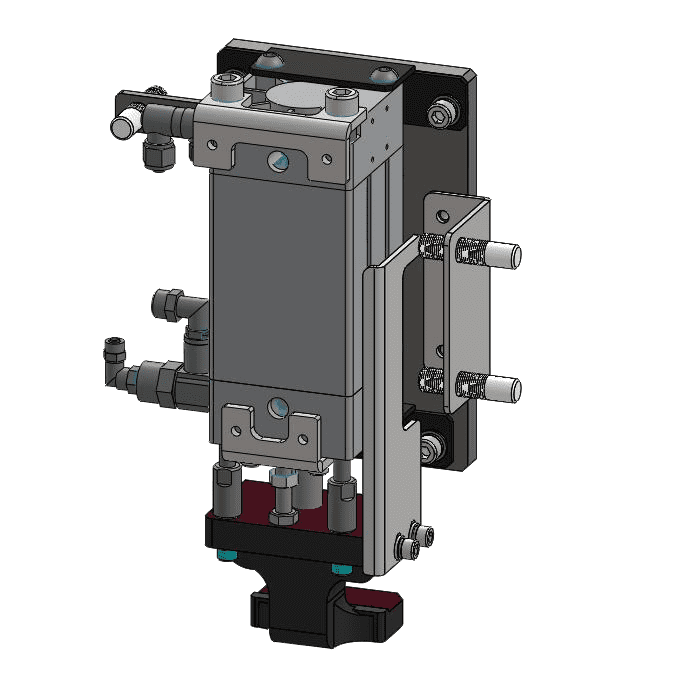

Reverse knife mechanism characteristics

- The reverse knife mechanism adopts the front reverse knife, which is easy to disassemble and assemble, greatly shortens the maintenance time, and has a high speed.

- The cylinders are imported brands, and the cylinder has its own buffer function, which reduces the impact of the tool sleeve and the tool handle when running to the reverse tool and the tool return position, and improves the ATC’s reverse tool performance.

- The reverse knife mechanism adopts a mechanical self-locking design, which can effectively prevent the problem of mechanical failure caused by the incorrect position of the reverse knife mechanism due to insufficient air pressure or gas compression in the cylinder after a long-term shutdown. Make sure that the reverse knife mechanism is in the correct position.

Tool selection control

- Knife selection

Adopt Taiwan brand motor, motor protection grade IP65.

- Detection switch

ATC standard configuration: counting, tool selection, origin, 3 proximity switches. The switch uses the Omron brand.

Tool changer as standard

Tool change control can choose two modes:

- Ordinary brake motor plus proximity switch position control type (optional).

- Variable frequency brake motor plus encoder control type (with software copyright).

3.The ATC motor is controlled by the electronic brake of the inverter, and the ATC motor is also controlled by the inverter.

4.The ATC motor is controlled by the frequency converter at multiple speeds. It has the characteristics of buffering the knife, the large knife diameter of the buffering knife, and the early release of the knife, which greatly improves the speed of the tool change and the stability of the tool change.

If you also want to have this kind of tool magazine, please feel free to contact BORUI CNC, we have the most professional engineers!