Product Description

Main Component:Controller

System:GSK/KND/SIEMENS /FANUC /MITSUBISHI

Tool change:OKADA (Taiwan)/DETA /HDW

Spindle UNIT :TaiWan Posa/ Taiwan VOLIS / Roral

X/Y/Z BALL SCREW:Hiwin/PMI

Pneumatic element:Air TAC (Taiwan)

Unclamping cylinder:Hao cheng (Taiwan)

Auto oil lubricator:Hu run (Taiwan)/Japanese HERG

Screw Bearing:TPI (Taiwan brand)/NSK/SKF

Three axis motor:Unit with the cnc controller

Cooling the pump:PMY-25-5

Lubrication system:Single wire damping

Optional accessories:

1.Dividing Head

2.Automatic chip conveyor

3.Clamping kits

4.Flat vice

5.Spindle speed above 12000rpm (Spindle directly contact)

6.Centering 65mm +seperate needle

7.Z axis Indictor

8.The spindle out the water itself +oil-water separator

9.Spindle 10000rpm

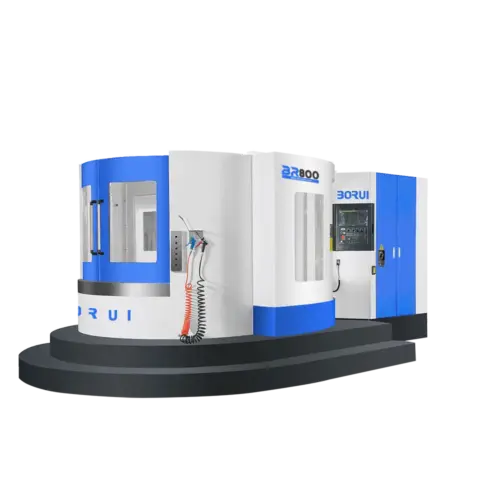

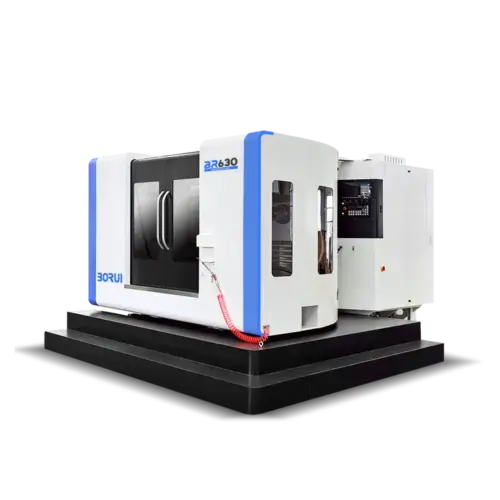

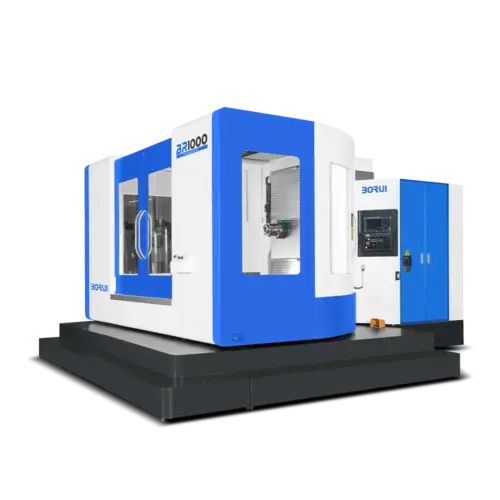

Technical Specs

| Specifications | Units | HMC630 |

|---|---|---|

| X-axis travel | mm | 1050 |

| Y-axis travel | mm | 900 |

| Z-axis travel | mm | 900 |

| Table number | 2 | |

| Table indexing | ° | 1°x360 |

| Spindle nose to table center | mm | 130-1030 |

| Spindle center to table surface | mm | 120-870 |

| Spindle speed | rpm | 20000 |

| Spindle taper | BT50-φ190 | |

| Spindle power(continous/30 min) | kw | 25 |

| Table size | 630×630mm | |

| Max. load of table | Kg | 2000 |

| Rapid traverse (X/Y/Z) | m/min | 54 |

| Feed rate(X/Y) | mm/min | 10—20000 |

| Control system | FANUC 31I | |

| BT50 arm type ATC | 40T | |

| Machine weight | kg | 40000 |

| Air pressure source | kg/cm2 | 6 |

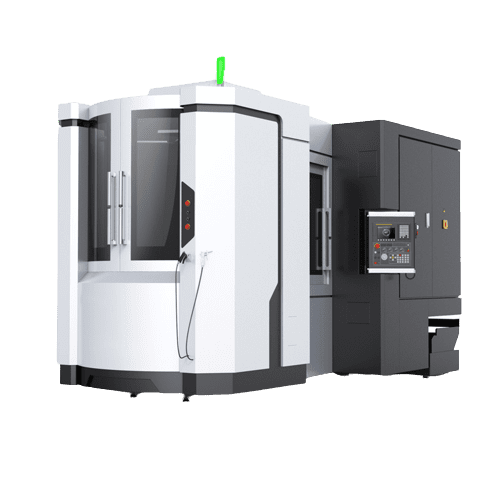

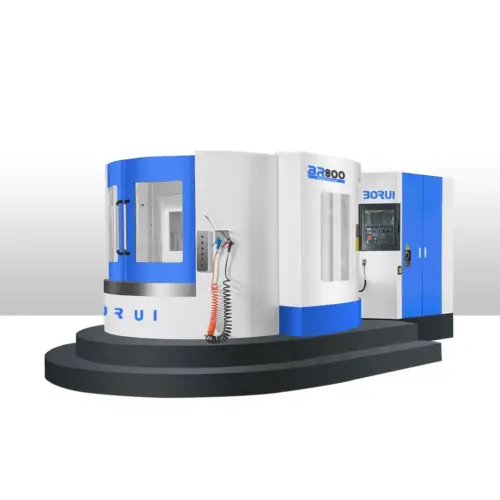

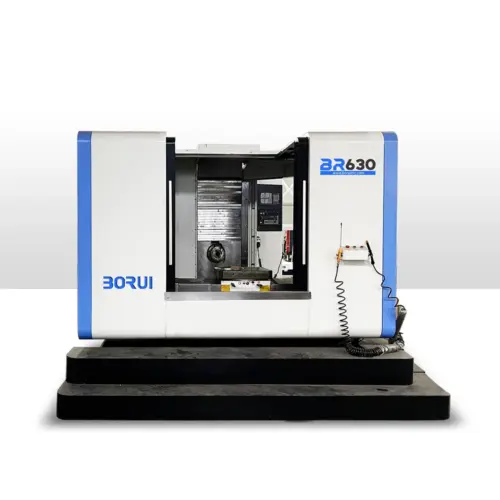

TAIWAN SPINDLE

Famous Taiwan spindle.High speed,high precision,Good surface finishing.

STAND COLUMN

Standard with Taiwan 16 ATC. Armless type.24 Arm ATC can be choose as optional.

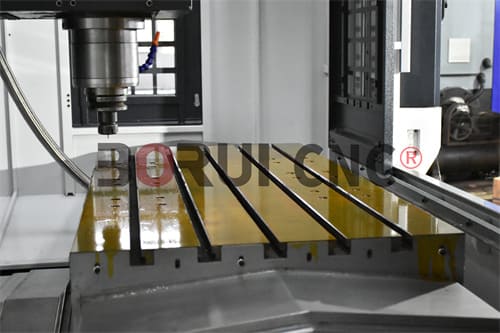

WORKBENCH

Made of high-density,high-rigidity materials,high strength and good wear resistance.

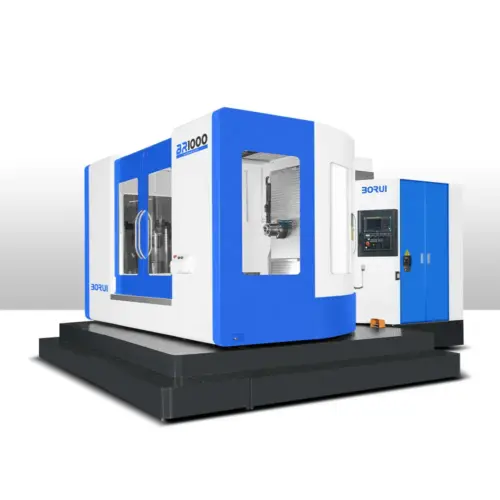

OPTICAL MACHINE

Precision casting,precision machining,precision assembly.

CNC CONTROL SYSTEM

Optional:GSK/KND/SIEMENS /FANUC /MITSUBISHI

TAIWAN LEAD SCREW

The lead screw rail adopts Taiwan HIWIN brand, which ensures high strength and high precision.

FOURTH AND FIFTH AXIS

The fourth axis or the fifth axis can be added according to customer needs to realize 4 axis 4 linkage and 5 axis 5 linkage.

Video Display

Reviews

There are no reviews yet.