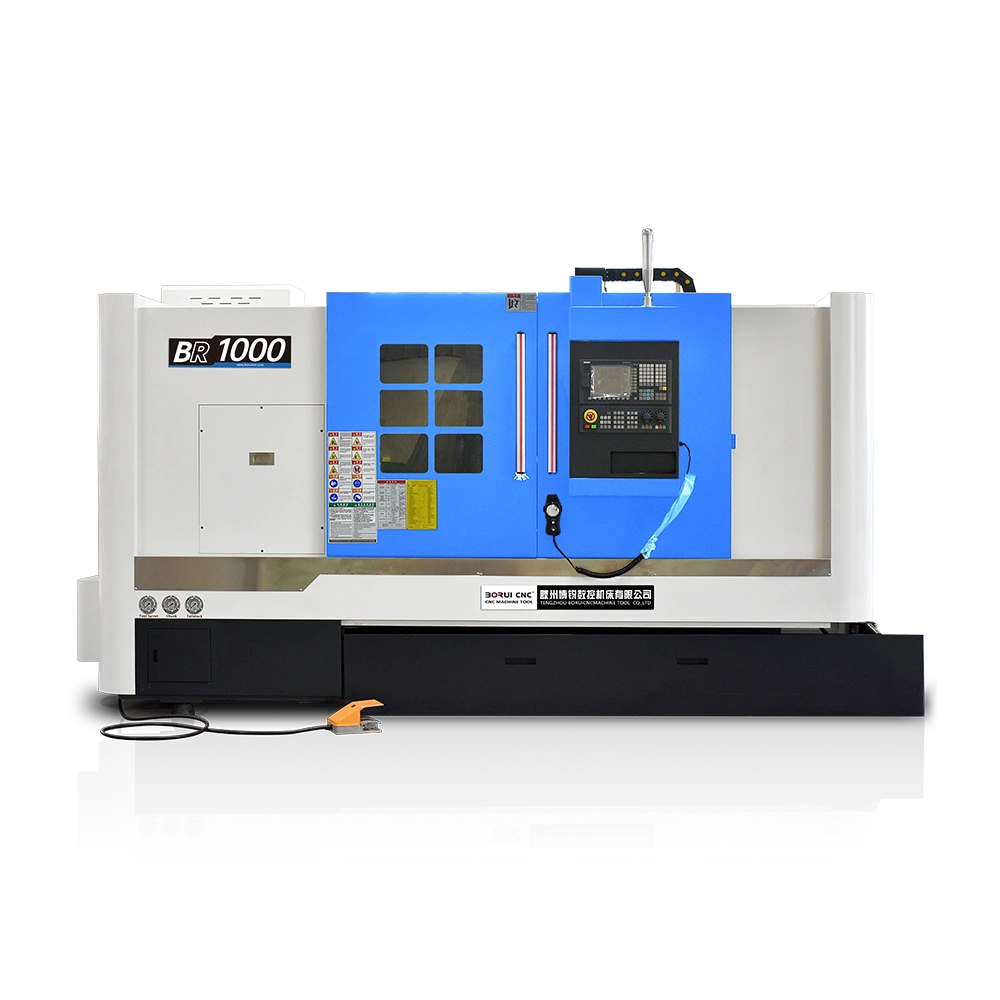

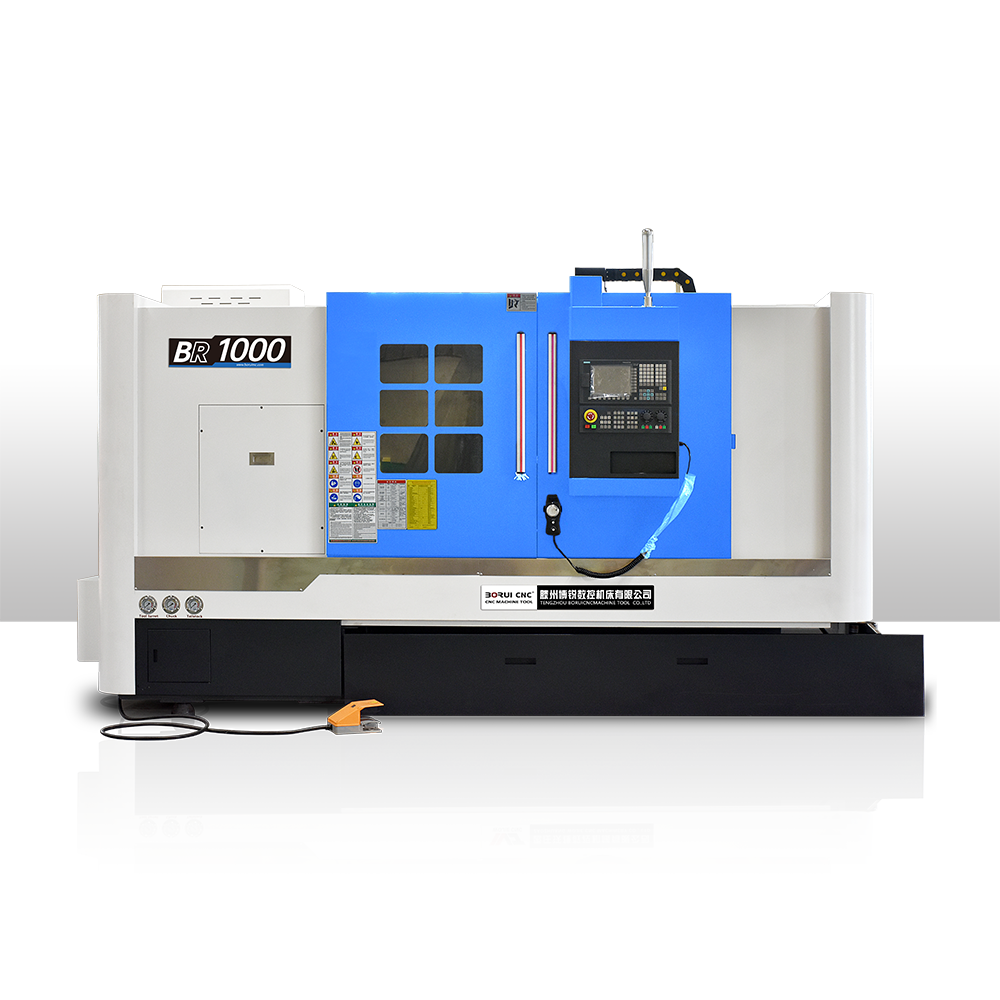

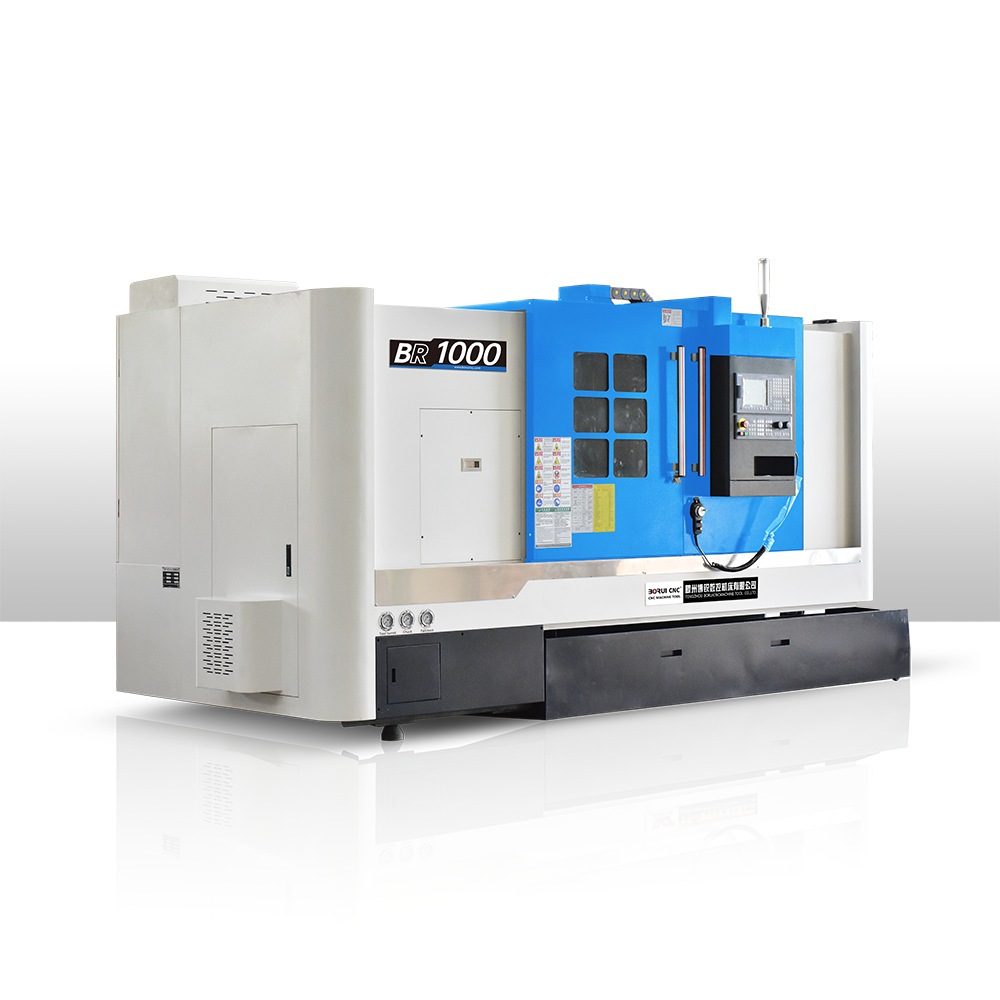

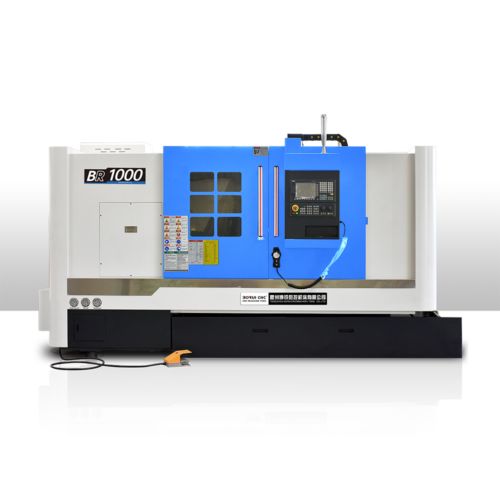

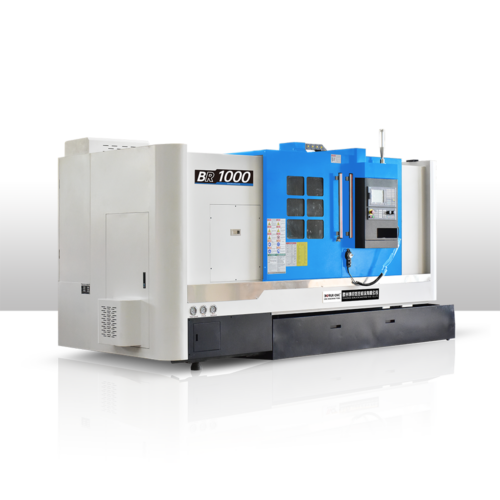

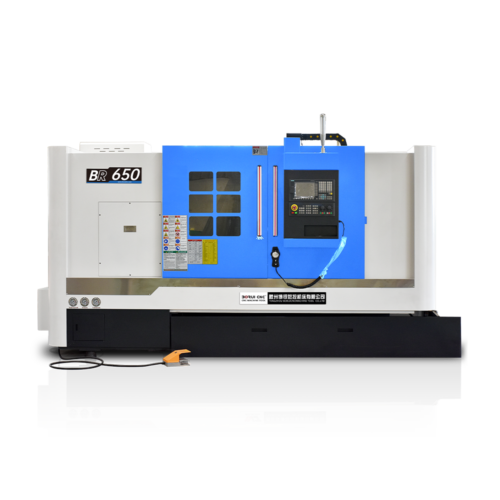

BR-1000 CNC Slant Bed Lathe Machine Features

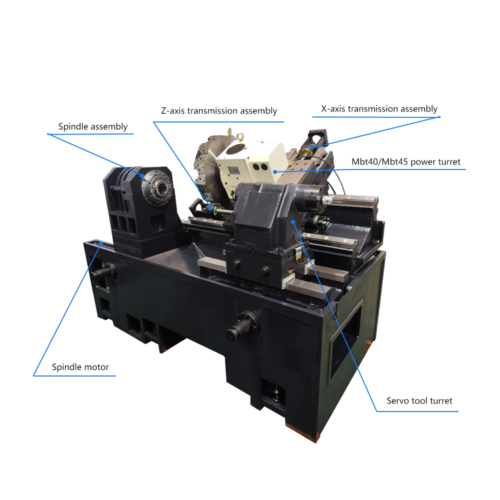

- Overall 45° inclined bed

- Strong rigidity

- Independent spindle

- Chip conveying capacity is large and convenient

- Chip conveying in the right or in the back

- Screw pre-stretching structure

- Hydraulic tailstock

- Operation manual and tool kit

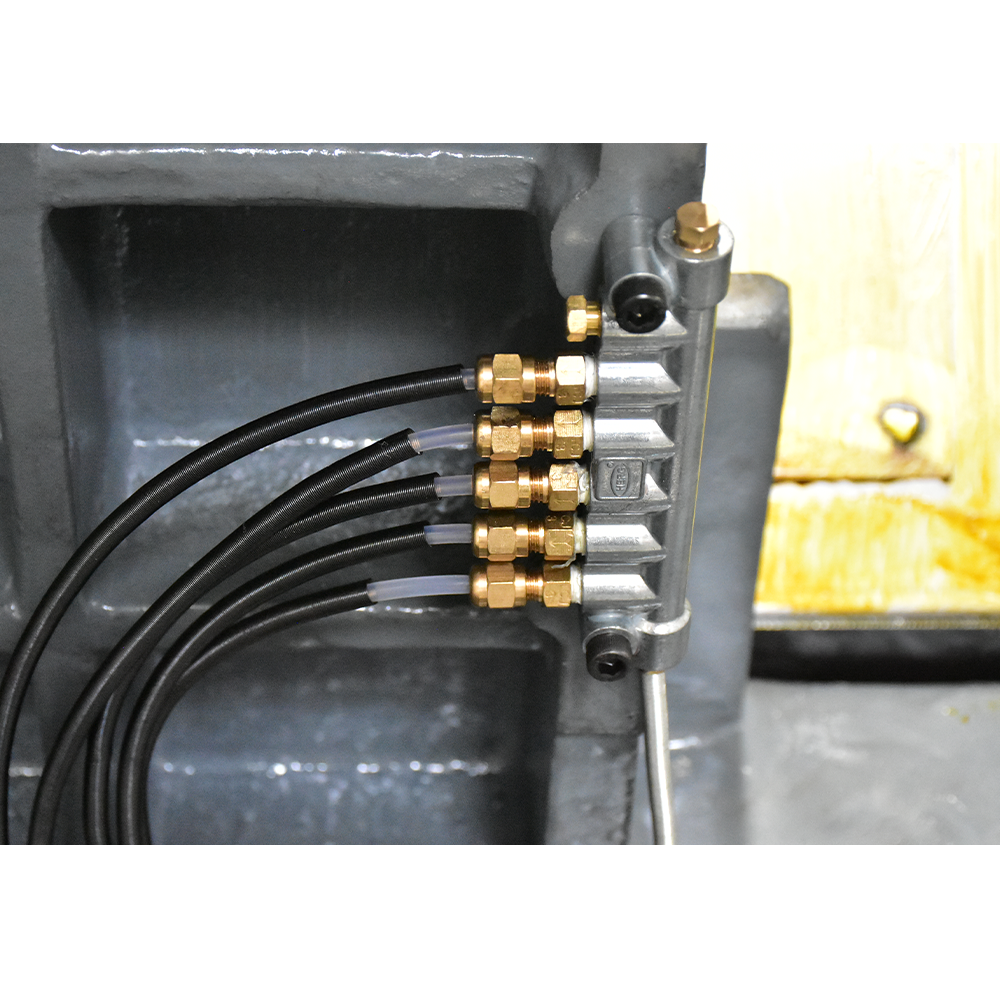

- Full-enclosed X/Z axis way cover

- Chain chip conveyor

- Servo spindle

- Taiwan screw rail

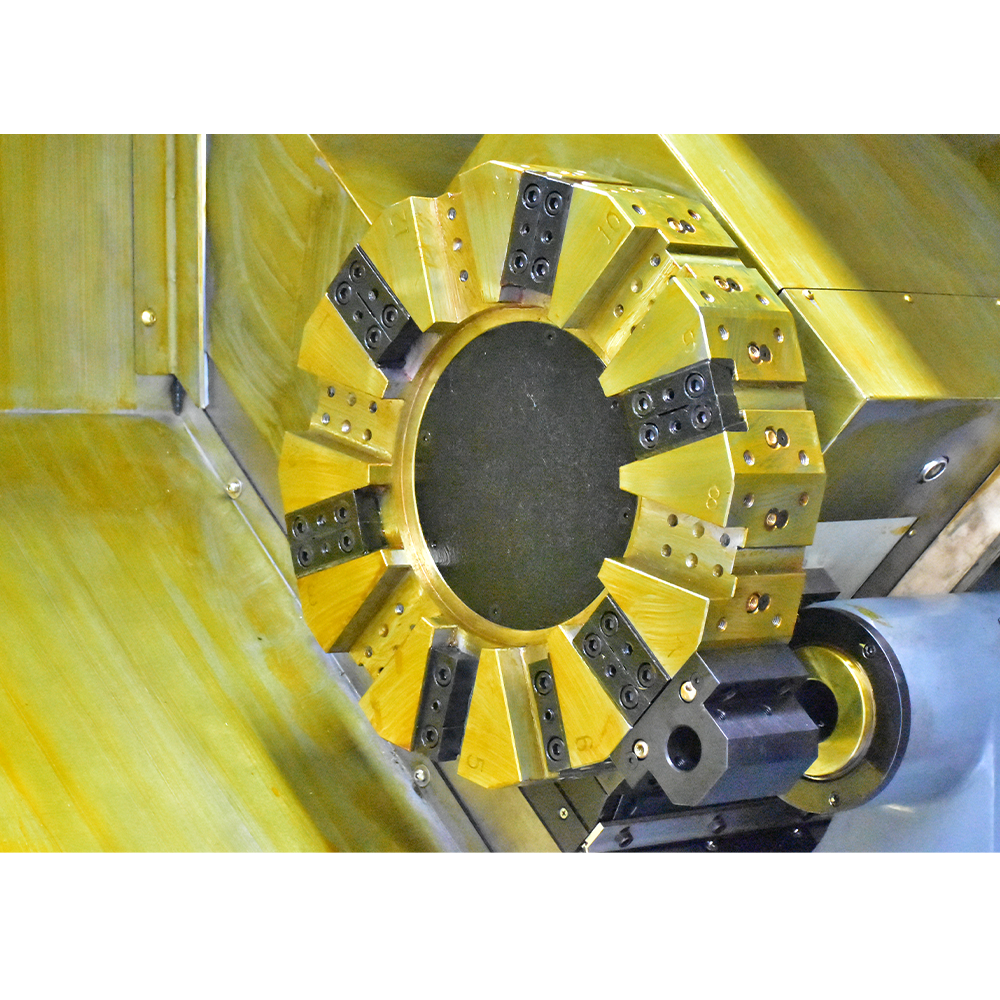

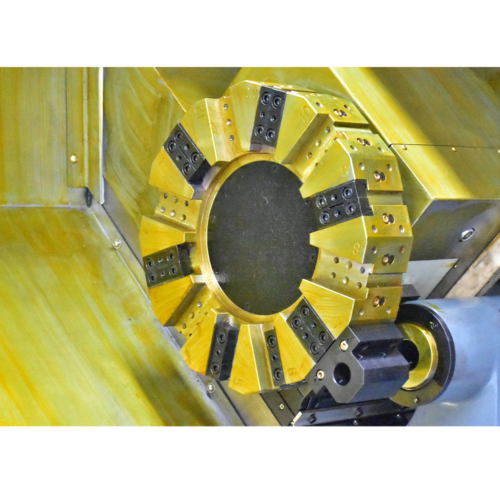

- Standard hydraulic turret, optional power turret

- CNC system Standard: GSK, Optional: Siemens, Fanuc, Mitsubishi and others.

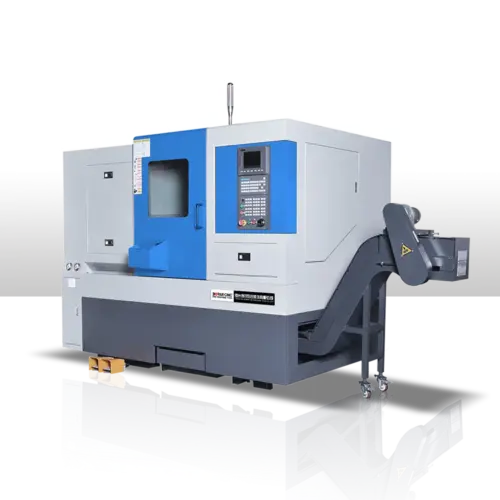

Advantages Of CNC Slant Bed Lathe Machine

- It adopts 45° oblique layout, bed base-integrated structure.

- The Independentspindle unit design is adopted, and the tolerances of the entire spindle parts are carefully selected and assembled.

- The guide rail adopts high-frequency audio quenching treatment and then carries out precision grinding, which has good precision retention.

- Turning of internal and external circles, arcs, end faces and threads can be performed on various disc and shaft parts.

- Turning of internal and external circles, arcs, end faces and threads can be performed on various disc and shaft parts.

- The screw rod and the motor shaft are directly connected without gap by coupling.

- System, chuck, tool holder and other configurations,Can be flexibly selected according to customer’s products.

Product Main Technical Parameters

| Model | Unit | BR-1000 |

|---|---|---|

| The maximum turning diameter on the bed | mm | 1000 |

| Maximum cutting diameter | mm | 900 |

| Swing over cross slide | mm | 800 |

| Distance between center | mm | 1000/1500/2000/3000 |

| Slant bed layout angle | ° | 45 |

| Spindle nose type | ΦA2-15 | |

| Spindle bore taper | mm | 120 |

| Spindle bore | mm | 100 |

| Spindle speed steps | Hydraulic 2nd gear,Stepless | |

| Spindle speed range | r/min | 50-800 |

| Hydraulic chuck | in | 24 |

| Main spindle motor | kw | 37 |

| Turret /tool post | Hydraulic turret 12 position | |

| Tool shank size | mm | 32×32 |

| Boring tool holder size | mm | Φ60/Φ80 |

| X axis travel | mm | 475 |

| Z axis travel | mm | 1000/1500/2000/3000 |

| Motor torque | Nm | 30/30 |

| X axis rapid traverse | mm/min | 12000 Hard guideway |

| Z axis rapid traverse | mm/min | 12000 Hard guideway |

| X/Z axis | mm | 0.001 |

| Tailstock quill diameter | mm | Φ120/170 |

| Tailstock quill taper | MT6 | |

| Tailstock quill taper | mm | 120 |

| Coolant pump motor | kw | 0.37 |

| Finishing machining accuracy of outer circle | IT6 | |

| Surface roughness of the outer circle of finishing car | μm | 0.8 |

| Width x Height | mm | 2570×2400 |

| Net weight | T | 105/15/18/20 |

Reviews

There are no reviews yet.