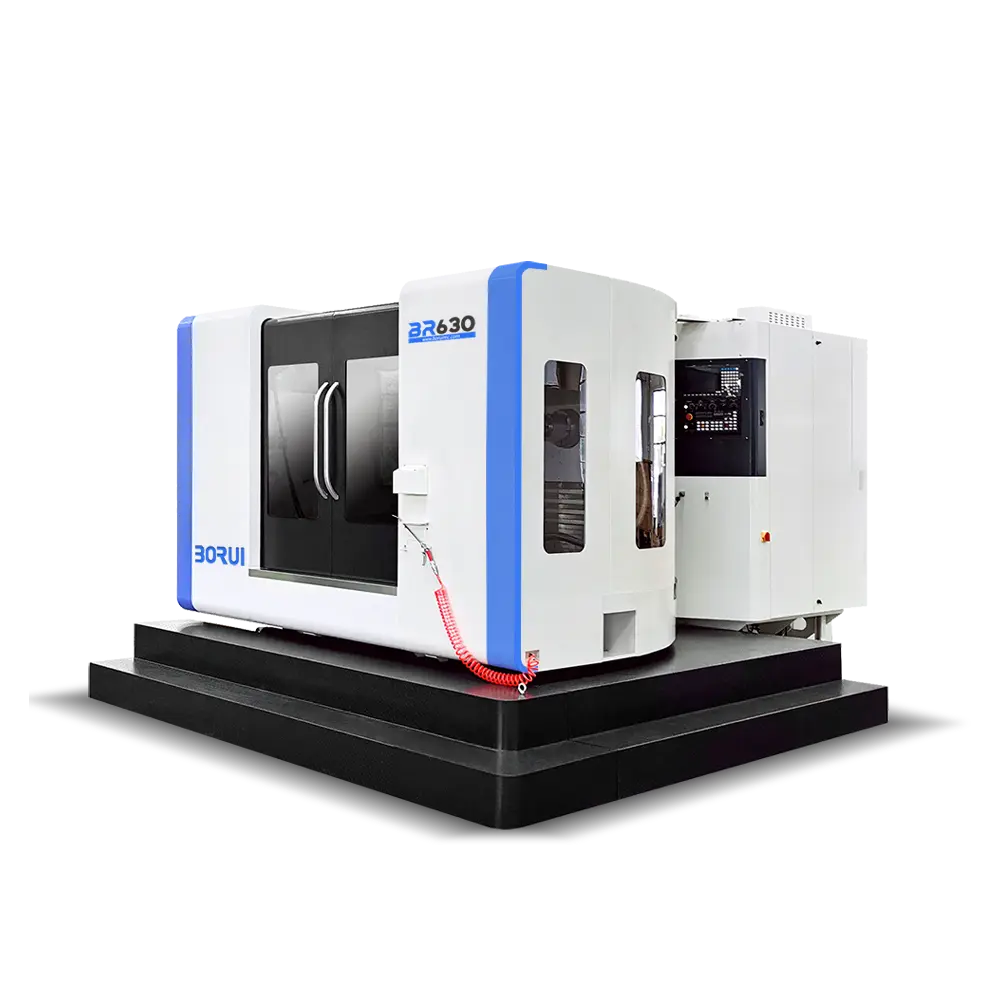

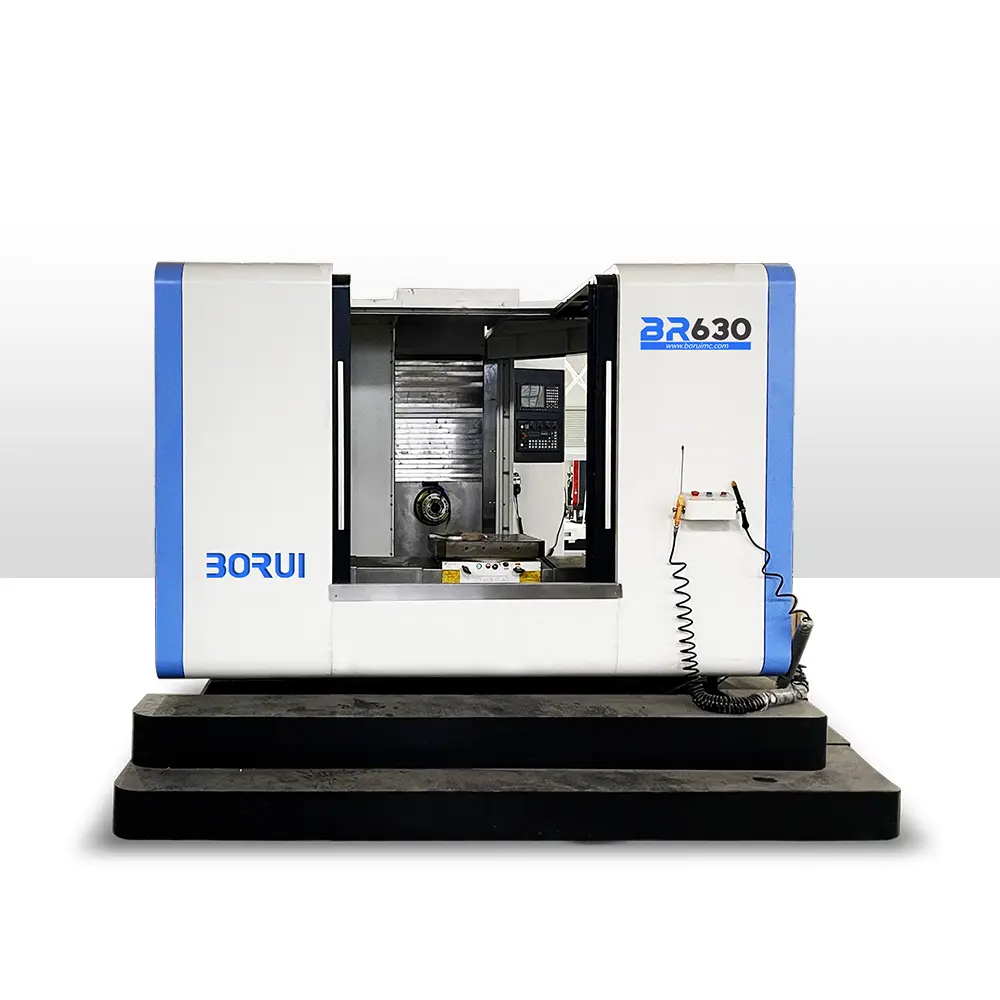

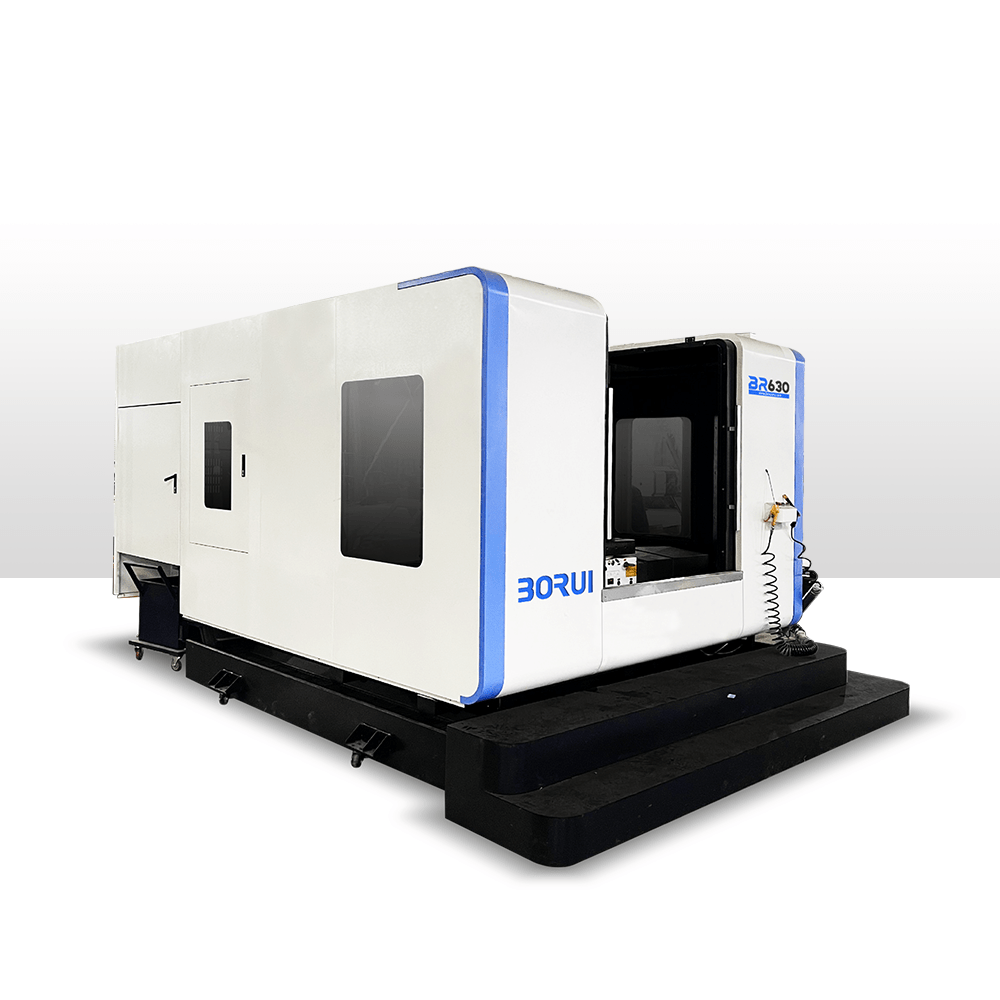

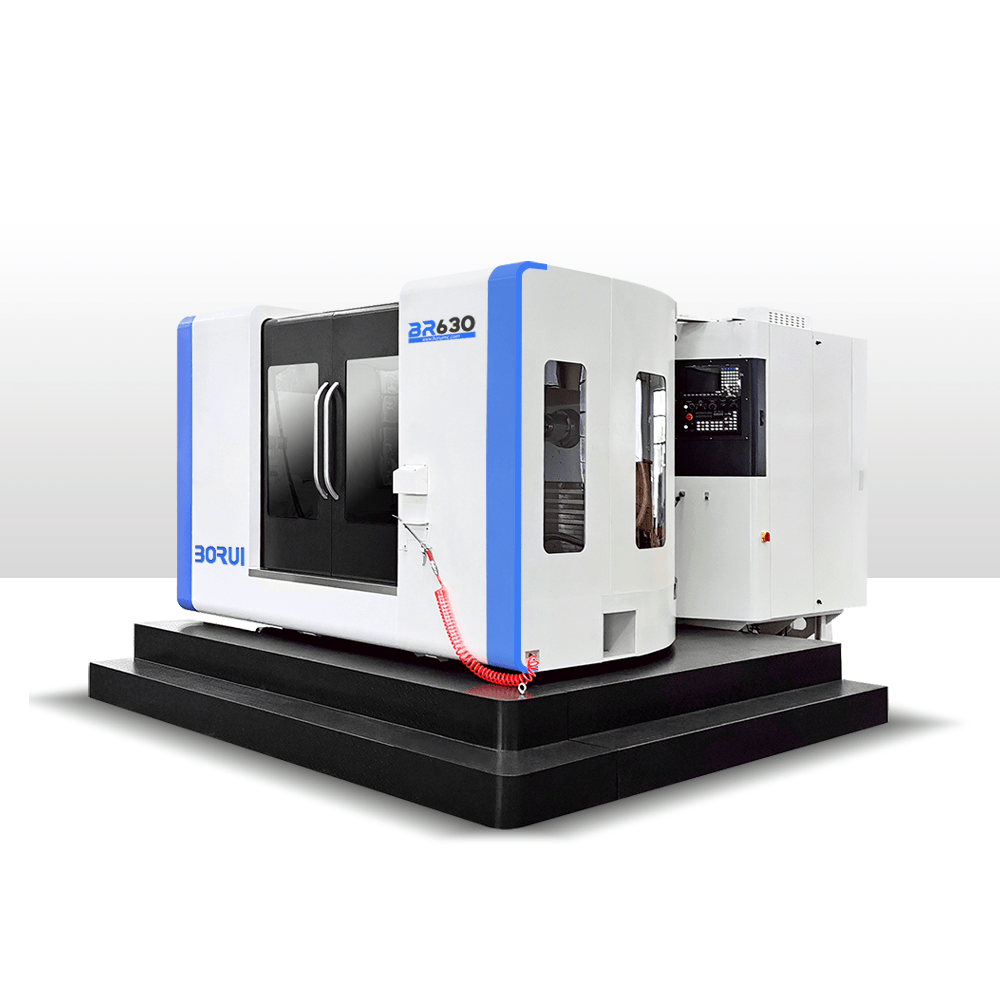

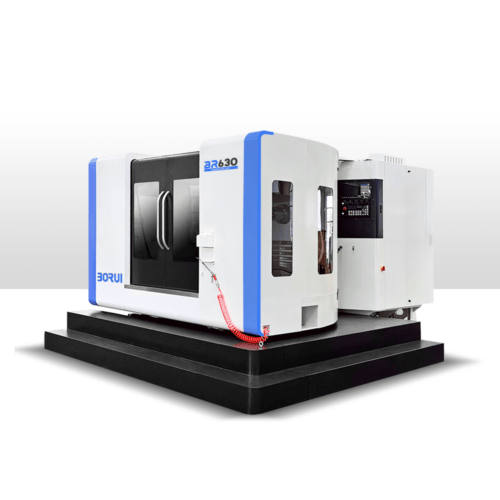

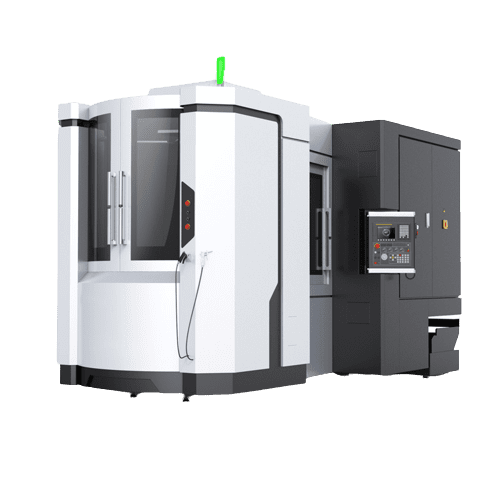

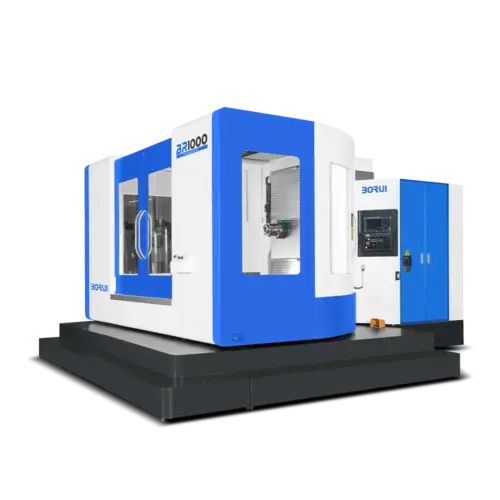

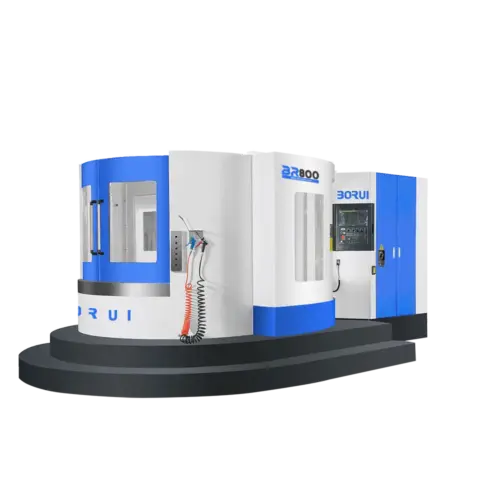

Advantages Of BR-630 CNC Horizontal Machining Center:

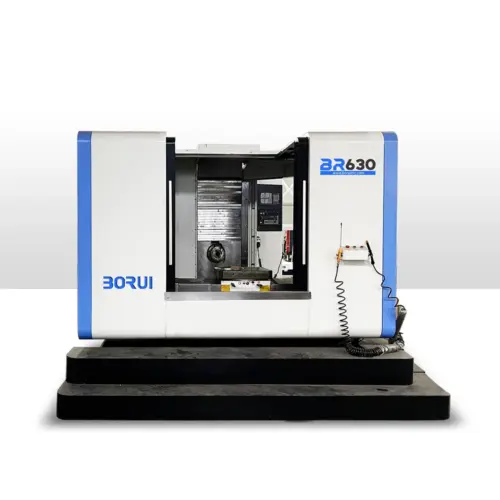

- The horizontal machining center can carry out a variety of processing processes, such as drilling, milling, boring, tapping, etc.

- A wide range of applications. It can meet the processing needs of different workpieces, improve production efficiency and flexibility.

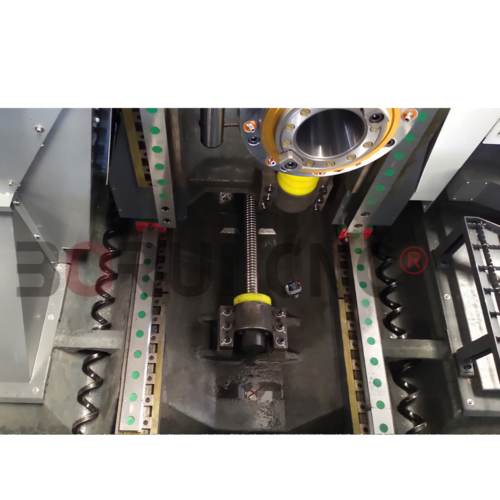

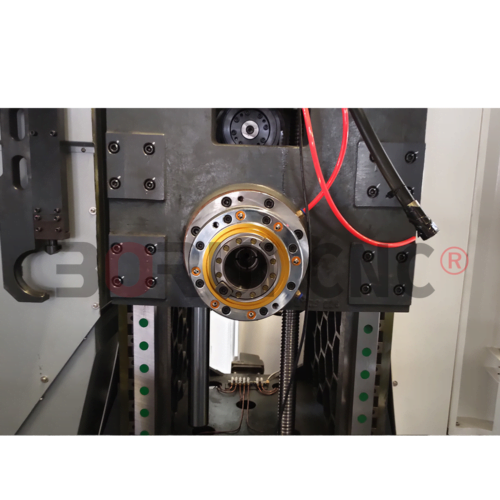

- The horizontal machining center adopts advanced CNC system and precise mechanical structure, which can realize high-precision machining.

- It can maintain the accuracy of the size and shape of the workpiece to meet the demanding processing needs.

- The horizontal machining center has high-speed cutting capability and a fast tool change system.

- Enables fast and continuous processing operations.

- The processing speed is fast, which can improve production efficiency and shorten processing cycle.

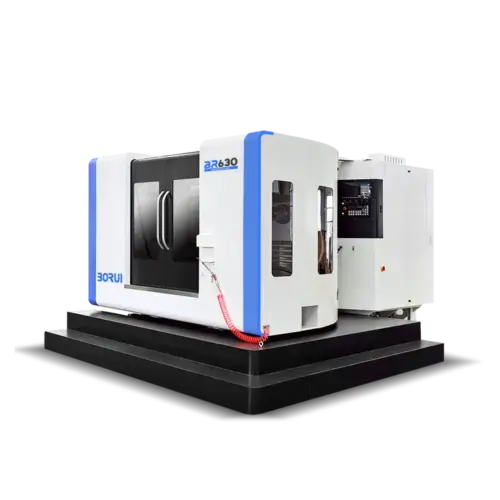

Technical Parameters Of BR-630 CNC Horizontal Machining Center:

| Description | Unit | VMC630 (Optional double station) |

|---|---|---|

| Table size | mm | 630*630 |

| Table loading | kg | 1200 |

| maximum dimensions of workpiece | mm | 1000×900 |

| Distance from countertop to bottom | mm | 1130 |

| X-axis travel | mm | 1050 |

| Y-axis travel | mm | 800 |

| Z-axis travel | mm | 900 |

| Worktable center to spindle end face | mm | 120~1020 |

| Table surface to spindle center | mm | 80~880 |

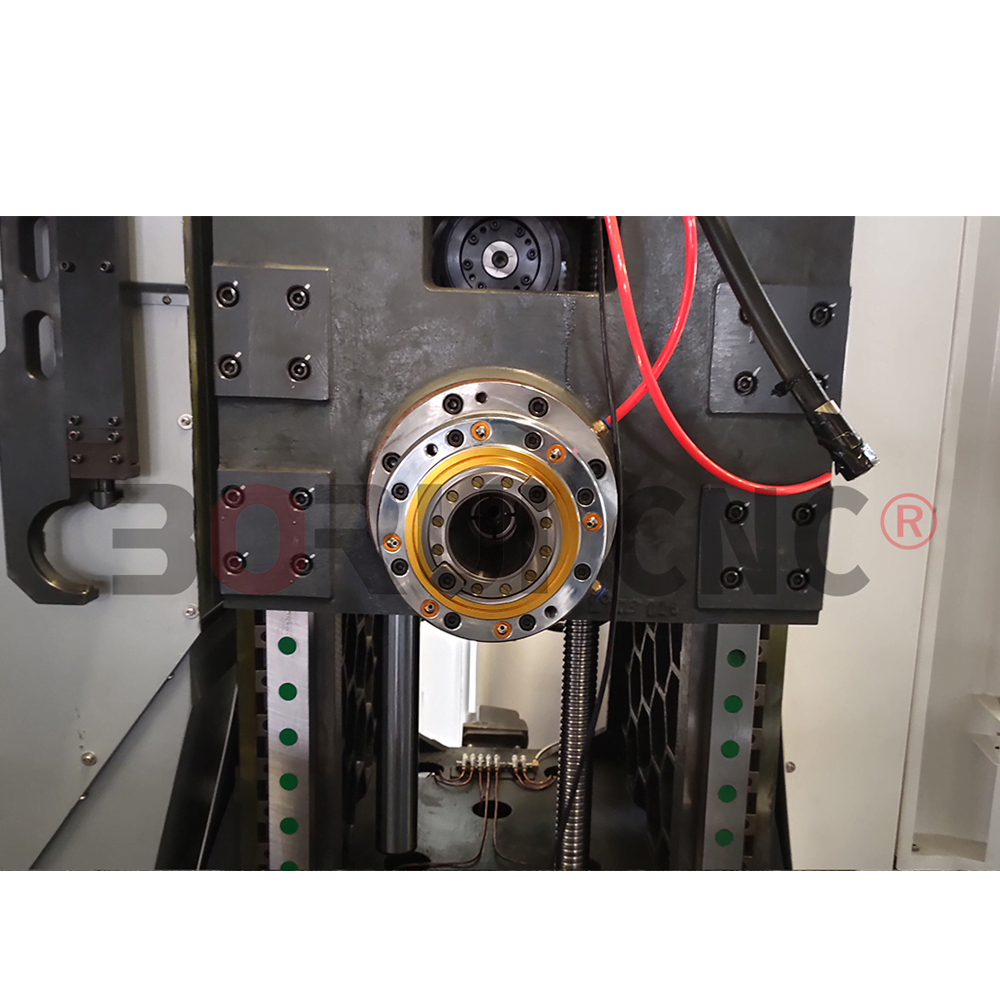

| Spindle speed | rpm | 50~4000(Belt 1:2 deceleration) |

| spindle motor | kw | 15/18.5KW |

| Spindle speed change | stepless speed | |

| taper hole of spindle | BT50 | |

| Fast feed speed | m/min | X、Z:24,Y:18 |

| Feed cutting speed | m/min | 10 |

| positional accuracy | mm | 0.012 |

| repeated positioning accuracy | mm | 0.008 |

| B axis positioning accuracy | ±6 | |

| B axis repeated positioning accuracy | ±2 | |

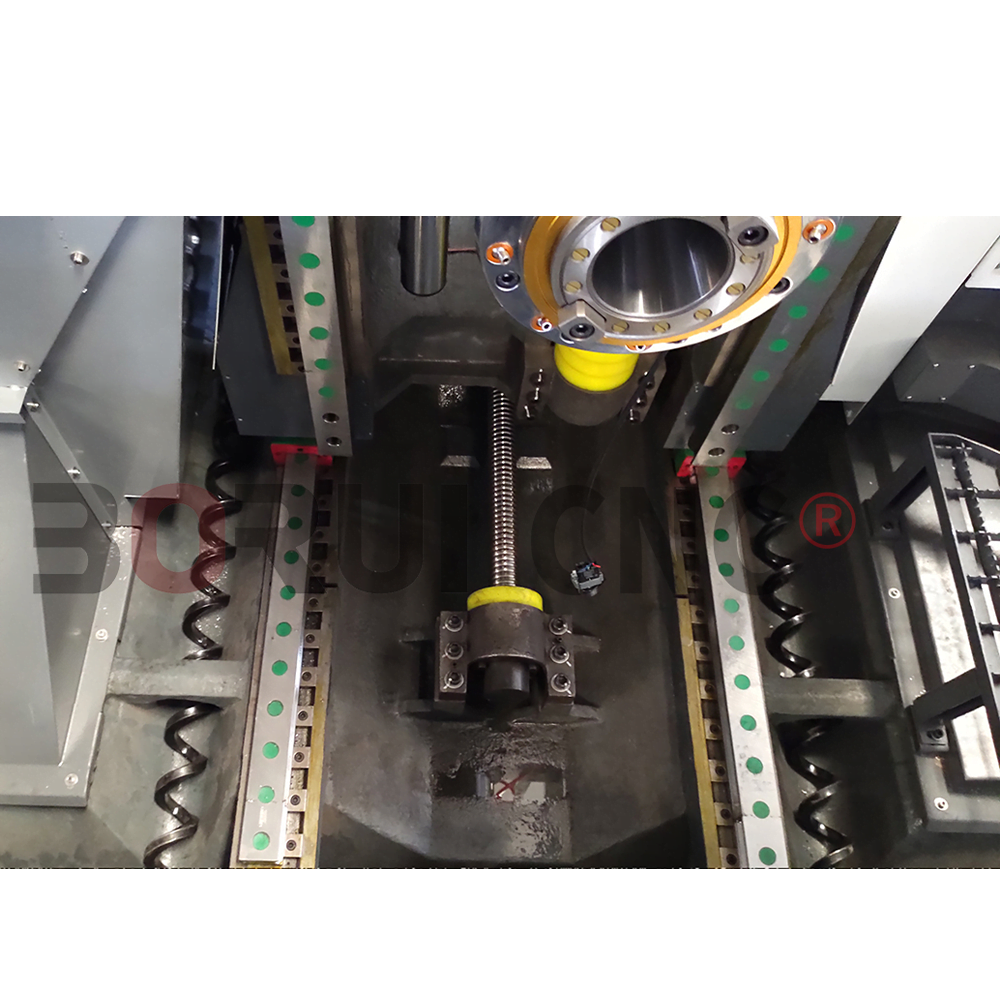

| lead screw | X/Y:φ4012 Z:φ5012 | |

| guide rail | X/Y:45 rollers Z:55 rollers | |

| Machine size | mm | 3000×4200×3500 |

| weight | t | 7.8 |

Reviews

There are no reviews yet.