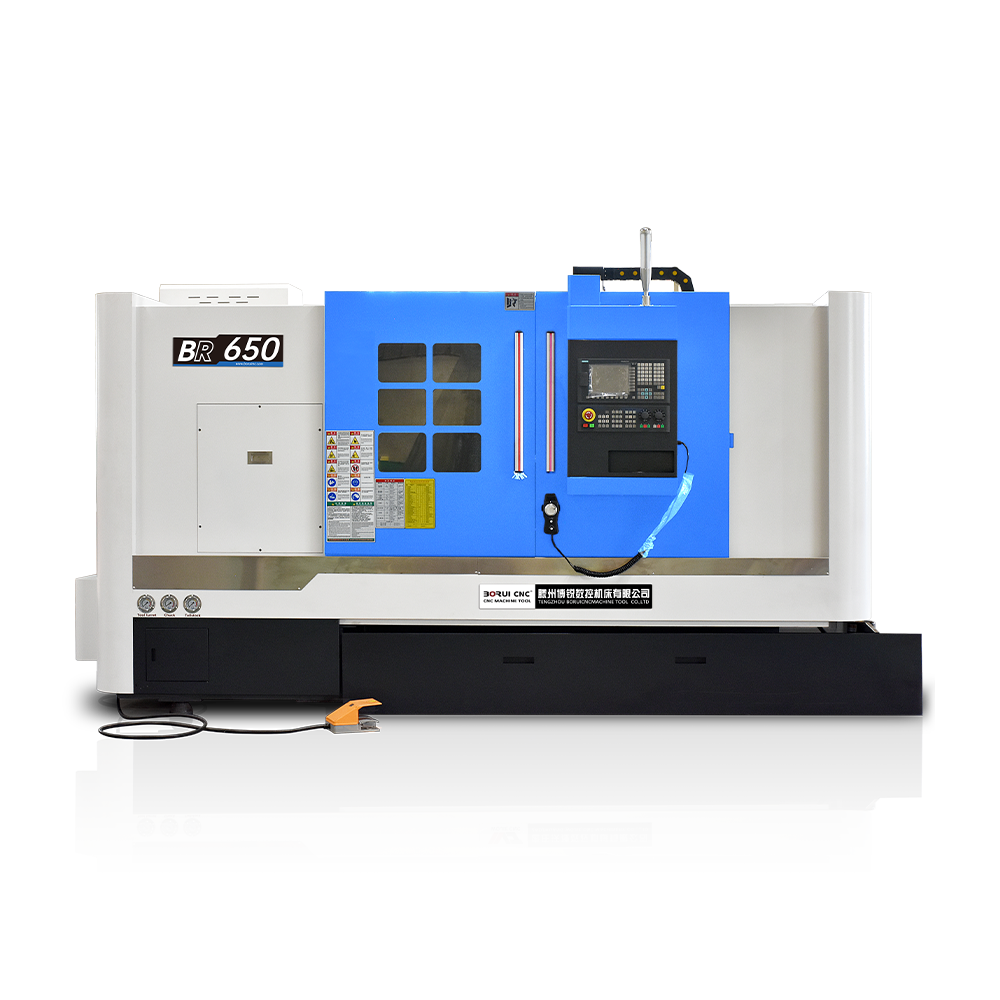

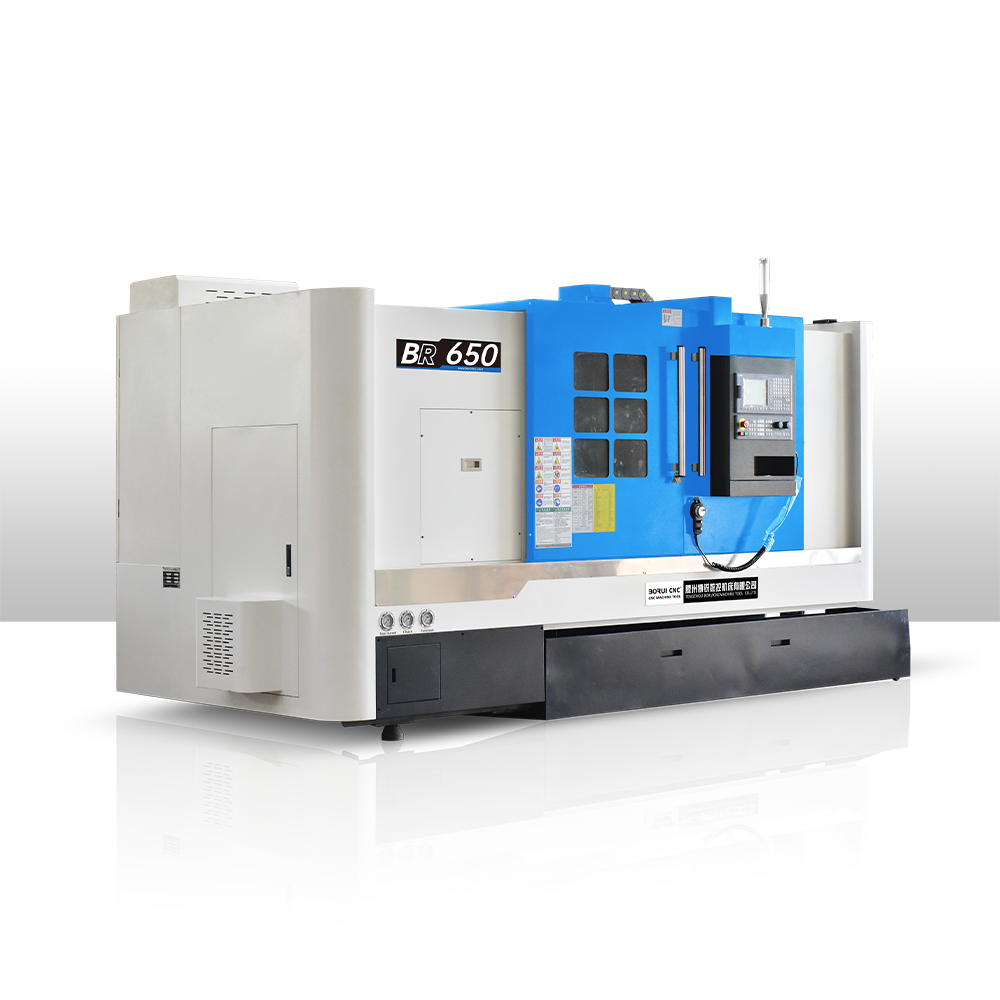

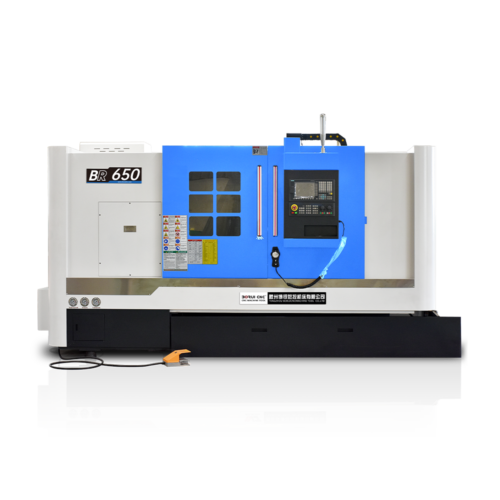

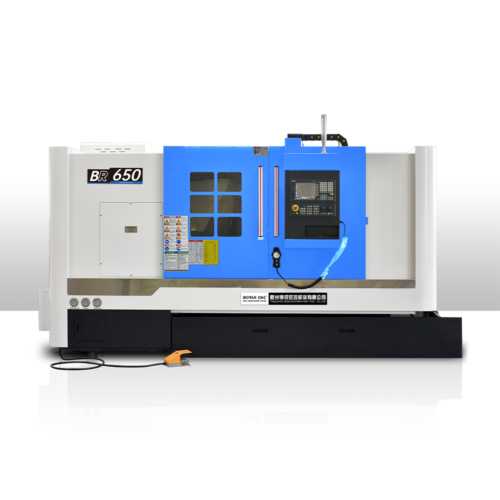

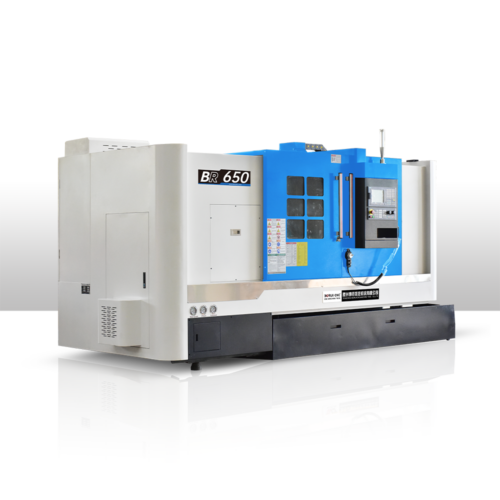

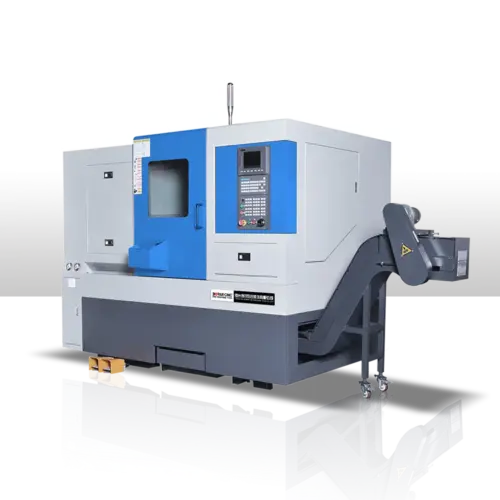

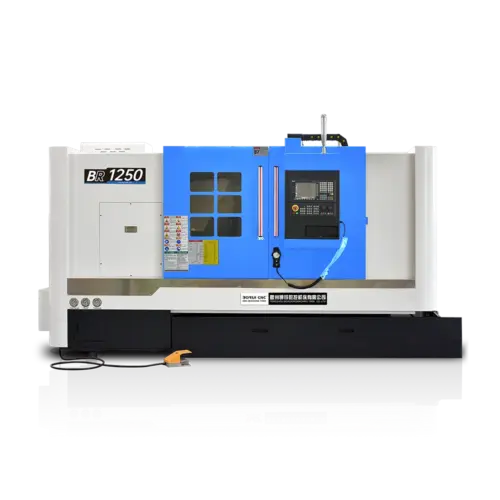

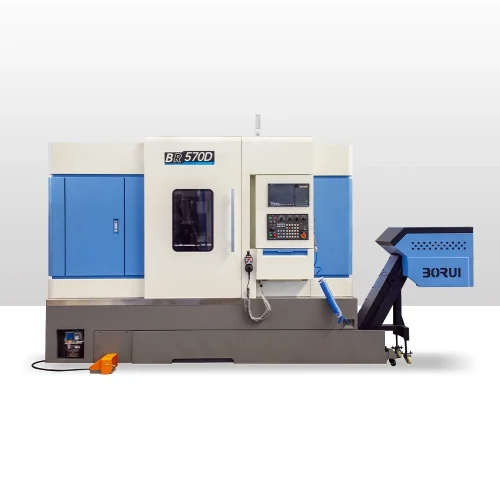

BR-650 CNC Slant Bed Lathe Machine Features

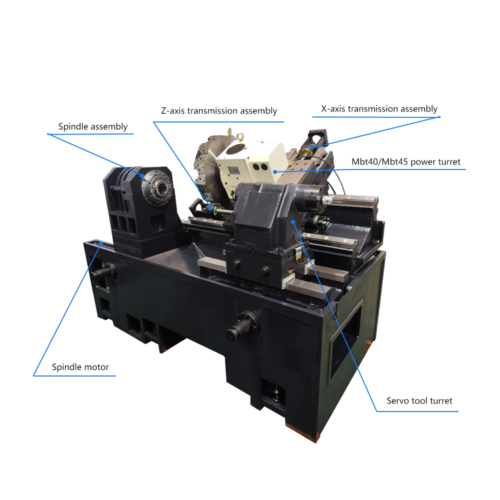

- Overall 45° inclined bed

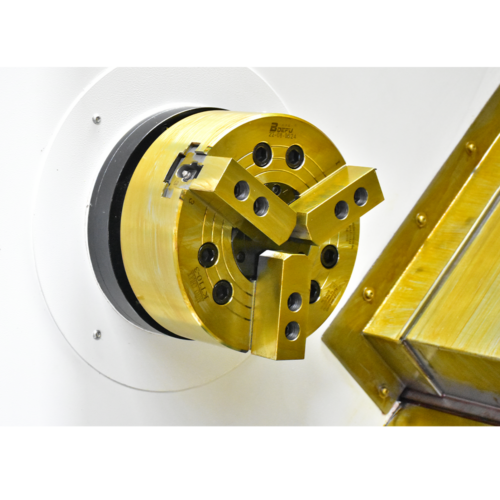

- Taiwa famous spindle

- Independent sleeve spindle

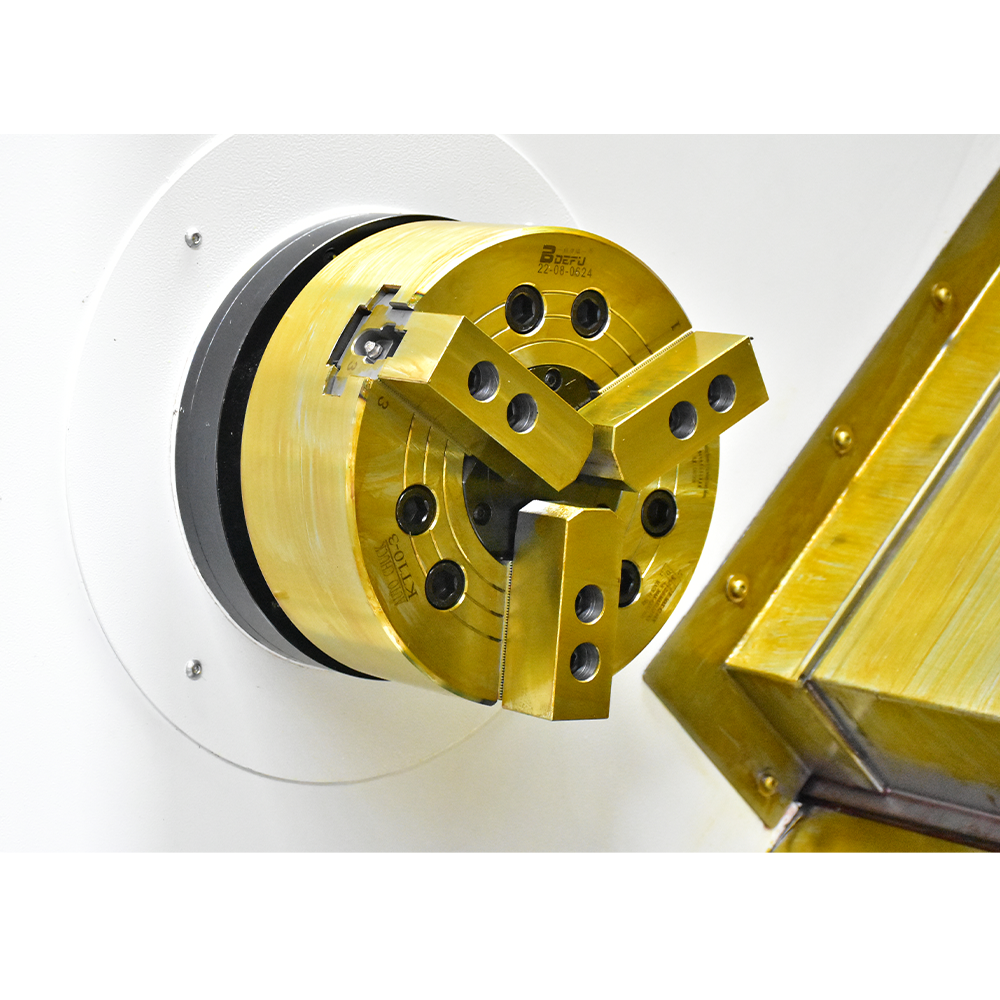

- 3-jaw hydraulic chuck

- Automatic lubrication

- Hydraulic turret

- Hydraulic tailstock

- Three-color warning light

- Operation manual and tool kit

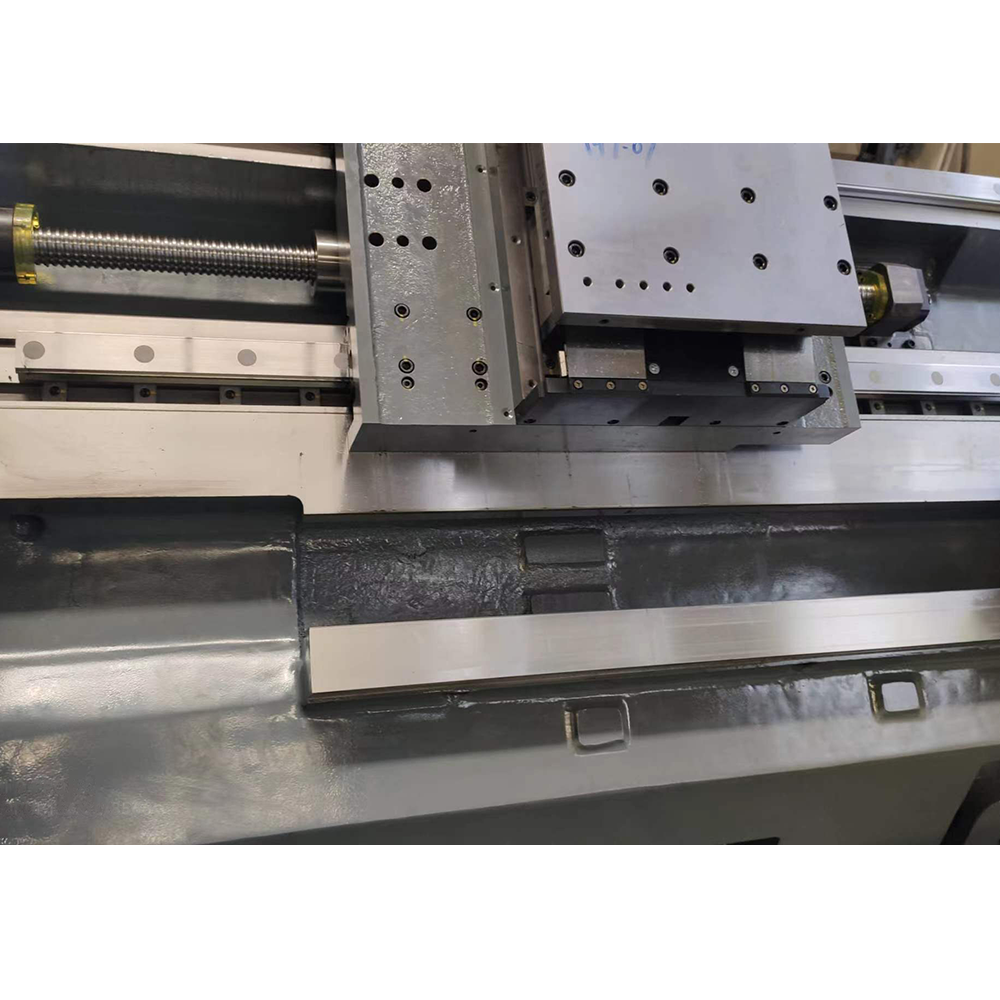

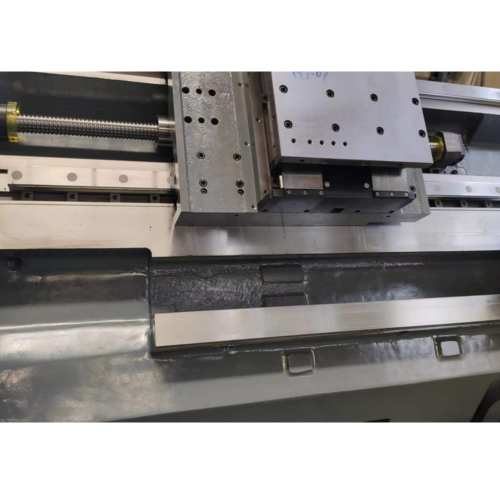

- Full-enclosed X/Z axis way cover

- Chain chip conveyor

- Servo spindle

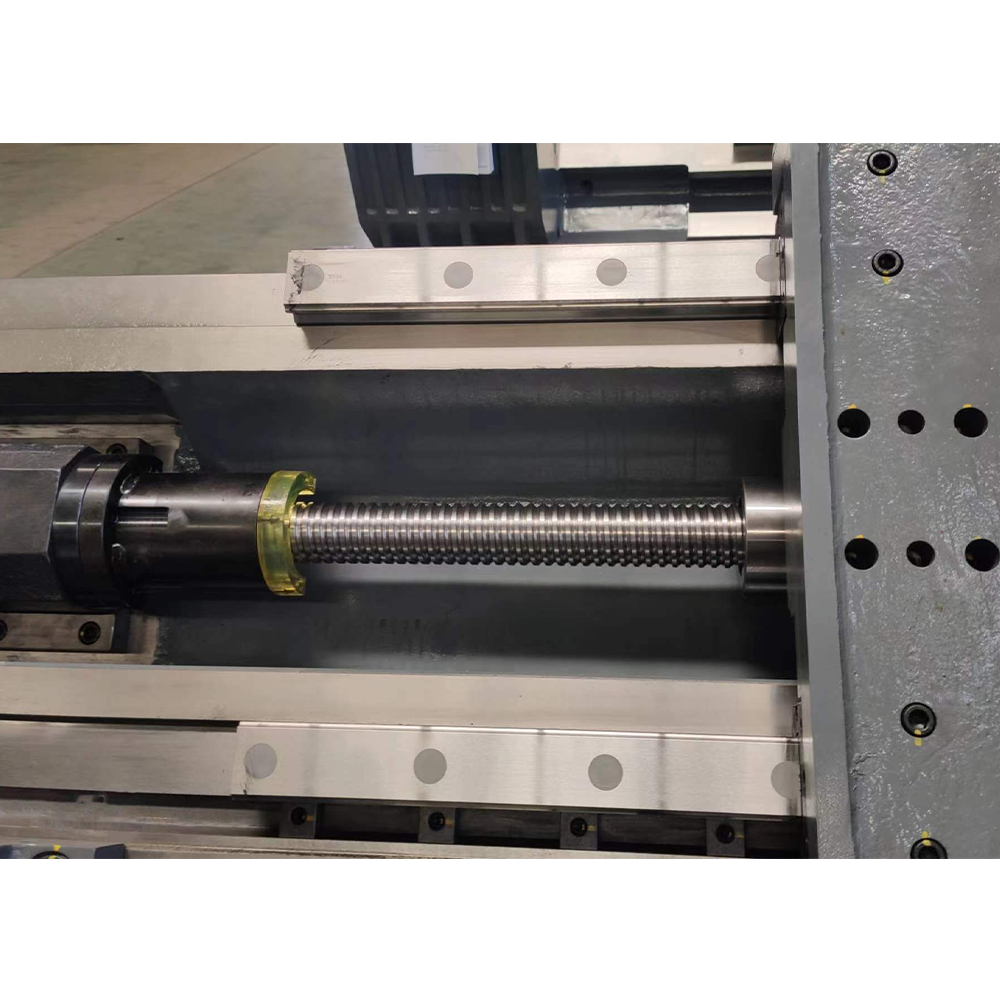

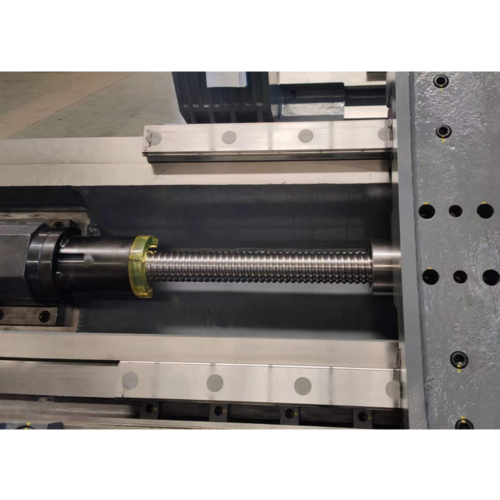

- Taiwan screw rail

- Standard hydraulic turret, optional power turret

- CNC system Standard: GSK, Optional: Siemens, Fanuc, Mitsubishi and others.

Video Display

BR-650 CNC Slant Bed Lathe Machine Technical Parameters

| Machine Model | Model | BR650-1500 | BR650-2000 |

|---|---|---|---|

| Major parameter | The maximum turning diameter on the bed | Φ650 | Φ650 |

| maximum machining diameter | Φ630(varies according to the turret) | Φ630(varies according to the turret) | |

| Maximum machining diameter on the tool holder | Φ360 | Φ360 | |

| Maximum processing length | 1500(10″) (varies according to the turret) | 2000(10″) (varies according to the turret) | |

| Spindle and chuck parameters | Spindle head form (optional chuck) | A2-8(Assembled) | A2-8(Assembled) |

| Recommended spindle motor power | 15-18.5KW | 15-18.5KW | |

| Spindle speed | 2600rpm | 2600rpm | |

| Spindle hole diameter | Φ87 | Φ87 | |

| Bar diameter | Φ72 | Φ72 | |

| Feed section parameters | X/Z axis screw specifications | 4010/5512 | 4010/5512 |

| X-axis limit travel | 350 | 350 | |

| Recommended X-axis motor torque | 21N.M | 21N.M | |

| X/Z axis rail specifications | 55/55 | 55/55 | |

| Z axis limit travel | 1620 | 2120 | |

| Recommended Z-axis motor torque | 21N.M | 21N.M | |

| X, Z axis connection mode | Direct | Direct | |

| Turret or Gang | Optional turret (special configuration) | 12T(The opposite side of the cutter head is not less than 400) | 12T(The opposite side of the cutter head is not less than 400) |

| Recommended turret center height dimension | 125mm | 125mm | |

| Tailstock | Socket diameter | 140(swivel tailstock) | 140(swivel tailstock) |

| Socket travel | 140 | 140 | |

| Tailstock maximum stroke | 1560 | 1560 | |

| Tailstock sleeve tapered hole | MT5# | MT5# | |

| Overall Dimension | Bed type and inclination | Integrated/30° | Integrated/30° |

| Machine size(L * W * H) | 3800×1720×1560 | 3800×1720×1560 | |

| Weight | Weight (approx. weight) | 5100kg | 5600kg |

Advantages Of The CNC Slant Bed Lathe Machine

- The linear rolling guide meets high-speed requirements. It can reduce frictional resistance and temperature rise deformation.

- The CNC lathe slant bed machine can improve machining accuracy. It can ensure the long-term stability of cutting machining accuracy.

- It reduces the settling time when changing the tool. It can also automatically compensate for the wear of the tooltip.

- This full-featured CNC inclined bed lathe has high rigidity, precision, and good precision retention.

- The inclined bed CNC lathe adopts domestic or imported high-rigidity horizontal turret tool posts.

- High positioning accuracy and small deformation in heavy cutting.

- The inclined bed CNC lathe adopts the overall inclined bed structure. It can still maintain the stability of the machine tool precision during heavy cutting.

- Both ends of the machine are fixed with screws. It improves the support rigidity of the support base.

Reviews

There are no reviews yet.