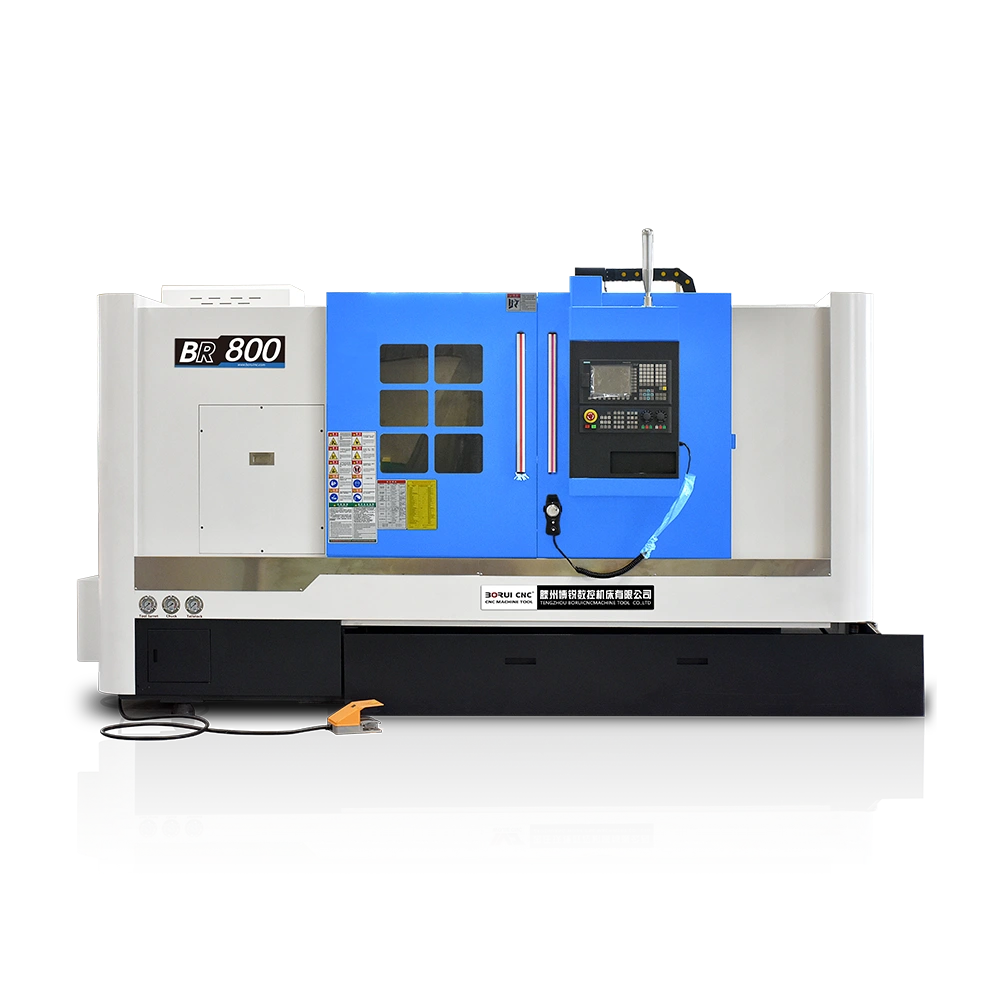

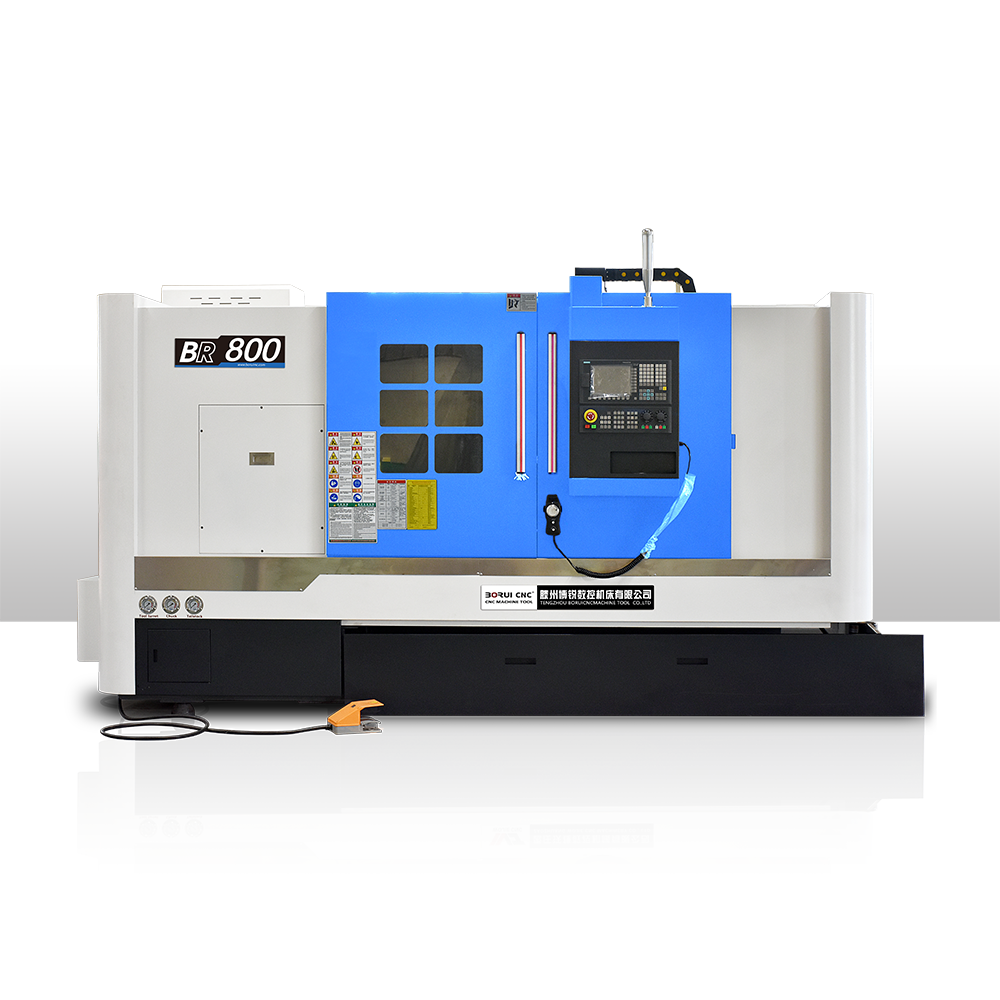

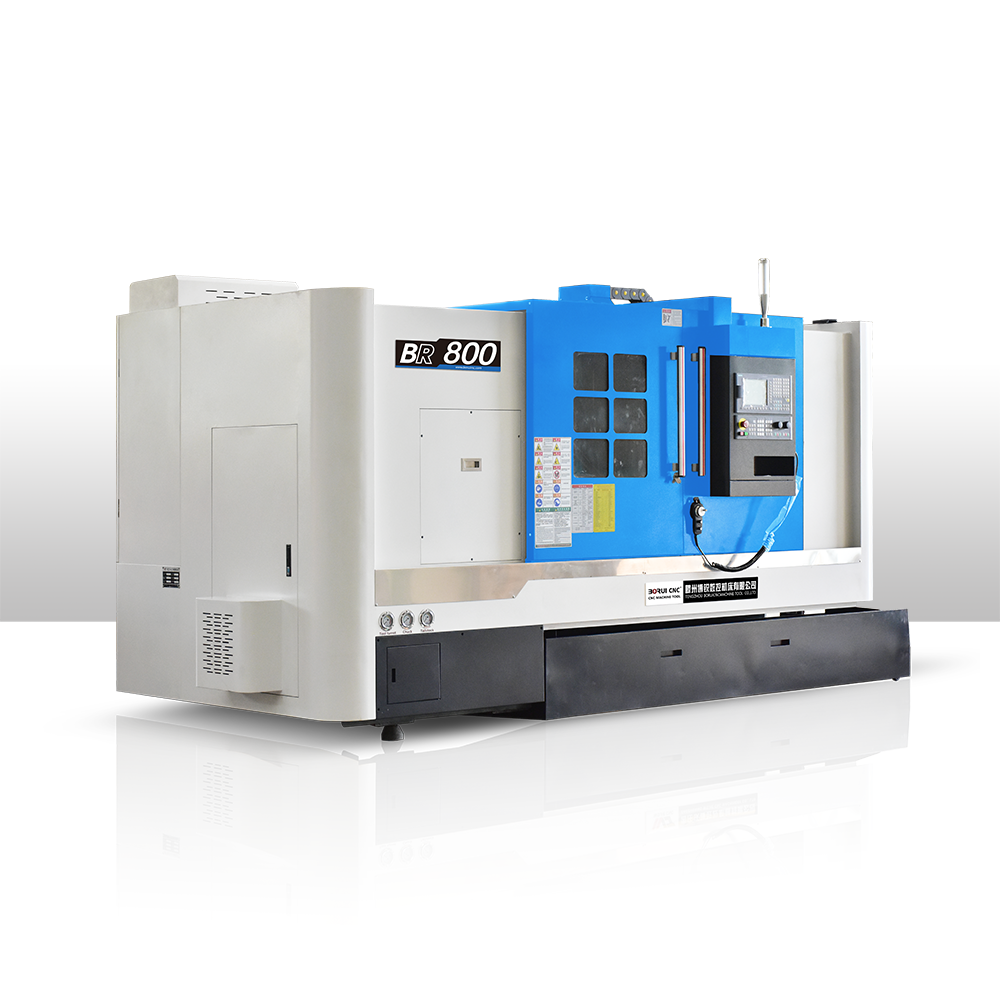

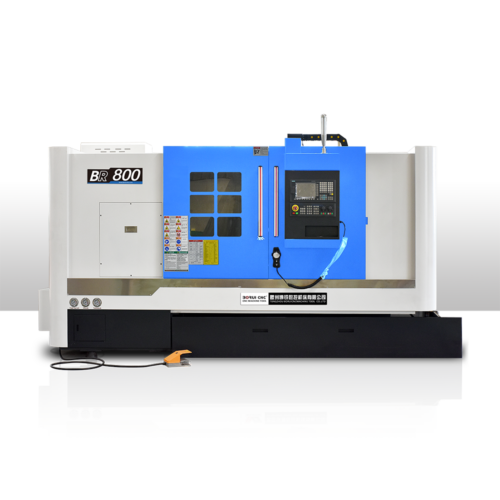

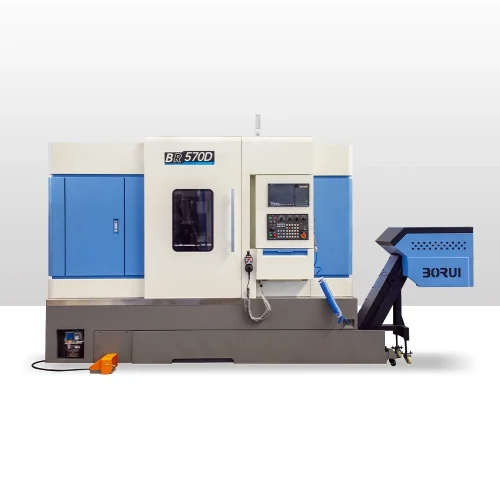

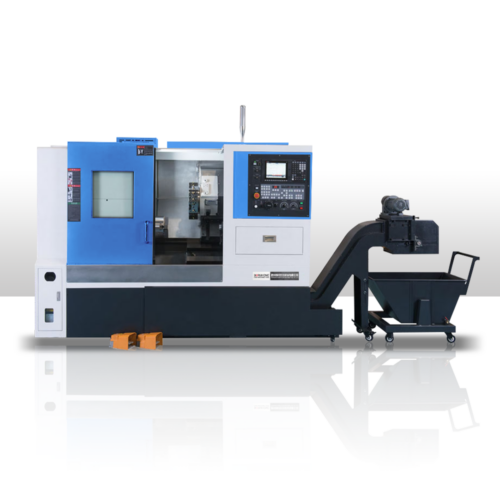

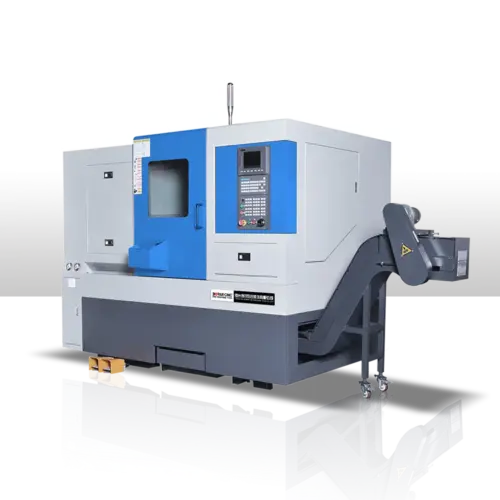

BR-800 Slant Bed CNC Lathe Machine

- Overall 45° inclined bed

- Higher accuracy Taiwan linear guide ways

- Chip conveying capacity is large and convenient

- Chip conveying in the right or in the back

- Automatic lubrication

- Screw pre-stretching structure

- Hydraulic tailstock

- Operation manual and tool kit

- Full-enclosed X/Z axis way cover

- Chain chip conveyor

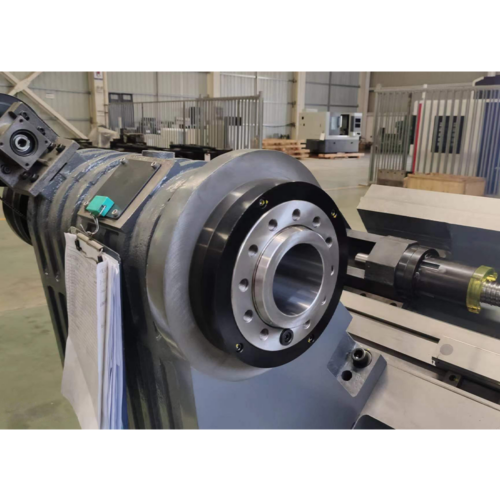

- Servo spindle

- Taiwan screw rail

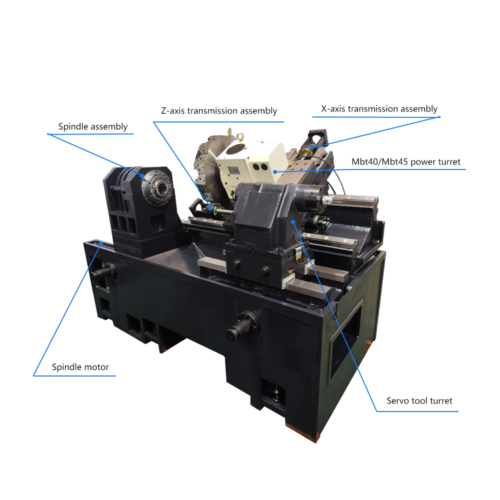

- Standard hydraulic turret, optional power turret

- CNC system Standard: GSK, Optional: Siemens, Fanuc, Mitsubishi and others.

Video Display

BR-800 CNC Lathe Slant Bed Machine Technical Parameters

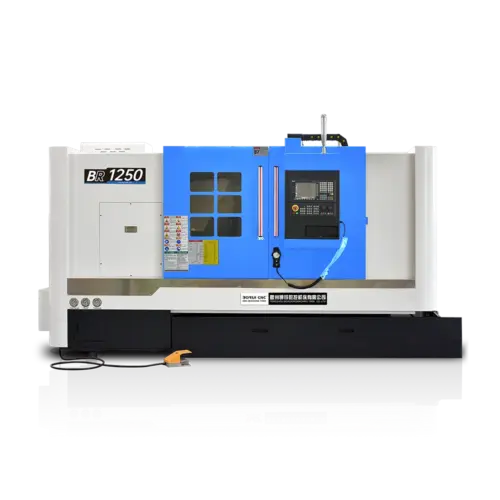

| MODEL | UNIT | BR-800 | BR-1000 | BR-1250 |

|---|---|---|---|---|

| The maximum turning diameter on the bed | mm | 800 | 1000 | 1250 |

| Maximum cutting diameter | mm | 720 | 900 | 1200 |

| Swing over cross slide | mm | 630 | 800 | 1000 |

| Distance between center | mm | 1000/1500/2000/3000 | 1000/1500/2000/3000 | 1500/3000 |

| Slant bed layout angle | – | 45 | 45 | 60 |

| Spindle nose type | – | ΦA2-11 | ΦA2-15 | A2-15 |

| Spindle bore taper | mm | 120 | 120 | 140 |

| Spindle bore | mm | 90 | 100 | 120 |

| Spindle speed steps | – | Hydraulic 2nd gear,Stepless | Hydraulic 2nd gear,Stepless | Electromagnetic 2nd gear,Stepless |

| Spindle speed range | r/min | 50-1000 | 50-800 | 50-630 |

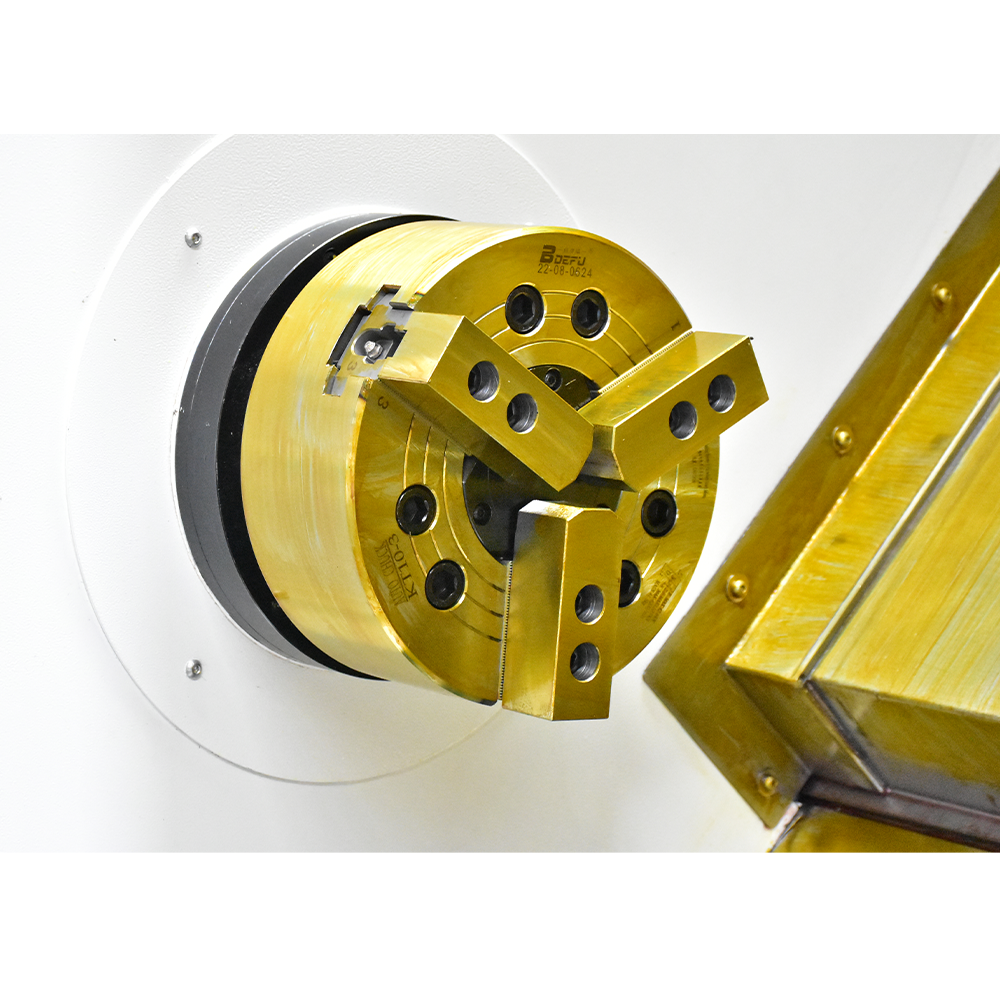

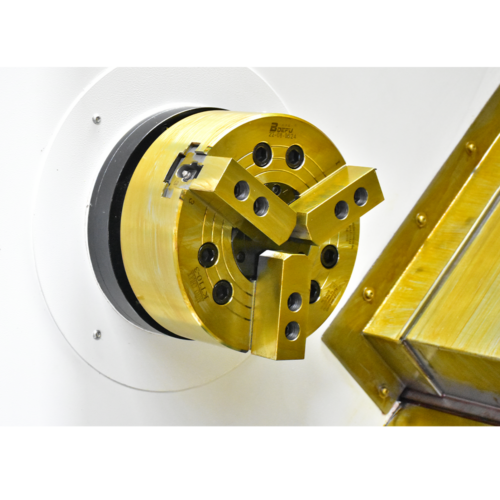

| Hydraulic chuck | in | 18 | 24 | 32 |

| Main spindle motor | kw | 30 | 37 | 37 |

| Turret /tool post | – | Hydraulic turret 12 position | Hydraulic turret 12 position | Hydraulic turret 12 position |

| Tool shank size | mm | 32×32 | 32×32 | 32×32 |

| Boring tool holder size | mm | Φ60 | Φ60/Φ80 | Φ80 |

| X axis travel | mm | 375 | 475 | 625 |

| Z axis travel | mm | 1000/1500/2000/3000 | 1000/1500/2000/3000 | 1000/1500/2000/3000 |

| Motor torque | Nm | 22/30 | 30/30 | 30/30 |

| X axis rapid traverse | mm/min | 12000 Hard guideway | 12000 Hard guideway | 10000 Linear guideway |

| Z axis rapid traverse | mm/min | 12000 Hard guideway | 12000 Hard guideway | 10000 Linear guideway |

| X/Z axis | mm | 0.001 | 0.001 | 0.001 |

| Tailstock quill diameter | mm | Φ120/170 | Φ120/170 | Φ130 |

| Tailstock quill taper | – | MT6 | MT6 | MT6 |

| Tailstock quill taper | mm | 120 | 120 | 150 |

| Coolant pump motor | kw | 0.37 | 0.37 | 0.37 |

| Finishing machining accuracy of outer circle | – | IT6 | IT6 | IT6 |

| Surface roughness of the outer circle of finishing car | μm | 0.8 | 0.8 | 0.8 |

| Width x Heigh | mm | 2570×2400 | 2570×2400 | 2570×2400 |

| Net weight | T | 8.5/12.5/16.5/20.5 | 105/15/18/20 | 18/35 |

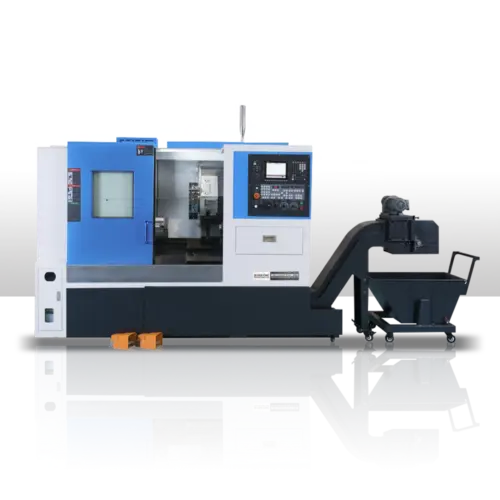

Advantages Of The CNC Slant Bed Lathe Machine

- The slant bed lathe adopts the turret method. It has fast tool-changing speed and high positioning accuracy.

- The Servo motor is used for feeding in X and Z directions. It can ensure positioning accuracy and repeated positioning accuracy.

- The slant bed CNC lathe adopts an advanced centralized automatic lubricating device. It can regularly quantitatively automate intermittent lubrication and provide stable and reliable work.

- CNC lathe adopts hydraulic chuck.

- The hydraulic tailstock is manually adjusted and locked. The hydraulic piston pushes the workpiece for processing.

- The BR-800 series is ideal for various industrial applications.

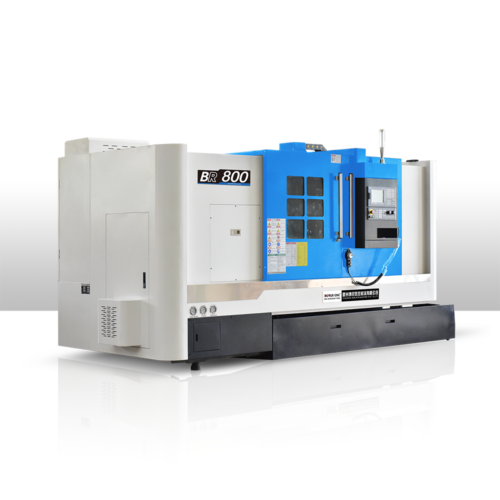

- To ensure precision and thermal stability, the headstock, tailstock, and saddle are all mounted on the same plane at 45°.

Reviews

There are no reviews yet.