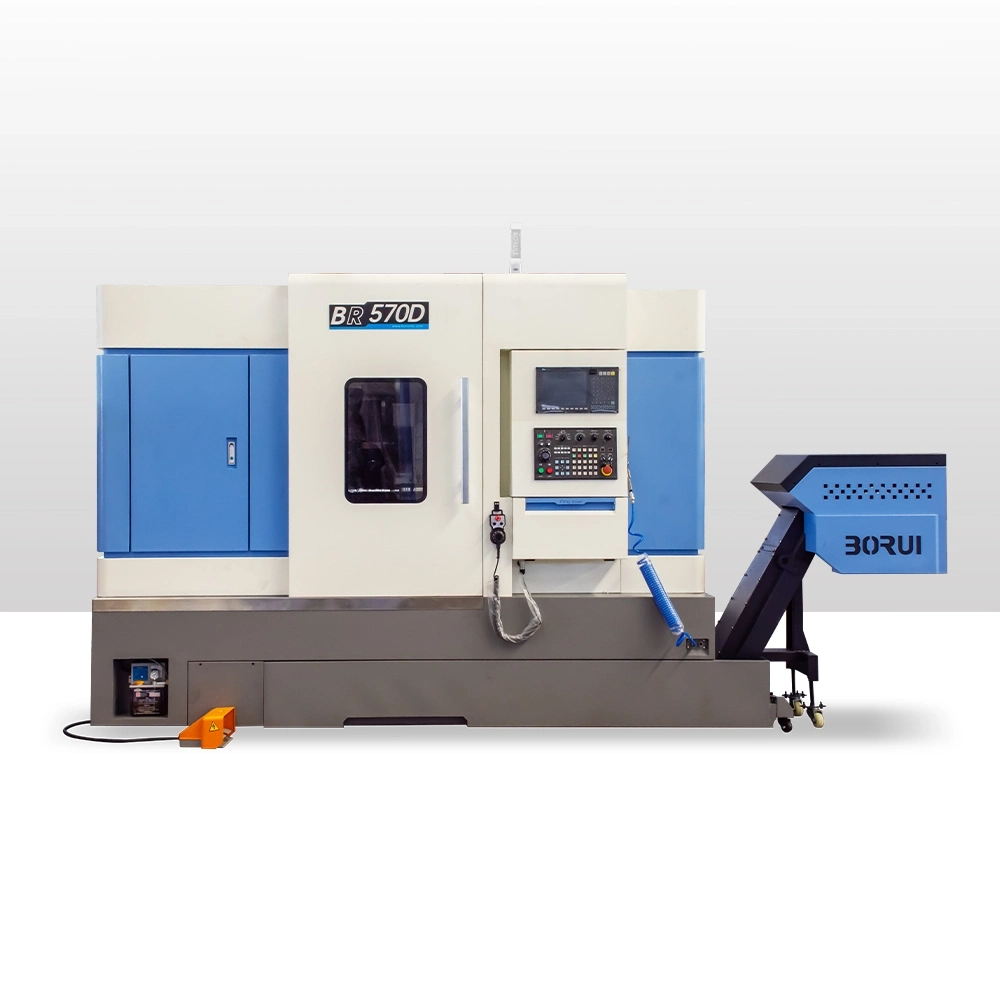

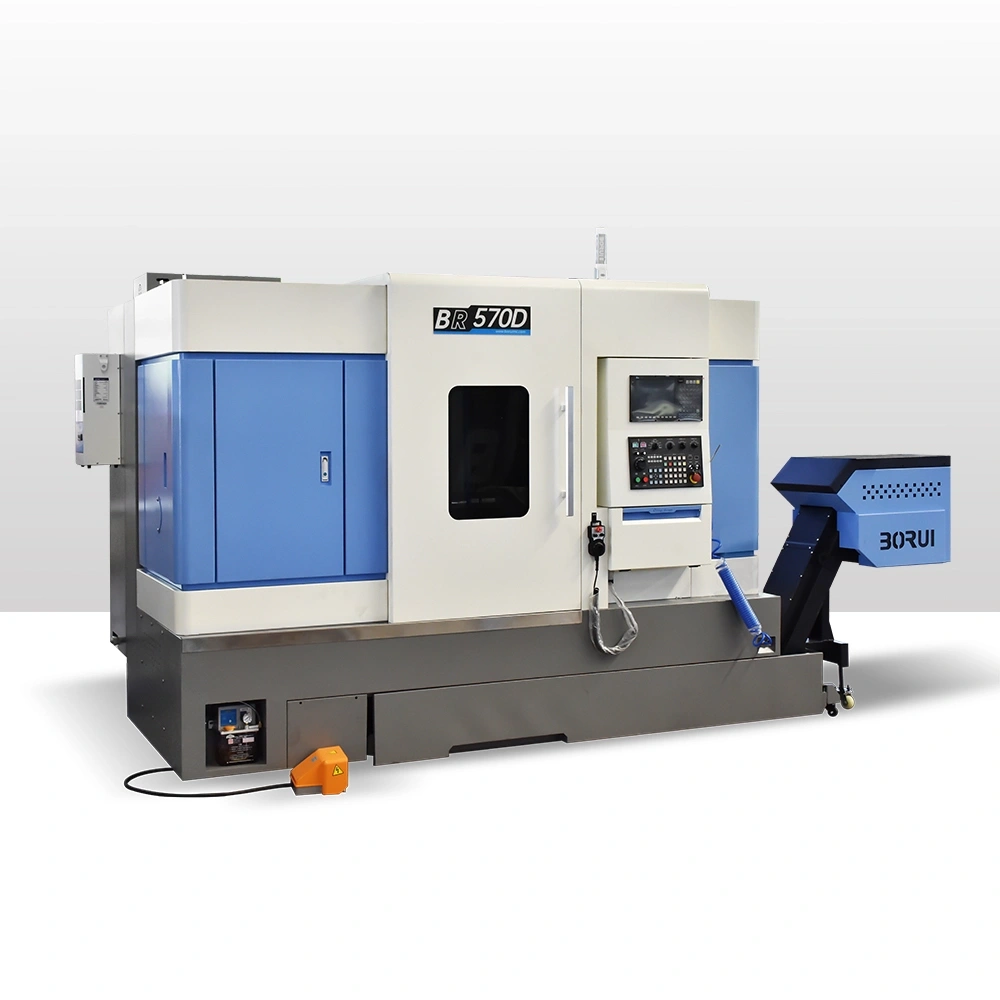

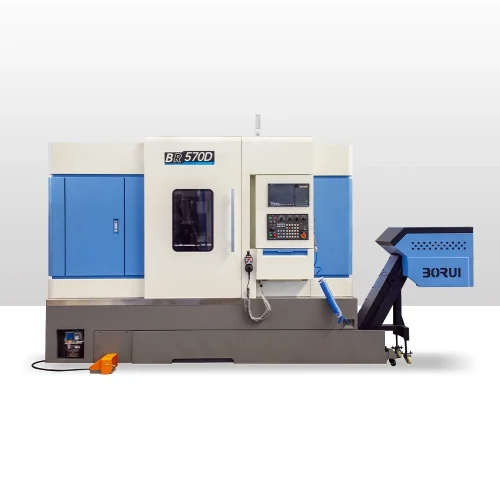

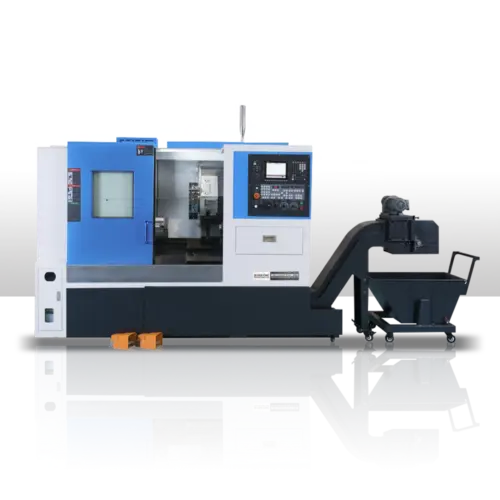

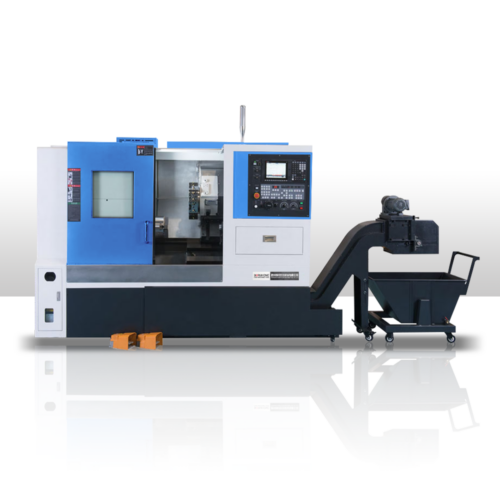

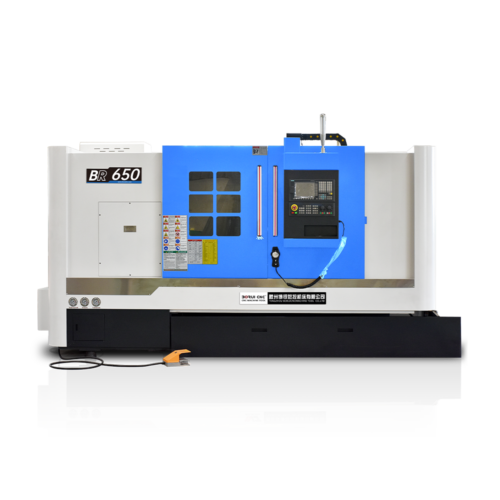

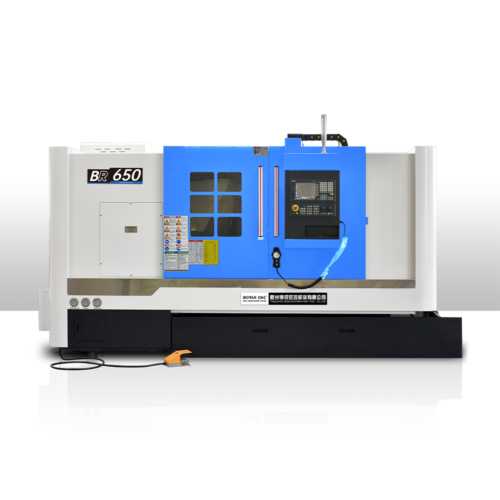

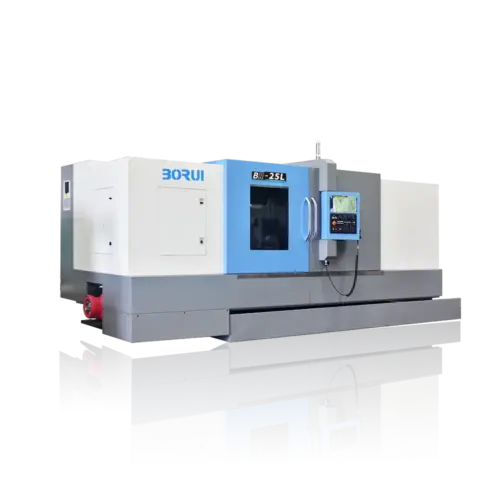

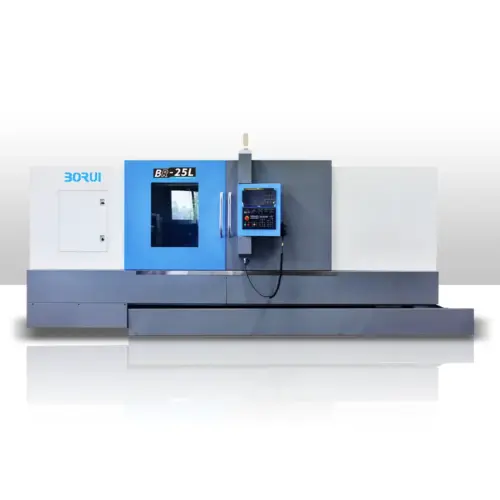

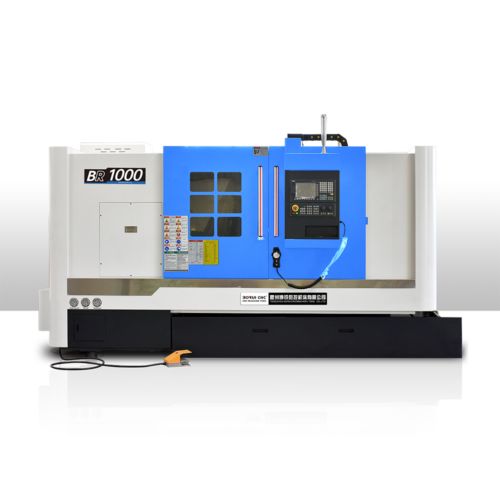

BR570D CNC Turning and Milling Center Features

- Rugged and Durable: The machine weighs 5000 kg and has a compact and sturdy structure, ensuring stability during high-speed machining.

- High-precision Machining: Supports three control axes (X, Z, C), provides advanced contour machining capabilities, and is suitable for high-precision operations.

- Medium and Heavy Machining Capabilities: The maximum turning diameter is 380 mm and the machining length is 750 mm, which meets the needs of medium and heavy machining.

- High-performance Spindle: Equipped with an A2-6 spindle, the speed reaches 4200 rpm, driven by an 11/15 kW main motor, and has strong power.

- Flexible Tool System: 12-station BMT55 turret, all stations are equipped with powered tools, with a speed of up to 5000 rpm, which improves machining flexibility.

- Efficient Clamping and Support: Equipped with an 8-inch hydraulic three-jaw chuck and a programmable tailstock with MT5 taper, further enhancing flexibility.

- Advanced Control System: Adopts FANUC 0i TF CNC system, supports USB interface and MPG handwheel, and is easy to operate.

- Automation Support: Equipped with automatic lubrication device, chip conveyor, tool cooling system, tool presetter and safety protection device to improve productivity.

- Compact Design: The compact appearance is suitable for complex and demanding processing tasks to meet the needs of the modern metal processing industry.

Technical Parameters

| SPECIFICATIONS | BR570D-520/750/1000 | |||||||

|---|---|---|---|---|---|---|---|---|

| Swing over bed | Φ650 | |||||||

| The max swing diameter overslide | Φ380 | |||||||

| Maximum machining diameter on the tool holder | Φ380 | |||||||

| Maximum processing length | 480/700/950 | |||||||

| Spindle head form(optional chuck) | A2-6 ( 8″ )/A2-8(10″) | |||||||

| Recommended spindle motor power |

11-15KW | |||||||

| Spindle maximum speed | 4200/3500rpm | |||||||

| Spindle hole diameter | 66/86 | |||||||

| Bar diameter | 52/72 | |||||||

| X axis screw specifications | 3210 | |||||||

| Z axis screw specifications | 4010 | |||||||

| Y axis screw specifications | – | |||||||

| X axis limit travel | 260 | |||||||

| Z axis limit travel | 610/830/1050 | |||||||

| Y axis limit travel | – | |||||||

| Recommended X/Z axis motor torque | 11N.M/15N.M | |||||||

| X/Z axis rail specifications | 45/45 | |||||||

| X/Z axis connection mode | Direct | |||||||

| Optional turret (special configuration) |

12T power turret BMT45/55 | |||||||

| Recommended turret center height dimension |

100/170/170 | |||||||

| Socket diameter | 80 | |||||||

| Socket travel | 80(Opt.150) | |||||||

| Maximum travel of tailstock | 500 | 380 | 500 | 750 | 630 | 600 | 1000 | 930 |

| Screw linear rail or linear rail cylinder specifications | – | 3205/35 | 35 /HOB- 50 |

– | 3205/35 | 35 /HOB- 50 |

– | 3205/35 |

| Recommended motor torque | – | 8N.M | – | – | 11N.M | – | – | 11N.M |

| Tailstock sleeve tapered hole | MT5 | |||||||

| Machine size(L * W * H) | 2800×1870×1950/3000×1870×1950/3360×1870×1950 | |||||||

| Weight (approx. weight) | 3700kg/4200kg/5000kg | |||||||

Product Detail Display

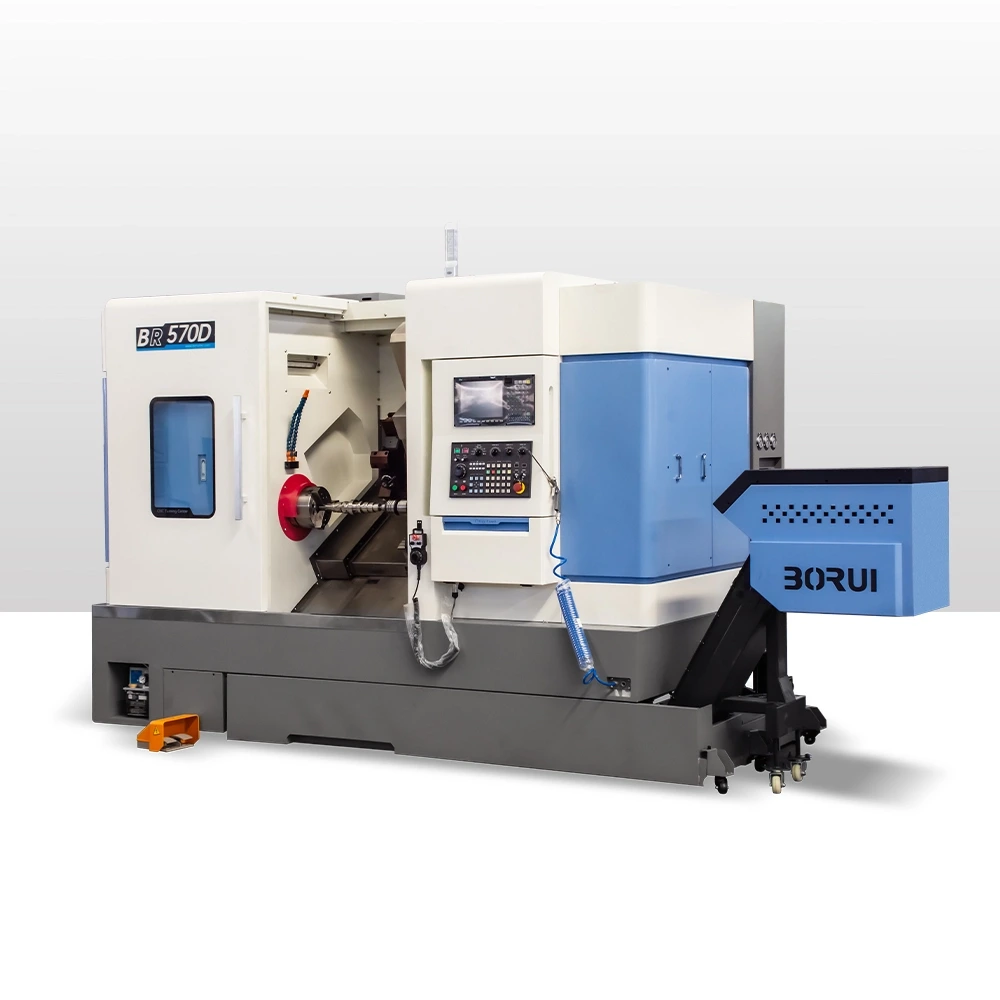

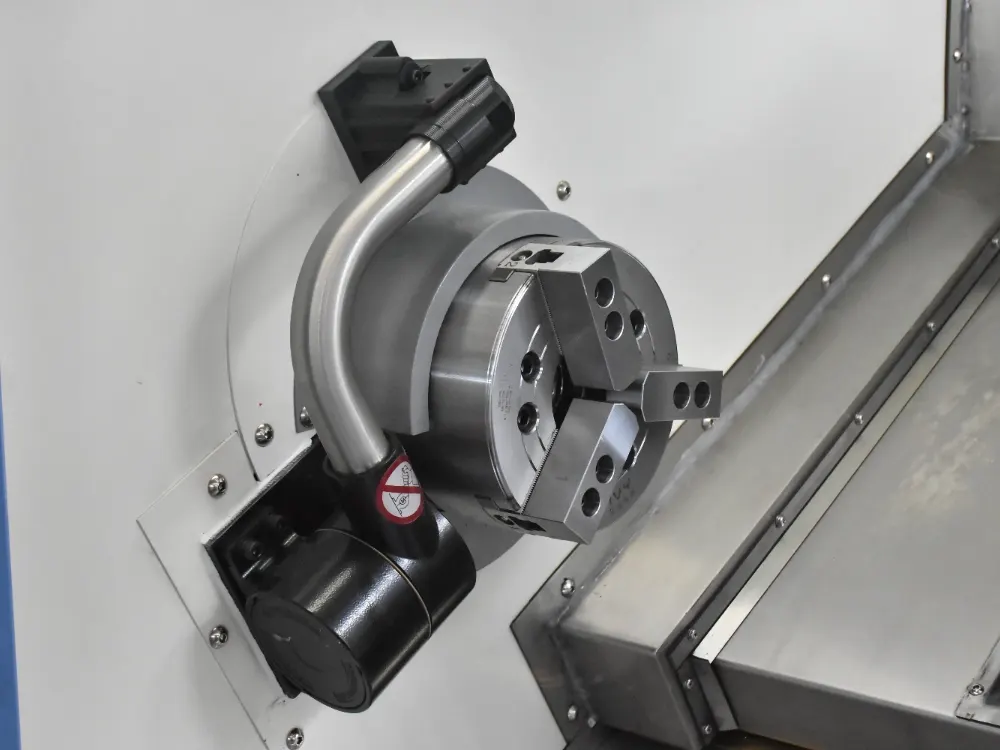

Chuck

- Standard hydraulic three-jaw chuck optional hydraulic four-jaw chuck;

- Workholding and tightening;

- High rigidity cast iron for long service life.

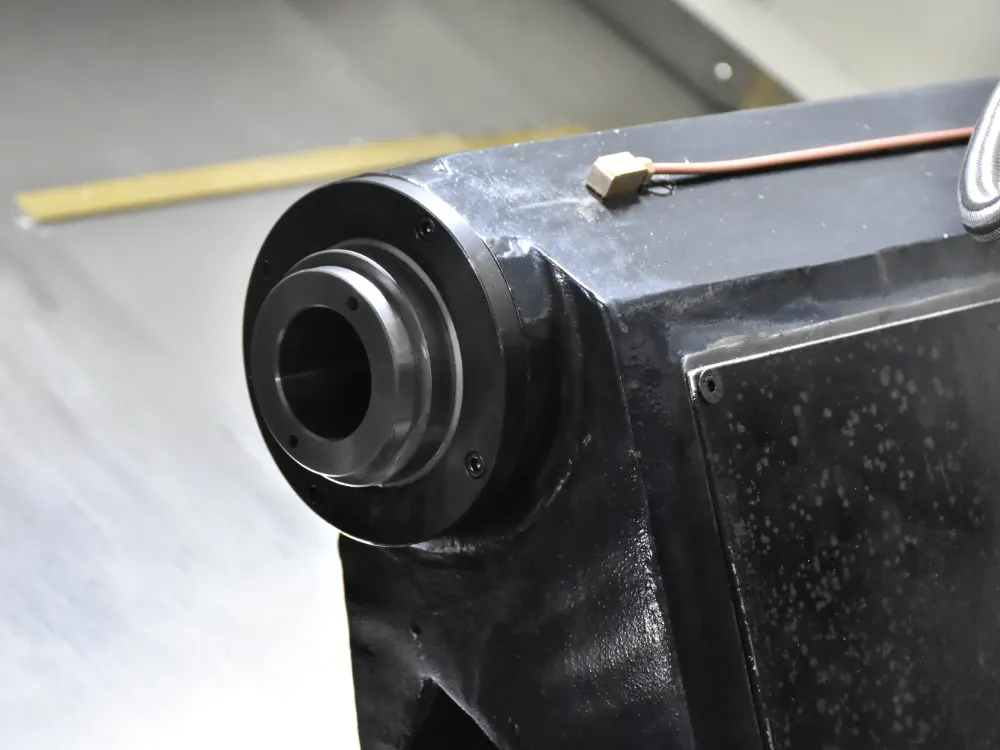

Spindle Box

The integrated assembled spindle adopts a high-rigidity bearing structure to ensure axial and radial forces.

Tool Setting Arm (Optional)

Significantly improve machine tools’ machining efficiency and accuracy, and reliably detect tool breakage.

Tool Turret

Standard hydraulic servo tool turret Optional:

- Power tool turret

- WithYaxispowertoolturret

- VDI Power tool turret

Tailstock

High-precision lead screw guide rail; Medium frequency quenching and precise scraping ensure the rigidity of the machine tool.

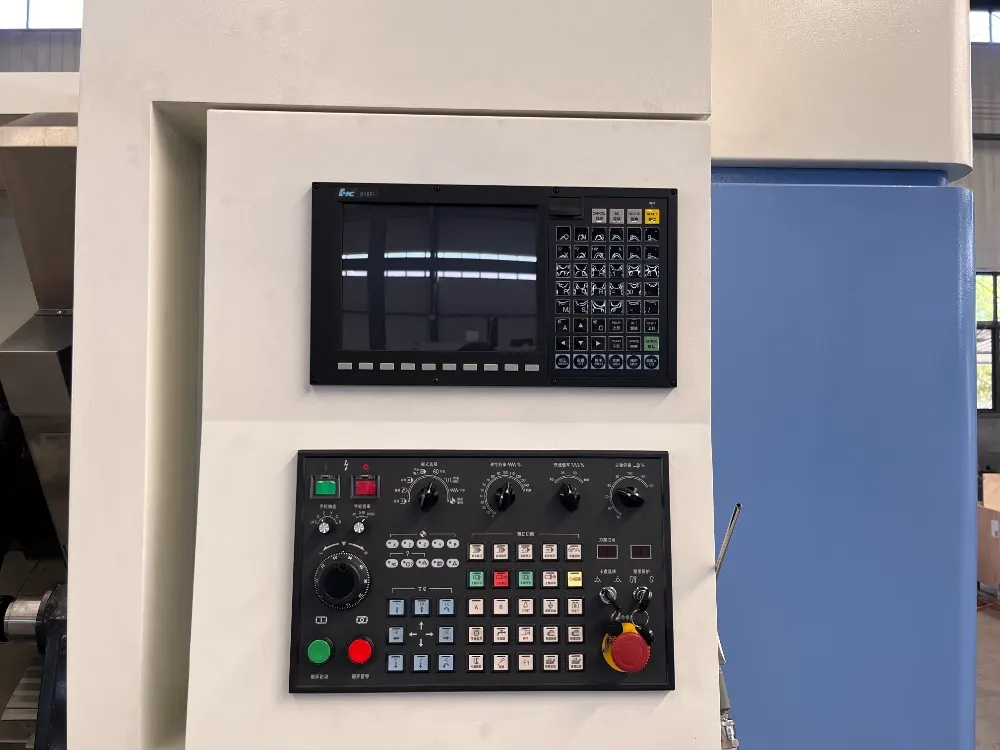

Advanced System

SIEMENS, KND, FANUC, MITSUBISHI, GSK, and other operating systems can be selected according to customer requirements.

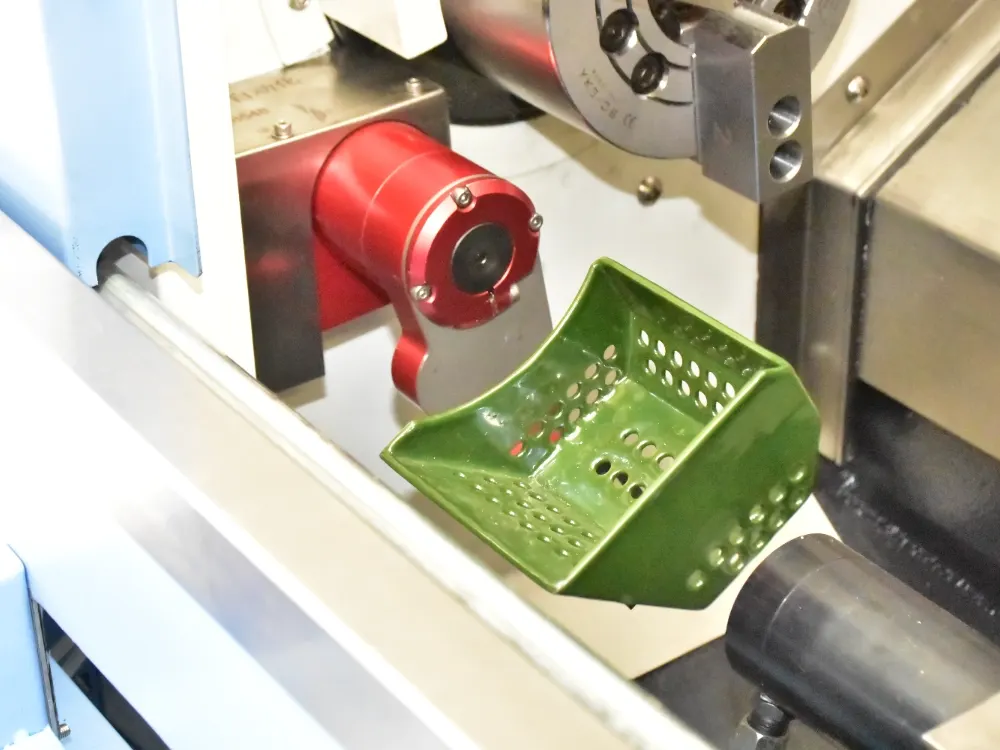

Automatic Parts Catcher (Optional)

A CNC lathe parts catcher can solve the blanking and splicing of

Automatic processing cooperates with the automatic bar feeder to realize automatic processing.