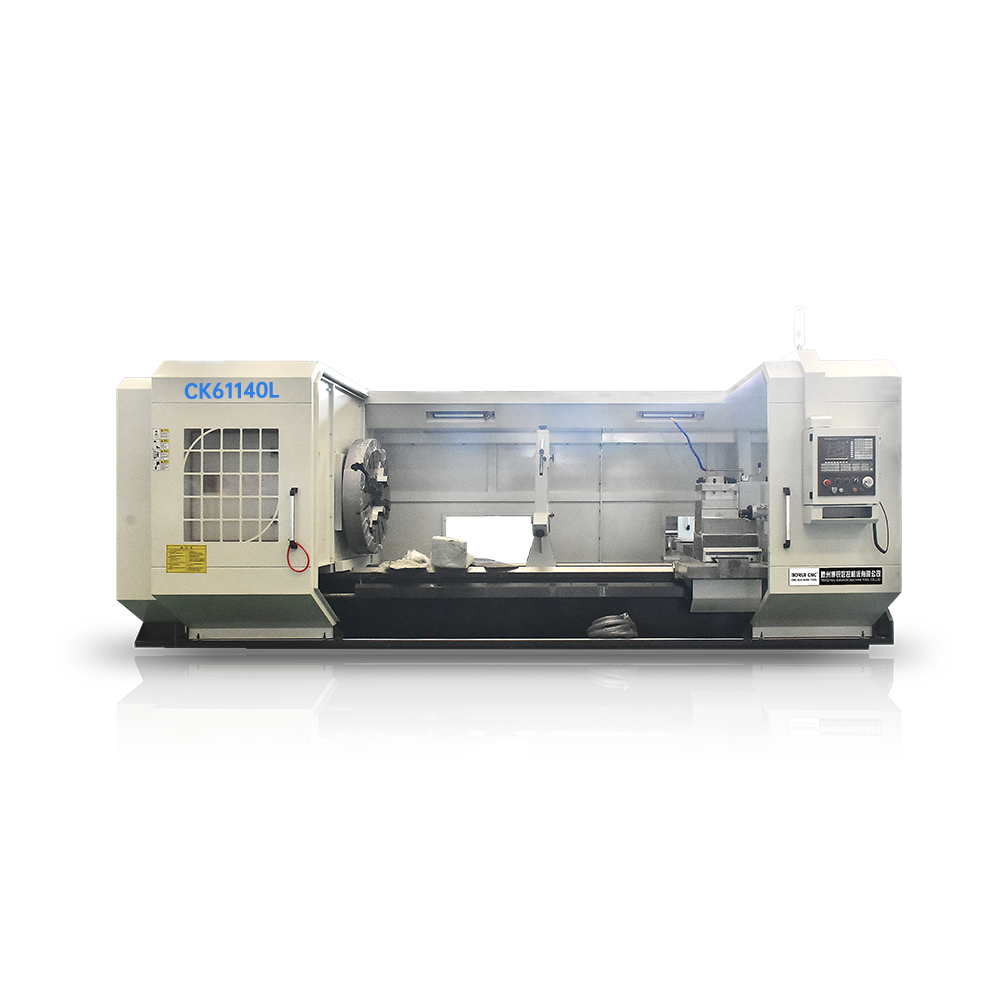

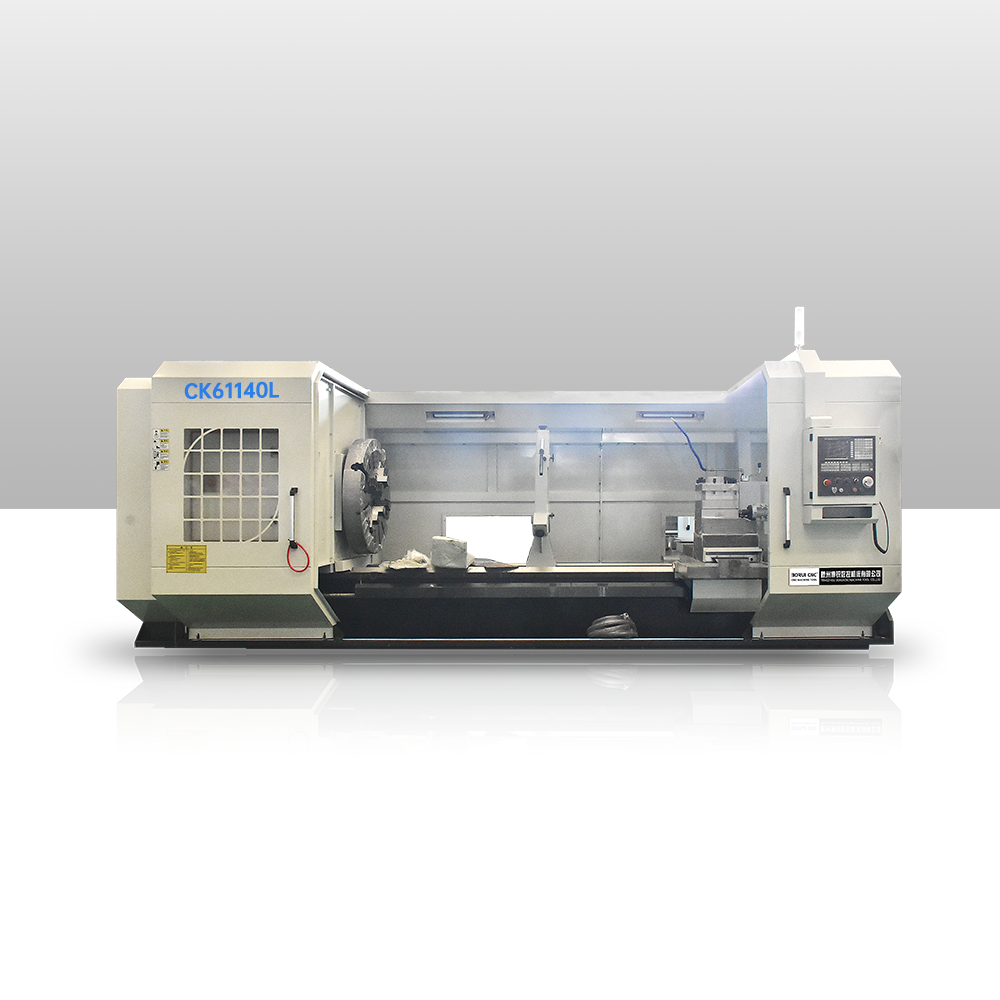

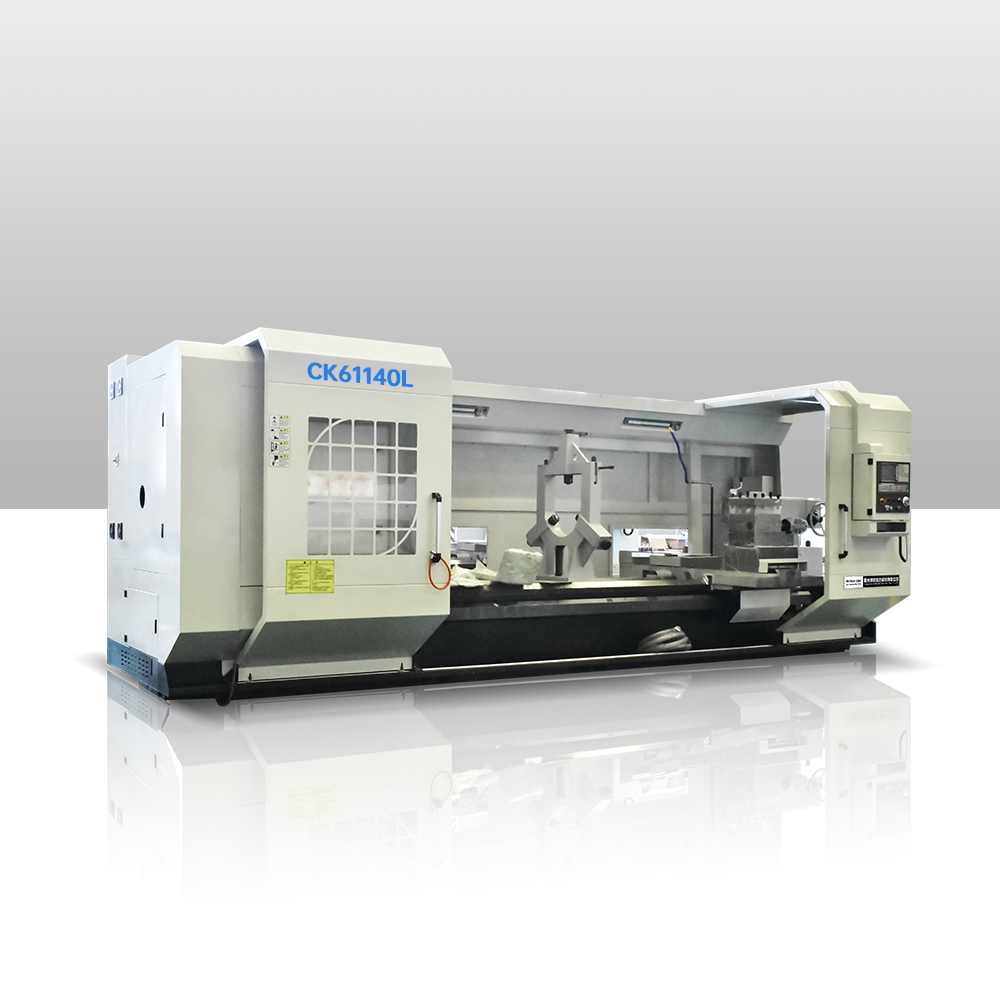

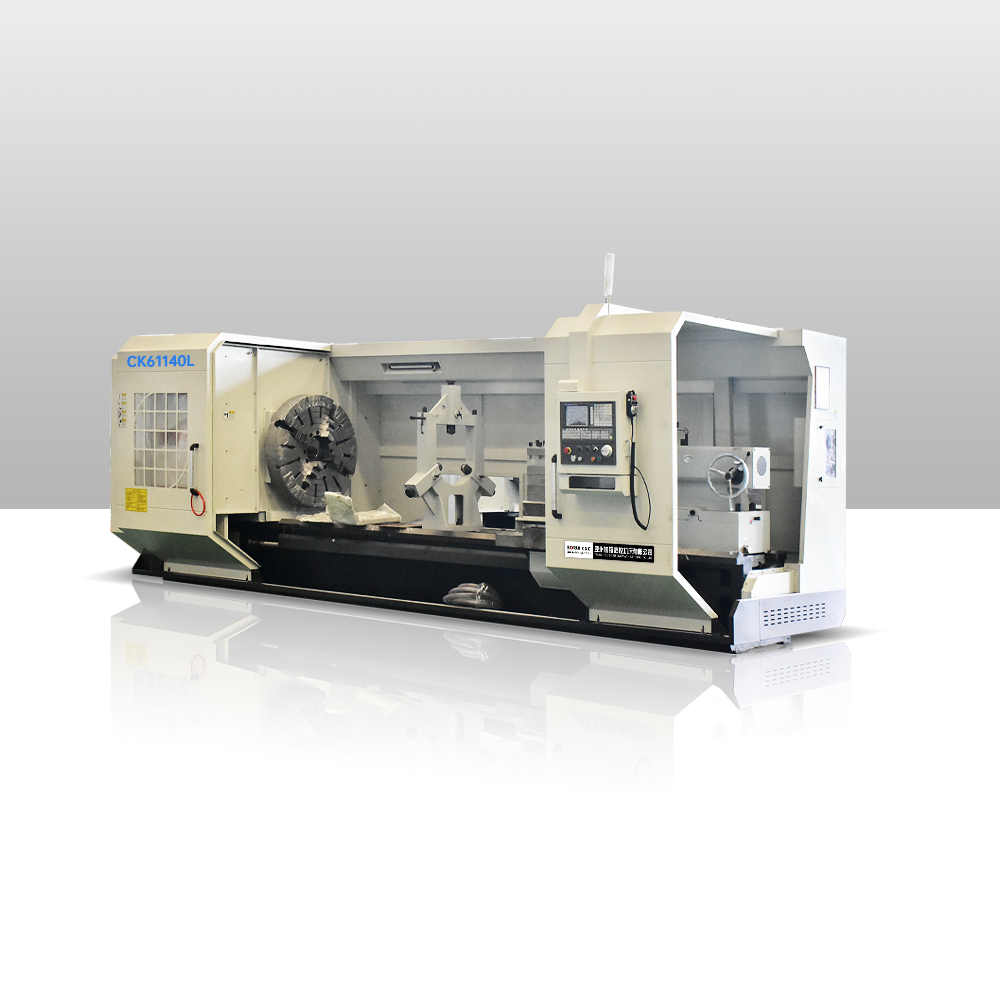

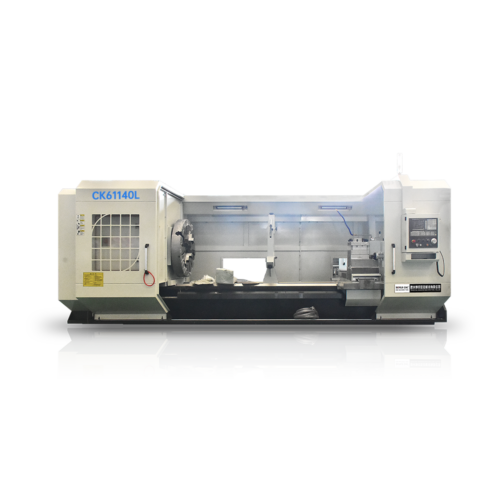

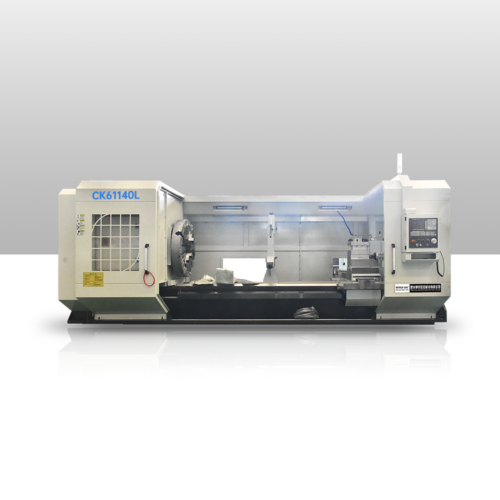

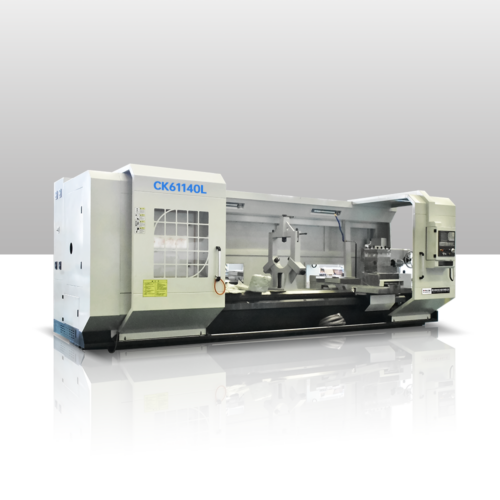

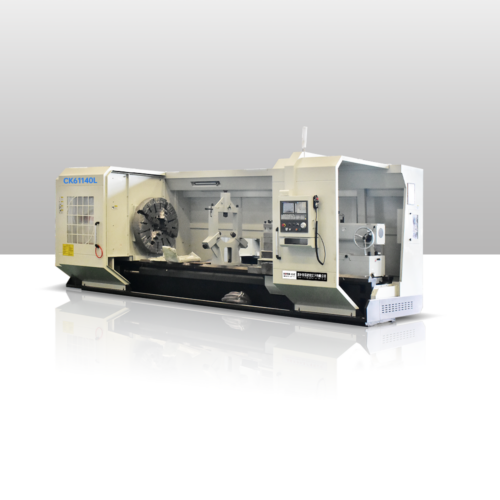

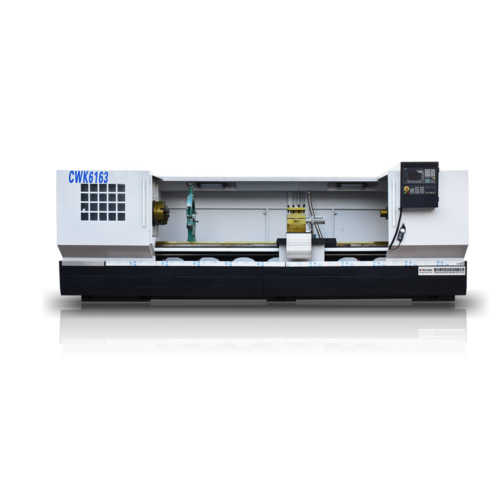

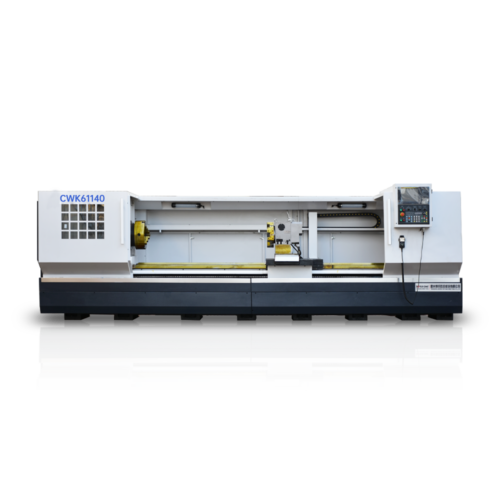

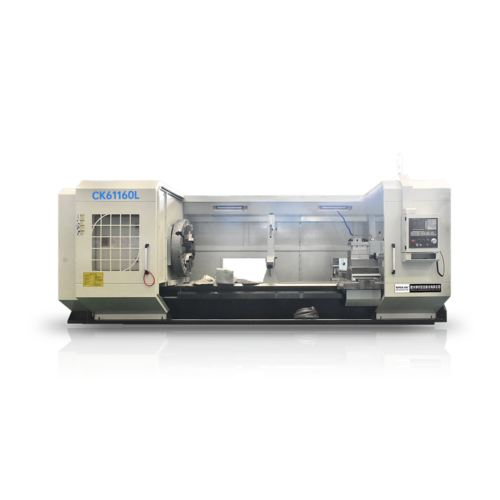

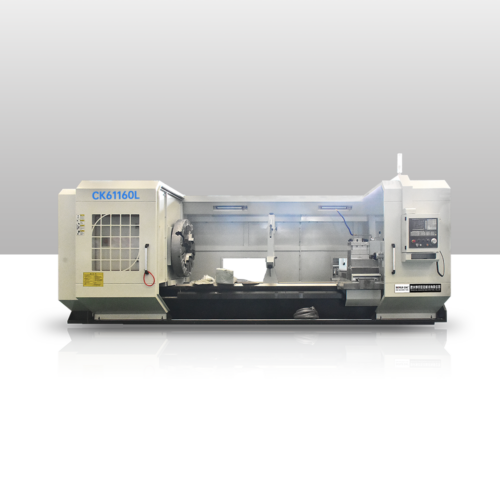

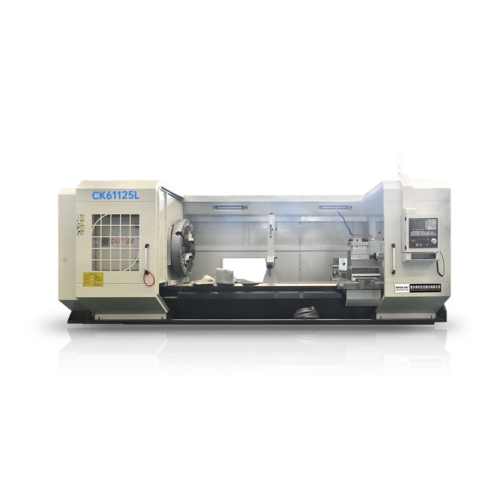

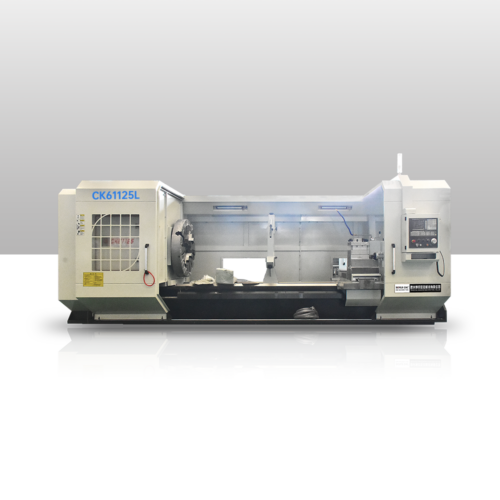

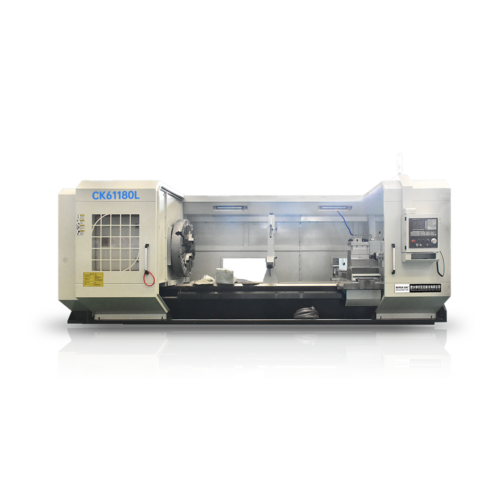

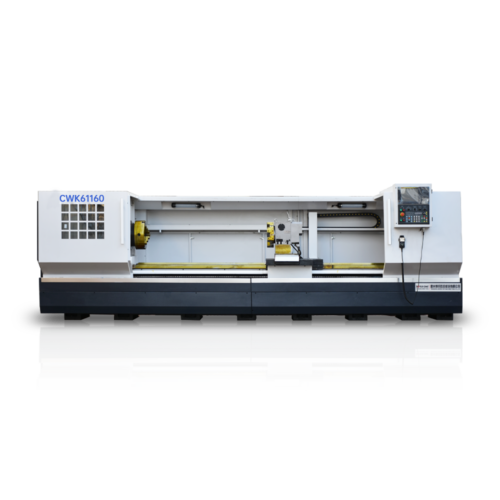

Advantages Of CNC Flat Bed Lathe Machine:

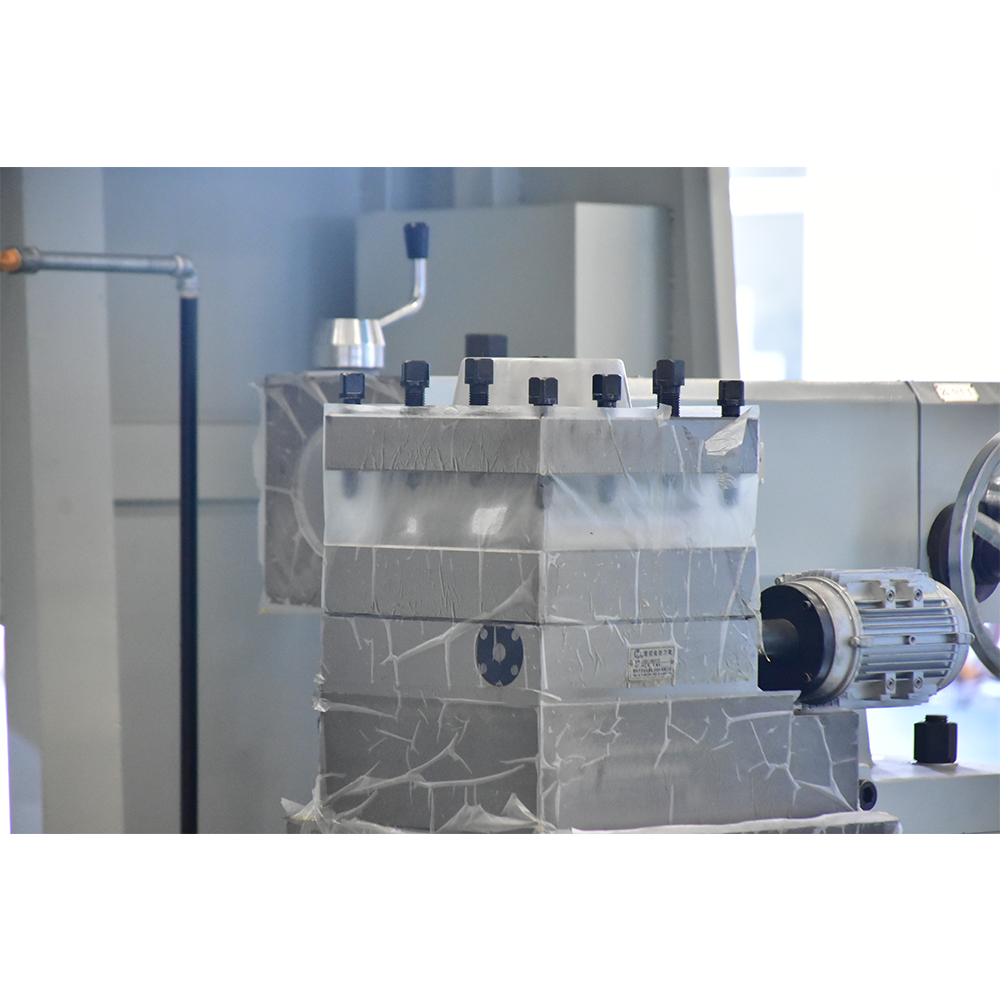

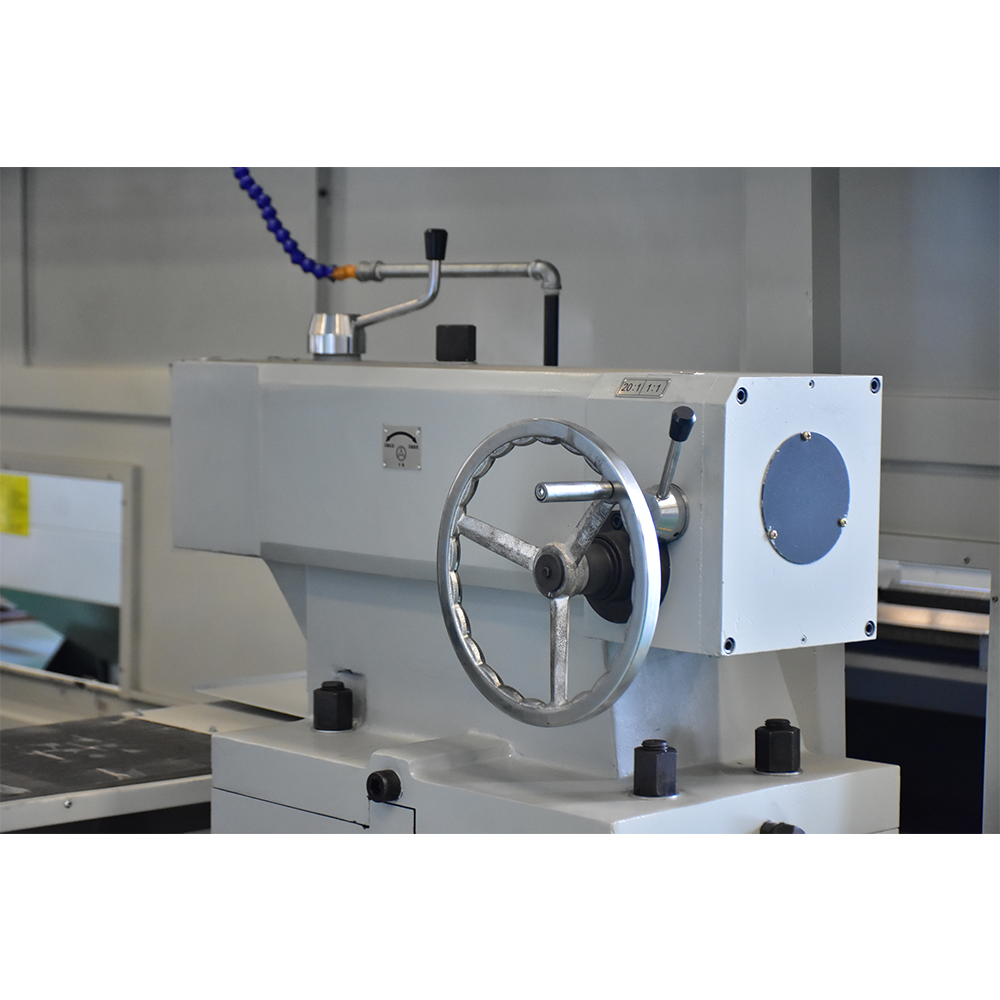

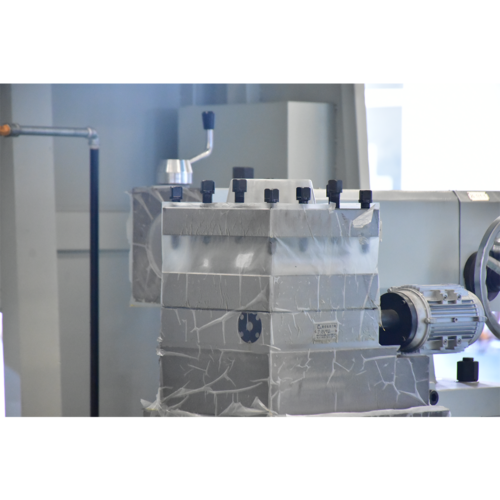

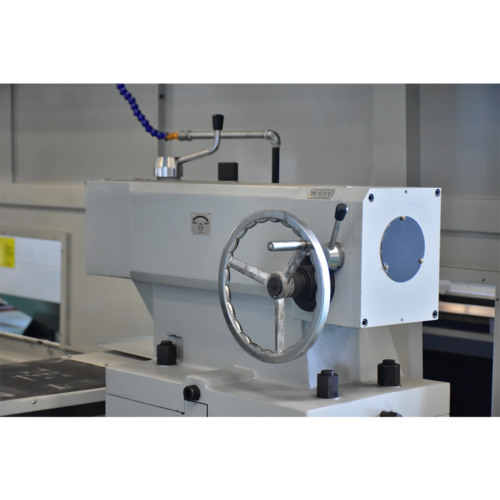

- Manual scraping and grinding between the joint surfaces of the bedside box, the bed, the tailstock, and the pallet.

- CK61140Lis detected by laser interferometer, which effectively guarantees the positioning accuracy of Z-axis and X-axis, and repeats the positioning accuracy.

- CK61140Ltool is made of high-strength cast iron.

- Effectively improve the wear resistance and stability of the machine tool.

- The gear of the machine tool adopts precision grinding, which effectively improves the hardness of the gear and reduces the noise of the machine tool.

- CK61140L tool adopts northern ball screw, Z-axis ball screw, and X-axis ball screw adopts tensile structure.

- Improve the accuracy of machining the outer circle and inner hole dimensions of the workpiece.

- Spindle box gears are fully ground, with high precision.

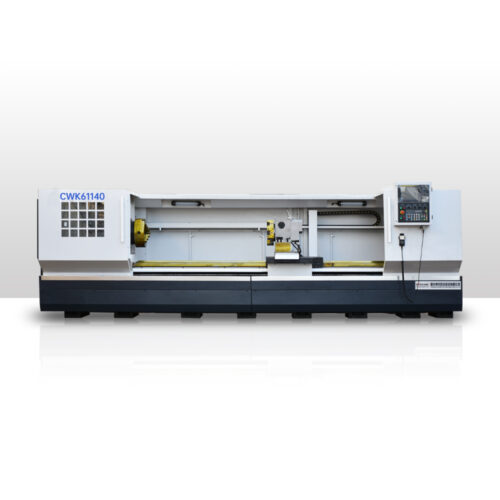

Product Main Technical Parameters:

| SPECIFICATION | UNIT | CK61140L |

|---|---|---|

| Swing over bed | mm | 1500 |

| Swing over cross slide | mm | 1050 |

| Distance between centers | mm | 3000-10000 |

| Guideway width | mm | 1100 |

| Max. load capacity | T | 10 |

| Spindle bore | mm | 100 |

| Spindle bore taper | – | Metric φ120 |

| Spindle nose type | – | 1:30 |

| Spindle speed steps | – | VF. 4steps |

| Spindle speed range | rpm | 10-300 |

| Chuck | mm | φ1250 4-jaw manual |

| Turret/tool post | – | NC turret 4 position |

| Tool shank size | mm | 50 x540 |

| X axis travel | mm | 750 |

| Z axis travel | mm | 3000-10000 |

| X axis rapid traverse | mm/min | 4000 |

| Z axis rapid traverse | mm/min | 6000 |

| Tailstock quill diameter | mm | Φ260 |

| Tailstock quill taper | – | Metric 80 |

| Tailstock quill travel | mm | 300 |

| Main spindle motor | kW | 30 |

| Coolant pump motor | kW | 0.25 |

| Width x Height | mm | 2600 x 2050 |

| Length | mm | 6700-13700 |

| Net weight | T | 23.6-29.9 |

Reviews

There are no reviews yet.