Features

- Servo spindle motor&driver

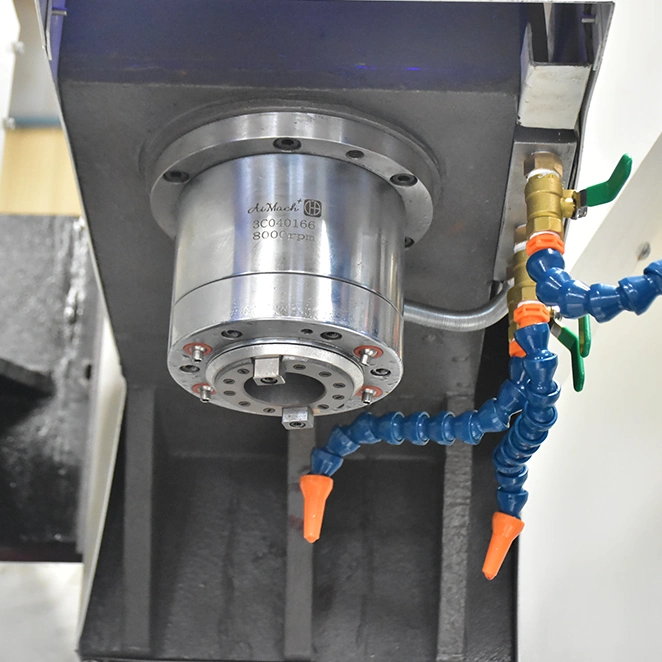

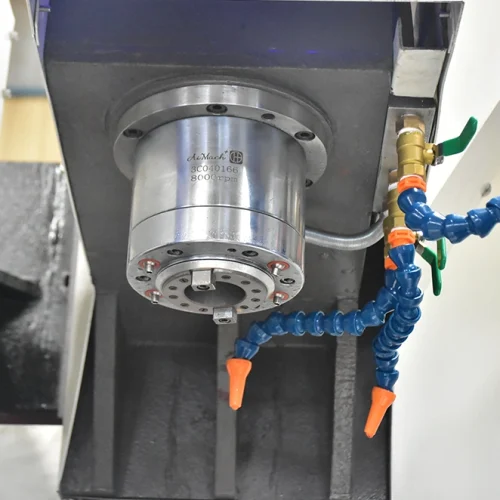

- Taiwan-made spindle unit, 8000, 10000 rpm speed available.

- Umbrella type 16T ATC can be chosen.

- Reliable control systems: Fanuc, Siemens, Mitsubishi, GSK.

- Systems can be selected according to customer requirements.

- Automatic central lubrication system.

- Full protection

- Three-axis lubricating system

- Separate hand-wheel

- Machine tool lighting work light

- Random technology document

- Spindle cone Hole cleaning air

- Electric cabinet cooling and heat exchanger

- Cleaning air gun

- Chip storage tank

- Servo transformer

- Foundation pad iron and adjusting bolt

Advantages Of CNC Milling Machine

- Straight line and circular arc cutting: It can complete the fine milling of straight line and circular arc at any angle, and multi-point drilling and tapping.

- Backlash-free transmission: The ball screw drive with preload is adopted, greatly improving speed and accuracy.

- Protection: A protection system suitable for processing and teaching, electronic timing, and strong lubrication to prevent artificial lack of oil on the track surface.

- Backlash-free transmission: The ball screw drive with preload is adopted, greatly improving speed and accuracy.

- Protection A protection system suitable for processing and teaching, electronic timing and strong lubrication to prevent artificial lack of oil on the track surface.

- High reliability: The body casting technology is advanced, and the aging treatment technology is adopted, and the casting label reaches the national standard.

- CNC control system: The standard configuration provides many CNC functions to achieve high-speed and high-precision four-axis motion control.

Technical Parameters

| Specifications | XK7136 |

|---|---|

| Table size(mm) | 1250×360 |

| X axis travel(mm) | 860 |

| Y axis travel(mm) | 450 |

| Z axis travel(mm) | 550 |

| Max. worktable load(kg) | 460 |

| T slot(number-width-pitch) (mm) | 3-18×80 |

| Max. spindle speed(rpm) | 10000 |

| Spindle taper | BT40 |

| Main motor power(kw) | 5.5 |

| X/Y/Z rapid traverse speed(m/min) | 20/20/20 |

| Cutting feed speed(m/min) | 1-6000 |

| Guide rail type | Hard rail |

| Distance from spindle axis to column surface(mm) | 465 |

| Distance between spindle nose and worktable surface(mm) | 100-600 |

| Positioning accuracy(mm) | ±0.008 |

| Repeat positioning accuracy(mm) | ±0.005 |

| Machine weight(kg) | 3000 |

| Overall dimension(mm) | 2380×1900×2350 |

| Max.tool weight(kg) | 18 |

| Overall dimension(mm) | 3000×2300×25500 |

Reviews

There are no reviews yet.