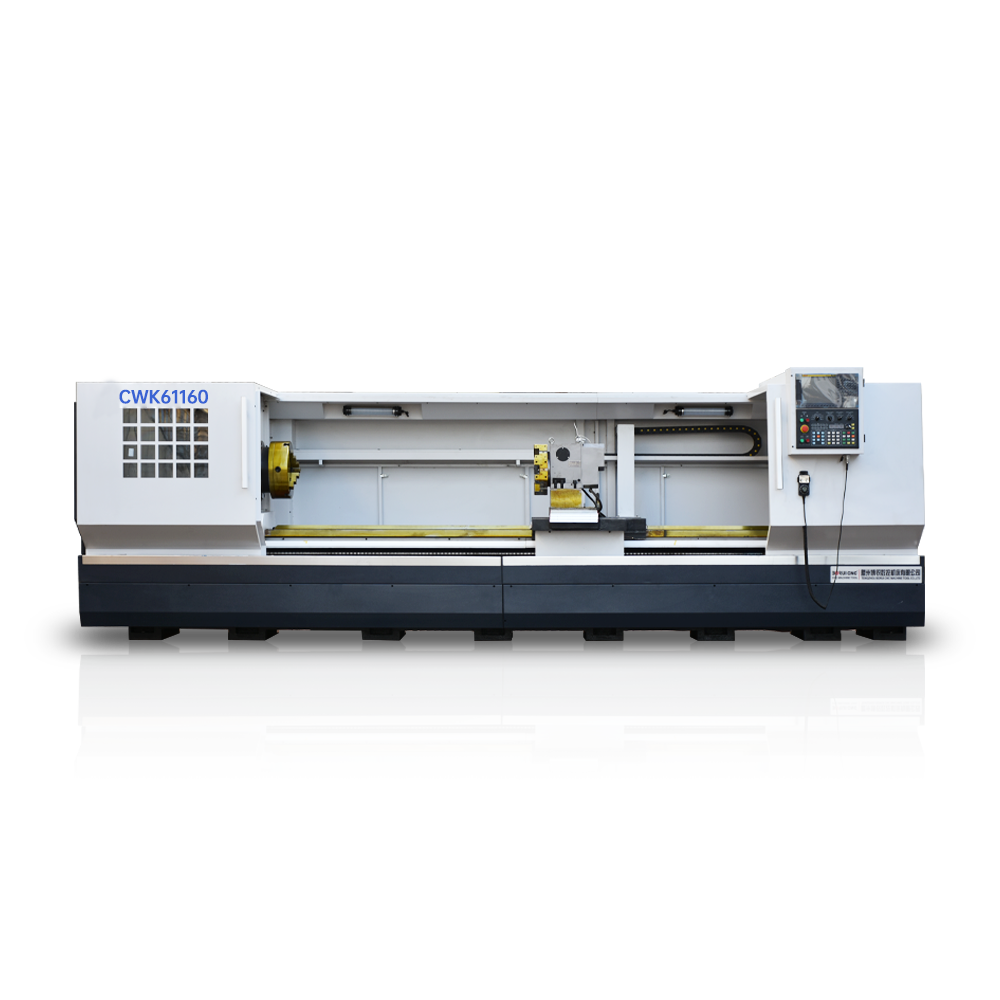

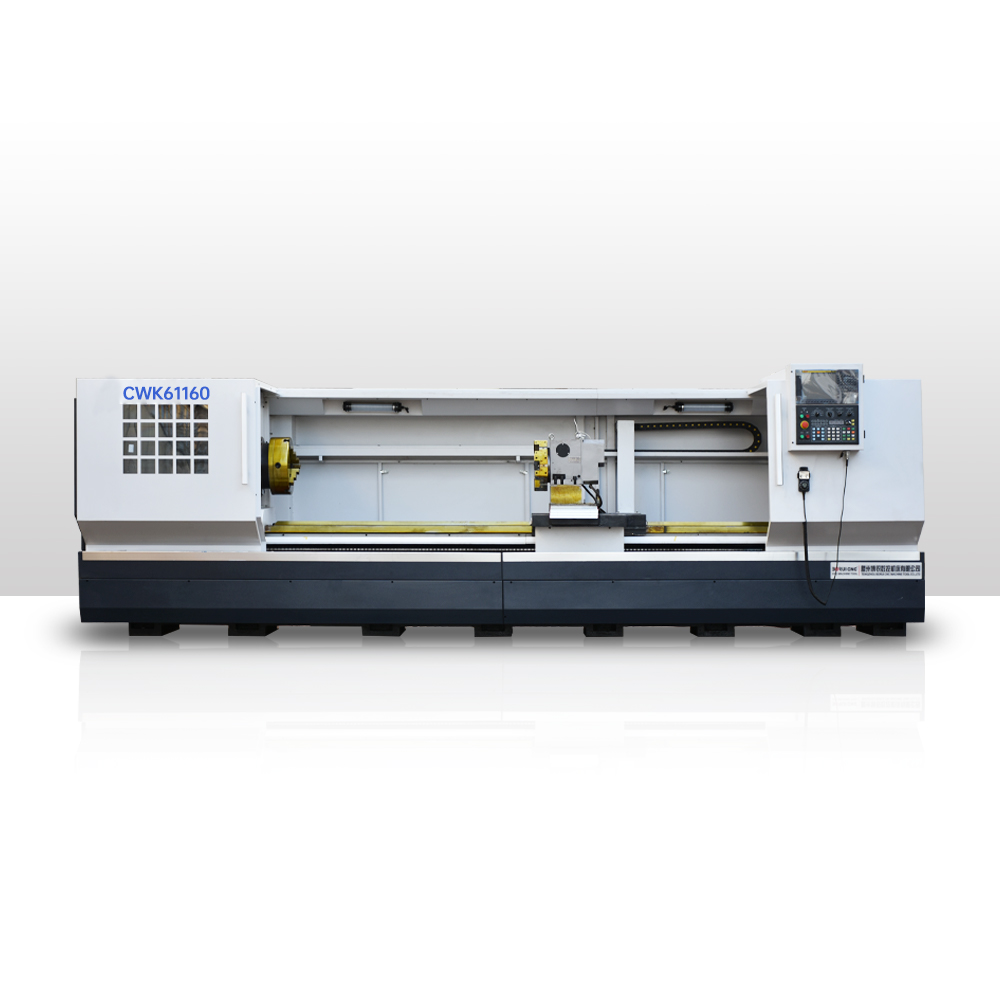

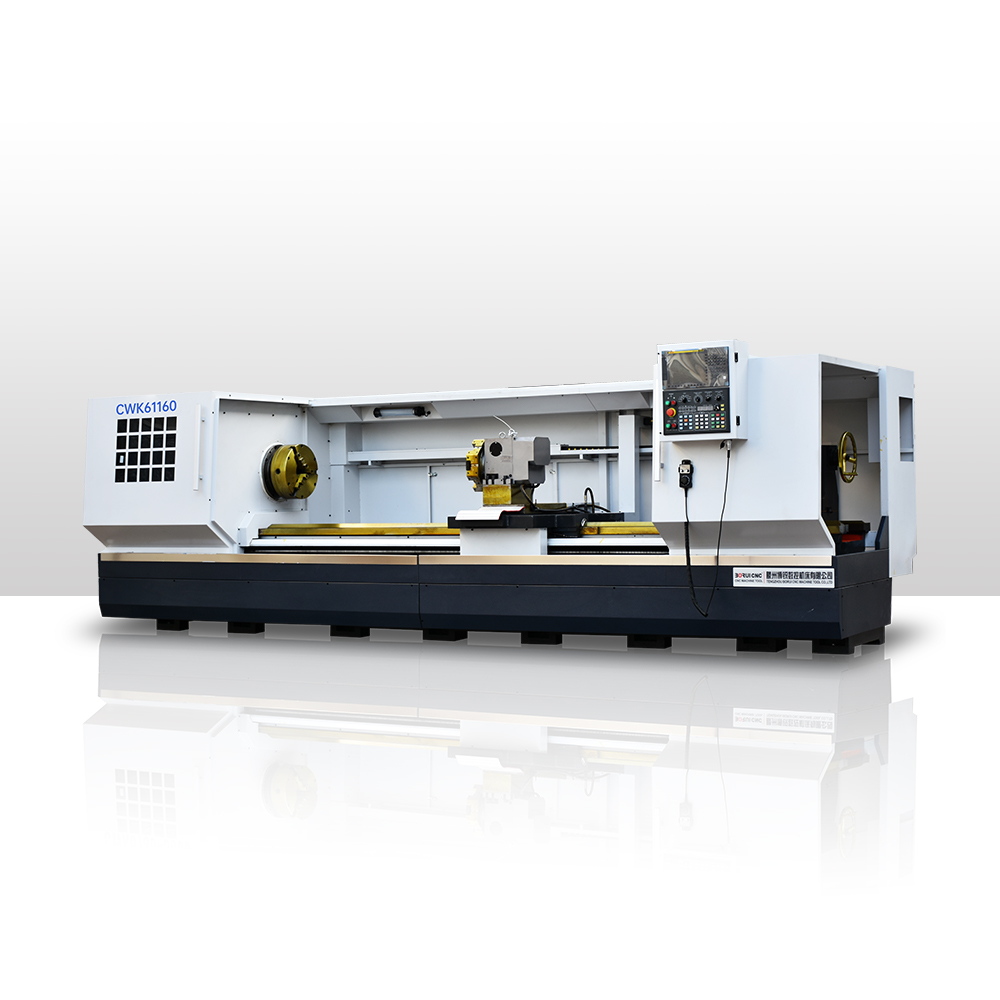

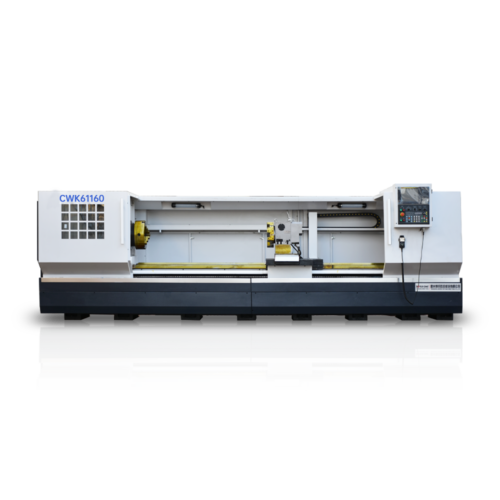

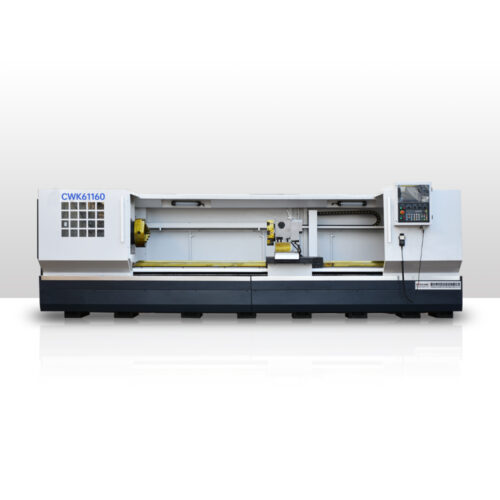

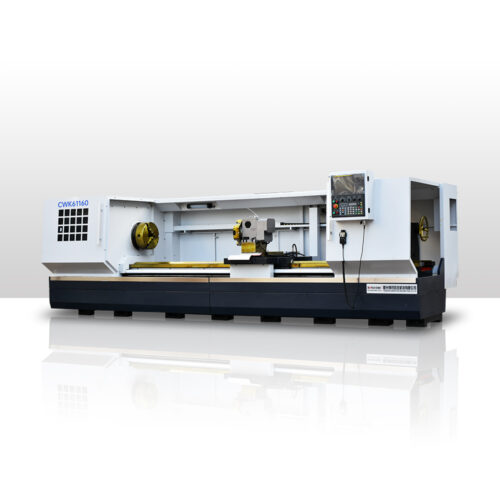

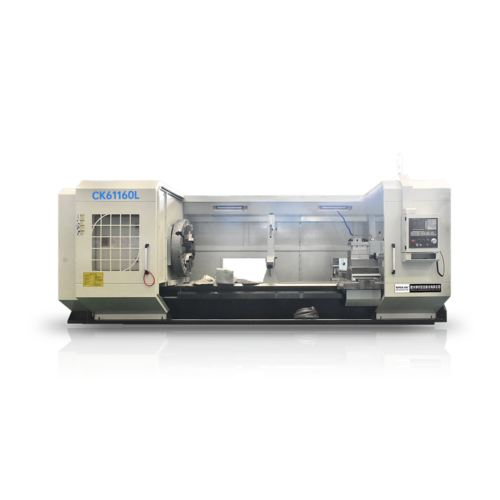

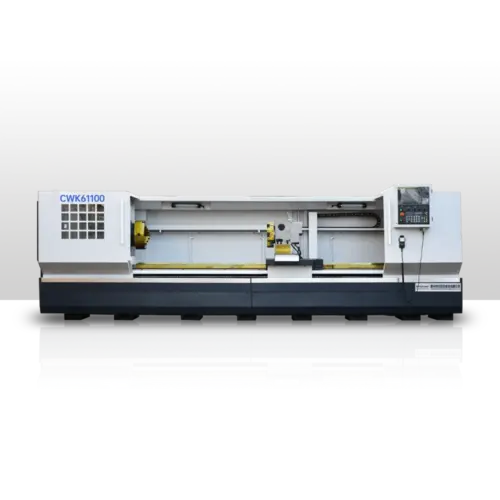

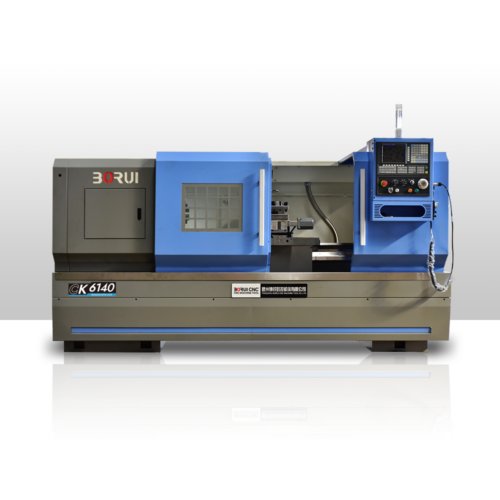

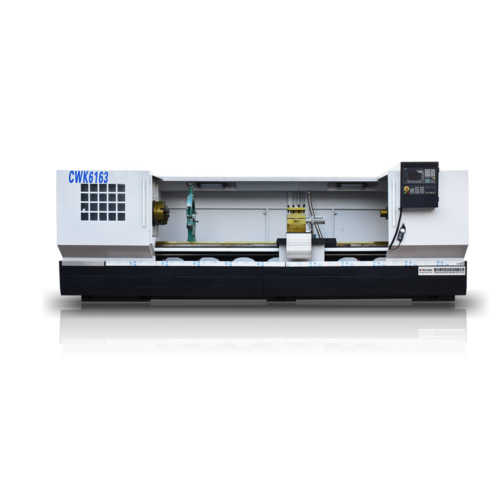

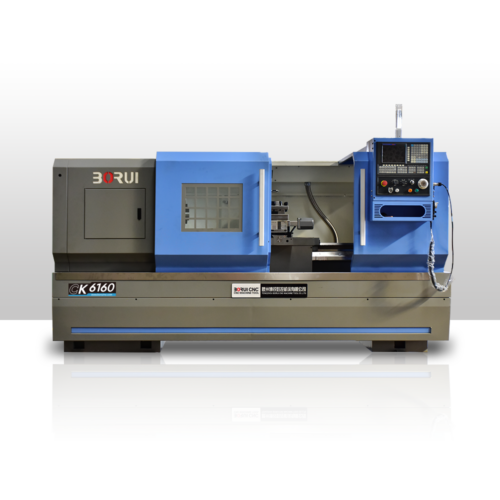

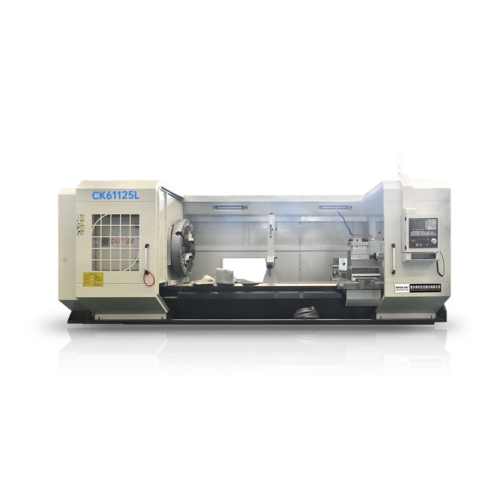

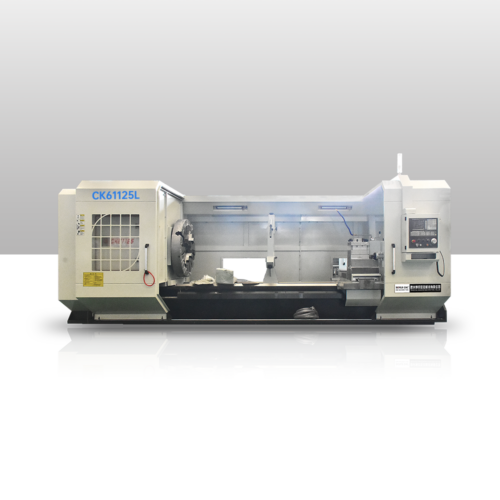

Advantages Of Heavy Duty CNC Flat Bed Lathe Machine:

- Adopt flat bed structure, resin sand molding, high quality cast iron.

- The guide rail adopts medium frequency quenching grinding and plastering process, which has good wear resistance and accuracy preservation.

- Each transmission pair and rolling bearing are lubricated by strong oil, with good high speed and low temperature rising performance.

- The design of the headstock box takes full account of heat dissipation measures and shock absorption mechanism, so that the main axle box has low noise.

- The characteristics of high transmission precision, machine noise does not exceed the national standard value.

- The control system is fully functional and meets the needs of many industries.

- The main drive system has been carefully optimized.

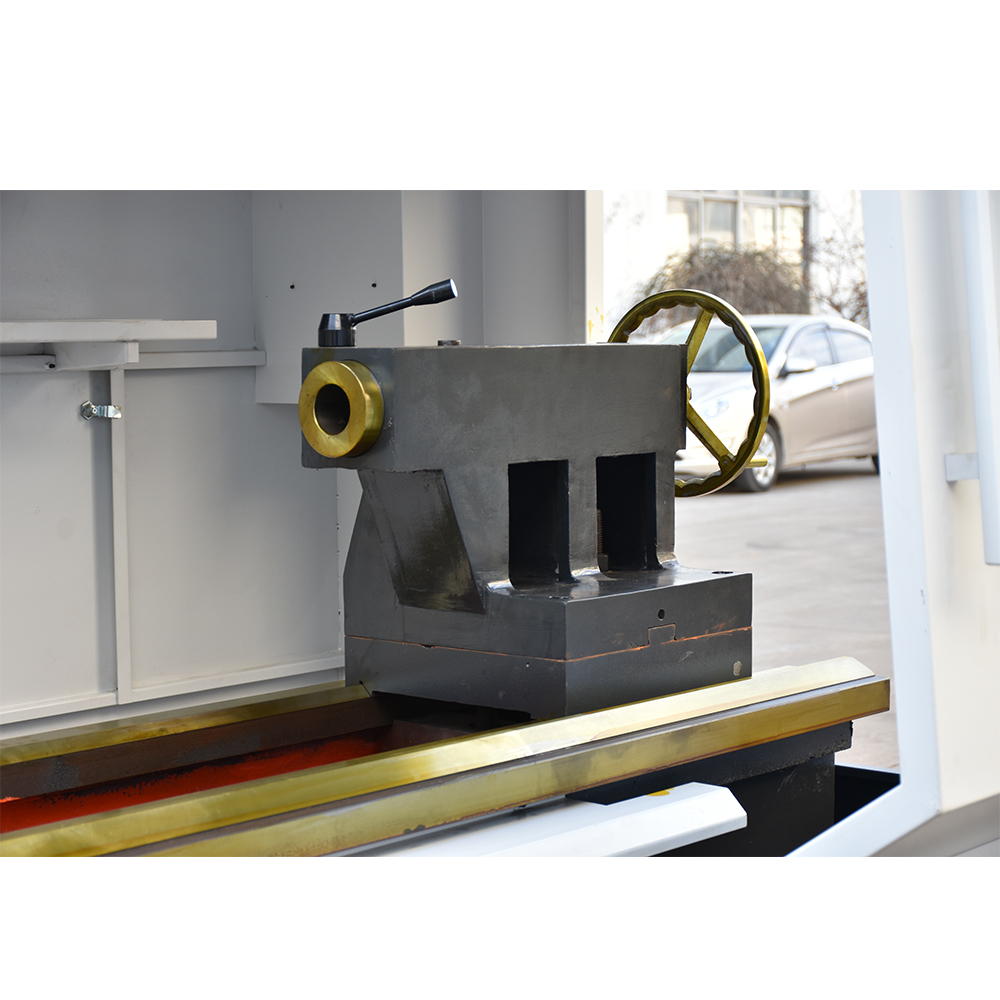

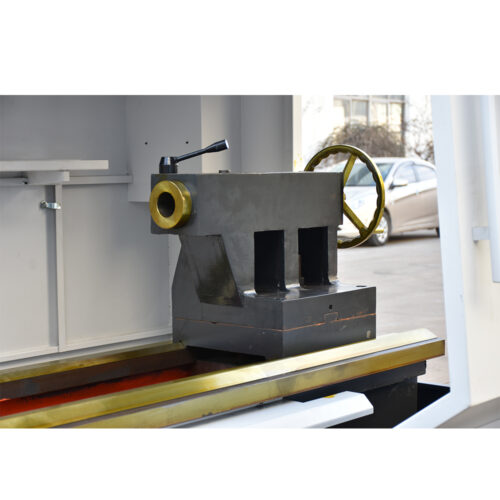

- Hydraulic or pneumatic tailseat can be configured to improve processing efficiency

Product Main Technical Parameters:

| SPECIFICATION | UNIT | CWK61160 |

|---|---|---|

| Swing over bed | mm | 1600 |

| Swing over cross slide | mm | 1200 |

| Distance between centers | mm | 1500-8000 |

| Guideway width | mm | 755 |

| Max. load capacity | T | 6 |

| Spindle bore | mm | 130 |

| Spindle bore taper | – | Metric φ160/MT6 |

| Spindle nose type | – | A2-15 |

| Spindle speed steps | – | VF. 4steps |

| Spindle speed range | rpm | 4-300 |

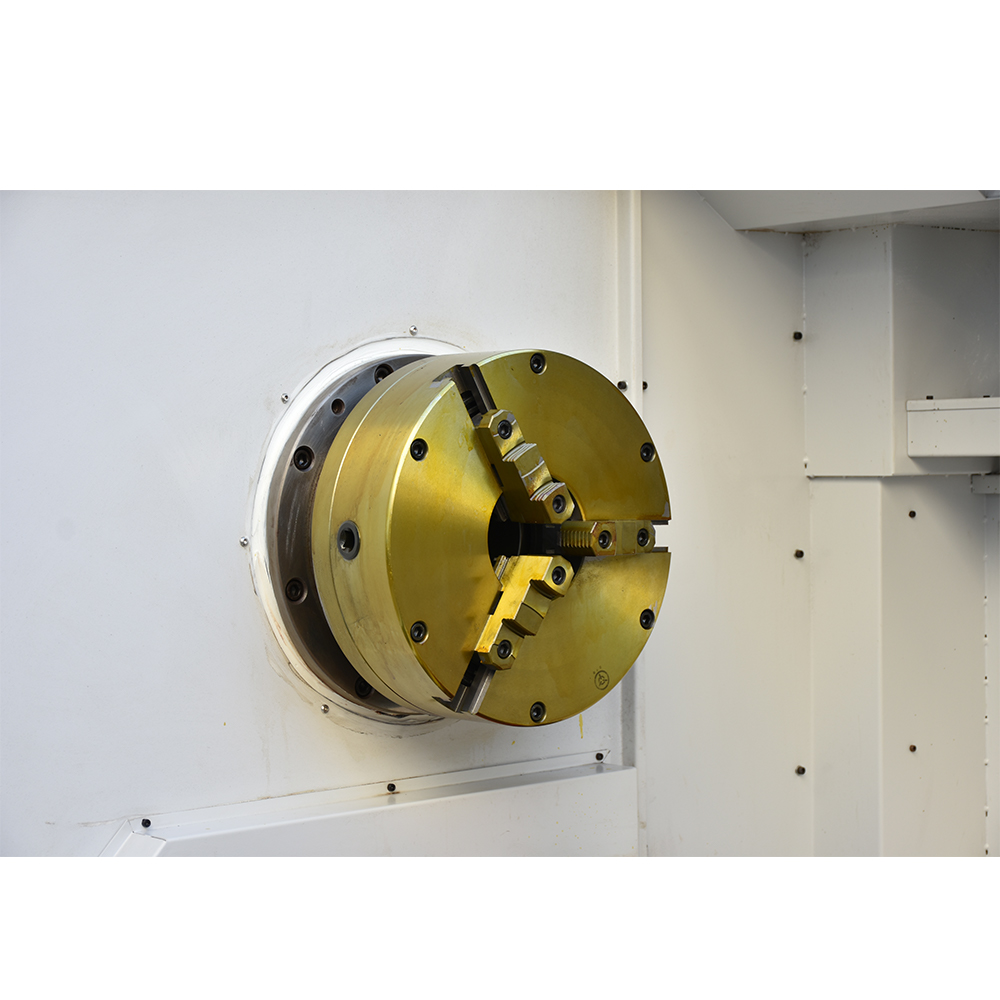

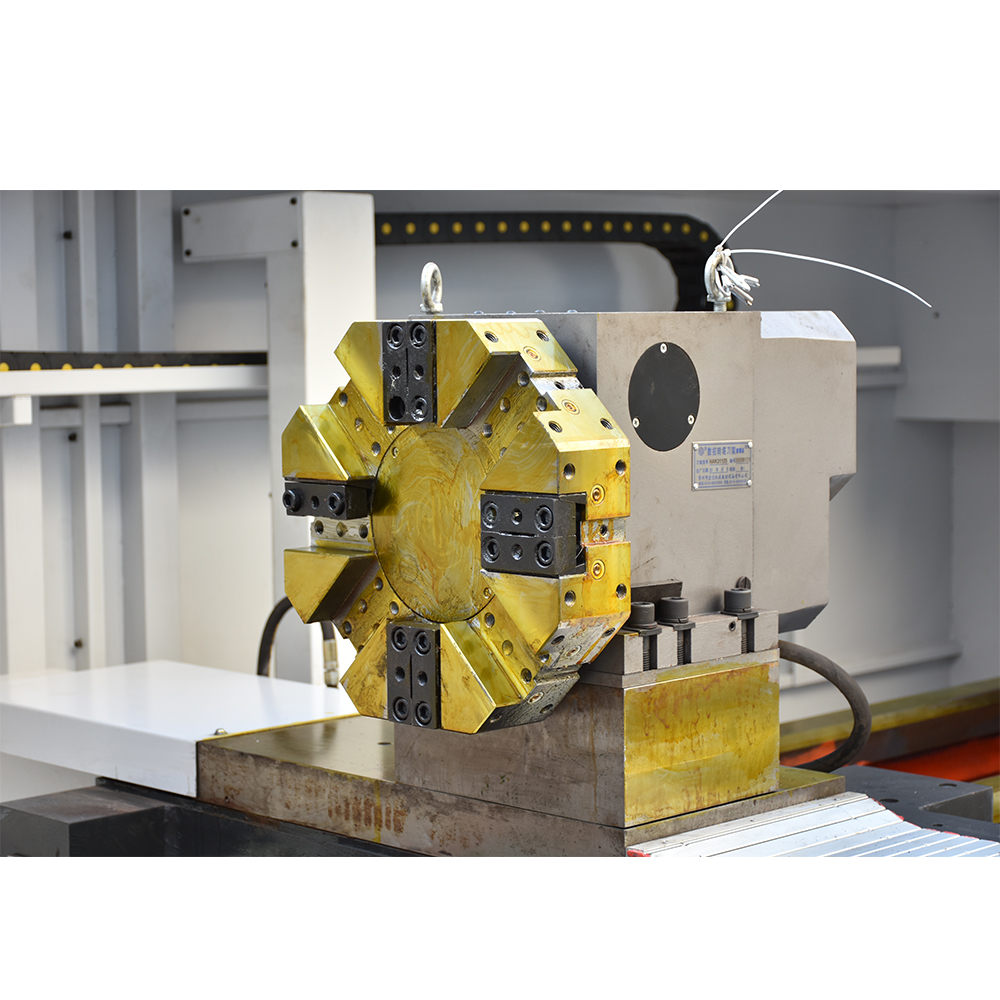

| Chuck | mm | φ1000 4-jaw manual |

| Turret/tool post | – | NC turret 4 position |

| Tool shank size | mm | 40 x 40 |

| X axis travel | mm | 720 |

| Z axis travel | mm | 1350/2850/3850/4850/5850 |

| X axis rapid traverse | mm/min | 4000 |

| Z axis rapid traverse | mm/min | 6000 |

| Tailstock quill diameter | mm | φ160 |

| Tailstock quill taper | – | MT6 |

| Tailstock quill travel | mm | 300 |

| Main spindle motor | kW | 22 |

| Coolant pump motor | kW | 0.25 |

| Width x Height | mm | 2350 x 2600 |

| Length | mm | 5000/6500/7500/8500/9500 |

| Net weight | T | 13.0/14.5/15.5/16.5/17.5 |

Video Display

Reviews

There are no reviews yet.