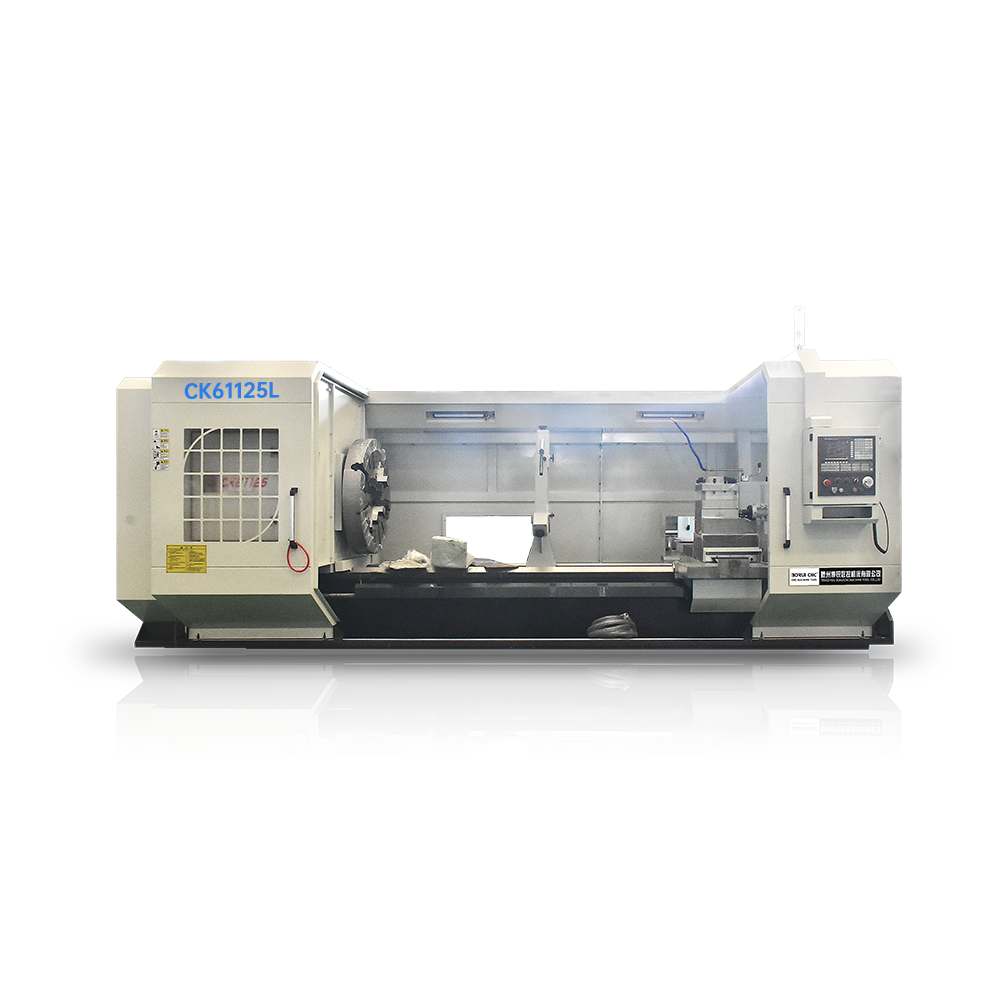

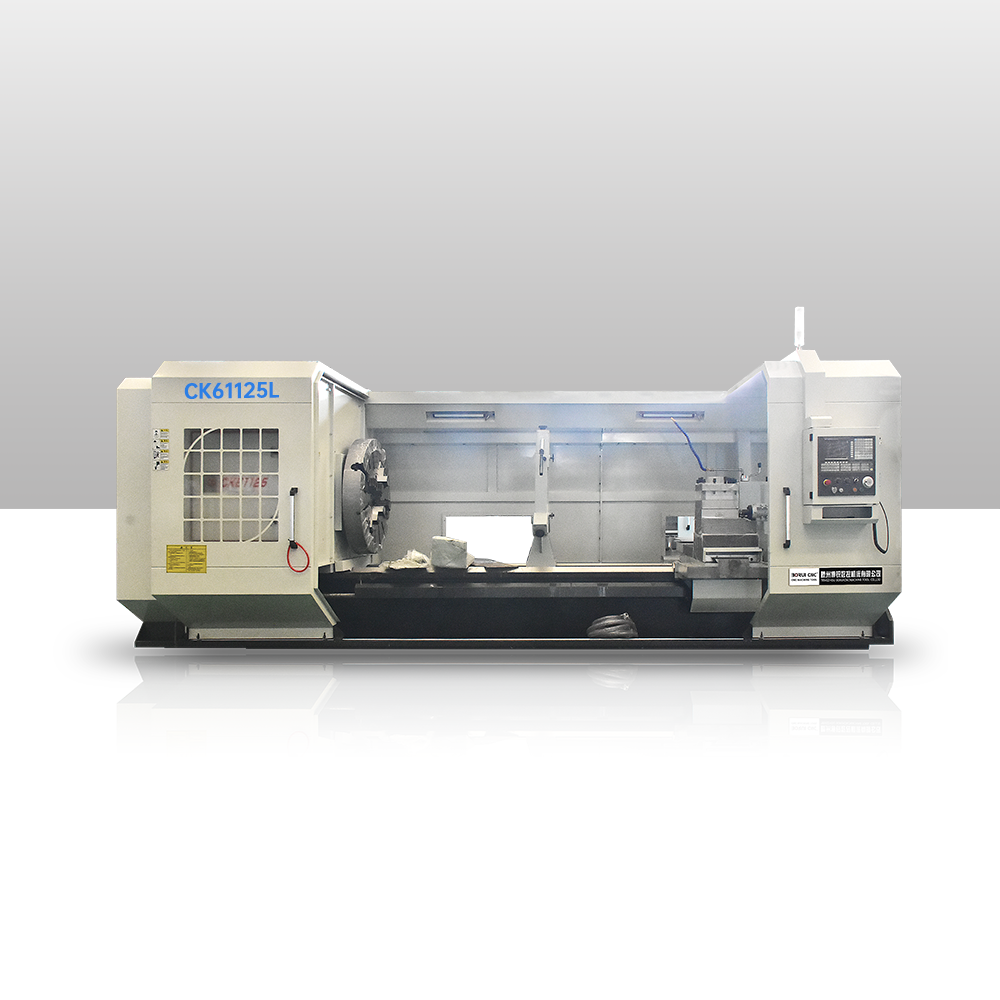

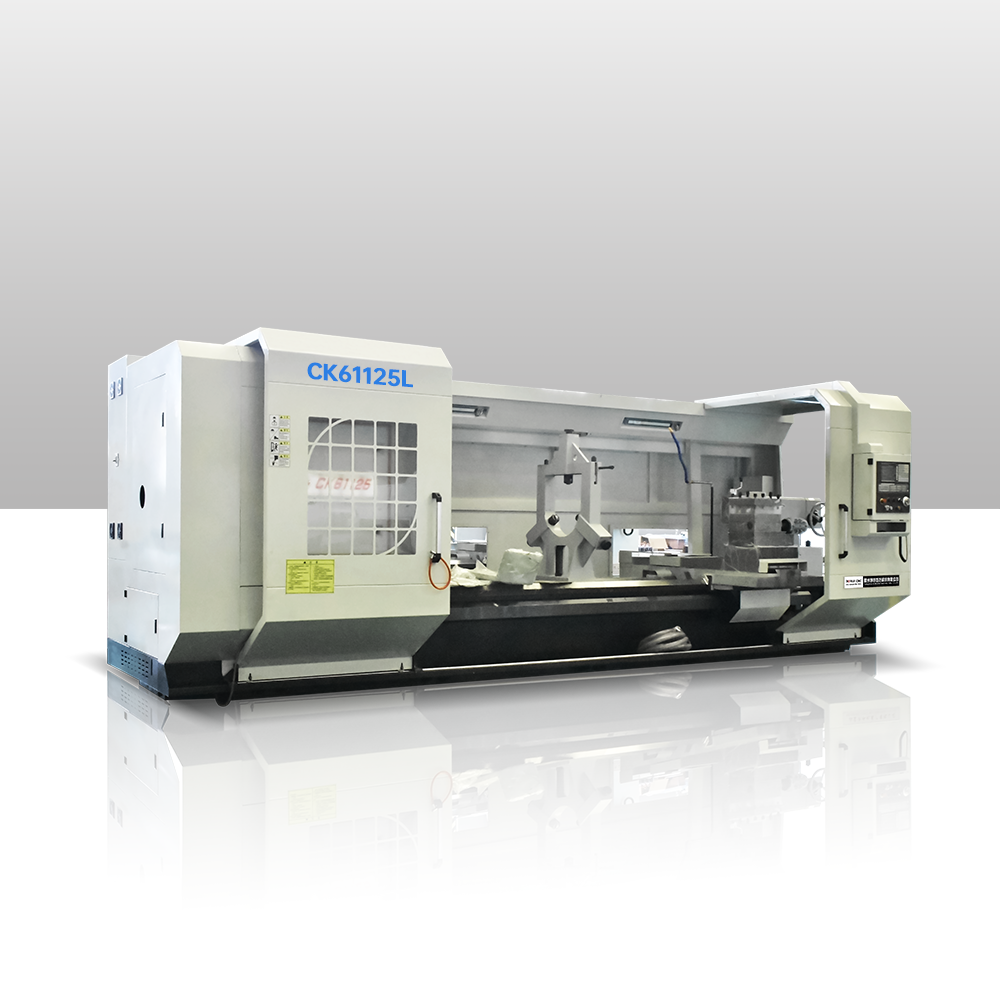

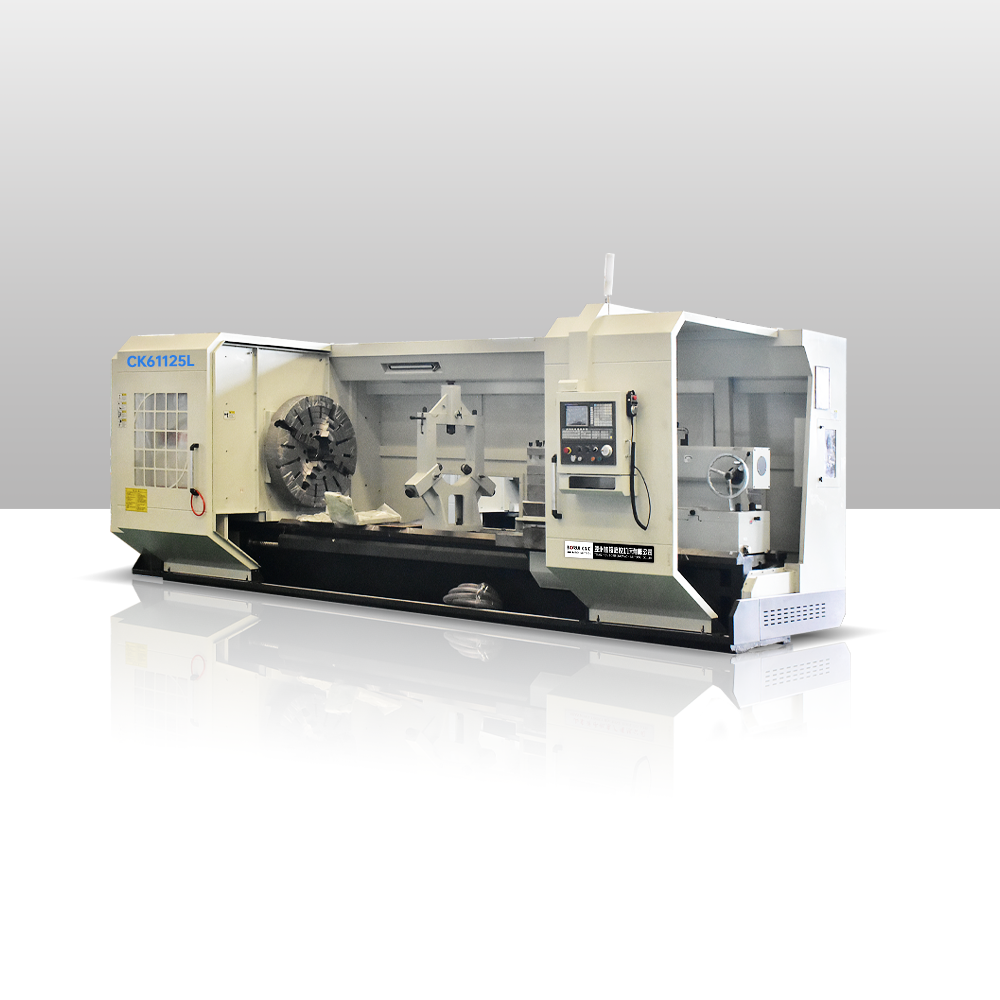

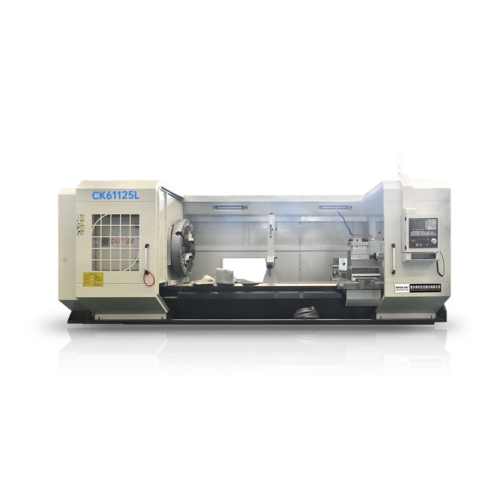

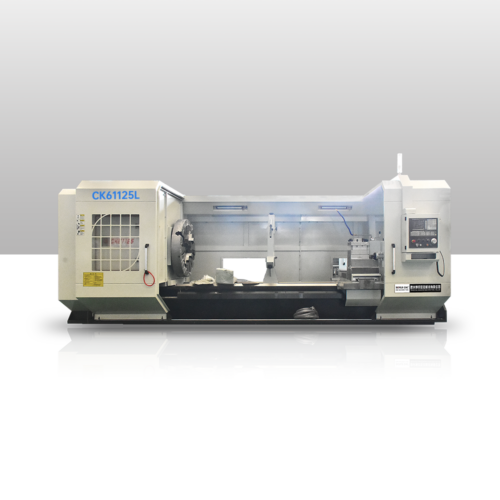

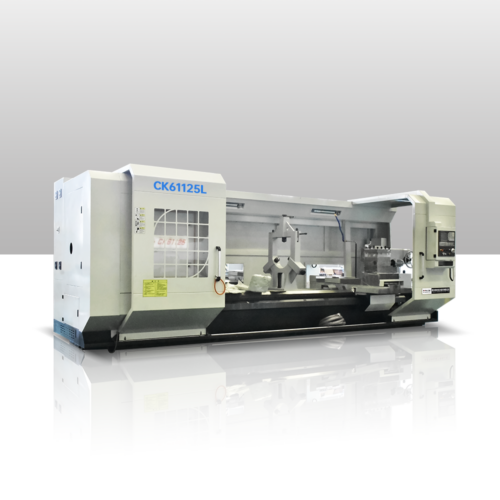

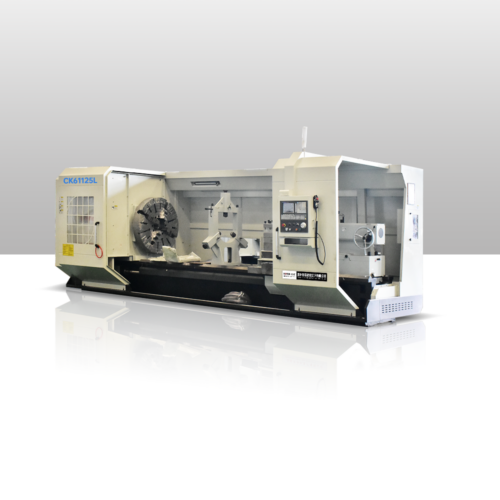

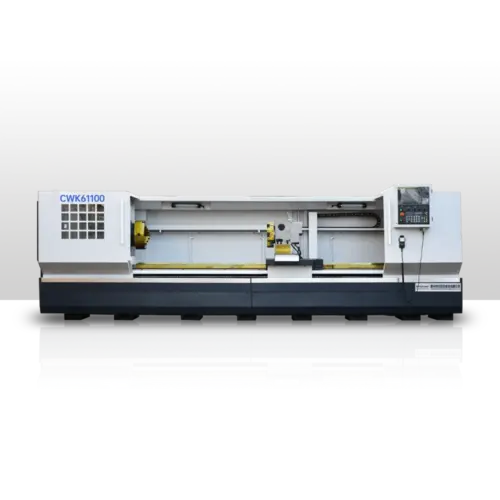

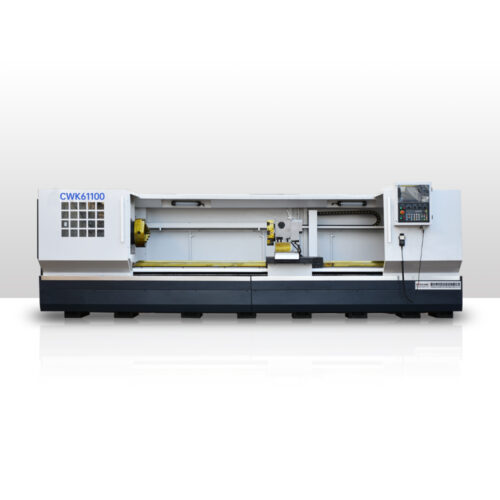

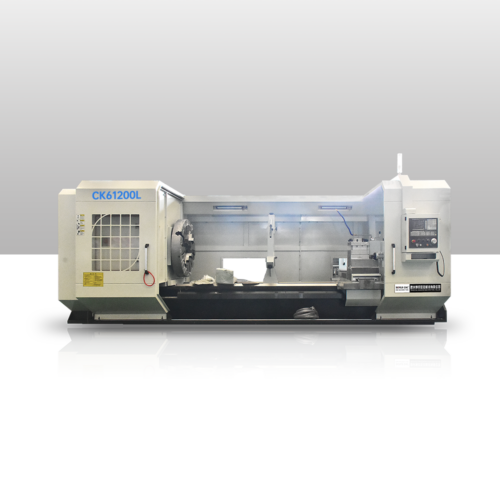

CK CNC Flat Bed Lathe Machine Features

- Wear-resistant cast iron

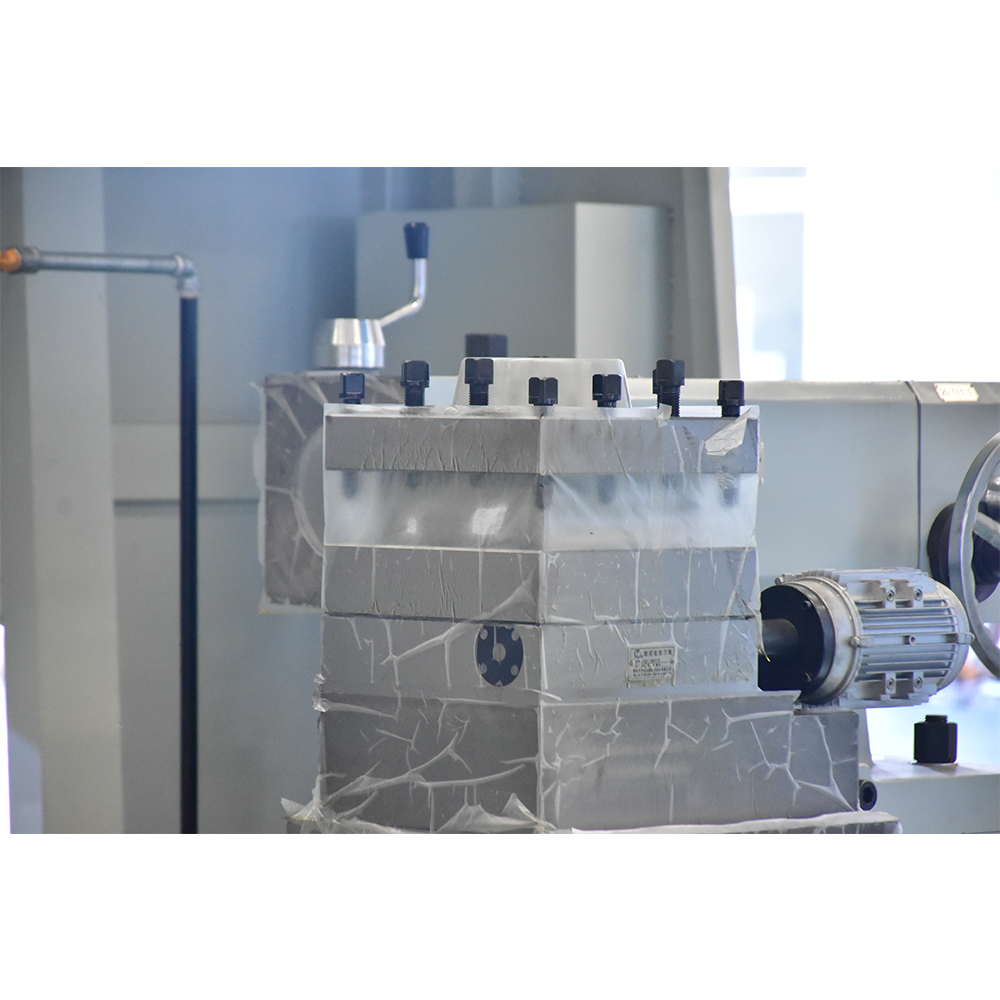

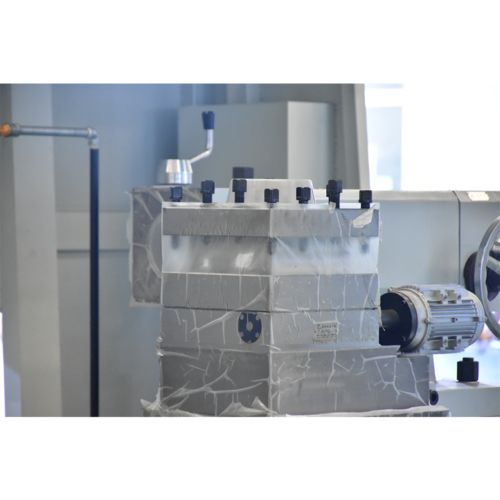

- Electric 4 position

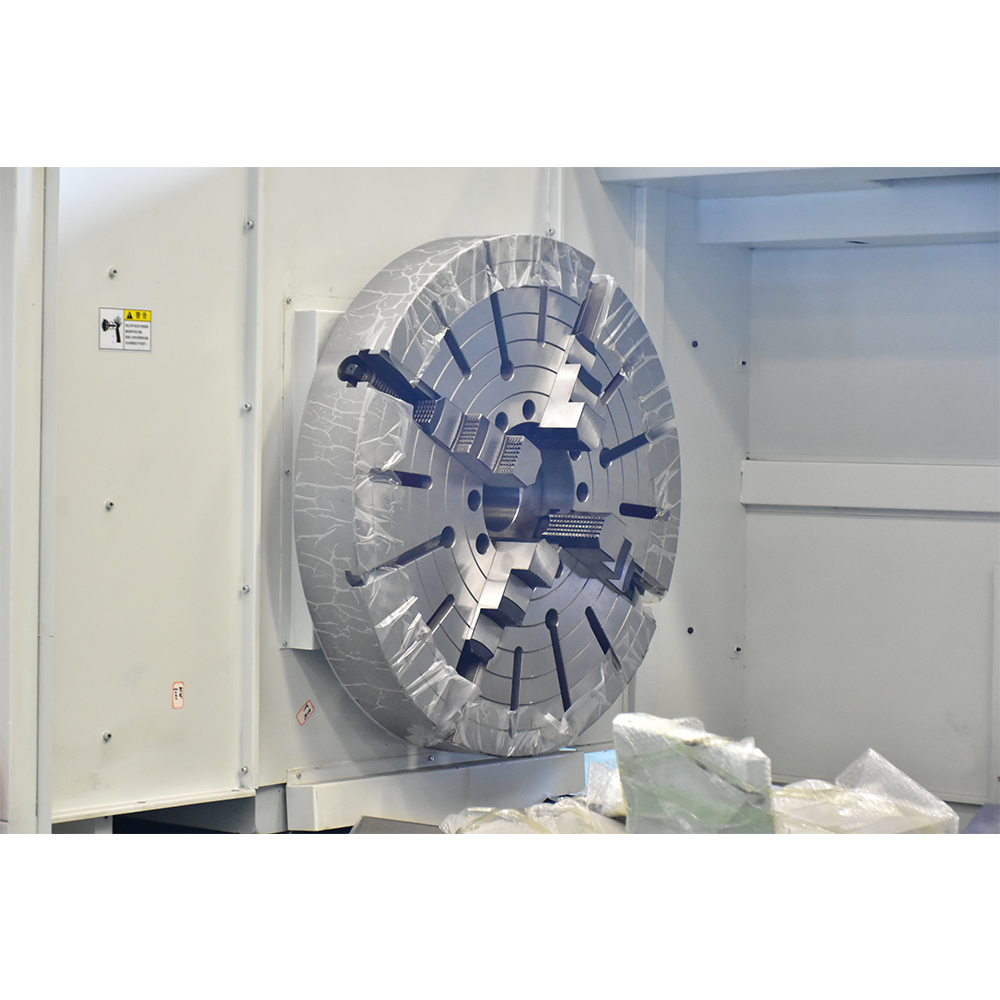

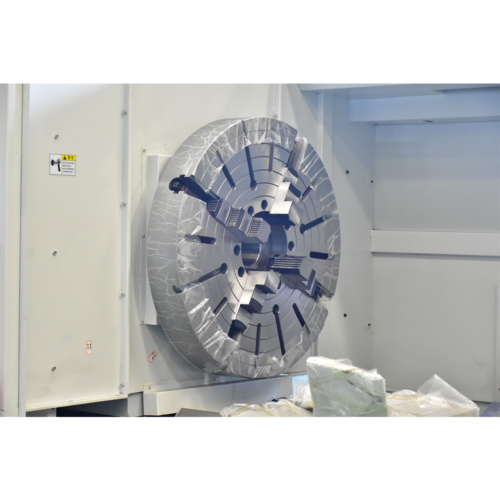

- 4-jaw manual

- Manual tailstock

- Cooling system

- Lighten system

- Full protection cabin

- Automatic lubrication system

- CNC system Standard: GSK, Optional: Siemens, Fanuc, Mitsubishi and others

- Audio quenching rail

- Hydraulic tailstock, pneumatic tailstock

- Automatic bar feeder, chip conveyor

- Inverter control spindle motor, stepless speed

- High precision ball screws and rigid precision bearings

- Fast response of moving axis, high accuracy and long lifespan

- Hydraulic chuck, easy to operate

- Has high transmission accuracy and high positioning accuracy

Product Main Technical Parameters

|

SPECIFICATION

|

UNIT

|

CK61125L

|

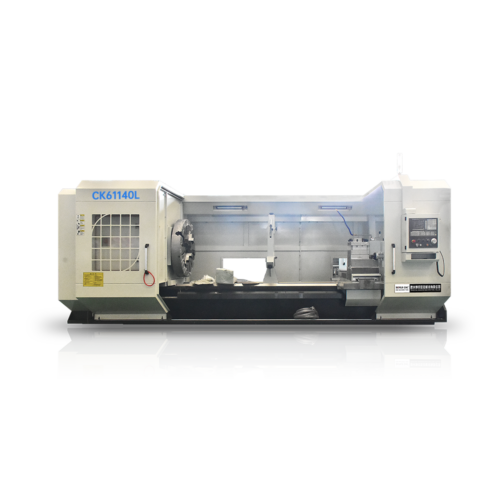

CK61140L

|

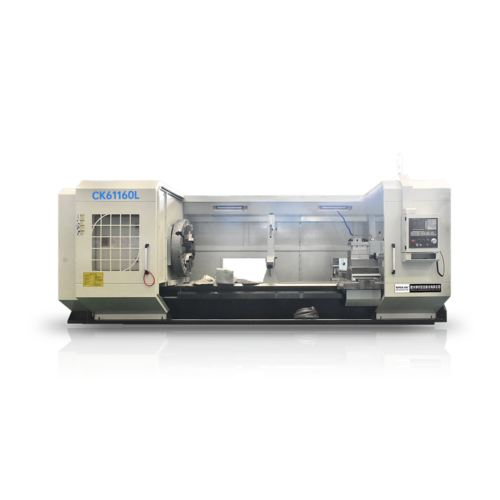

CK61160L

|

CK61180L

|

|

|

Swing over bed

|

mm

|

1300

|

1500

|

1700

|

1900

|

2100

|

|

Swing over cross slide

|

mm

|

850

|

1050

|

1250

|

1450

|

1650

|

|

Distance between centers

|

mm

|

3000-10000

|

3000-10000

|

3000-10000

|

3000-10000

|

3000-10000

|

|

Guideway width

|

mm

|

1100

|

1100

|

1100

|

1100

|

1100

|

|

Max. load capacity

|

T

|

10

|

10

|

10

|

10

|

10

|

|

Spindle bore

|

mm

|

130

|

100

|

100

|

100

|

100

|

|

Spindle bore taper

|

–

|

Metric 120

|

Metric φ120

|

Metric φ120

|

Metric 120

|

Metric 120

|

|

Spindle nose type

|

–

|

1:30

|

1:30

|

1:30

|

1:30

|

1:30

|

|

Spindle speed steps

|

–

|

VF. 4 steps

|

VF. 4 steps

|

VF. 4 steps

|

VF. 4 steps

|

VF. 4 steps

|

|

Spindle speed range

|

rpm

|

10-300

|

10-300

|

10-300

|

1-200

|

10-200

|

|

Chuck

|

mm

|

Φ1250 4-jaw manual

|

φ1250 4-jaw manual

|

Φ 1250 4-jaw manual

|

φ1600 4-jaw manual

|

Φ1600 4-jaw manual

|

|

Turret/tool post

|

–

|

NC turret 4 position

|

NC turret 4 position

|

NC turret 4 position

|

NC turret 4 position

|

NC turret 4 position

|

|

Tool shank size

|

mm

|

50 x 50

|

50 x 50

|

50 x 50

|

50 x 50

|

50 x 50

|

|

X axis travel

|

mm

|

700

|

750

|

850

|

850

|

850

|

|

Z axis travel

|

mm

|

3000-10000

|

3000-10000

|

300-10000

|

3000-1000

|

3000-1000

|

|

X axis rapid traverse

|

mm/min

|

4000

|

4000

|

4000

|

4000

|

4000

|

|

Z axis rapid traverse

|

mm/min

|

6000

|

6000

|

6000

|

6000

|

6000

|

|

Tailstock quill diameter

|

mm

|

Φ260

|

Φ260

|

Φ260

|

Φ260

|

Φ260

|

|

Tailstock quill taper

|

–

|

Metric 80

|

Metric 80

|

Metric 80

|

Metric 80

|

Metric 80

|

|

Tailstock quill travel

|

mm

|

300

|

300

|

300

|

300

|

300

|

|

Main spindle motor

|

kW

|

30

|

30

|

30

|

30

|

30

|

|

Coolant pump motor

|

kW

|

0.25

|

0.25

|

0.25

|

0.25

|

0.25

|

|

Width x Height

|

mm

|

2250 x 2350

|

2600 x 2050

|

2700 x 2560

|

2800 x 27600

|

80/Metric 80

|

|

Length

|

mm

|

6700-13700

|

6700-13700

|

6700-13700

|

6700-13700

|

6700-13700

|

|

Net weight

|

T

|

22.6-28.9

|

23.6-29.9

|

24.6-30.9

|

25.6-31.9

|

26.6-32.9

|

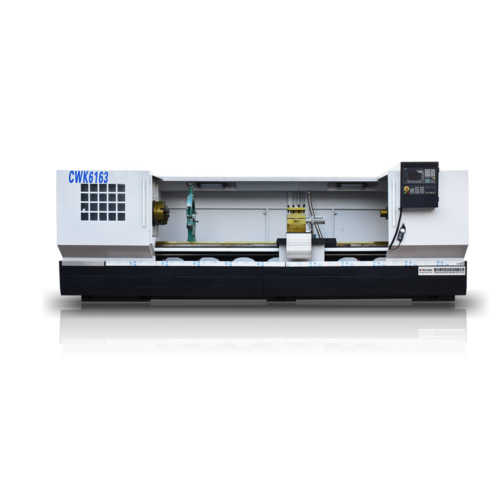

Advantages Of CNC Flat Bed Lathe Machine

- CK series is an economical and practical machine tool with good quality.

- It is suitable for all kinds of turning, such as internal and external cylindrical surfaces, various metric cutting, modular and diameter pitch threads, tapered turning, facing, drilling, reaming, and broaching for oil grooves and keyways.

- Workpieces produced on the machine can achieve good precision and surface roughness.

- CK flat bed CNC lathe can also be used for rigid cutter knives and powerful cutters and to process various ferrous and non-ferrous metals.

- The width of the side wall is double bed reinforcement. Inner reinforcement adopts the overall bed structure of box shape and oblique reinforcement. The overall rigidity is high.

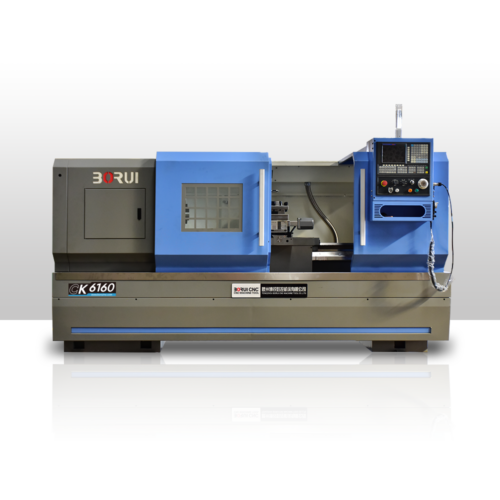

- The CK61125L CNC lathe is a universal standard extra heavy-duty automatic machining equipment for metal processing. It is suitable for processing extra.

- This machine tool has the characteristics of high power, high speed, low noise, and strong rigidity, among others.

- The flat bed CNC lathe machine uses an AC frequency conversion speed regulating device to realize step-less speed regulation and improve working stability compared to the original ordinary lathe.

Reviews

There are no reviews yet.