Spindle components: It is the main component that affects the machining accuracy of the machining center Rotation accuracy affects the machining accuracy of the workpiece Power and rotation speed affect processing efficiency Automatic shifts, exact stops and tool changes that affect the automation of the machine tool Common faults of machining center spindle Machining accuracy…

Programming skills for large-scale CNC lathe processing 1. The processing sequence of the parts:(1) Drill first and then flat end (to prevent shrinkage during drilling).(2) Rough machining first, then finish machining (to ensure the accuracy of the parts).(3) Machining large tolerances first and then machining small tolerances (to ensure that the surface of small tolerance…

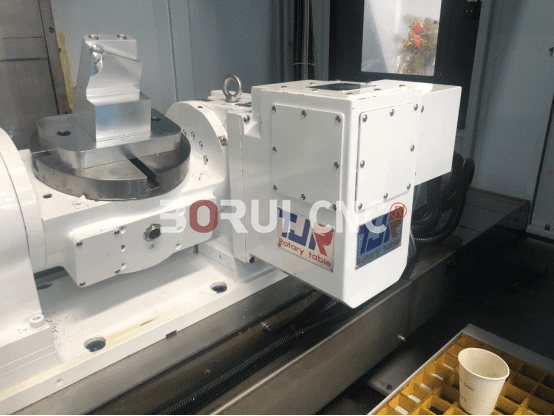

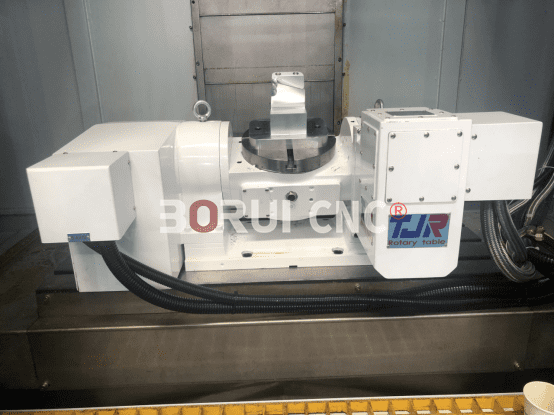

5 Axis Turning And Milling Center 5-axis turning and milling techniques are typical of multi-axis machining techniques. The 5-axis turning and milling center is the vehicle for 5-axis turning and milling technology. It refers to the turning function and integrates functions such as milling and drilling, with at least three functions. Linear machine feed axis…

One is the turntable axis. It can be rotated around the X-axis when placed on the worktable, which is defined as the A-axis, and the A-axis usually works within the range of 30 degrees to -120 degrees. There is also a turntable at the center of the watch, which when rotated about the Z axis…

How to choose a vertical machining center depends on your situation and requirements. For example, do you need new or used equipment for your daily machining needs? What is your capital budget? What kind of order is dealt with in peacetime? Which are the most qualified or most used processes, and so on. Once you’ve…

Machining center is a kind of hole processing equipment, which can be used for various forms of processing such as drilling, reaming, reaming, tapping and scraping end faces. According to the clamping layout of the machine tool, the machining center can be divided into a hydraulic machining center and a mechanical machining center. The machining…

1. Which brand of 5-axis machining center is good? There are many brands of five-axis machining centers. Different brands of five-axis machining centers have different positioning and have different prices. Some brands are positioned in the high-end market, such as Germany’s Demagie, Hammer, Switzerland’s Baume, Weiliming, Japan. Some international first-line brands such as Mazak and…

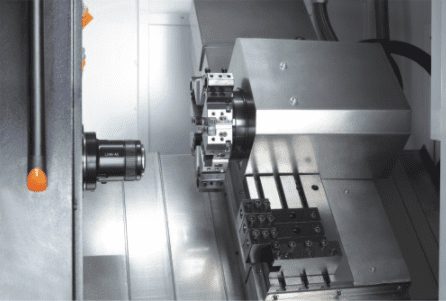

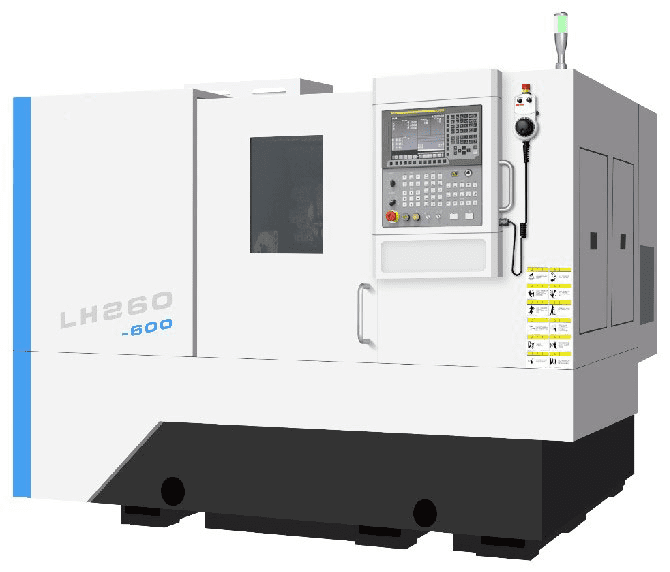

1.Product Positioning BORUI LH260 Hardinge GS200 BORUI LH260’s advanced design concept and mature manufacturing technology have further improved the rigidity, precision and stability of the machine tool, and the performance of the whole machine has reached the level of imported brands of the same specification. 2.Product Introduction—LH260 ◇The sleeve-type headstock adopts a large-span symmetrical structure,…

1. The size of the workpiece is accurate and the surface finish is poorReasons: The tool tip is damaged and not sharp; the machine tool resonates and the placement is not stable; the machine tool has a creeping phenomenon; the processing technology is not good.Solution: After the tool is worn or damaged, it is not…

VMC850 vertical machining center in the use of the process, because of the environment, temperature, humidity and the use of their own parts wear, internal force deformation, loss of wear parts and other factors, its comprehensive performance will change over time, the existence of small problems in the machine tool, may lead to the scrapping…