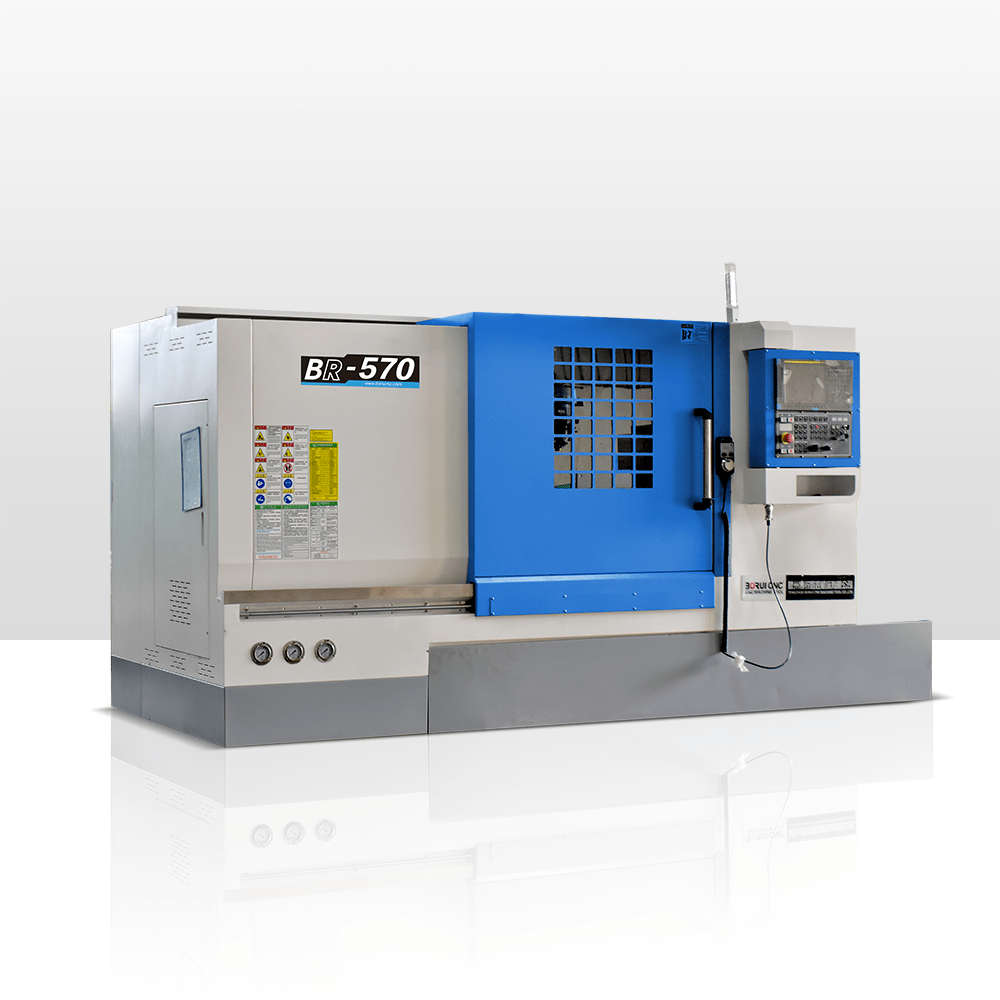

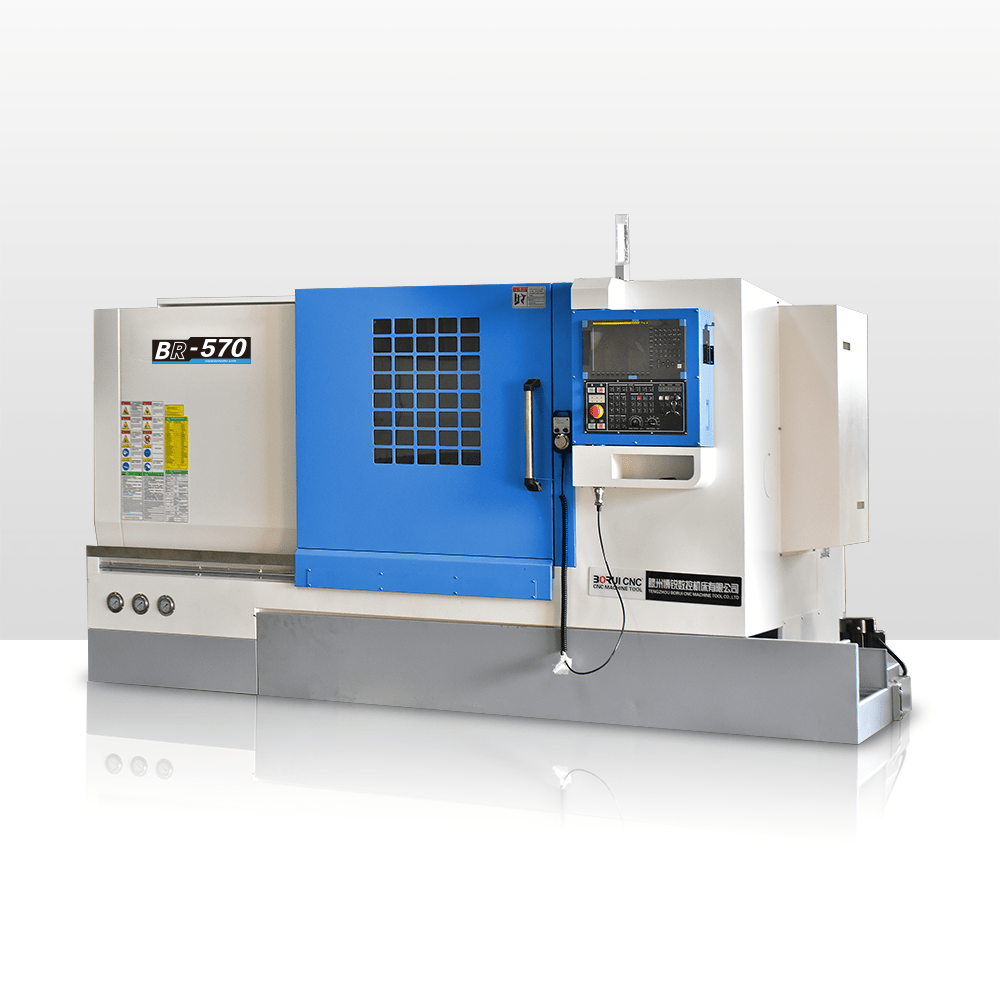

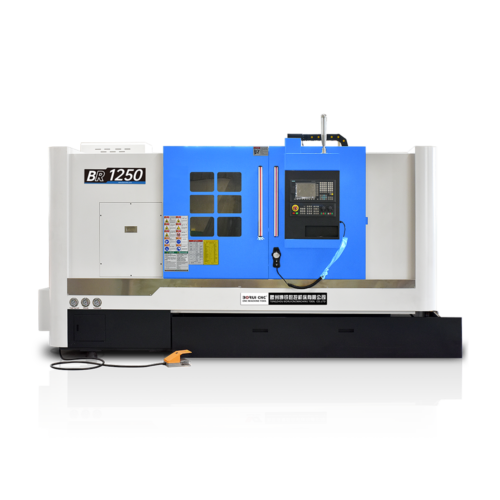

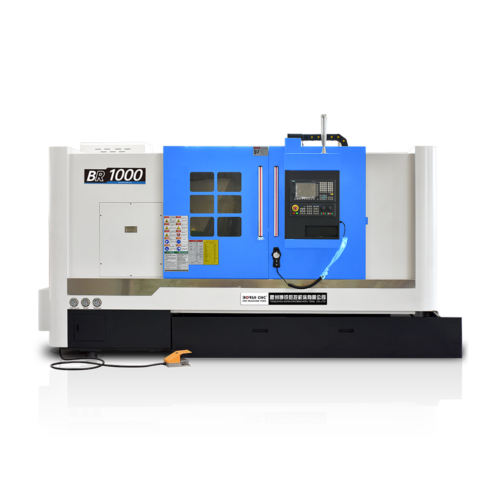

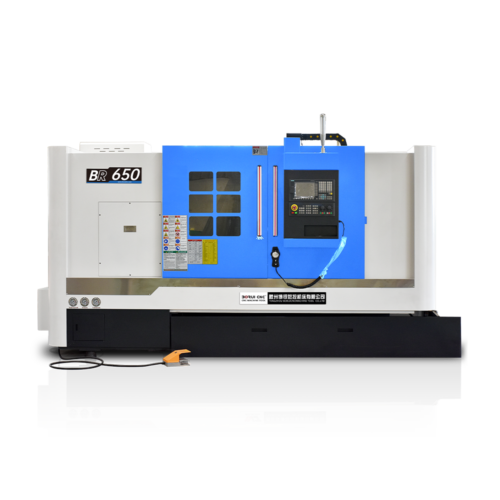

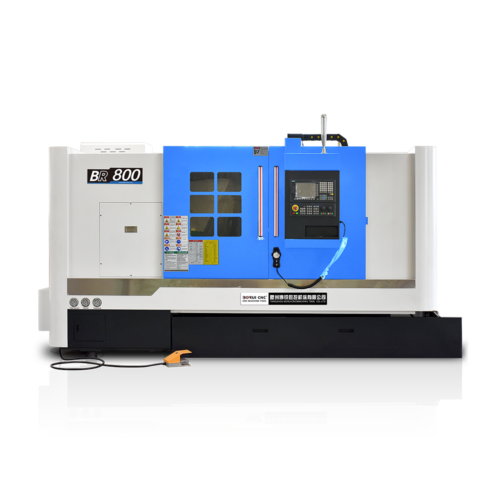

Advantages Of CNC Slant Bed Lathe Machine:

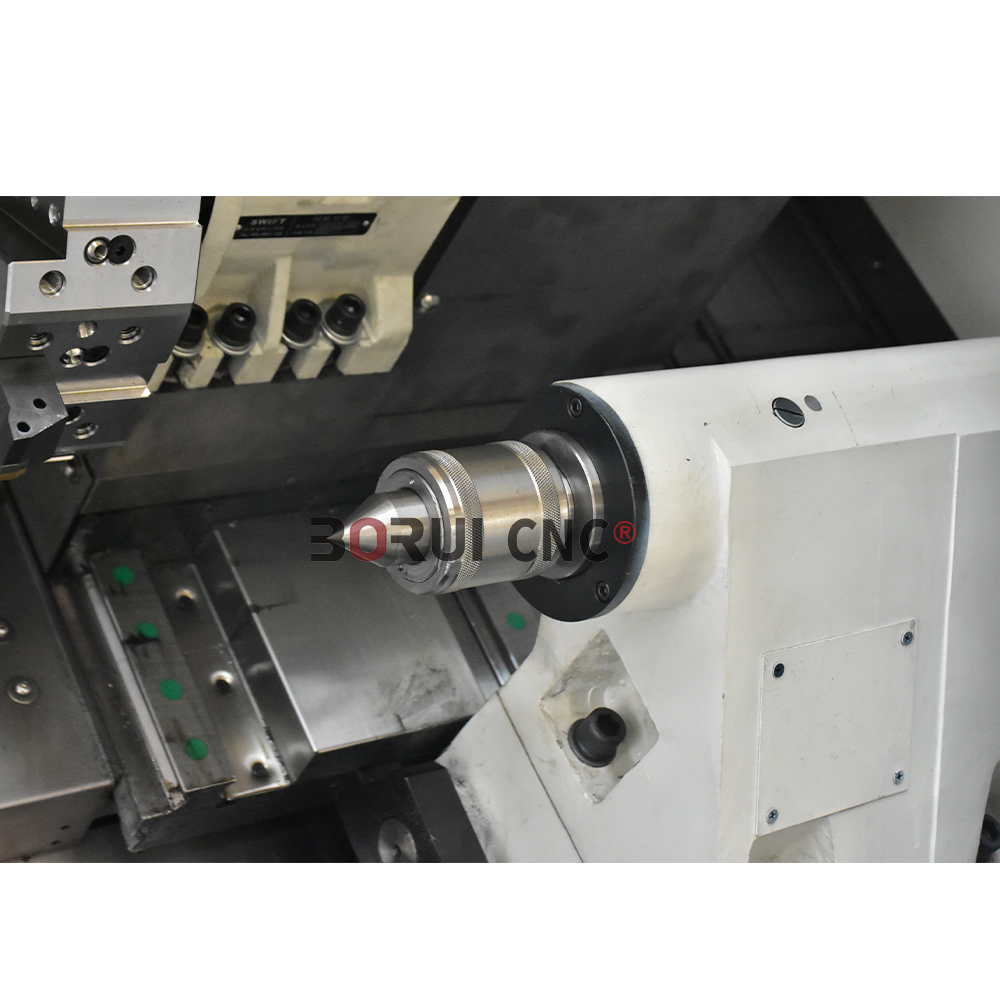

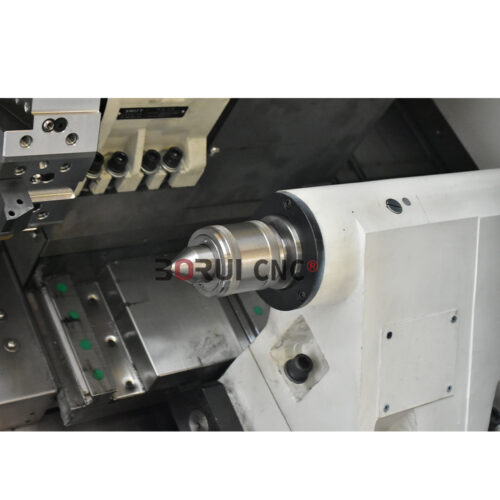

- The slant bed lathe adopts the turret method, which has fast tool changing speed and high positioning accuracy.

- Servo motor is used for feeding in X and Z directions,so as to ensure the positioning accuracy and repeated positioning accuracy.

- The CNC lathe adopts advanced centralized automatic lubricating device, regular quantitative automatic intermittent lubricating, stable and reliable work.

- CNC lathe adopts hydraulic chuck.

- The hydraulic tailstock is manually adjusted and locked, and the hydraulic piston pushes the workpiece for processing.

- The BR-570 series is ideal for various industrial applications.

- To ensure precision and thermal stability, the head-stock, tailstock, and saddle all are mounted on the same plane at a 45˚ degree angle.

Product Main Technical Parameters:

| Machine Model | Model | BR570-520 | BR570-750 |

|---|---|---|---|

| Major parameter | The maximum turning diameter on the bed | Φ570 | Φ570 |

| maximum machining diameter | Φ500 | Φ500 | |

| Maximum machining diameter on the tool holder | Φ230 | Φ230 | |

| Maximum processing length | 520(8″) | 750(8″) | |

| Spindle and chuck parameters | Spindle head form (optional chuck) | A2-6(8″) | A2-6(8″) |

| Recommended spindle motor power | 11-15KW | 11-15KW | |

| Spindle speed | 4200rpm | 4200rpm | |

| Spindle hole diameter | Φ66 | Φ66 | |

| Bar diameter | Φ52 | Φ52 | |

| Feed section parameters | X/Z axis screw specifications | 3210/4010 | 3210/4010 |

| X-axis limit travel | 270 | 270 | |

| Recommended X-axis motor torque | 11N.M | 11N.M | |

| X/Z axis rail specifications | 45/45 | 45/45 | |

| Z axis limit travel | 610 | 810 | |

| Recommended Z-axis motor torque | 11 N.M | 11 N.M | |

| X, Z axis connection mode | Direct | Direct | |

| Turret or Gang | Optional turret (special configuration) | 12T | 12T |

| Recommended turret center height dimension | 100mm | 100mm | |

| Tailstock | Socket diameter | 80 | 80 |

| Socket travel | 80 | 80 | |

| Tailstock maximum stroke | 480 | 480 | |

| Tailstock sleeve tapered hole | MT5# | MT5# | |

| Overall Dimension | Bed type and inclination | Integrated/30° | Integrated/30° |

| Machine size(L * W * H) | 1800×1320×1438 | 2100×1386×1435 | |

| Weight | Weight (approx. weight) | 2500kg | 2700kg |

Zilberberg Yafim –

I am interested in this machine.

what price? production time

[email protected] –

Hi,Can you tell me your Whatsapp or Wechat?