Product Video Display

Universal Rotary Head Milling Machine Technical Parameters

| SPECIFICATIONS | Units | X6432 | X6436 |

|---|---|---|---|

| Table size | mm | 1500*320 | 1500*360 |

| Table travel | mm | 1000/320/400 | 1000/320/400 |

| T slot(number-width*pitch) | 3-16*60 | 3-18*80 | |

| Spindle taper | ISO40 | ISO40 | |

| Horizontal spindle taper | ISO40 | ISO40 | |

| Spindle speed range(steps) | rpm | 48-1660(12) | 48-1660(12) |

| Horizontal spindle speed range(steps) | rpm | 40-1300(12) | 40-1300(12) |

| Distance between spindle nose and table surface | mm | 120-520 | 150-550 |

| Distance between horizontal spindle axis and table surface | mm | 0-400 | 0-400 |

| Table feed range(steps) | mm | XY:22-555(8)Z:electric | XY:22-555(8)Z:electric |

| Swivel angle of milling head | ° | 360 | 360 |

| Main motor power | kw | 3(V)/3(H) | 4(V)/4(H) |

| Feed motor power | kw | 1.1 | 1.1 |

| Machine weight | kg | 2100 | 2580 |

| Overall dimension | mm | 2050*1750*2000 | 2550*2050*2050 |

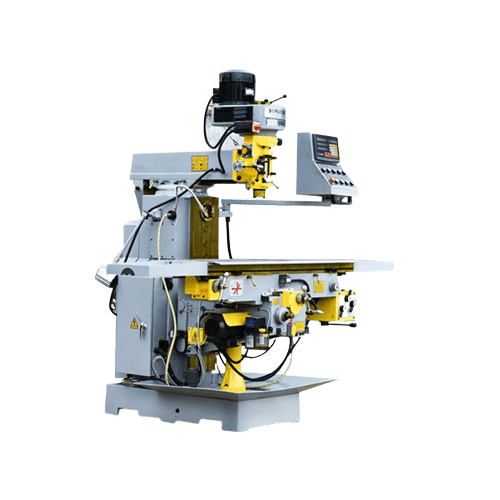

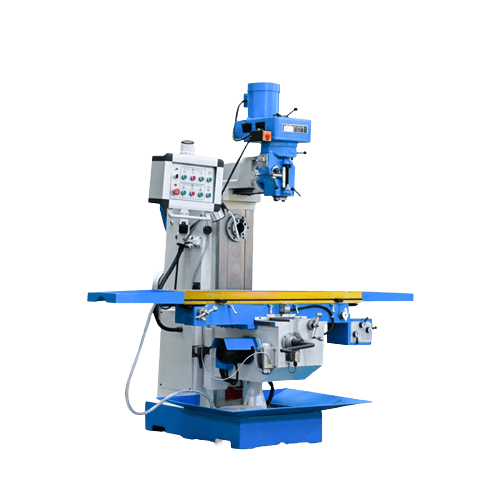

Main Structural Features of Universal Milling Machine

- The machine tool has good rigidity. It can withstand heavy load cutting.

- The power of the spindle motor of the machine tool is high, and the speed change range is wide. It can give full play to the efficiency of the tool and can perform heavy cutting.

- The machine tool has a perfect lubrication system.

- The digital display device can be configured according to user needs.

- The wear-resistant castings of the machine tool are made of vanadium-titanium wear-resistant cast iron. The critical parts are made of high-quality alloy steel, which is stable and durable.

- The spindle has good rigidity and strong bearing capacity. The X6436 universal rotary head milling machine bed is a rectangular guide rail bed with good stability.

- Three items XYZ of the worktable are all automatic feeding. In the three directions of X, Y, and Z, the guide rail pair is supersonic quenching and precision grinding.

- The manual lubricating device can force lubricating the lead screw and guide rail.

- The universal milling machine can realize two functions: vertical milling machine and horizontal milling machine. The two-section rotary spindle can be rotated and adjusted at any angle. They can be used to process shells and molds.

- If appropriate accessories are used, parts with unique shapes, such as gears, cams, arc grooves, and helical surfaces, can be processed. Milling machine accessories such as universal milling heads, circular tables, and indexing heads can be configured. They can further expand the range of use of the machine tool.

Product Image Display

MILLING HEAD

The milling head can be rotated at any angle, with six speed changes.

BOOM TYPE OPERATION BOX

Operation with a three-axis digital display is more accurate.

MULTI-SPEED TRANSMISSION

X/Y axis automatic feed. It can be a low, medium, and high multi-speed speed change.

HORIZONTAL MILLING SPINDLE

Can drill and mill, multi-purpose machine.

RECTANGULAR GUIDEWAY

X-axis,Y-axis, Z-axis adopt rectangular guide rails.

LIFTING MOTOR

Standard lifting motor,high efficiency, low noise, easy to operate.

Reviews

There are no reviews yet.