Main Structure And Technical Characteristics Of BR Series CNC Vertical Lathe:

1. Base and column

The rib shape of the base and column is optimized by Ansys software, which makes the machine tool have high rigidity; the material is made of high-density cast iron, which has high strength and good shock absorption.

2. Spindle

The spindle of this series of machine tools can be equipped with A2-6/8/11/15 domestic or imported spindle units, or self-made spindle units. The design of the spindle units adopts the current international advanced and mature structure. The front support of the spindle is composed of a double row cylindrical roller bearing and a two-way thrust angular contact ball bearing, and the rear support is a double row cylindrical roller bearing; the bearing adopts imported precision spindle bearing, and the bearing is lubricated with imported high-speed grease. The axial and radial preload of the spindle system can be adjusted with a nut, which has high radial and axial rigidity. The radial clearance can be adjusted with the inner ring of the roller bearing, so as to obtain the best machining accuracy and lower operating temperature.

The main motor of this series of machine tools drives the spindle to rotate through imported narrow V-belts or synchronous belts, so as to ensure the high efficiency, low noise and low vibration of the entire transmission system to meet the requirements of various conditions such as low-speed, high-torque, high-speed and high-power machine tools. cutting requirements. The headstock and the base are integrated, so that the machine tool spindle assembly has high rigidity.

3. Feeding system

The X-axis and Z-axis are driven by servo motors and are directly connected with the ball screws through elastic couplings. The ball screw adopts the installation method with both ends fixed.

The two-axis guide rails are hardened hard rails with high wear resistance, the slide plate is plastic-coated, the friction resistance is small, and the noise is low; the VTCS600L/900L/1000L two-axis guide rails are all imported rolling guide rails, which are four-direction equal-load type. , High precision and large load, the rollers are separated by cages to reduce frictional resistance, temperature rise and thermal deformation during rapid movement, thereby greatly improving machining accuracy, rapid movement speed and production efficiency. Its outstanding advantages are small size, high precision, low maintenance cost, and it is the first choice for users who pursue high precision and high cost performance.

4. Tool holder

The tool holder has a variety of configurations, and users can freely choose according to their actual needs and usage habits.

Standard configuration: Universal servo horizontal eight-station tool rest, this series of tool rests are indexed by servo motors, can quickly select tools in two directions, hydraulically locked, and have high rigidity; or arranging tool rests, this tool rest has minimalist The design structure and high rigidity are especially suitable for machining workpieces with few tools.

5. Chuck cylinder

The standard chuck of this machine tool adopts Taiwan hydraulic chuck, which is a waterproof chuck, and there is a sealing strip at the sliding cooperation between the jaw sliding seat and the disk body, which can effectively prevent the leakage of coolant to the spindle through the chuck, and also prevent chipping. Enter the sliding surface to grind the slider. There are 3 T-slots on the end face of the chuck, which can easily replace various fixtures. It has good adaptability and can meet the requirements of users for processing various parts. Imported hydraulic chucks and oil cylinders, domestic waterproof power chucks and Taiwan oil cylinders can also be selected. The oil cylinder can also be equipped with an optional detection function.

6. Protection

The machine is fully protected, beautiful and easy to use. Safety grating can be installed to better take into account the safety. Optional automatic protective doors are also available to facilitate the formation of automatic production lines and the addition of robots.

7. Hydraulic system and nitrogen balance system

This machine tool is a CNC machine tool with a high degree of automation, equipped with a hydraulic system; in order to balance the Z-axis load weight, it is equipped with a balance cylinder. The main hydraulic control components of the hydraulic system are selected from Taiwan famous brands or domestic high-quality products. The hydraulic oil tank is placed on the right side of the base and is isolated from the outside world by a protective cover. The main hydraulic components are installed in a superimposed manner, and the structure is compact and easy to install.

8. Lubrication station

The machine tool adopts Japanese brand centralized automatic lubrication system, and has the functions of liquid level alarm and pressure alarm.

9. Cooling system

The cooling pump of this machine tool has a flow rate of 133L/min and a head of 40 meters. The cooling tank is separated from the main engine (the cooling water tank is installed behind or on the side of the main engine) to ensure that the accuracy of the machine tool is not affected by the cutting heat. Imported cooling pump is adopted, and the cooling water is led out by the cooling pump and divided into three channels by the water separator: one channel is connected to the cooling water port on the tool holder, and is sprayed through the tool holder nozzle to provide cooling and lubrication for the parts and tools, and is used for cooling and lubrication. To ensure the machining accuracy of the workpiece and improve the service life of the tool; the other way is connected to the water pipe on the left base of the spindle to flush out the iron filings on the bed; the third way is connected to the water gun for cleaning parts and machine tools.

10. Chip conveyor

This machine tool can be equipped with chain plate type chip conveyor, scraper or magnetic scraper type chip conveyor according to the different materials of the workpiece. The chain plate type chip conveyor is suitable for collecting and conveying all kinds of rolled, lump and block chips; the scraper chip conveyor is suitable for the conveying of copper, aluminum, cast iron and other chips; the magnetic scraper type chip conveyor is mainly used for wet Conveying of cast iron chips with a length of less than 150 mm during machining. The chip conveyors are all automatic chip removal, and the start and stop of the chip conveyor can be controlled by the M command.

11. Electrical system

11.1 CNC system and servo system

The standard configuration of the CNC system of the machine tool adopts the FANUC0iTF CNC system produced by FANUC Company, and Siemens or China GSK/KND system can be selected. high advantage.

The four-servo axis system is a high-precision digital servo system with high-speed microprocessor and software servo control functions, which can realize high-speed and high-precision servo control.

11.2 Machine tool electrical system

The power circuit of the circuit has over-current and short-circuit protection, and the relevant actions of the machine tool have corresponding interlocks to ensure equipment and personal safety. The electrical system has a self-diagnosis function, and operators and maintenance personnel can observe the running status of each part of the machine tool at any time according to the indicator lights and displays.

The main electrical components of the machine tool are imported and Sino-foreign cooperation products to ensure the safety and reliability of the machine tool.

CNC machine tools have strict power requirements. When the grid voltage fluctuation exceeds AC380V±10% and the frequency exceeds 50Hz±1Hz, the power supply voltage regulator must be added, otherwise the normal operation of the CNC machine tool will be affected.

11.3 Electrical Cabinets

The standard configuration of the electrical cabinet adopts a fully enclosed structure and is equipped with an electric box air conditioner/heat exchanger to achieve the purpose of dustproof and cooling. The protection level of the electrical cabinet is IP54, and a certain space is reserved in the electrical cabinet to facilitate the expansion of functions.

11.4 Others

The machine tool can be equipped with other functional components such as grating rulers according to user requirements.

12. Security protection

This machine tool has full shield protection, and considers a number of safety protection measures, such as: electric control cabinet safety lock, protective door safety lock, and the strengthened glass design of the protective door to ensure the safety of machinery and people.

When the machine tool encounters an external power failure or its own failure, due to the special design of the control circuit, the machine tool axis cannot move, and the cooling motor, etc., if it is already in the “starting” state, will enter the “stop” state; if it is already in the “stop” state If it is in the state, it cannot enter the startup state by itself, which ensures the safety of the machine tool. In addition, since the control program in the machine tool computer is “solidified” in the chip, and the part processing program is protected by battery power supply, the program menu stored in the computer will not be lost in the event of an unexpected power failure or failure.

The machine tool has an alarm device and an emergency stop button, which can prevent various sudden failures from causing damage to the machine tool. Due to the reasonable design of the software, the alarm can be displayed with text and alarm number on the display, and indicated by the indicator light on the operation panel; the machine tool divides the processing methods of the alarm into three categories according to the situation: “emergency stop” for emergency alarms; “Feed hold”; only “prompt” for operation errors.

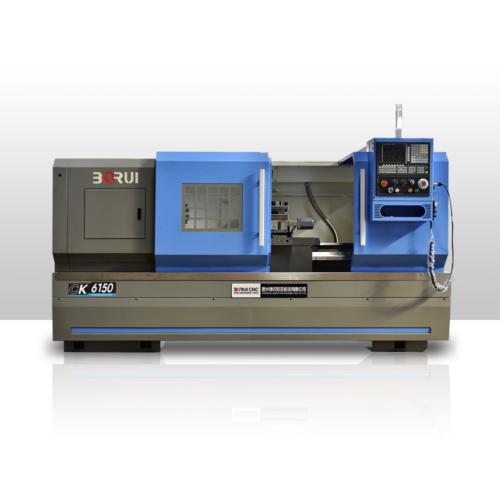

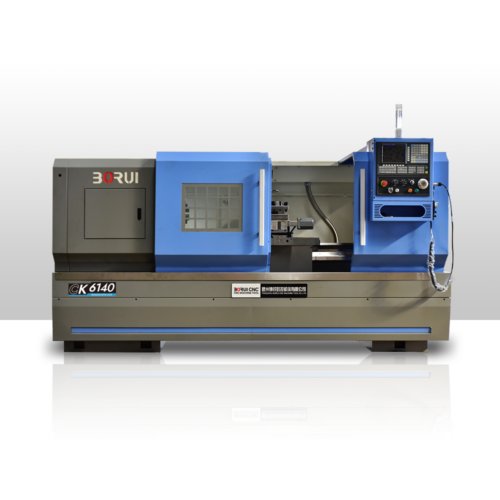

Technical Parameters Of Br Series CNC Vertical Lathe Machine:

| Project | BR 5060(L) | BR7080(L) | BR9010(L) | |

|---|---|---|---|---|

| maximum rotary diameter | Φ600 mm | Φ800mm | Φ1000mm | |

| maximum cutting length | 500mm | 700mm | 700mm | |

| maximum cutting diameter | 500mm | 700mm | 900mm | |

| Spindle Form and Code | A2-8 | A2-8/11 | A2-11 | |

| spindle speed | 80-2000 rpm | 80-2000 rpm | 80-1200 rpm | |

| Spindle Speed Series | Stepless | Stepless | Stepless | |

| main motor power | 15kw | 15/18.5kw | 18.5/22kw | |

| Main motor torque | 191 nm | 191/236 nm | 236/280 nm | |

| X axis servo motor | 2.4 Kw-15Nm | 2.4 Kw-15Nm | 2.8 Kw-18Nm | |

| Z axis servo motor | 2.4 Kw-15Nm | 2.4 Kw-15Nm | 2.8 Kw-18Nm | |

| Type of tool holder | Cutter | Cutter rack | Cutter rack | Cutter rack |

| Electric tool holder | 4/6 | 4/6 | 4/6 | |

| Hydraulic tool holder | 8/12 | 8/12 | 8/12 | |

| Power tool holder | 8/12 | 8/12 | 8/12 | |

| X axis travel | -50~+350 mm | -50~+400 mm | -50~+500 mm | |

| Z axis travel mm | 700 | 700 | 700 | |

| Electrical capacity | 16 KVA | 18 KVA | 22 KVA | |

| machine weight | 6.5 T | 7.5 T | 11.5 T | |

| size | 2100*1800*3200 mm | 2100*1900*3400 mm | 2200*2000*3900 mm |

CNC SYSTEM

Standard:GSK System

Optional:Siemens,FANUC,Mitsubishi.

TAIWAN SPINDLE

Famous Taiwan spindle,High speed,high precision,good surface finishing..

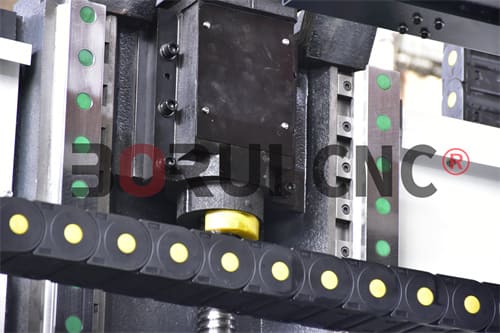

SIX-POSITION TOOL REST

Standard:Six-station tool rest

Optional:Tool rest protection

OTHER DETAILS

OTHER DETAILS

OTHER DETAILS

Safety operating procedures for CNC vertical lathes:

1. The operator of the brake pad CNC stand must strictly abide by the requirements for the maintenance and use of the equipment, and it is strictly forbidden to use the equipment with overload.

2. Before the brake pads are started upright by numerical control, they must be carefully checked according to the patrol inspection points, and lubricated according to the lubrication chart.

3. When the equipment is parked for more than eight hours and then started, it should be rotated at a low speed for three to five minutes to confirm that the lubrication system is smooth and all parts are running normally before starting to work.

4. It is strictly forbidden to drive and change the speed during use. When correcting the loading and unloading work, the main motor must be turned off.

5. When installing the chuck tooling, it must be firm and reliable. The chuck wrench must be removed at any time. When processing heavy workpieces, it must be balanced. When loading and unloading chucks and heavy workpieces, the rail surface must be well padded with wooden boards.

6. When the top holds the workpiece, the extension of the tailstock sleeve shall not be greater than twice the diameter of the sleeve.

7. It is forbidden to place workers, cards, measuring tools and workpieces on the bed.

8. When the processing materials are changed, the equipment must be cleaned.

9. When the brake pads are running numerically, always pay attention to the lubrication and sound of the machine tool. It is strictly forbidden to entrust others to take care of the running machine tool, and it is not allowed to disassemble the safety protection device.

10. Non-electricians are not allowed to open the door of the electrical box. Those who use the machine must clean it carefully, at least once a week.

Video Display

CNC Vertical Lathe Purchase Instructions:

1. Description of supply

The manufacturer’s primary source of goods, the company’s short production cycle, and the quality of the goods are guaranteed. Strictly standardize our product design, manufacturing, installation, and after-sales service behaviors in accordance with customer requirements, and use our sincerity, enthusiasm, persistence and pursuit to create high-quality, thoughtful installation and maintenance services for customers wholeheartedly.

2. About parameters

The size is manually measured and can be customized according to your needs due to factors such as different measuring tools and measuring methods.

3. About the color

The products in this store are all taken in kind, and the color has been professionally proofread, which is close to the actual tile, because the color contrast and color temperature of the computer monitor are different, etc.

4. About customer service

If your inquiry fails to respond in time, it may be due to excessive inquiries or system failure.

5. About after-sales

In order to rush to the installation and maintenance site as soon as possible in China, our company has built a complete system of intensive sales and after-sales service network. Our company’s “Three Guarantees” regulations for the products sold are one-year warranty and lifetime maintenance. All products purchased from our company will be repaired free of charge within one year from the date of installation and commissioning, and lifetime maintenance will be implemented if the product exceeds one year.

6. About delivery

Due to the large size of our machine, customers should carefully check whether the machine is damaged when receiving the goods. If there is damage, please negotiate with the freight driver to solve it, or if the driver does not leave, take photos and obtain evidence, and promptly contact the manufacturer Contact, we will negotiate with the logistics company.

yafim zilberberg –

I am interested in this machine.

what price? production time