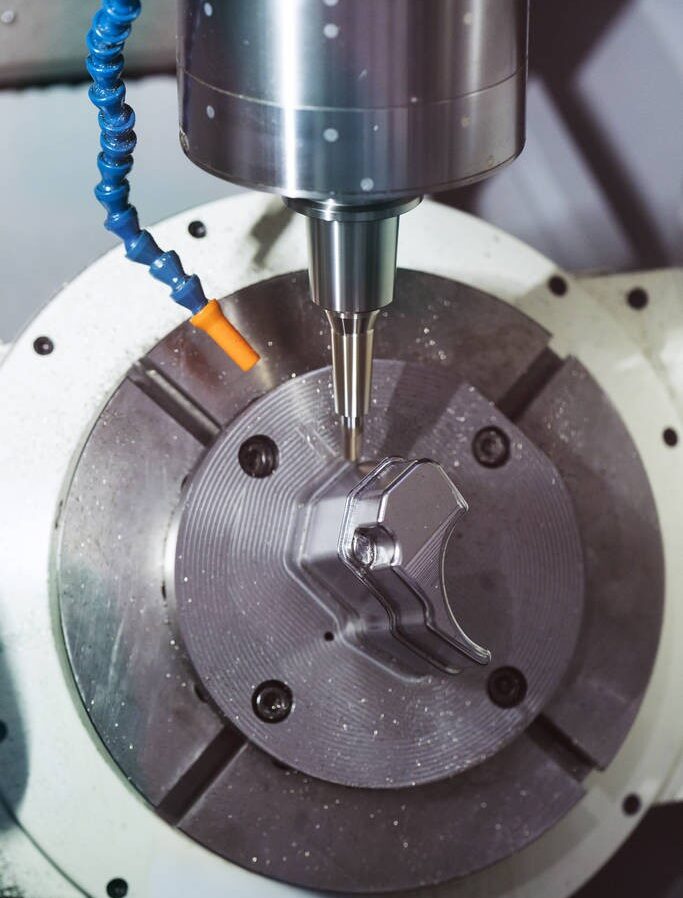

With the continuous development of the processing industry, some highly complex curved workpieces and multi-process workpieces have become commonplace, and their fine processing requirements are also getting higher and higher.

High-efficiency machining of highly complex curved surfaces and multi-process workpieces is the most important machining feature of vertical machining centers. In addition to being equipped with a tool magazine and an automatic tool changer, this kind of processing equipment enables the machine tool to automatically replace the processing tools of the workpiece, and also has the characteristics of high-speed processing.

However, high-speed cutting is different from ordinary cutting, and there are many factors that affect the final machining accuracy and surface quality of the workpiece. The following is a brief introduction to several factors that affect the high-speed cutting of workpieces in vertical machining centers, hoping to bring you some help

Machine Tool Factors

The high-speed cutting of the workpiece refers to the high-efficiency machining completed on the premise of ensuring the machining accuracy of the workpiece. Of course, the high-speed cutting performance of the machine tool is a necessary condition to realize the high-speed cutting of the workpiece. As we said earlier, the vertical machining center has the characteristics of this high-speed machining. In general, the realization of this type of machining requires the following aspects of the machine tool:

1. Spindle and feed system with high speed The core components of the vertical machining center are the spindle and the feed system. The rotation accuracy and rotation speed of the spindle system are the keys to ensuring high-speed cutting of the workpiece, which requires the configured spindle The system should have several key indicators such as compact structure, light weight, strong rigidity, minimal inertia and good corresponding characteristics. The feed system is also the same as the requirements of the spindle. While ensuring high-speed feed, it is also necessary to ensure that the positioning accuracy and repetitive positioning accuracy of the machine tool must meet the parameter requirements set by the machine tool.

2. More flexible lubrication and cooling methods High-speed operation of the machine tool spindle will inevitably generate a large amount of high temperature. In order not to cause deformation of the spindle system due to the high temperature, lubrication and cooling are very important. Generally, for long-term operation in a high-speed state The spindle of the vertical machining center is generally cooled by adding an oil cooler. In terms of lubrication, a closed oil immersion type is generally used. These two methods can ensure the accuracy of the machine tool spindle when it runs at high speed.

Tool-related factors

The tool is a component that directly acts on the workpiece, and its pros and cons are directly related to whether the high-speed cutting of the vertical machining center is normal or not. In addition to the reasonable selection of geometric parameters, the material of the tool is the key factor. Generally speaking, tool materials suitable for high-speed cutting of workpieces must have the following two points:

1. The tool used must have high wear resistance. Only in this way can it ensure that the tool is not easy to form intermittent chips with sawtooth shape and thickness change during high-speed cutting, and effectively prevent the dynamic balance of the tool from being damaged, which will lead to tool acceleration. wear.

2. It must have high hardness and toughness, and at the same time meet these two requirements to withstand the impact and vibration caused by the high-speed rotation of the tool, without chipping and fracture.

Factors in processing technology

We know that a vertical machining center completes its machining tasks by executing the machining program of the workpiece. The pros and cons of NC machining programs directly affect the final machining accuracy and machining efficiency of the workpiece during high-speed cutting. The key to the programming of the machining program is the selection of the workpiece technology. The cutting process mainly includes the process route suitable for high-speed cutting, the cutting method, the cutting route, the optimized high-speed machining parameters, and the method of sufficient cooling and lubrication.

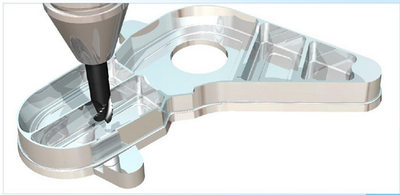

In principle, the tool path of high-speed cutting adopts layered ring cutting. Generally, the slash path feed method is used. Direct vertical downward feed is prone to chipping and other phenomena, so it should not be used; milling with slash path feed method The force is gradually increased, so the impact on the tool and the spindle of the vertical machining center is smaller than that of the vertical lower tool, which can significantly reduce the phenomenon of lower tool chipping.

If you want to know more about machining center, please contact me! When purchasing our machining center, we not only provide perfect after-sales service but also provide lifetime technical guidance.