At present, vertical machining centers and horizontal machining centers are very popular machines in the CNC machine tool industry, so what is the difference between them? How to choose?

There are many types of machining centers, gantry machining centers, vertical machining centers and horizontal machining centers. The most common is our vertical machining center, which should be known to everyone, and the horizontal machining center is rarely unclear. Today we will discuss the difference between vertical machining center and horizontal machining. Before that, you can compare our company’s VMC series and HMC series machines.

BORUI VMC Series

BORUI HMC Series

1. Differences in Z-axis structure

The vertical machining center is different from the horizontal machining center. The main difference between the vertical machining center and the horizontal machining center is that the Z-axis structure is different. The Z-axis of the vertical machining center moves vertically downward to complete the processing, and the Z-axis of the horizontal machining center moves horizontally downward to complete the processing. This is the vertical machining center. It is different from the horizontal machining center.

2. The difference of the workbench

Vertical machining centers and horizontal machining centers have different tables. The worktable of the vertical machining center is usually the structure of the cross-slide T-slot worktable. There are two sets of vertical motion mechanisms responsible for the direction of movement. The X-direction feed table cover is responsible for the Y-direction feed guide rail. The worktable and horizontal machining center only It is designed for X-direction or Y-direction movement, and the worktable is generally a grid screw-hole table top rotary worktable, which is relatively easy to choose and switch between double worktables.

So should you choose a vertical machining center or a horizontal machining center?

They handle object orientation differently. Due to the height constraints of the column and tool changer, vertical machining centers cannot handle tall parts. The volume of the workpiece is relatively small. To realize the lateral machining of the workpiece, an angle head or a CNC turntable must be installed. The horizontal clamping can complete the processing of the other four sides except the installation surface and the top surface. It is suitable for the processing of box parts. Pentahedral machining can be achieved by adding corner heads. Generally speaking, the structural complexity of horizontal machining centers is higher than that of vertical machining centers, and the price is much higher.

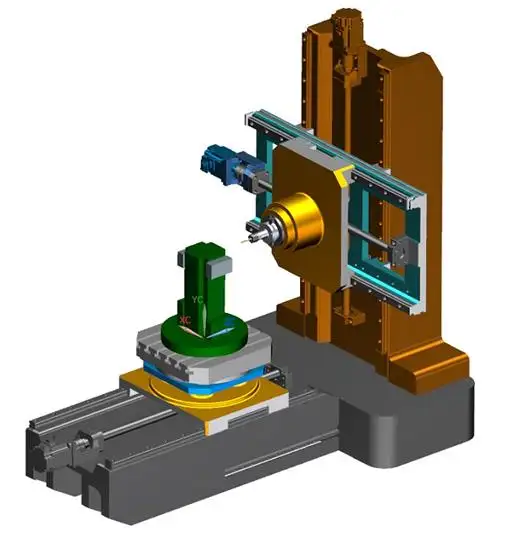

Want to implement vertical and horizontal machining on one machine?

Now many users will choose to install a fifth axis (also called rotary table) on the vertical machining center, such as VMC850, VMC1160, VMC1370, etc. produced by our company, many customers will choose to install a rotary table, BORUI 5-axis vertical machining center can realize 5-axis 4 linkage and 5-axis 5 linkage, which can meet the processing needs of most customers.

If the user’s budget is sufficient, they can also choose a universal machining center. The universal machining center is a five-sided machining center. It has the functions of a vertical machining center and a horizontal machining center. After the workpiece is clamped once, it can complete all the side and Machining of the top surface. Common universal machining centers are: 1) The spindle can be rotated 90°, which can work like a vertical machining center or a horizontal machining center. ) The spindle does not change its direction, and the worktable rotates 90° with the workpiece to complete the processing of five faces.

Customers who choose a universal machining center must have a very sufficient budget, because its price is very expensive, but if your budget is not very sufficient, then the BORUI 5-axis machining center must be your best choice!