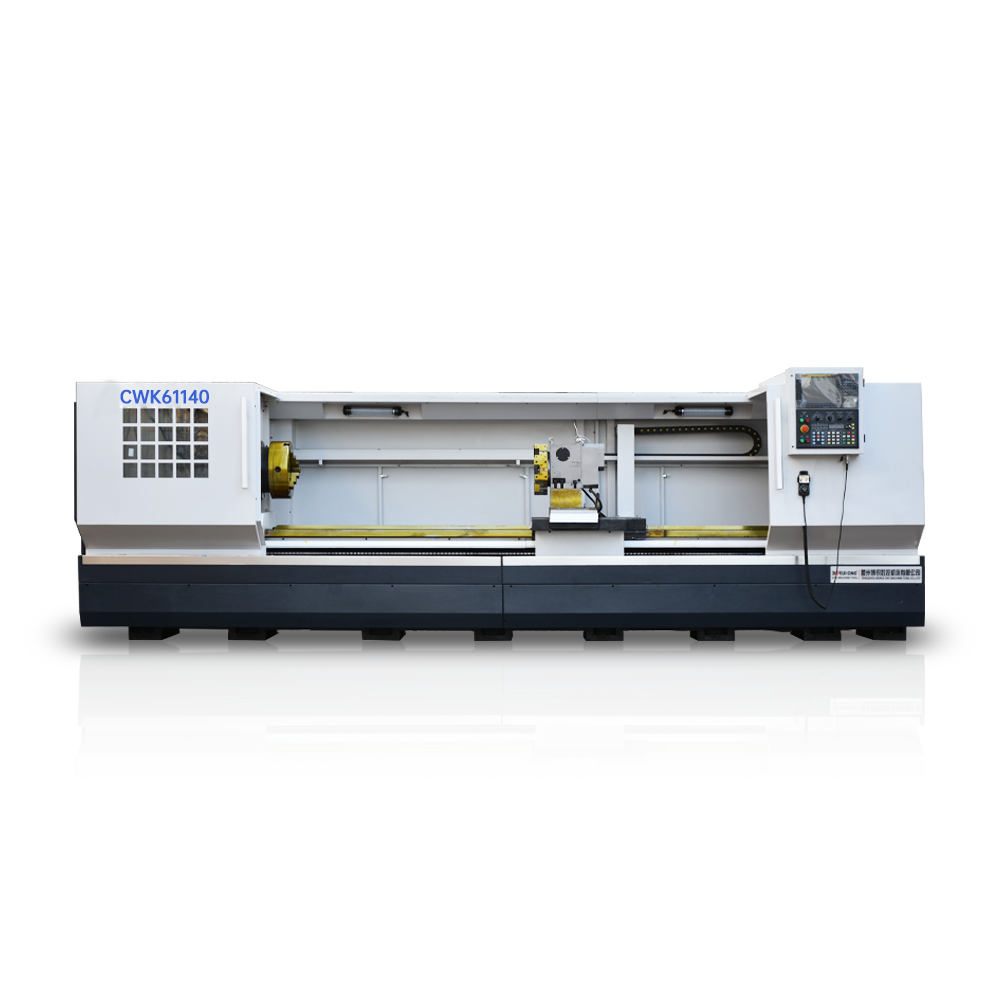

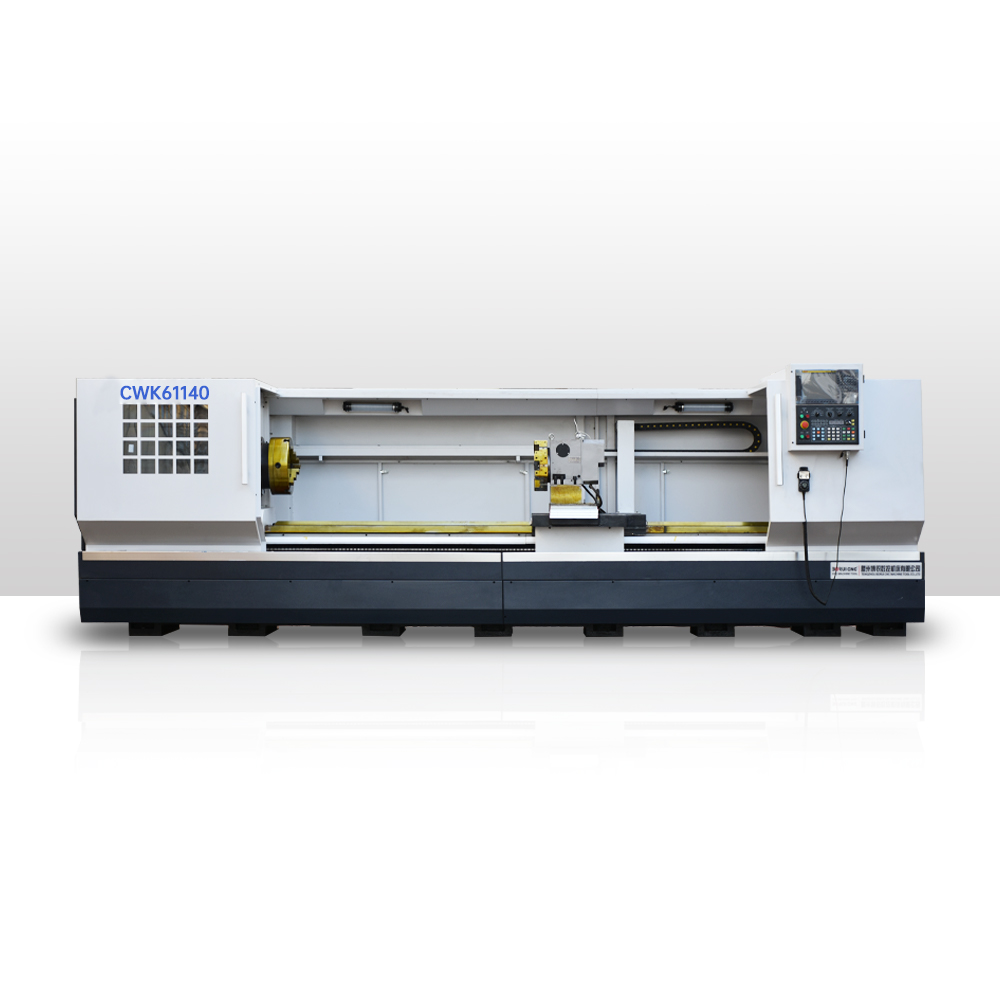

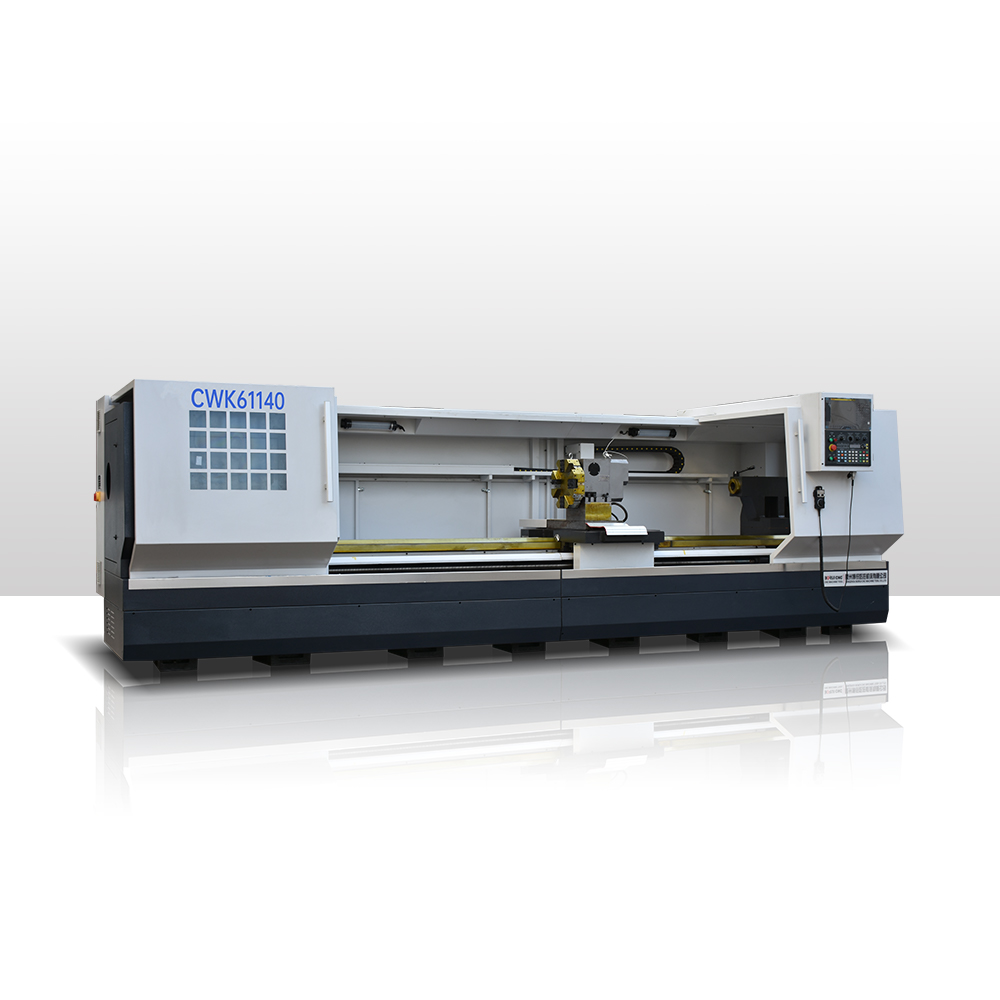

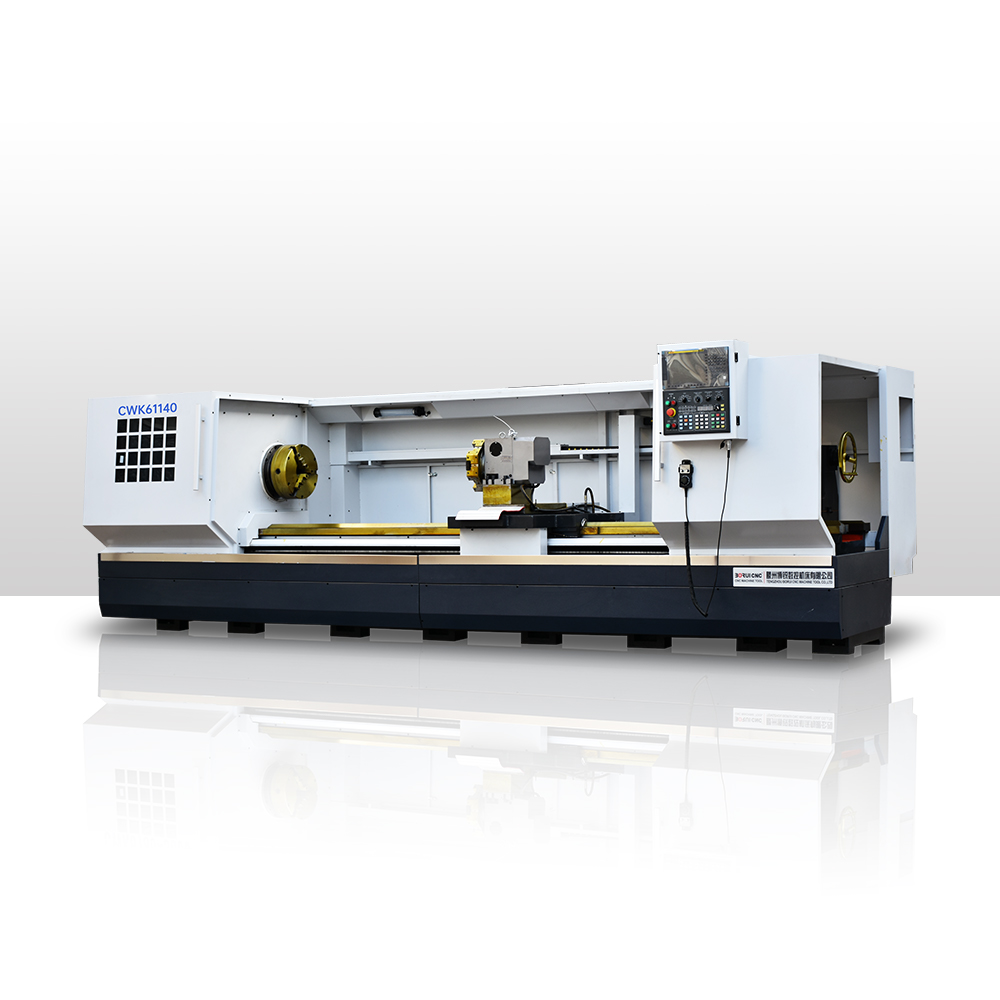

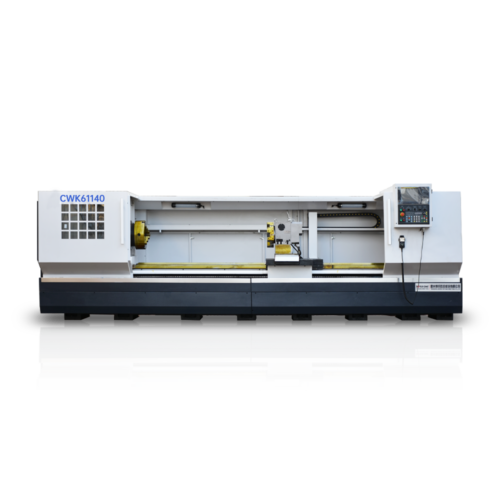

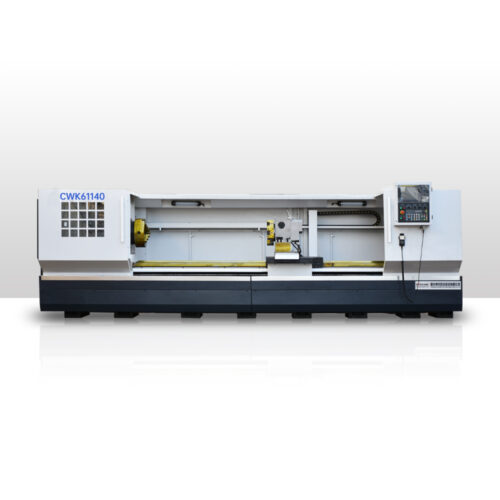

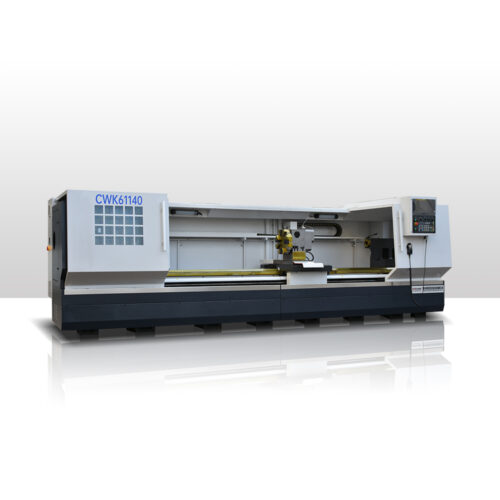

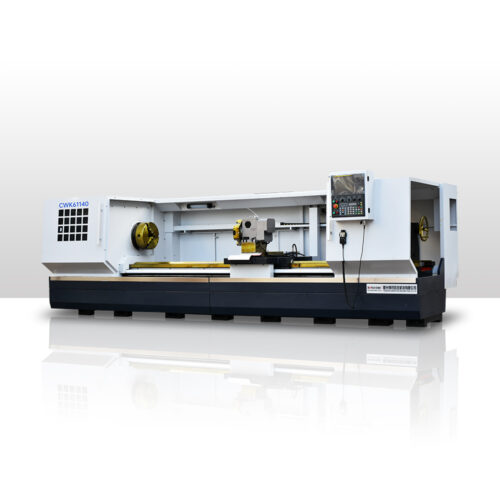

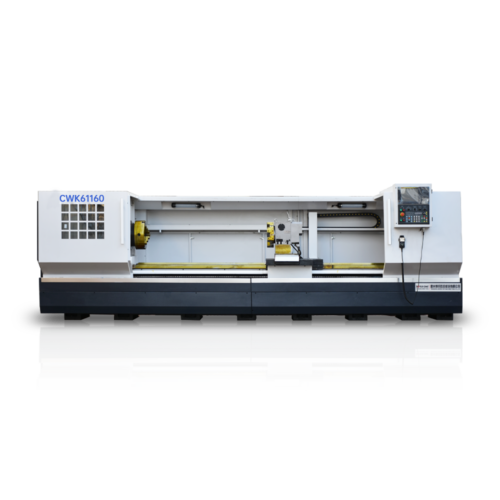

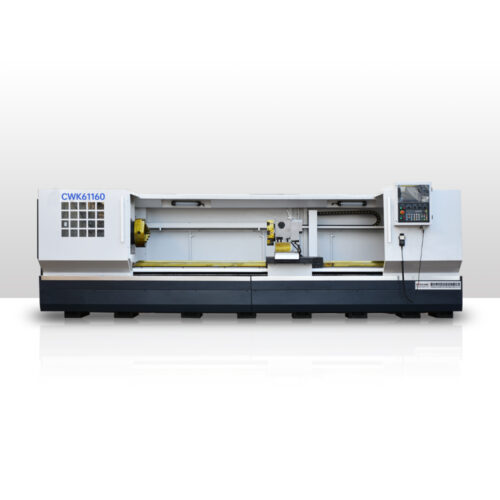

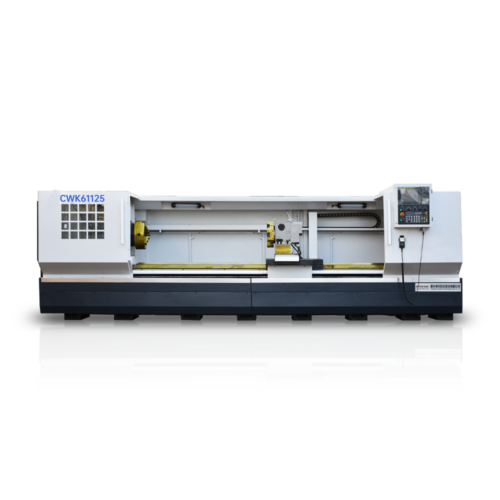

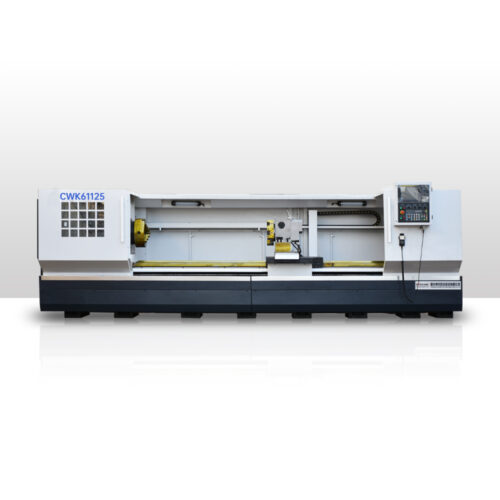

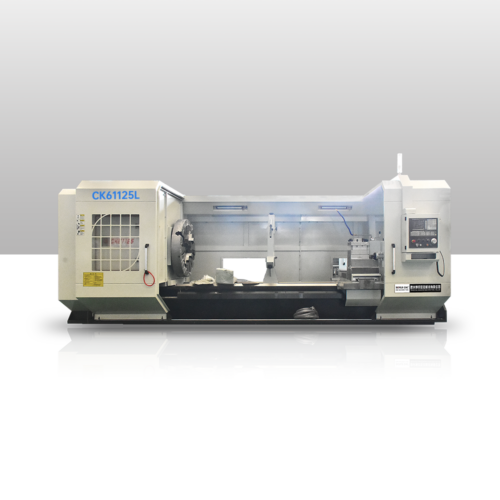

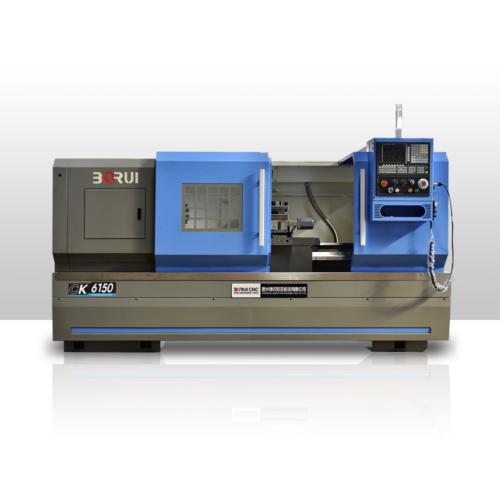

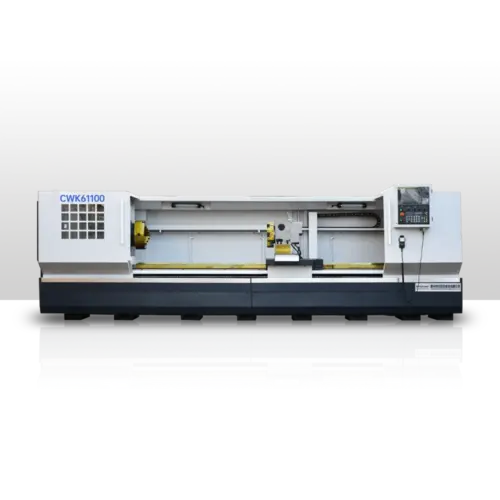

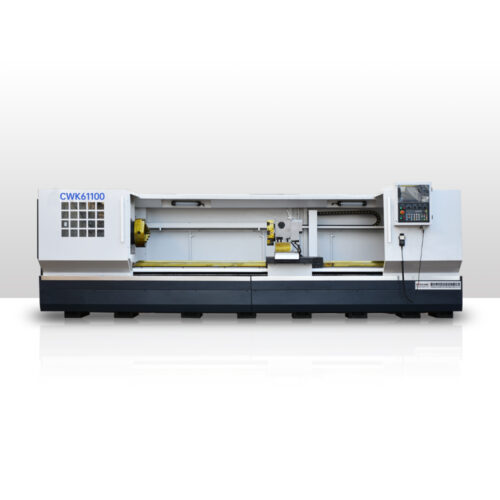

Advantages Of Heavy Duty CNC Flat Bed Lathe Machine:

- This machine is suitable for processing steel, cast iron, non-ferrous materials, large size workpiece. This machine has the characteristics of high power and high rigidity.

- Suitable for re-cutting of inner circle, outer circle, end face and thread in metric and British system. It can be drilled.

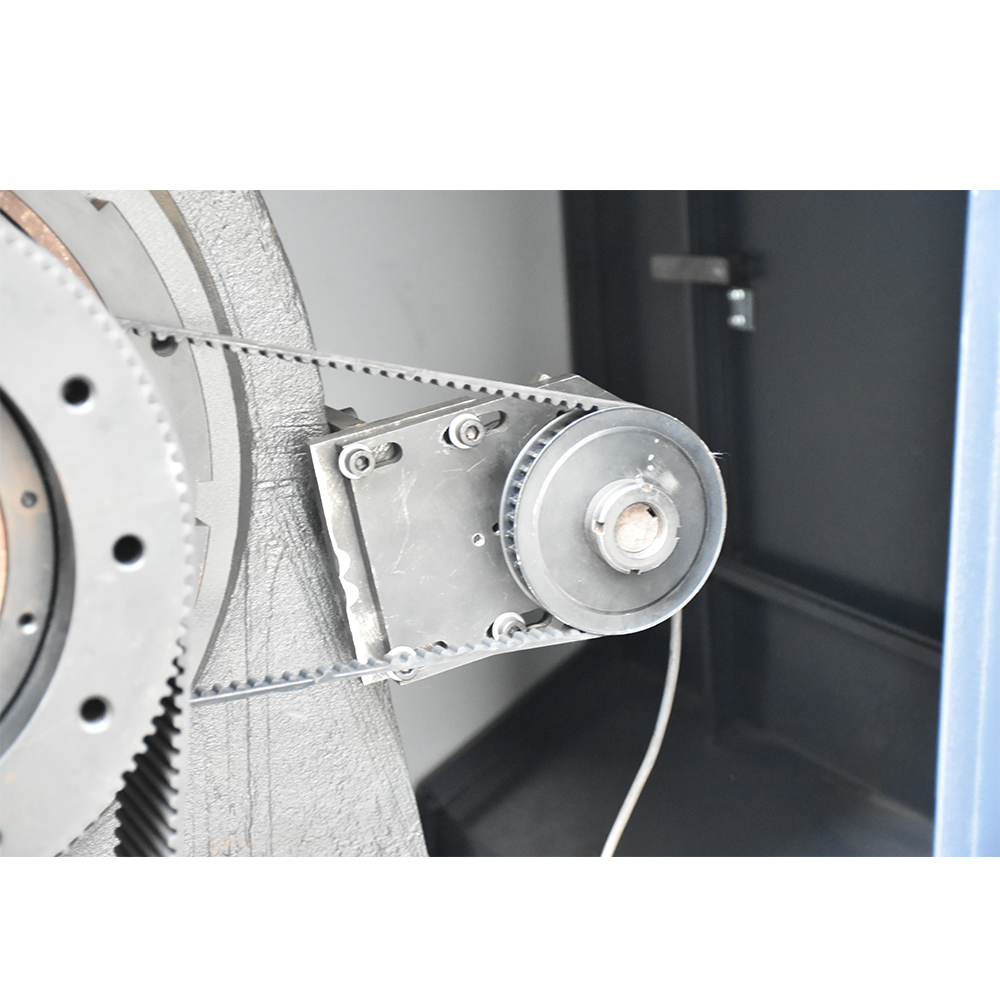

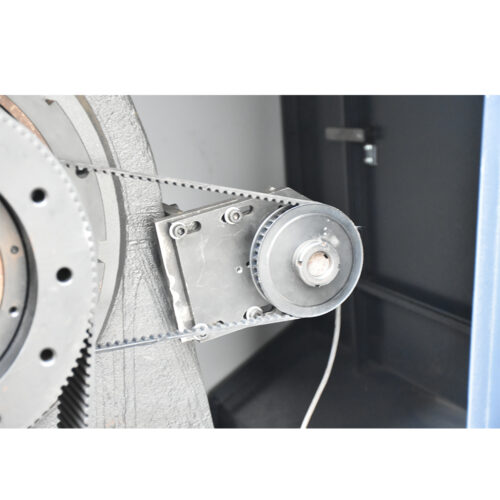

- Their bedways are hardened by the hyper acoustic quenching method and finish ground, thus assuring high working accuracy for the machines.

- CWK61140 CNC lathes are economical machining lathes.

- The machine tool can carry out rough machining and finishing of mechanical parts, with reliable structure, convenient operation and economical and practical.

- The control system is fully functional and meets the needs of many industries.

- X / Z to the use of domestic famous precision ball screw.

- It is used for high-efficiency, high-volume, high-precision machining of rotary parts.

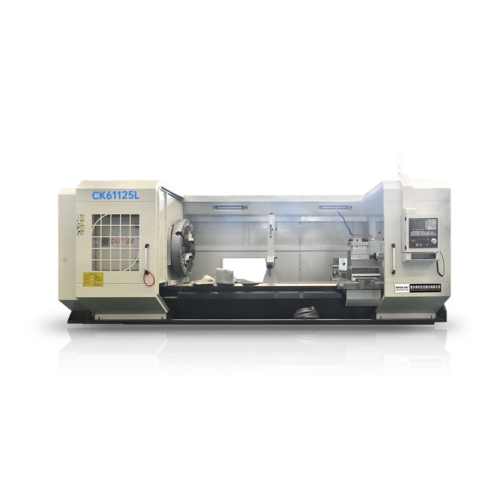

Product Main Technical Parameters:

| SPECIFICATION | UNIT | CWK61140 |

|---|---|---|

| Swing over bed | mm | 1400 |

| Swing over cross slide | mm | 1000 |

| Distance between centers | mm | 1500-8000 |

| Guideway width | mm | 755 |

| Max. load capacity | T | 6 |

| Spindle bore | mm | 130 |

| Spindle bore taper | – | Metric φ160/MT6 |

| Spindle nose type | – | A2-15 |

| Spindle speed steps | – | VF. 4steps |

| Spindle speed range | rpm | 4-300 |

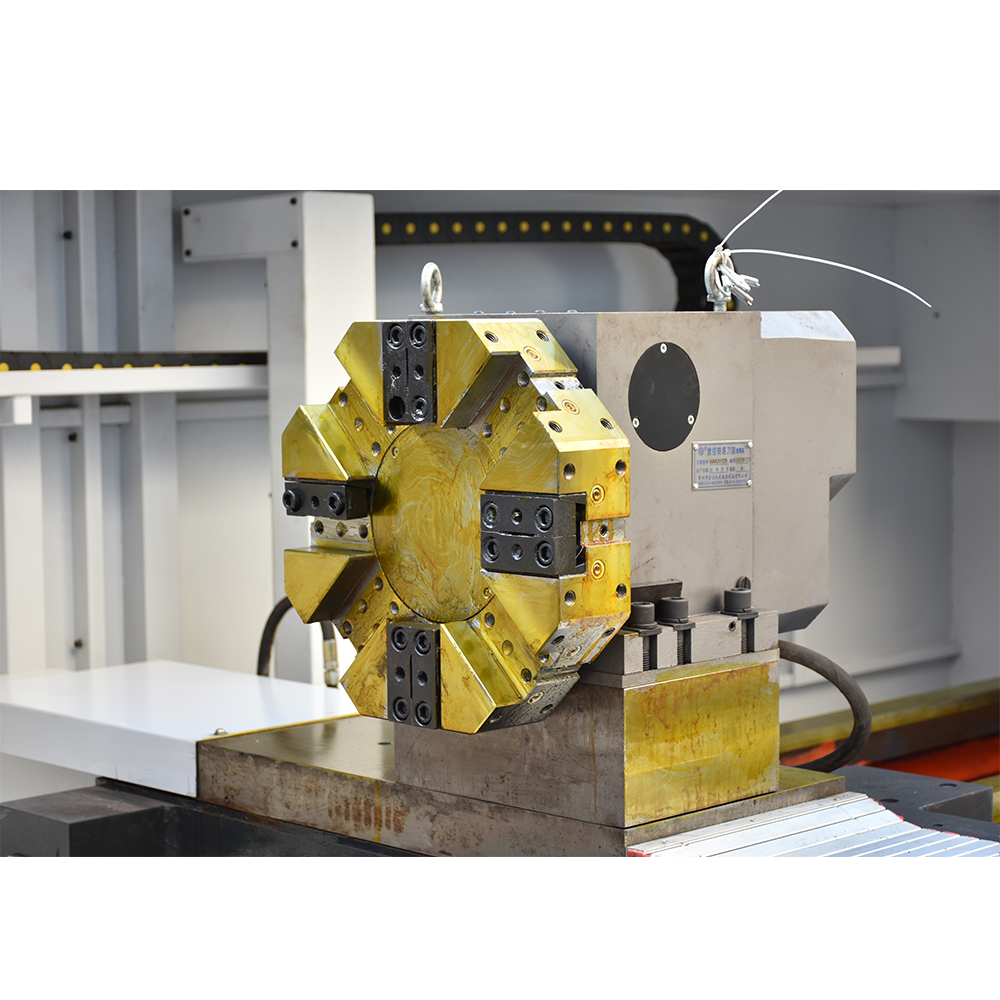

| Chuck | mm | φ1000 4-jaw manual |

| Turret/tool post | – | NC turret 4 position |

| Tool shank size | mm | 40 x 40 |

| X axis travel | mm | 720 |

| Z axis travel | mm | 1350/2850/3850/4850/5850 |

| X axis rapid traverse | mm/min | 4000 |

| Z axis rapid traverse | mm/min | 6000 |

| Tailstock quill diameter | mm | φ160 |

| Tailstock quill taper | – | MT6 |

| Tailstock quill travel | mm | 300 |

| Main spindle motor | kW | 22 |

| Coolant pump motor | kW | 0.25 |

| Width x Height | mm | 2350 x 2450 |

| Length | mm | 5000/6500/7500/8500/9500 |

| Net weight | T | 12.0/13.5/14.5/15.5/16.5 |

Reviews

There are no reviews yet.