Definition Of X、Y、Z Axis: In order to determine the movement direction and movement distance of the machine tool, a coordinate system must be established on the machine tool to describe the relative position of the tool and the workpiece and its changing relationship. Extend the thumb, index finger and middle finger…

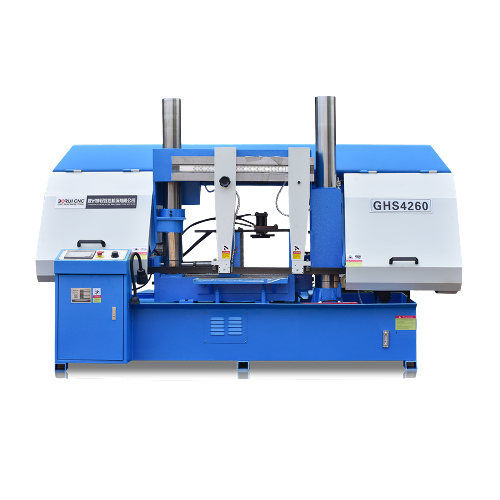

According to the structure, the sawing machine is divided into horizontal band sawing machine and vertical band sawing machine, and the horizontal type is divided into scissors type, double column and single column type band sawing machine. According to the usage, it is divided into manual type (economical manual feeding and manual cutting…

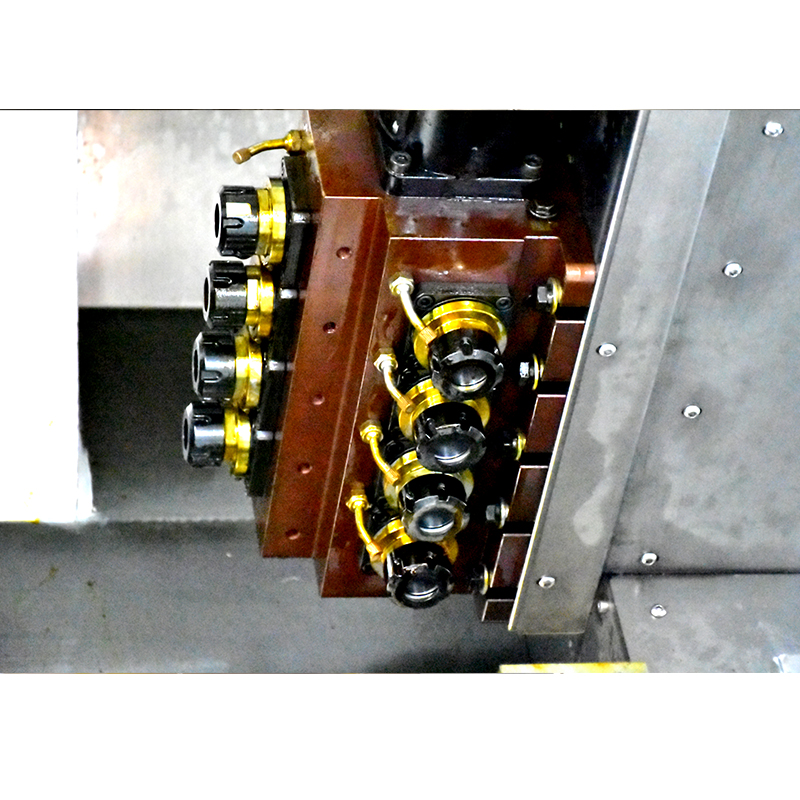

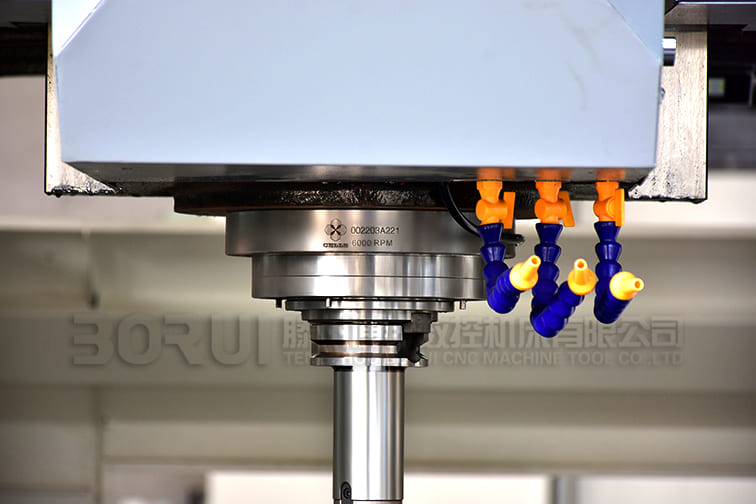

The tool arrangement of the CNC machine tool of the dual-spindle lathe, turning and milling compound machine tool adopts a three-dimensional tool arrangement structure. Compared with the turret tool holder, the tool change time is short and the failure rate is low. To meet the needs of machining parts, install multiple types of…

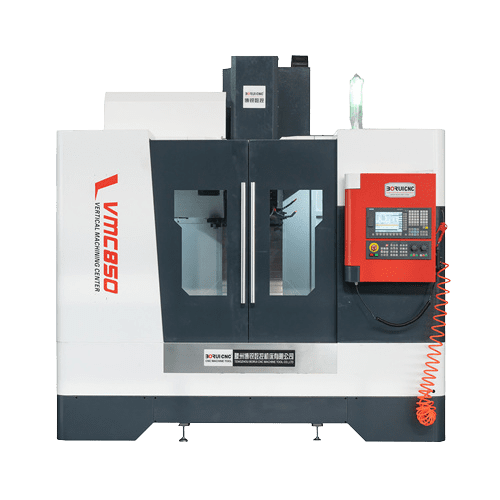

VMC850 vertical machining center adopts a vertical frame layout, the column is fixed on the bed, the headstock moves up and down along the column (Z direction), the slide moves longitudinally along the bed (Y direction), and the worktable moves laterally along the slide (X direction) )Structure. The bed, worktable, sliding seat,…

Threads are continuous protrusions and grooves with the same cross-section and specified profile formed along the helix on the cylindrical or conical surface. In various mechanical products, parts with threads are widely used. It is mainly used as connecting parts, fastening parts, transmission parts and measuring parts, etc. Machining threads on a CNC lathe is…

In recent years, CNC milling machines have been widely used in production. It is inevitable that abnormal machining accuracy will occur during use, which will affect the machining accuracy. There are four reasons for this problem: System parameters have changed or changed; The machine tool position loop is abnormal; The motor running state is abnormal,…

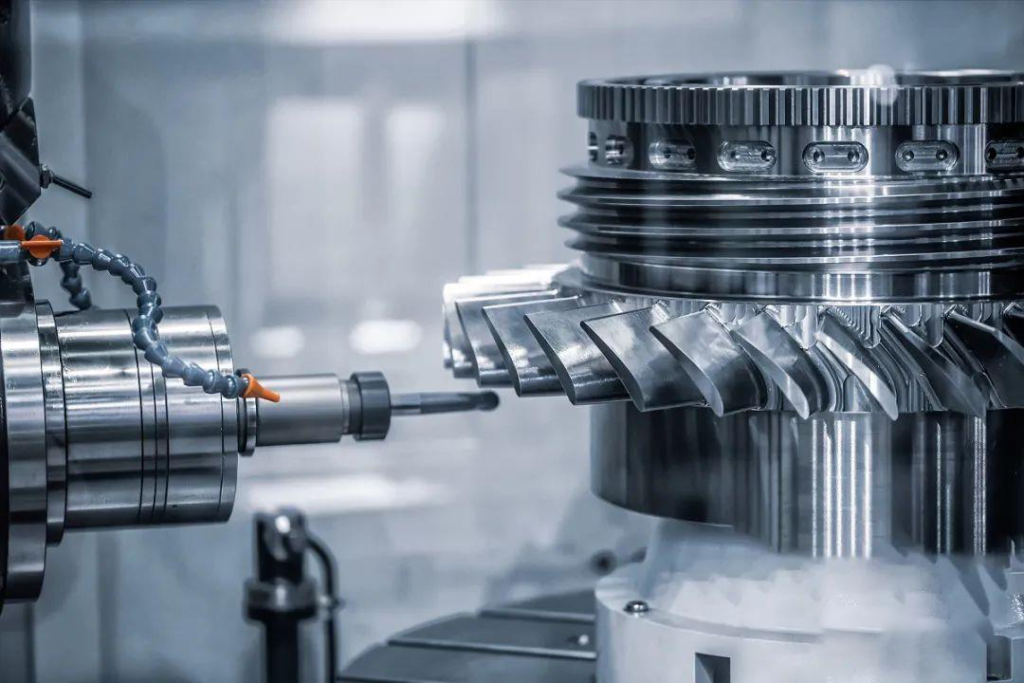

What Is CNC Lathe? CNC lathes are widely used. They are mainly used for cutting the inner and outer cylindrical surfaces of shaft parts or disc parts, inner and outer conical surfaces of arbitrary taper angles, complex rotating inner and outer surfaces, cylinders, conical threads, etc., and can perform grooving, Drilling, reaming, reaming and boring…

The line rail CNC lathe has the characteristics of high rigidity, high precision, high efficiency and low price. The overall structure of the bed is smooth in chip removal, compact in structure and beautiful in appearance. High-speed and accurate tool change can save processing time. It has various processing functions and is good at processing…

Spindle components: It is the main component that affects the machining accuracy of the machining center Rotation accuracy affects the machining accuracy of the workpiece Power and rotation speed affect processing efficiency Automatic shifts, exact stops and tool changes that affect the automation of the machine tool Common faults of machining center spindle Machining accuracy…

Programming skills for large-scale CNC lathe processing 1. The processing sequence of the parts:(1) Drill first and then flat end (to prevent shrinkage during drilling).(2) Rough machining first, then finish machining (to ensure the accuracy of the parts).(3) Machining large tolerances first and then machining small tolerances (to ensure that the surface of small tolerance…