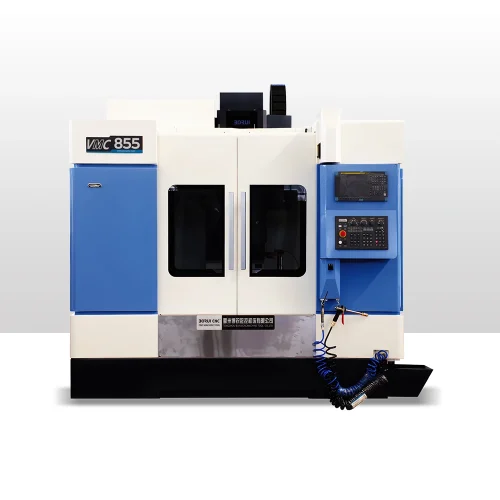

The VMC1060 vertical machining center adopts a vertical frame layout, the column is fixed on the bed, the headstock moves up and down along the column (Z direction), the sliding seat moves longitudinally along the bed (Y direction), and the worktable moves laterally along the sliding seat (X direction) to the structure.

Advantages of VMC1060 5 Axis Vertical Machining Center:

1.the spindle rotation mode is belt connection, high speed.

2. The standard configuration of knife library is 24 round knife library to meet the needs of customers.

3. The head group is a heavy-duty box structure with reinforced internal ribs and high rigidity.

4. The spindle punching method adopts oil pressure mechanism, punching spindle uniform force, prolong the bearing life.

5. The electrical box is designed in isolation type, the heat source part of the controller is separated, the heat exchanger is used in front of the heat dissipation, to avoid the outside dust into the electric box; The rear fan dissipates heat from the fan hot plate.

6. Three axis using high ball screw, combined with nut precompression and tail pretension device, to ensure that the machine backspace and thermal deformation for a long time to keep at a low value.

7. X, Y axis using ball linear guide, with high rigidity, low noise, can do displacement and obtain good cycle accuracy.

-100x100.png)

-500x500.png)

Reviews

There are no reviews yet.